Gasoline particulate filter regeneration strategy

A particle filter and particle technology, applied in the direction of machine/engine, electric spark ignition controller, electronic control of exhaust treatment device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses.

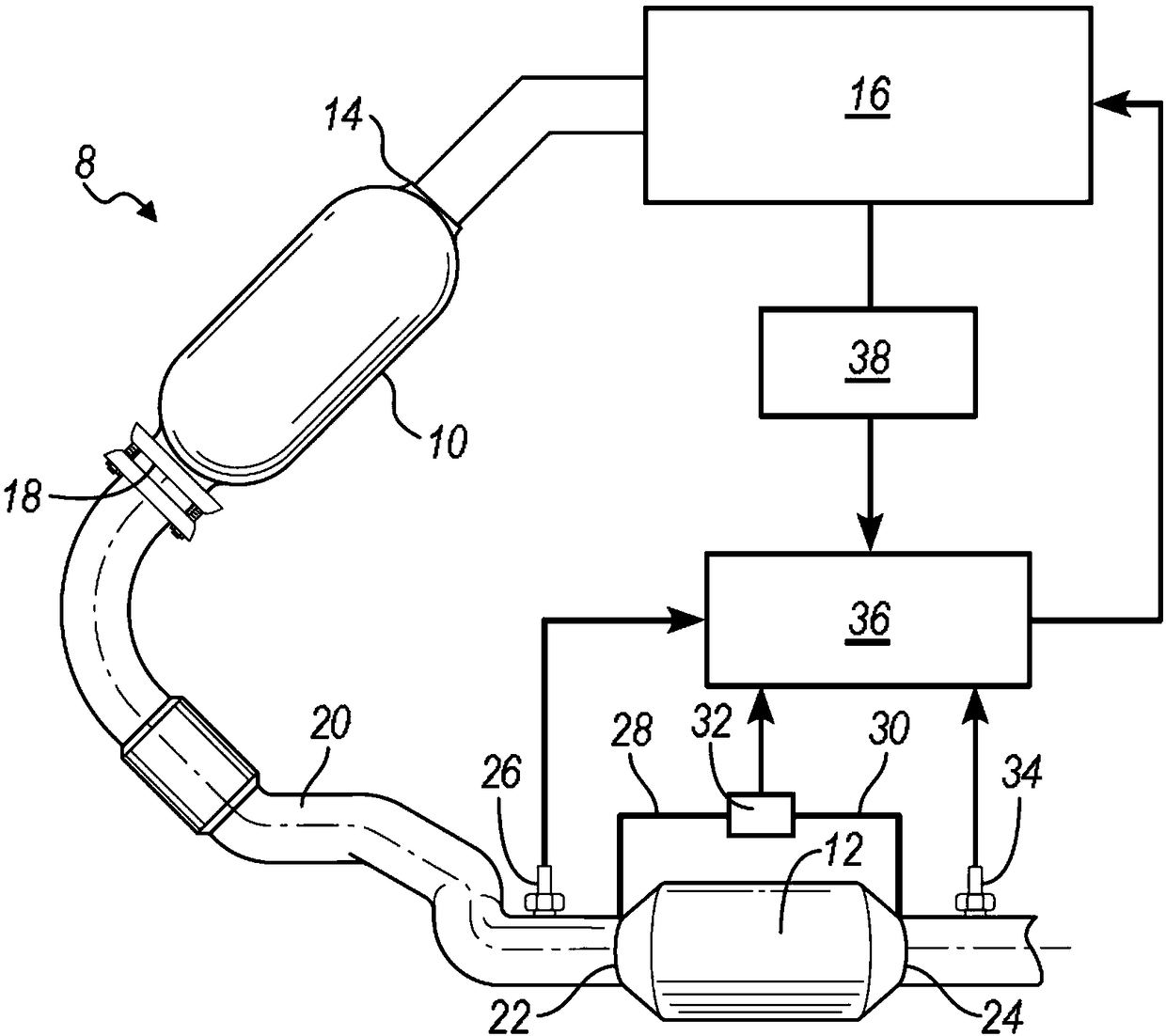

[0023] refer to Figure 1A , shows a first, underfloor system configuration 8 of a three-way catalytic converter (TWC) 10 and a separate gas particulate filter (GPF) 12 . A conventional three-way catalytic converter 10 includes an inlet port or opening 14 that receives exhaust gas from a gasoline fueled internal combustion engine 16 and an outlet port or opening 18 that connects to an inlet port or opening 22 of a gas particulate filter 12 through an exhaust pipe 20 . In turn, the gas particulate filter 12 has an outlet port or opening 24 that supplies the output of the particulate filter 12 to other components of the exhaust system, such as mufflers, resonators, and tailpipes (none of which are shown).

[0024] Upstream or forward of the gas particulate filter 12 and disposed in the exhaust duct 20 is a pre-GPF temperature sensor 26 which, as its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com