A series-rotatable fixed-bed residual oil hydrotreating method and system

A technology for hydrotreating and hydrotreating, which is applied in hydrotreating process, treating hydrocarbon oil, petroleum industry, etc., can solve the problem of increasing the load of the heating furnace, increasing the pressure drop of the hydrotreating pretreatment reactor rapidly, and affecting the refinery. Economic efficiency and other issues to achieve the effect of slowing down the deactivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

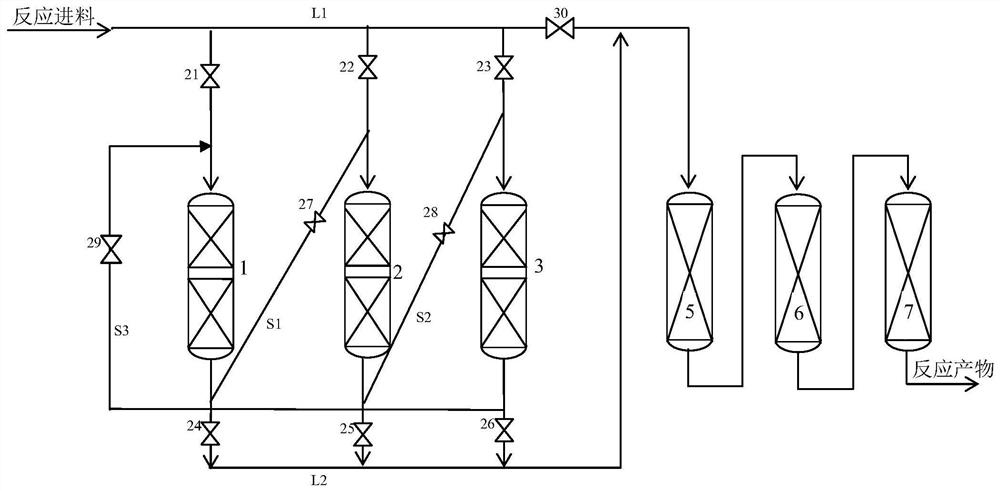

[0055] This embodiment adopts the figure 1 The reaction system shown, the specific reactor and connection relationship are as follows:

[0056] The reaction system includes a first hydroprocessing reactor 1, a second hydroprocessing reactor 2, a third hydroprocessing reactor 3, a hydroprocessing reactor 5, a hydroprocessing reactor 6, and a hydroprocessing Reactor 7. The main reaction feed pipeline L1 is connected to the first hydropretreatment reactor 1, the second hydropretreatment reactor 2, and the third hydropretreatment reactor 3 through the valve body 21, the valve body 22, and the valve body 23, respectively. The inlets are connected, and the outlets of the first hydropretreatment reactor 1, the second hydropretreatment reactor 2, and the third hydropretreatment reactor 3 are respectively connected to the reaction outlet through the valve body 24, the valve body 25, and the valve body 26. The main feed pipeline L2 is connected, and the first hydropretreatment reactor...

Embodiment 2

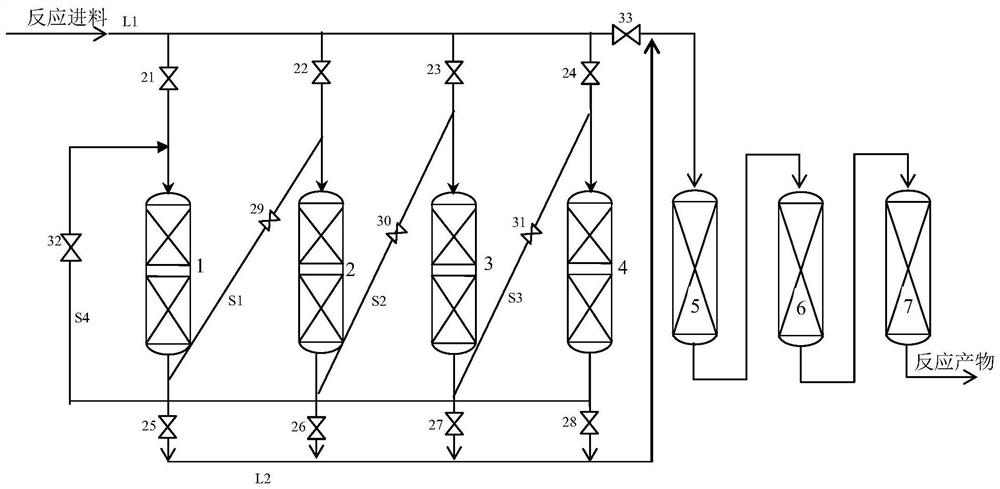

[0082] This embodiment adopts the figure 2 The reaction system shown, the specific reactor and connection relationship are as follows:

[0083]The reaction system comprises a first hydroprocessing reactor 1, a second hydroprocessing reactor 2, a third hydroprocessing reactor 3, a fourth hydroprocessing reactor 4, a hydroprocessing reactor 5, Hydrotreating reactor 6, Hydrotreating reactor 7. The main reaction feed pipeline L1 is connected with the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, and the third hydrogenation pretreatment reactor through valve body 21, valve body 22, valve body 23, and valve body 24, respectively. Reactor 3, the inlet of the fourth hydrogenation pretreatment reactor 4 are connected, the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, the third hydrogenation pretreatment reactor 3, the fourth hydrogenation pretreatment reactor The outlet of the hydrogen pret...

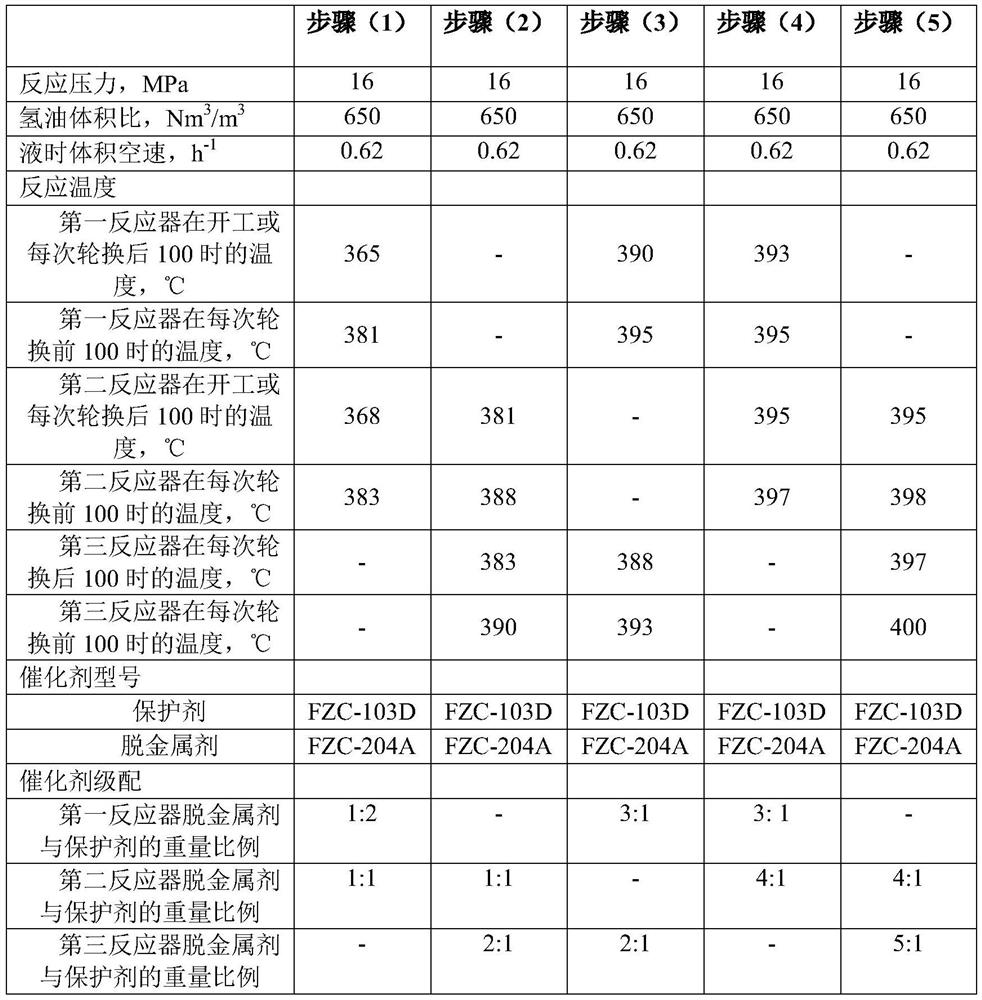

Embodiment 3

[0107] This example adopts the reaction system, reaction raw materials and reactor rotation method of Example 1, the difference is: the first hydrogenation pretreatment reactor 1, the second hydrogenation pretreatment reactor 2, the third hydrogenation pretreatment The ratio of demetallization agent to protective agent in reactor 3 is 1:1, and remains unchanged for each rotation. The switching time of the hydrogenation pretreatment reactor is shown in Table 6.

[0108] In Example 3, due to the deactivation of the hydrotreating catalyst and the pressure drop of the reactor in the main reaction zone reached the design value, the operation was forced to shut down. The operating cycle is shown in Table 7.

[0109] The switching time of hydrogenation pretreatment reactor in the embodiment 3 of table 6

[0110] Switch for the first time second switch third switch fourth switch switching time, h 5000 7500 9300 10800

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com