Series alternate residual oil hydrotreatment-catalytic cracking combined process method and system

A catalytic cracking and hydrotreating technology, which is applied in hydrotreating process, hydrocarbon oil treatment products, petroleum industry, etc. It can solve the problems of increasing the load of heating furnace, insufficient capacity of dirt and impurities, and affecting the catalytic activity of the main catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

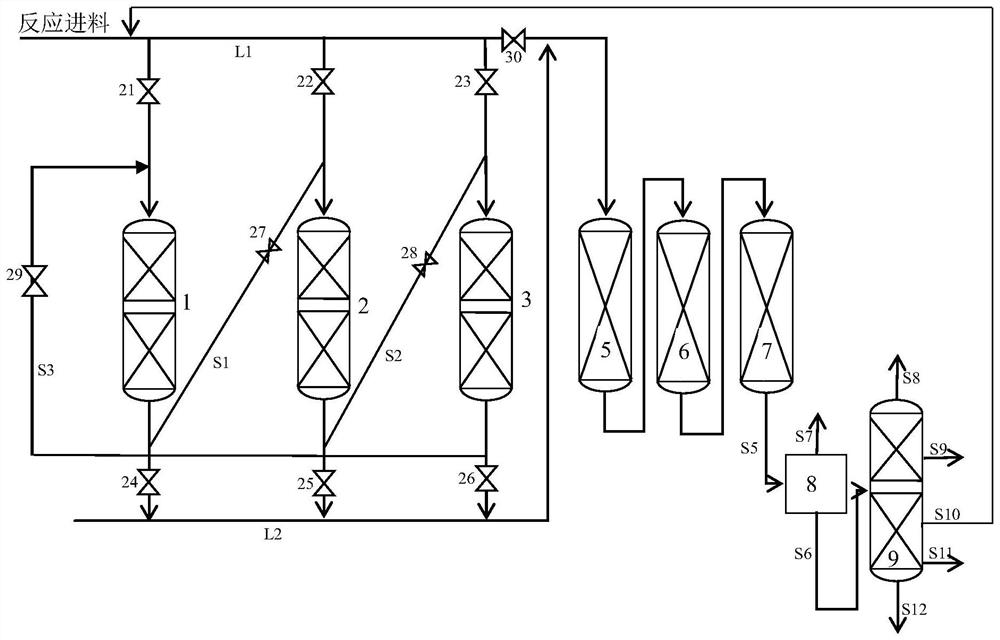

[0066] This embodiment adopts as figure 1 Shown reaction system, concrete reactor and connection relation are as follows:

[0067] The reaction system includes a first hydrotreating reactor 1, a second hydrotreating reactor 2, a third hydrotreating reactor 3, a hydrotreating reactor 5, a hydrotreating reactor 6, a hydrotreating Reactor 7. The main reaction feed pipeline L1 is connected with the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, and the third hydrogenation pretreatment reactor 3 through the valve body 21, the valve body 22, and the valve body 23 respectively. The inlets are connected, and the outlets of the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, and the third hydrogenation pretreatment reactor 3 are respectively connected with the reaction outlet through the valve body 24, the valve body 25, and the valve body 26. The main feed pipeline L2 is connected, and the fir...

Embodiment 2

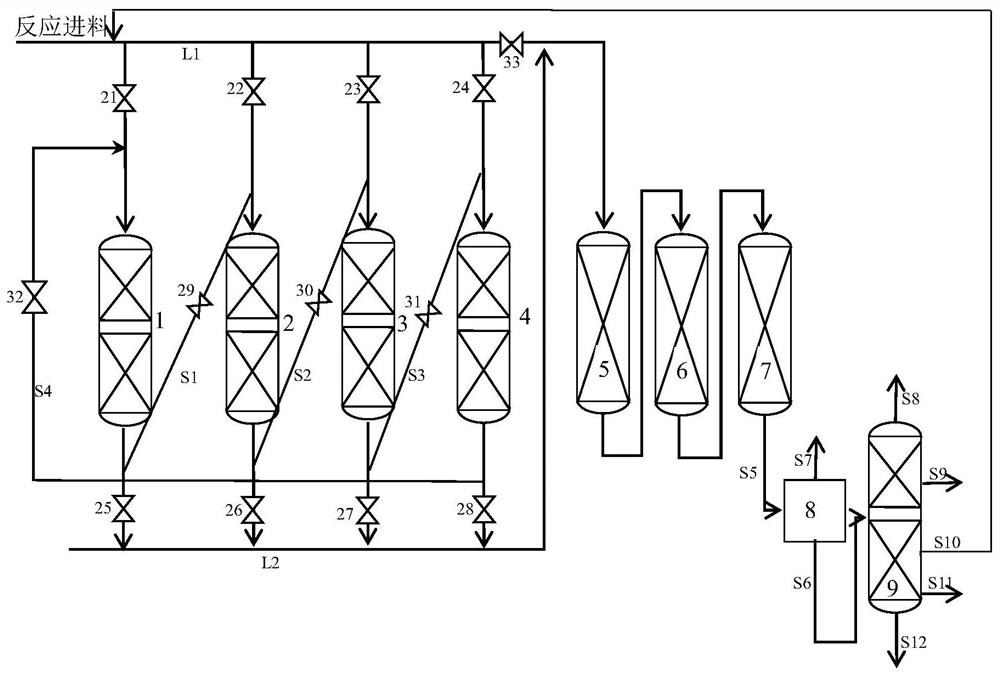

[0094] This embodiment adopts as figure 2 Shown reaction system, concrete reactor and connection relation are as follows:

[0095] The reaction system comprises a first hydroprocessing reactor 1, a second hydroprocessing reactor 2, a third hydroprocessing reactor 3, a fourth hydroprocessing reactor 4, a hydroprocessing reactor 5, Hydrotreating reactor 6, Hydrotreating reactor 7. The main reaction feed pipeline L1 is connected with the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, and the third hydrogenation pretreatment reactor through valve body 21, valve body 22, valve body 23, and valve body 24, respectively. Reactor 3, the inlet of the fourth hydrogenation pretreatment reactor 4 are connected, the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, the third hydrogenation pretreatment reactor 3, the fourth hydrogenation pretreatment reactor The outlet of the hydrogen pretreatment rea...

Embodiment 3

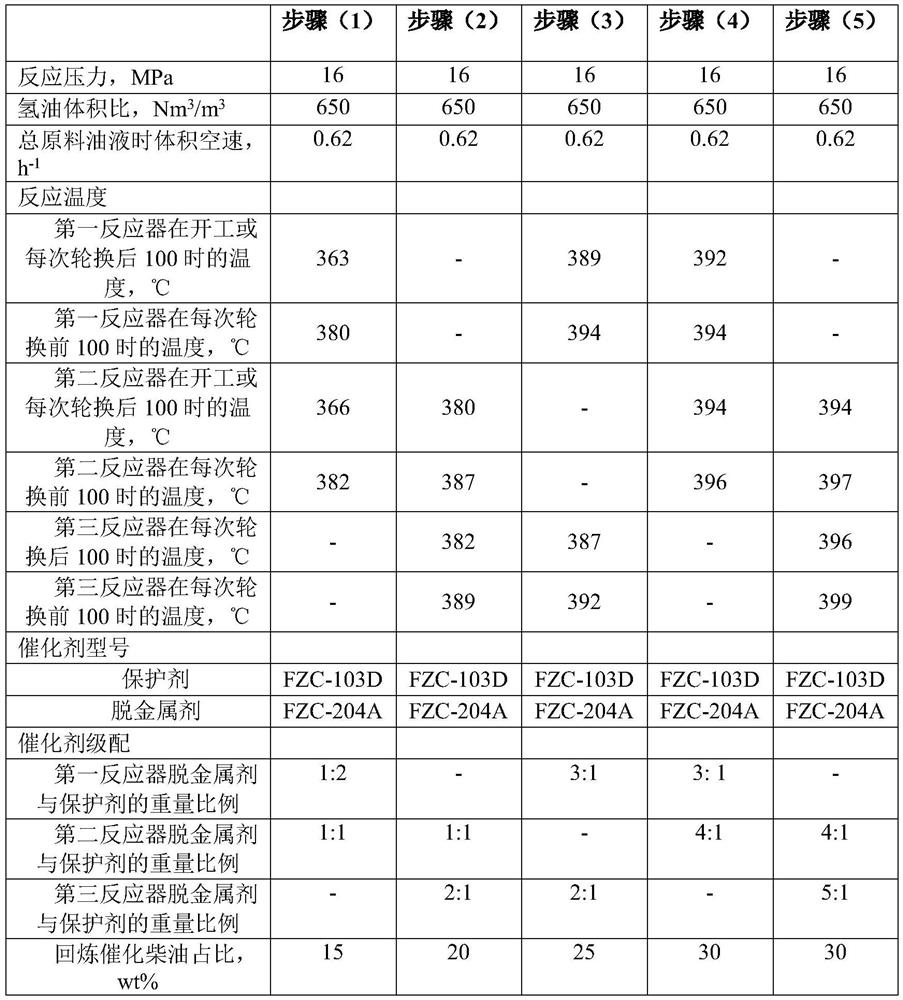

[0120] This example adopts the reaction system, reaction raw materials and reactor rotation method of Example 1, the difference is: the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, the third hydrogenation pretreatment The ratio of demetallization agent to protective agent in reactor 3 is 1:1, and remains unchanged for each rotation. The switching time of the hydrogenation pretreatment reactor is shown in Table 6. All catalytic cracking diesel fractions obtained after the catalytic cracking reaction are mixed with residual oil raw materials and enter the hydrogenation pretreatment reaction zone for reaction. Among them, based on the total weight of residual oil feedstock and catalytic cracking diesel oil fraction entering the hydrogenation pretreatment reaction area, the catalytic cracking diesel oil fraction returned to the hydrogenation pretreatment reaction area accounts for 30wt%.

[0121] Among them, the properties of the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com