Dust removing system pipe network resistance balance evaluation and debugging method

A technology of dust removal system and resistance balance, applied in special data processing applications, measuring devices, instruments, etc., can solve problems such as neglect, achieve efficient capture and save money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

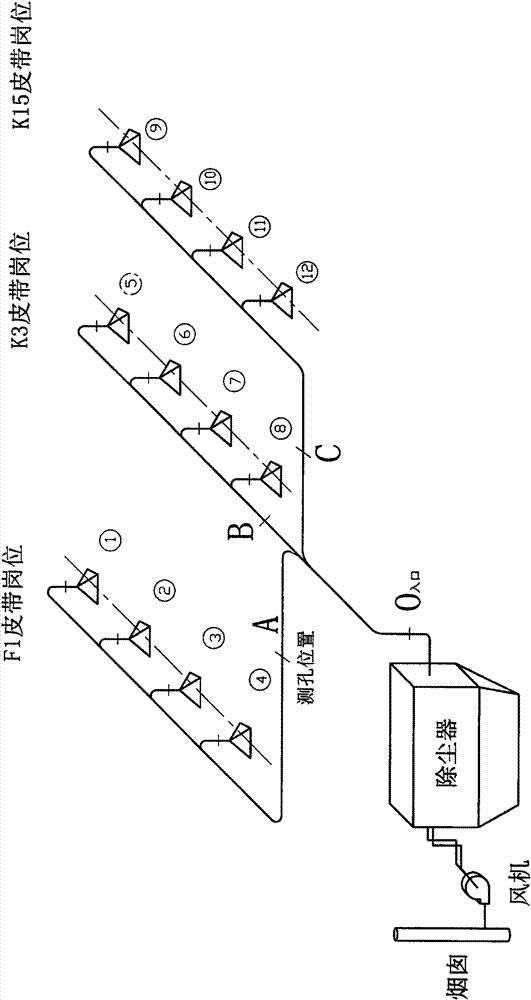

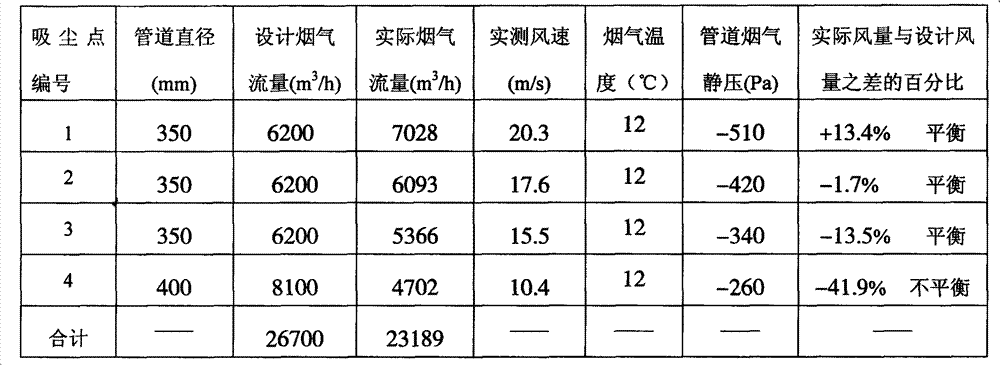

[0020] Combine below figure 1 and figure 2 The method of the present invention is described in further detail.

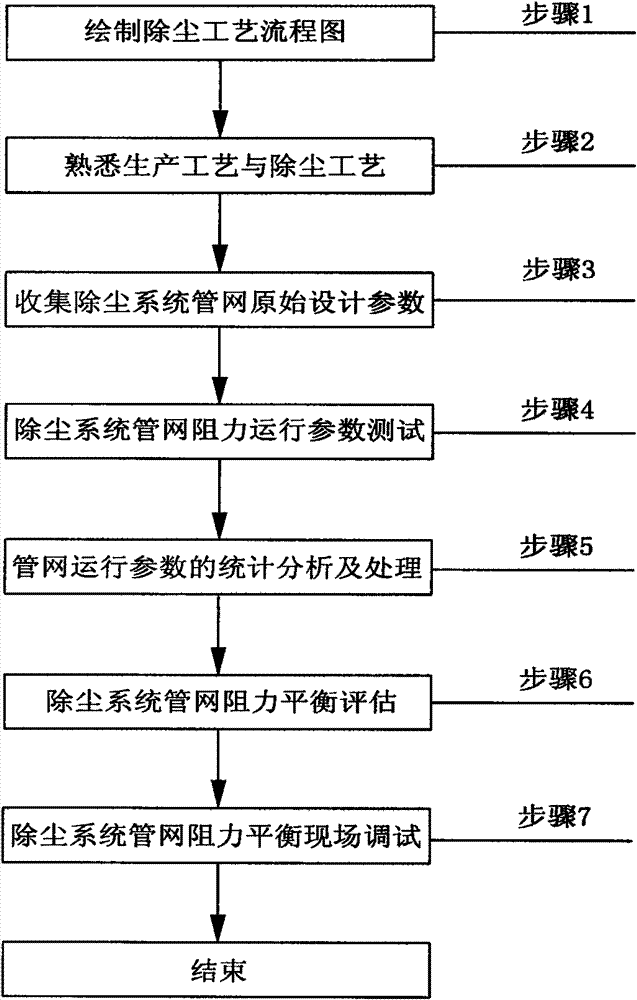

[0021] Such as figure 1 Shown:

[0022] Drawing the dust removal process figure 1 2. Familiar with the production process and dust removal process 2. On the basis of collecting the original design parameters of the dust removal system pipe network 3, test the resistance operation parameters of the dust removal system pipe network 4, conduct statistical analysis and processing of the dust removal system pipe network operating parameters 5, and communicate with them The original design parameters 3 of the dust removal system pipe network are benchmarked and compared to evaluate the resistance balance of the dust removal system pipe network 6 . According to the evaluation results of the pipe network resistance balance of the dust removal system, on-site debugging7 of the pipe network resistance balance of the dust removal system is carried out, so that the pipe ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com