Assessing and adjusting method of bag-type dedusting system

A technology of bag dust removal and dust removal system, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as neglect, and achieve the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

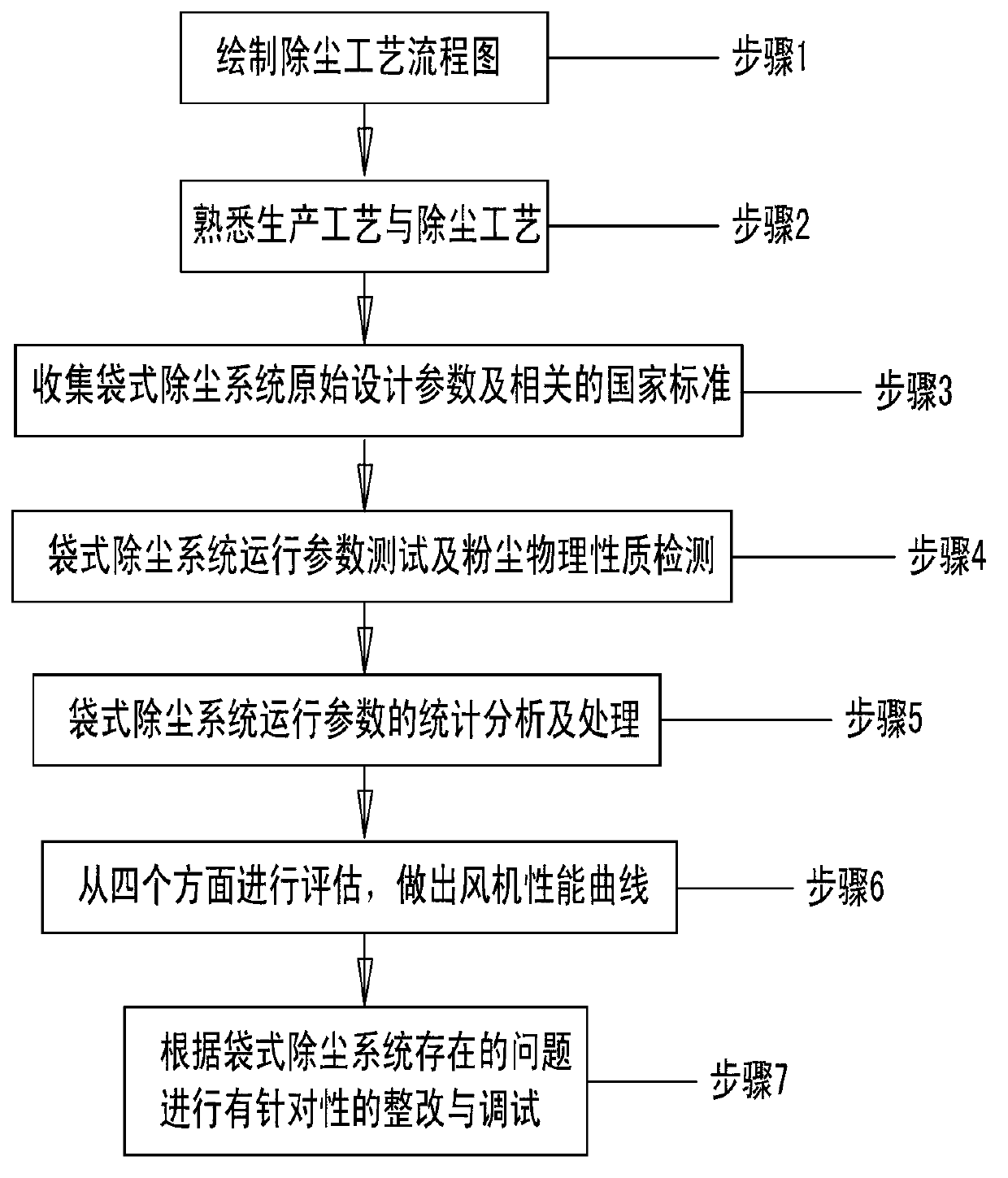

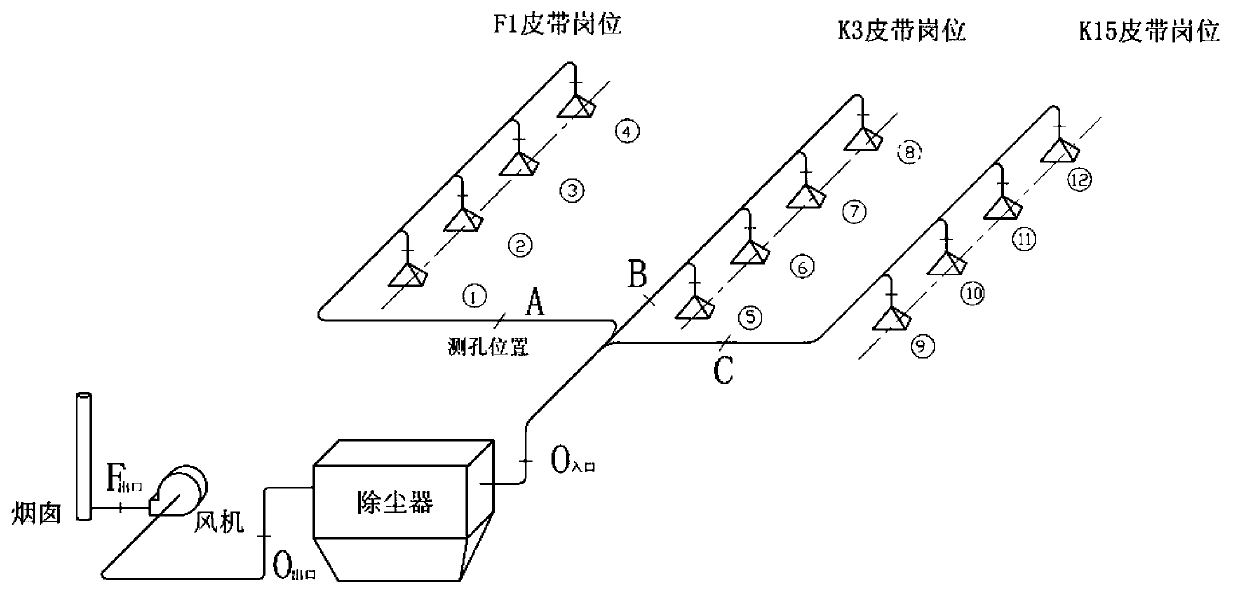

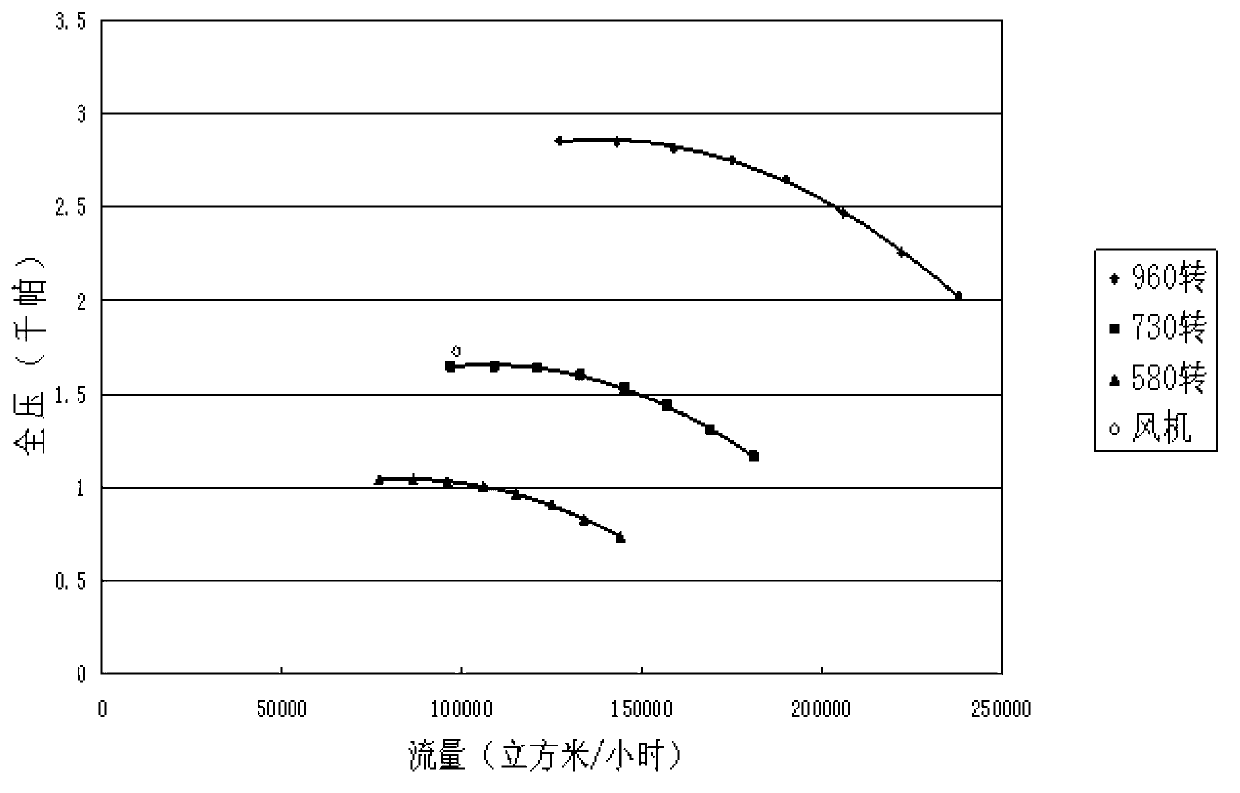

[0029] See figure 1 , the evaluation and debugging method of a bag type dust removal system of the present invention is realized in this way, on the basis of drawing the dust removal process flow chart, being familiar with the dust removal process and production process and collecting the original design parameters of the dust removal system pipe network, the bag type dust removal system The operating parameters are tested, and the measured operating parameters of each part of the bag type dust removal system are statistically analyzed and processed, and compared with the original design parameters of the dust removal system and related national standards, and then the operating conditions of the bag type dust removal system are evaluated. Conduct comprehensive diagnosis and assessment. The evaluation of the bag dust removal system starts from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com