Patents

Literature

58 results about "Process flowsheeting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process flowsheeting is the use of computer aids to perform steady-state heat and mass balancing, sizing and costing calculations for a chemical process. It is an essential and core component of process design.

Treatment of natural gas feeds

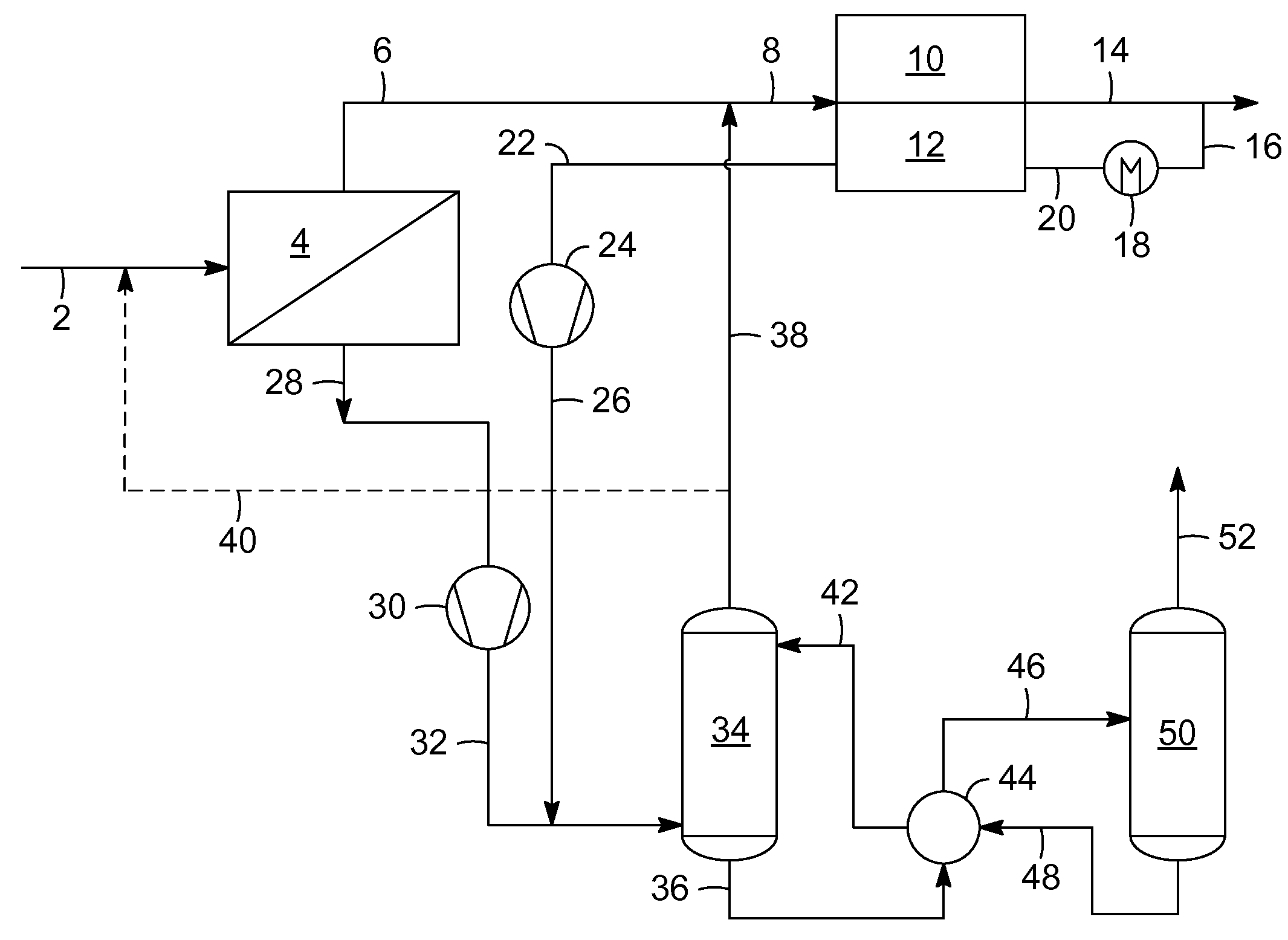

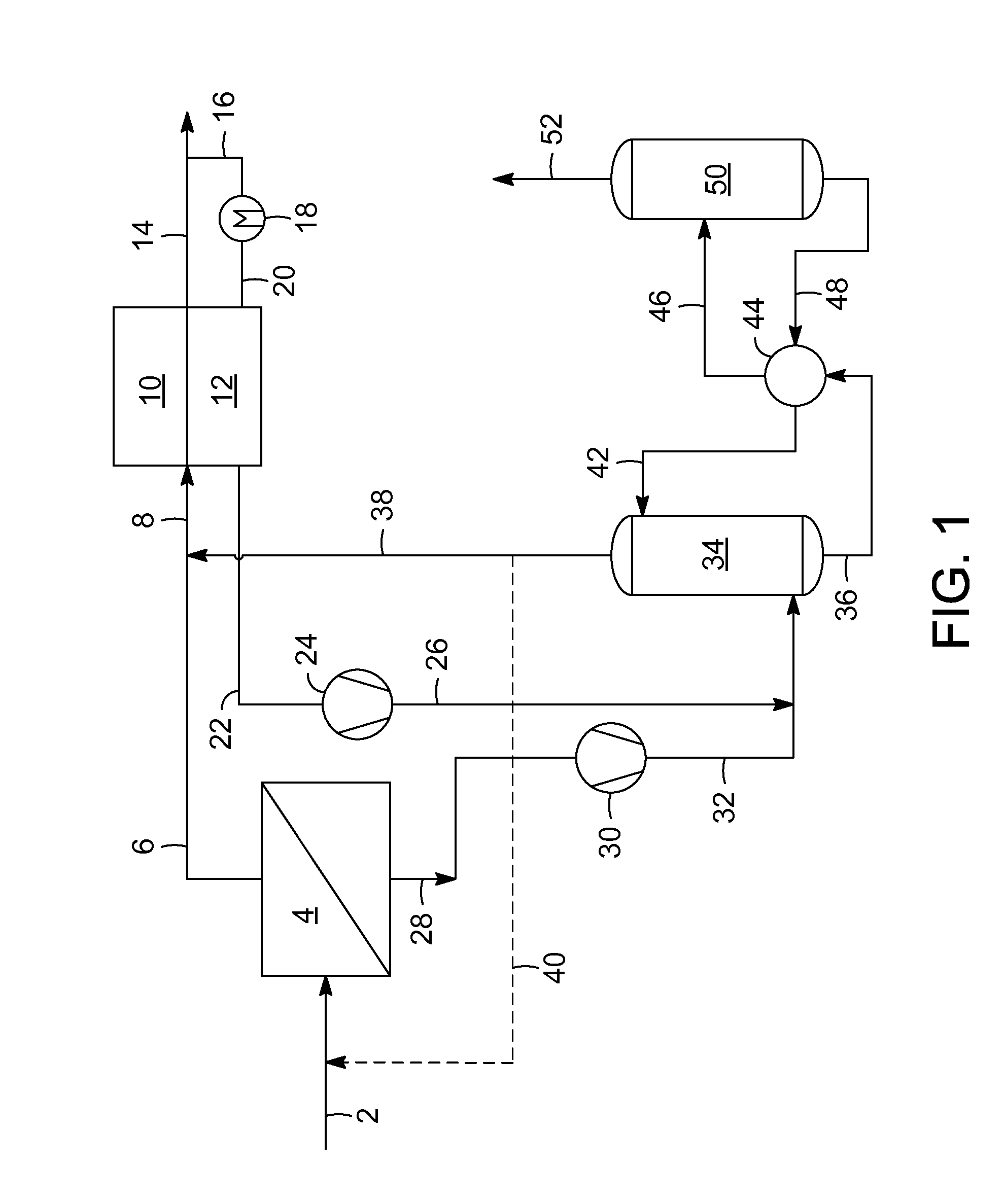

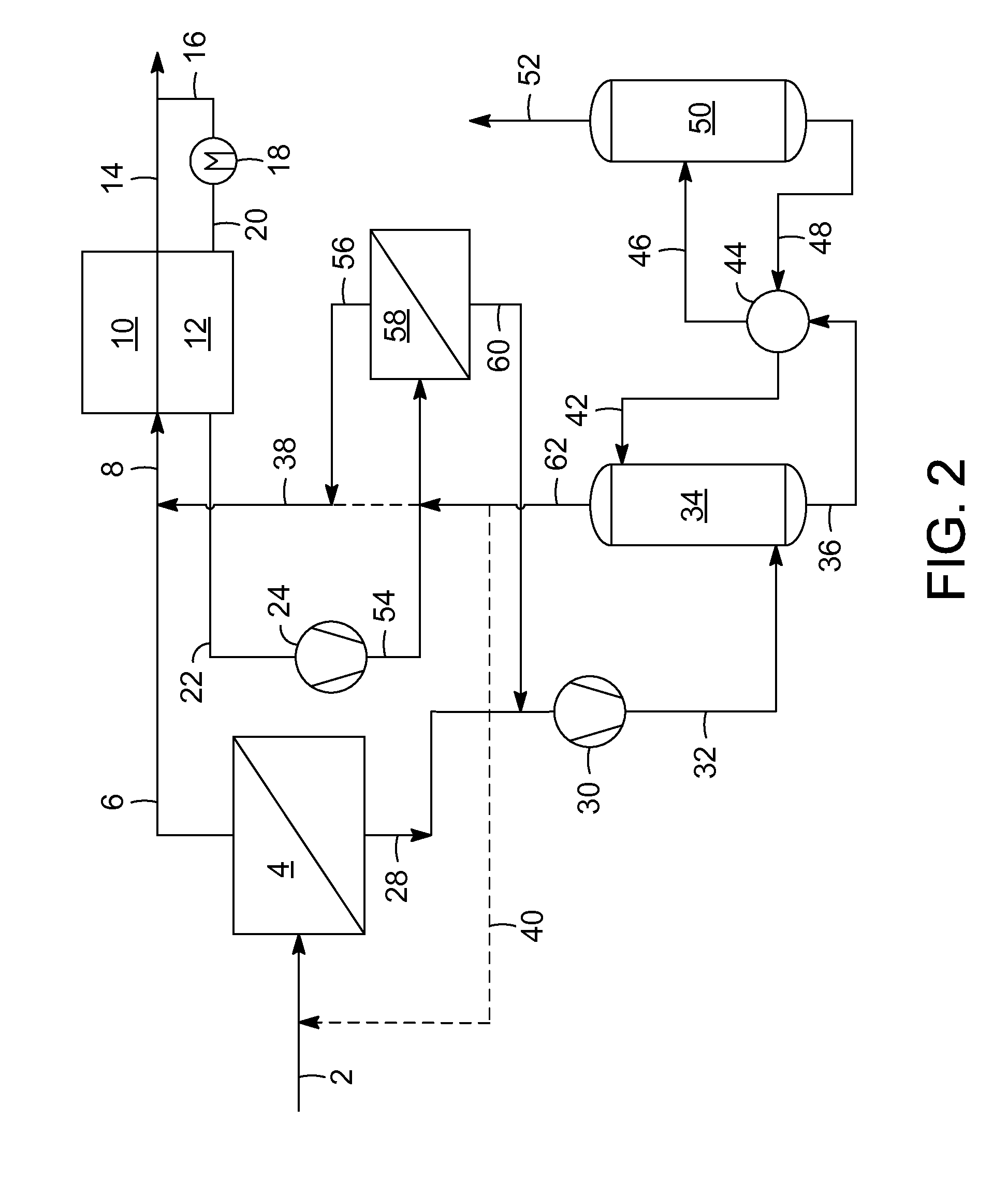

InactiveUS20110290111A1High carbon dioxide concentrationReduce concentrationMembranesGas treatmentHigh concentrationMolecular sieve

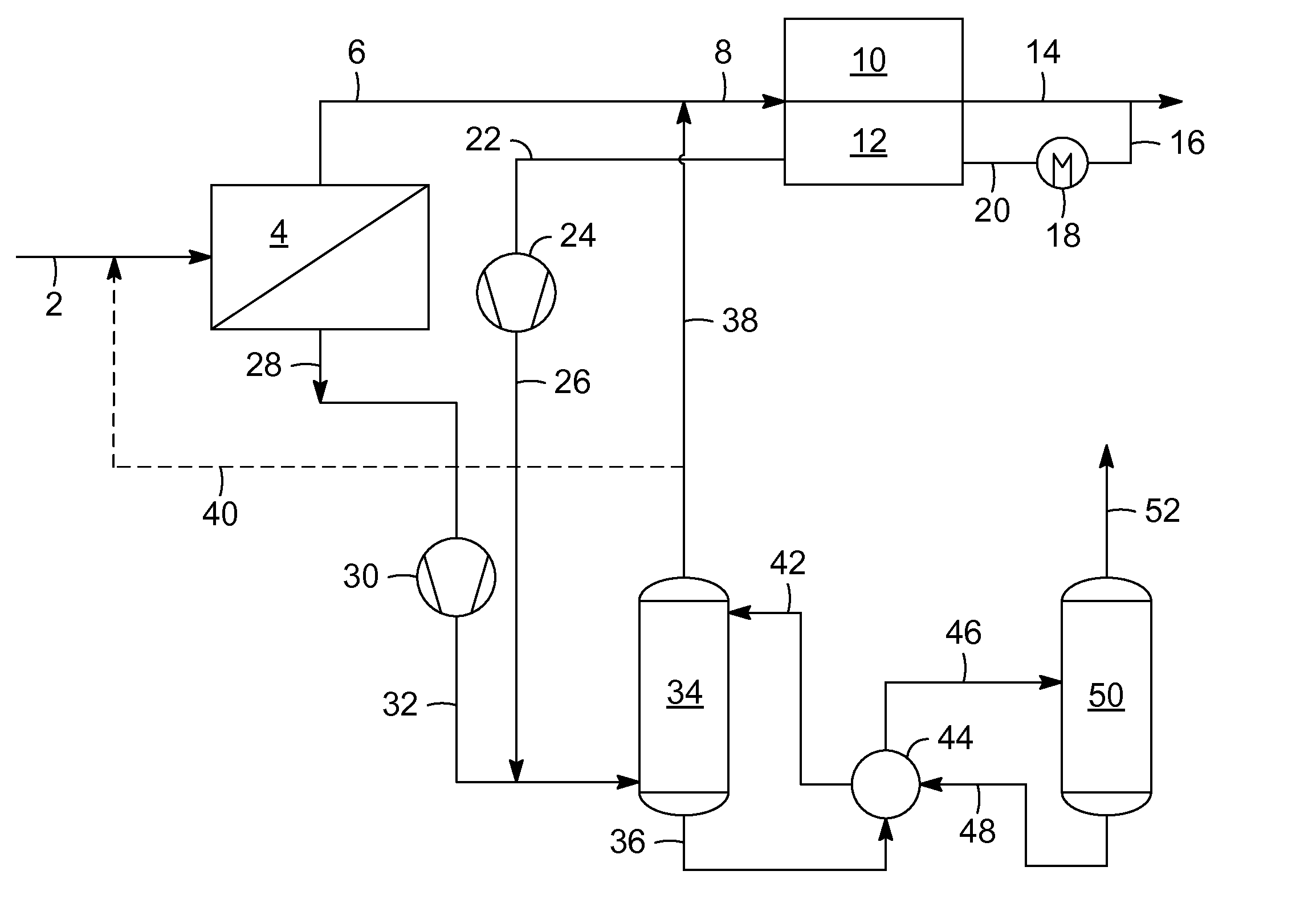

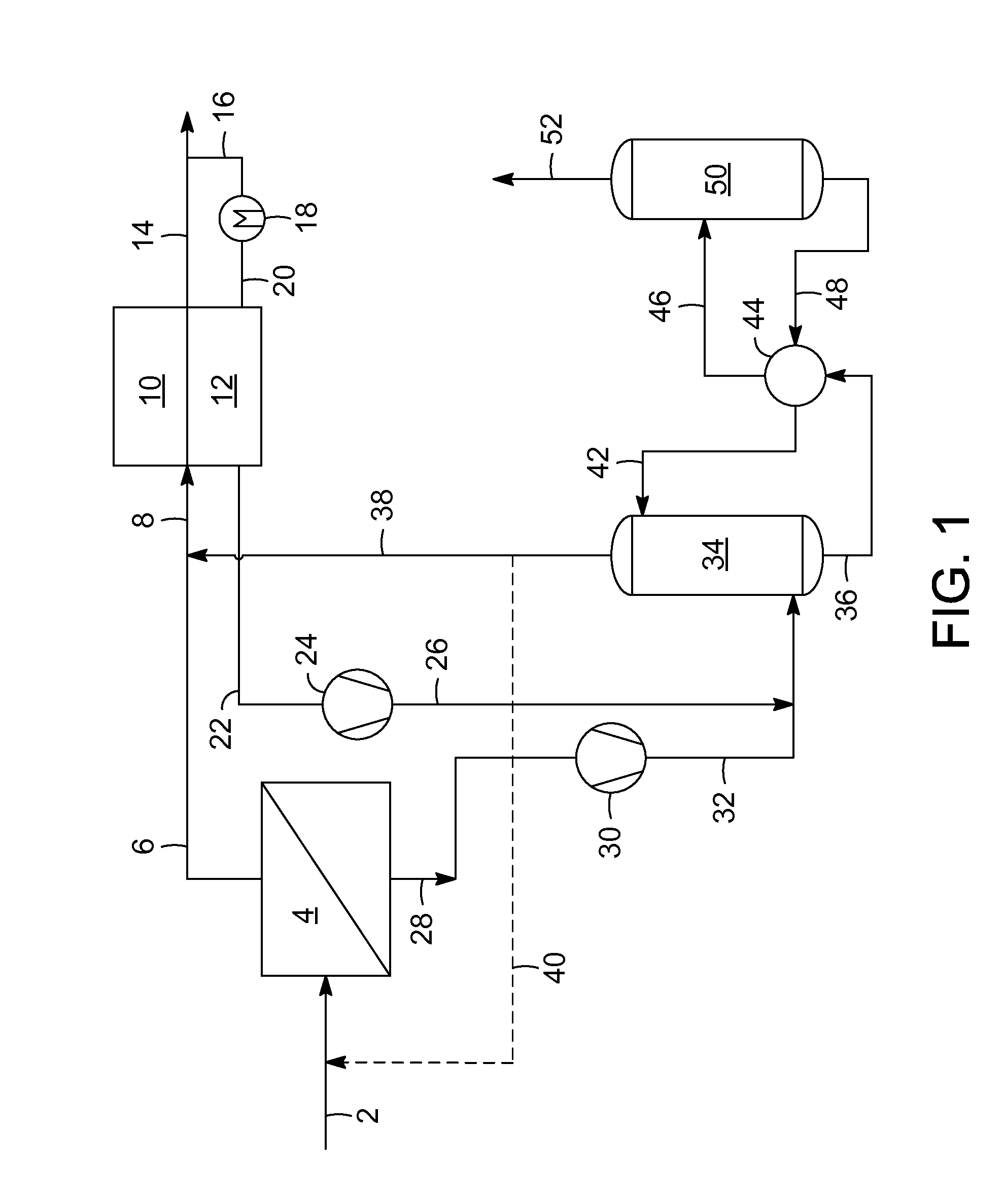

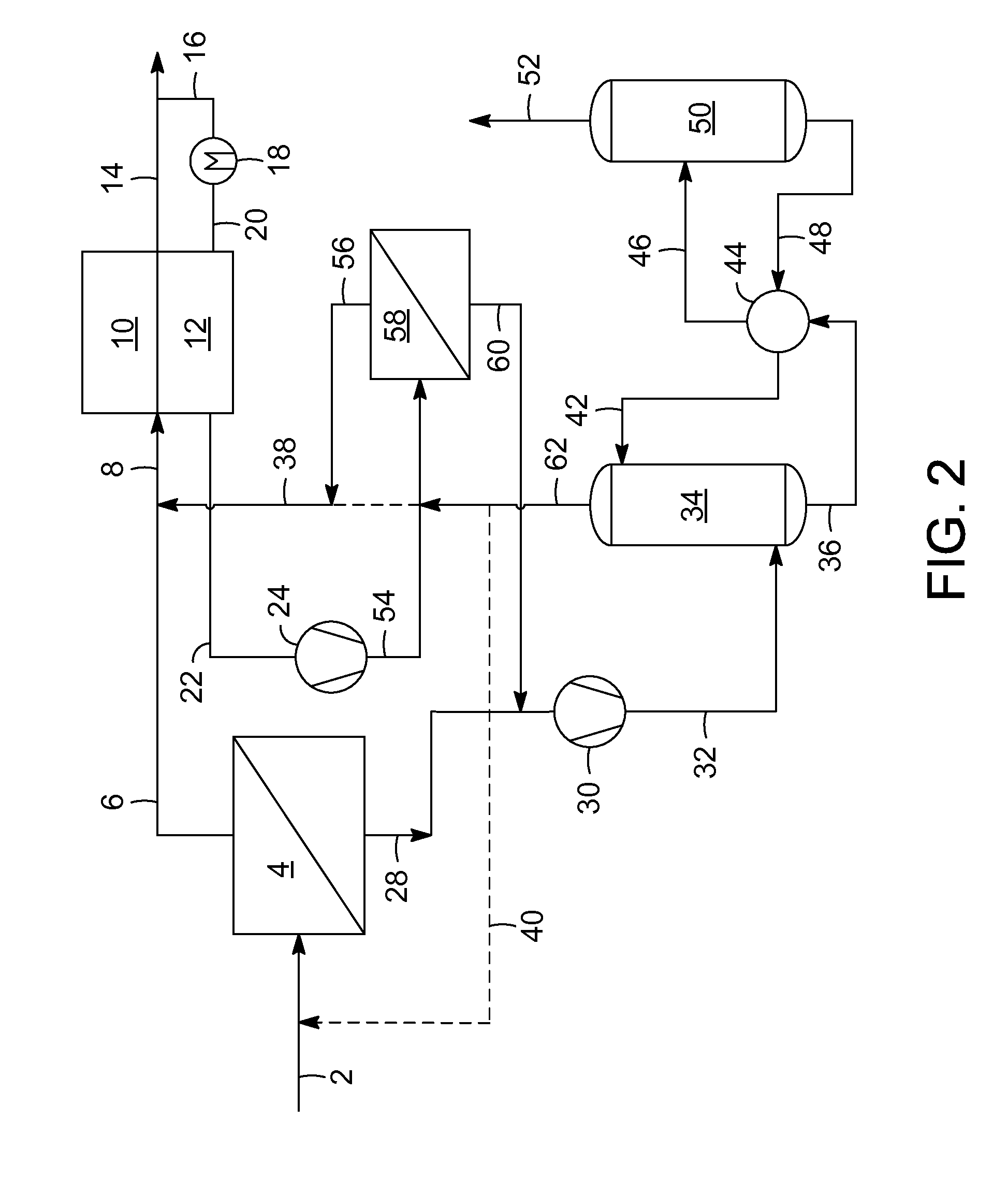

The present invention provides a process for treating a natural gas stream comprising sending a natural gas stream to at least one membrane unit to produce a permeate stream containing a higher concentration of carbon dioxide and a retentate stream containing a lower concentration of carbon dioxide. Then the retentate stream is sent to an adsorbent bed to remove carbon dioxide and other impurities to produce a natural gas product stream. The regeneration gas stream is sent through the molecular sieve adsorbent bed to desorb the carbon dioxide. In one process flow scheme, the regeneration stream is combined with the permeate stream from the membrane unit. Then the combined stream is sent to an absorbent column to remove carbon dioxide from the permeate stream to produce a second natural gas product stream. In the alternative flow scheme, a second membrane unit is used to improve efficiency.

Owner:UOP LLC

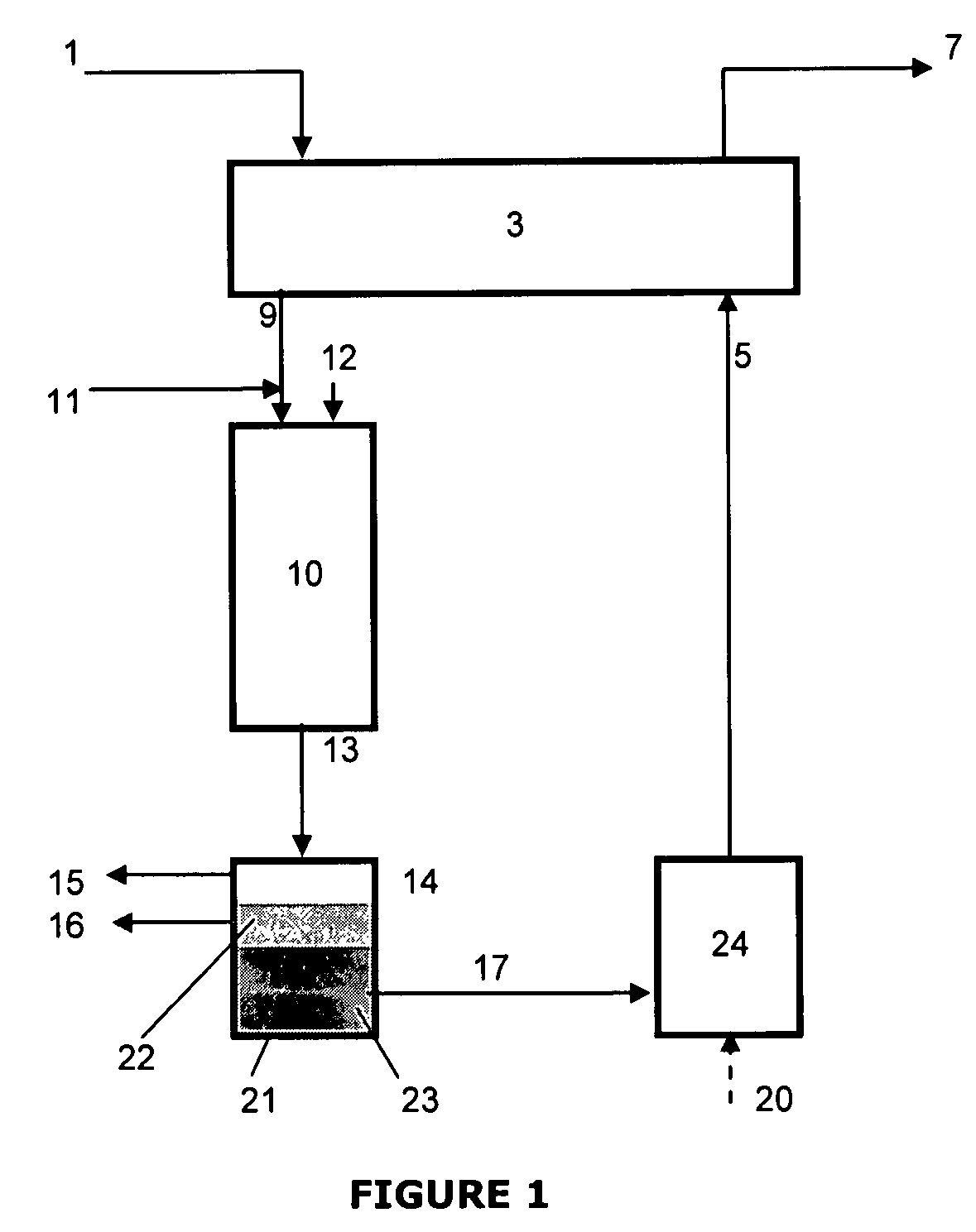

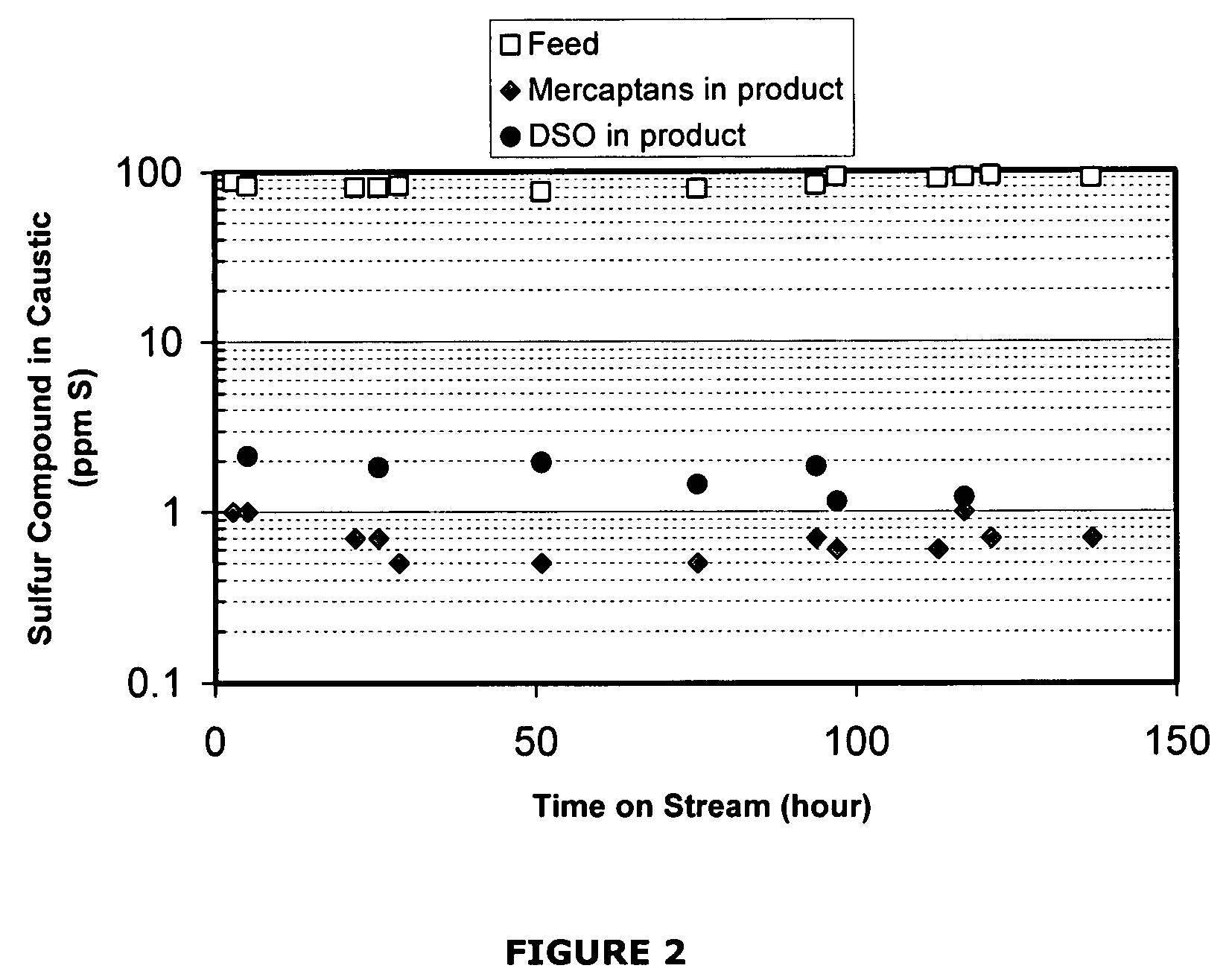

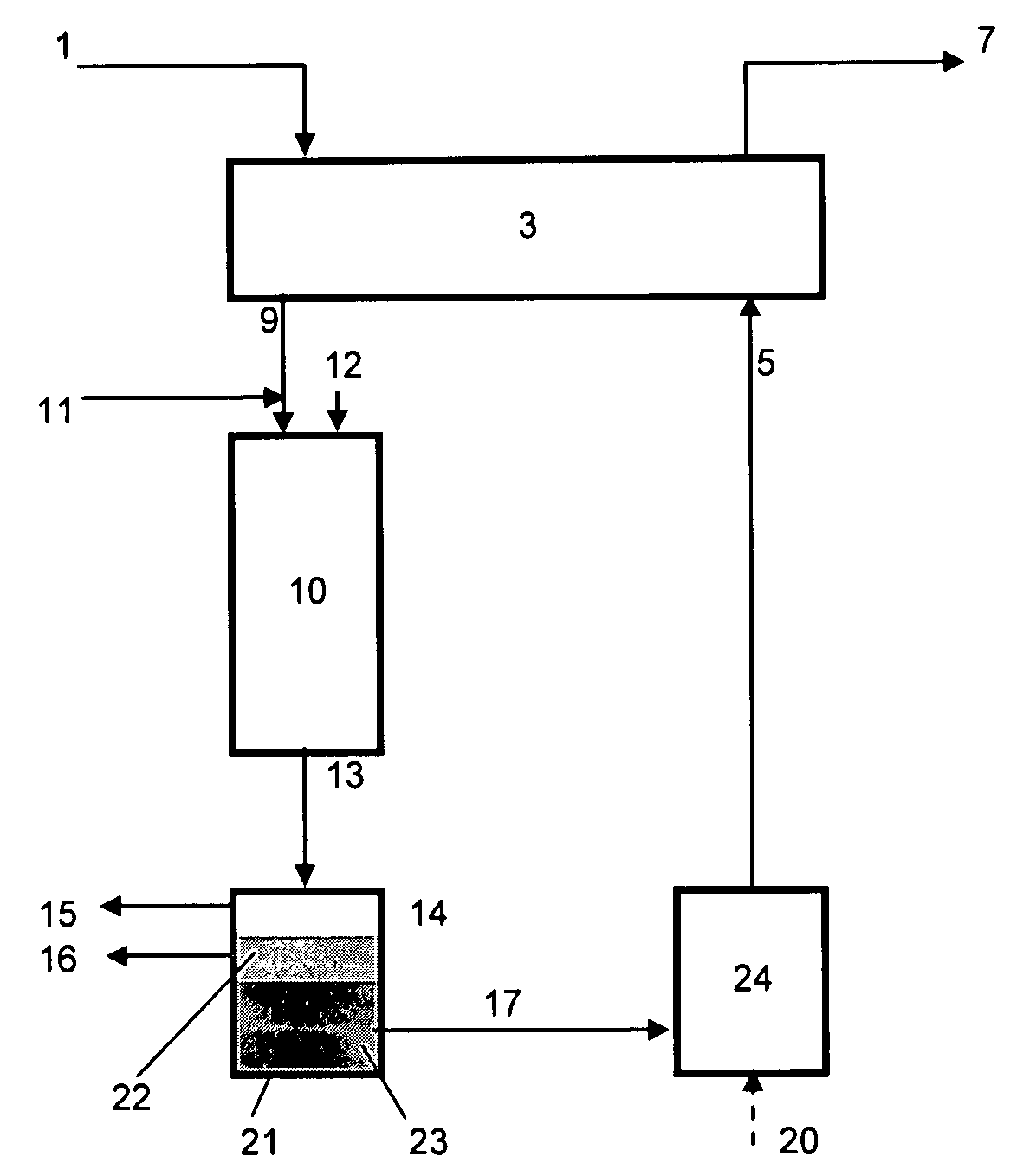

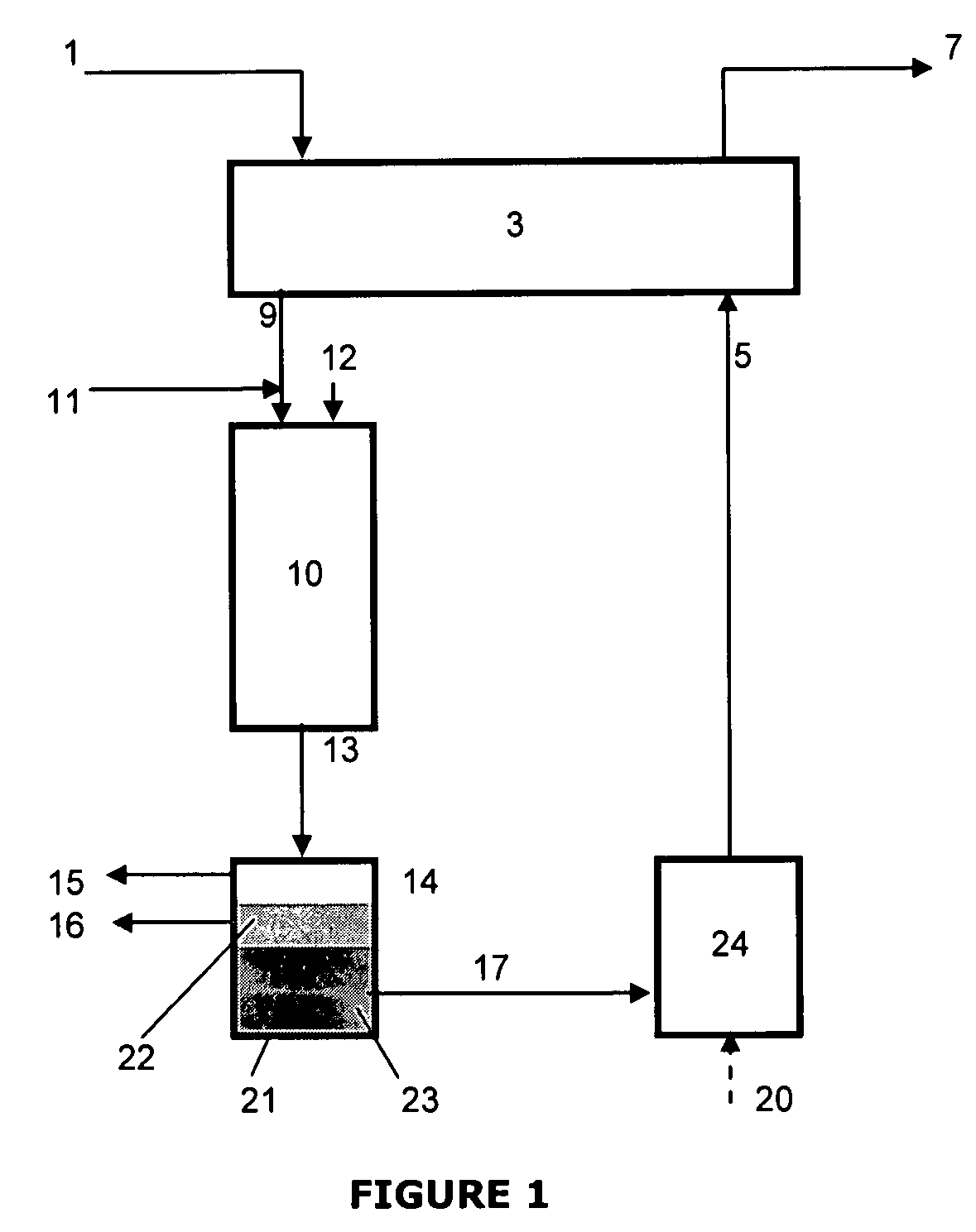

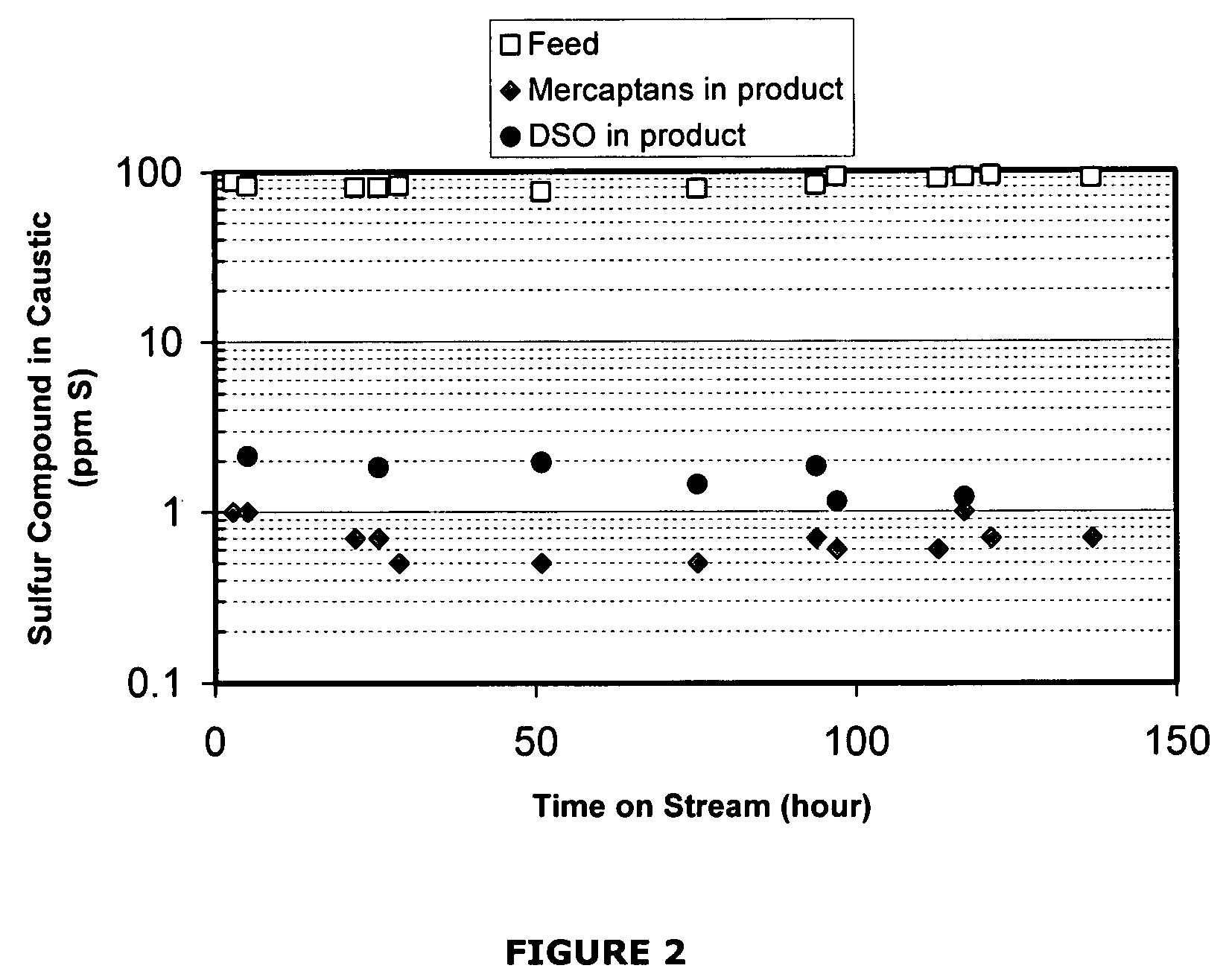

Removal of residual sulfur compounds from a caustic stream

Owner:MERICHEM CO

Removal of residual sulfur compounds from a caustic stream

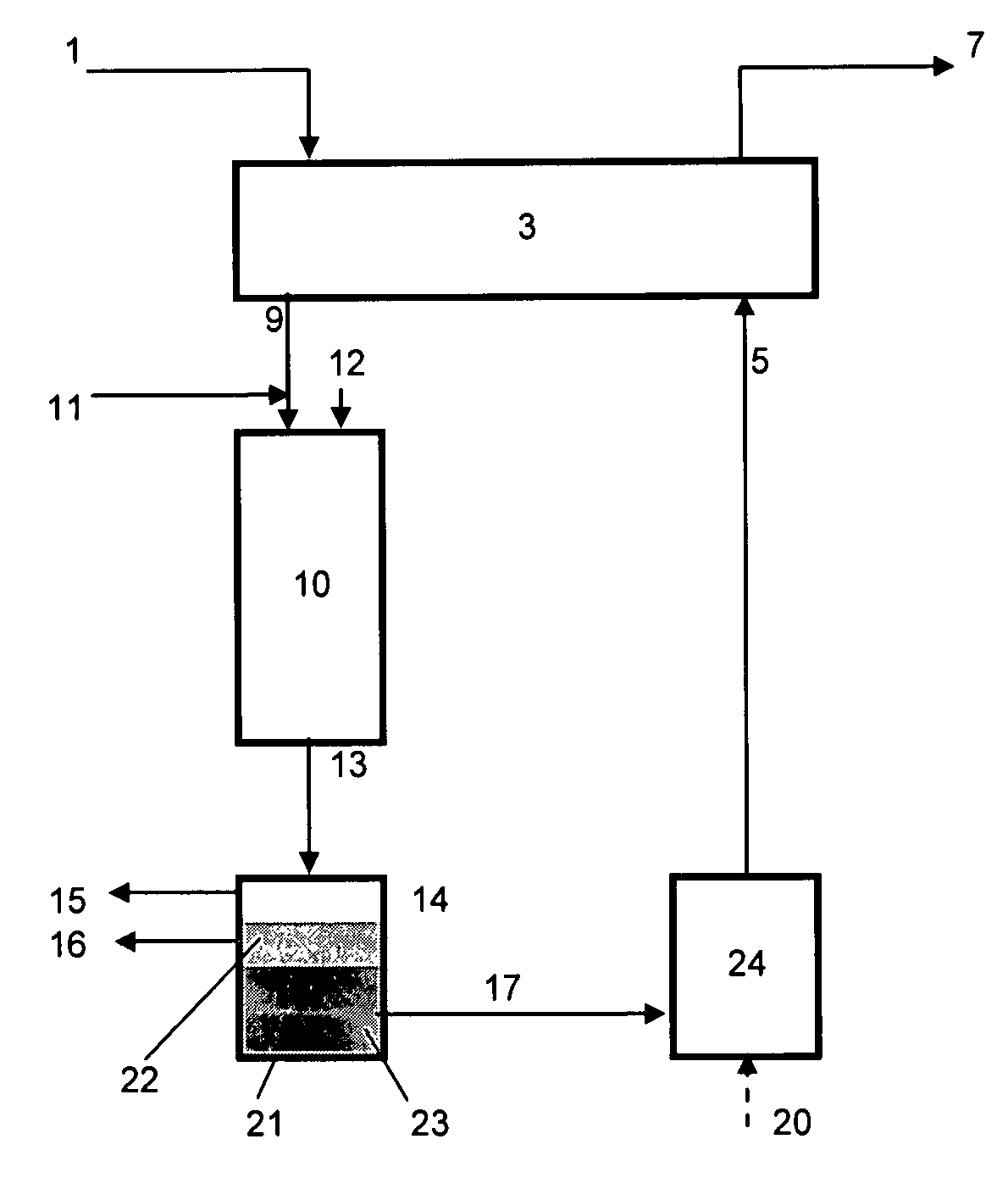

InactiveUS20090065434A1Ion-exchanger regenerationSolid sorbent liquid separationActivated carbonSorbent

A process for the removal of residual sulfur compounds from a liquid caustic stream is disclosed. One embodiment of my invention adsorbs disulfides from a caustic stream using an activated carbon adsorbent while another combines both oxidation and adsorption in single step to remove residual sulfur compounds from a rich caustic stream using metal phthalocyanine supported on a solid adsorbent. This process is especially useful as a polishing step in a caustic regeneration process flow scheme.

Owner:MERICHEM CO

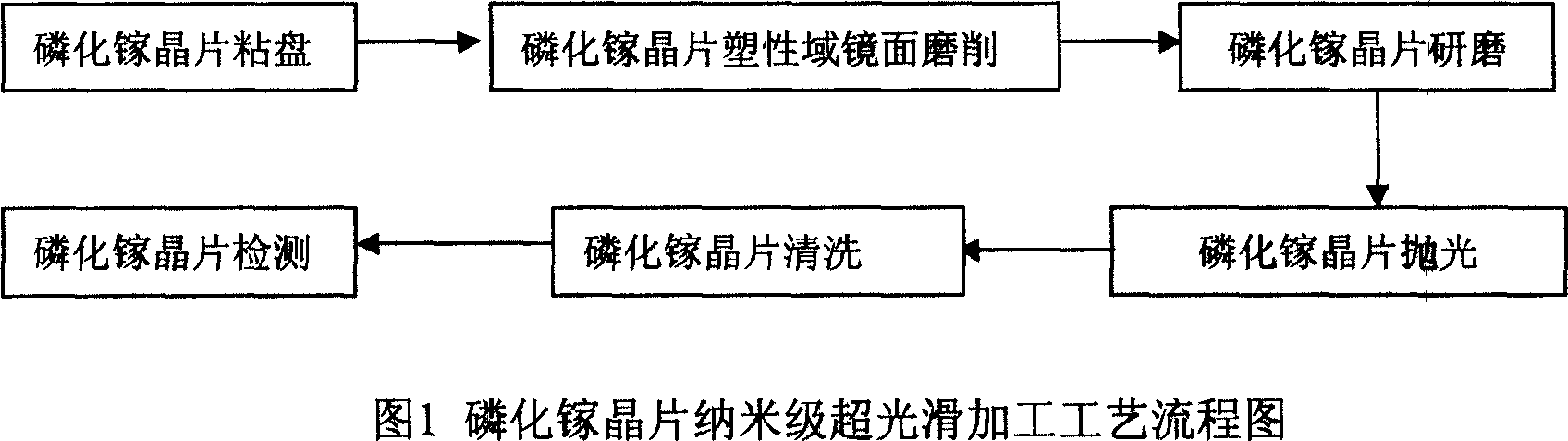

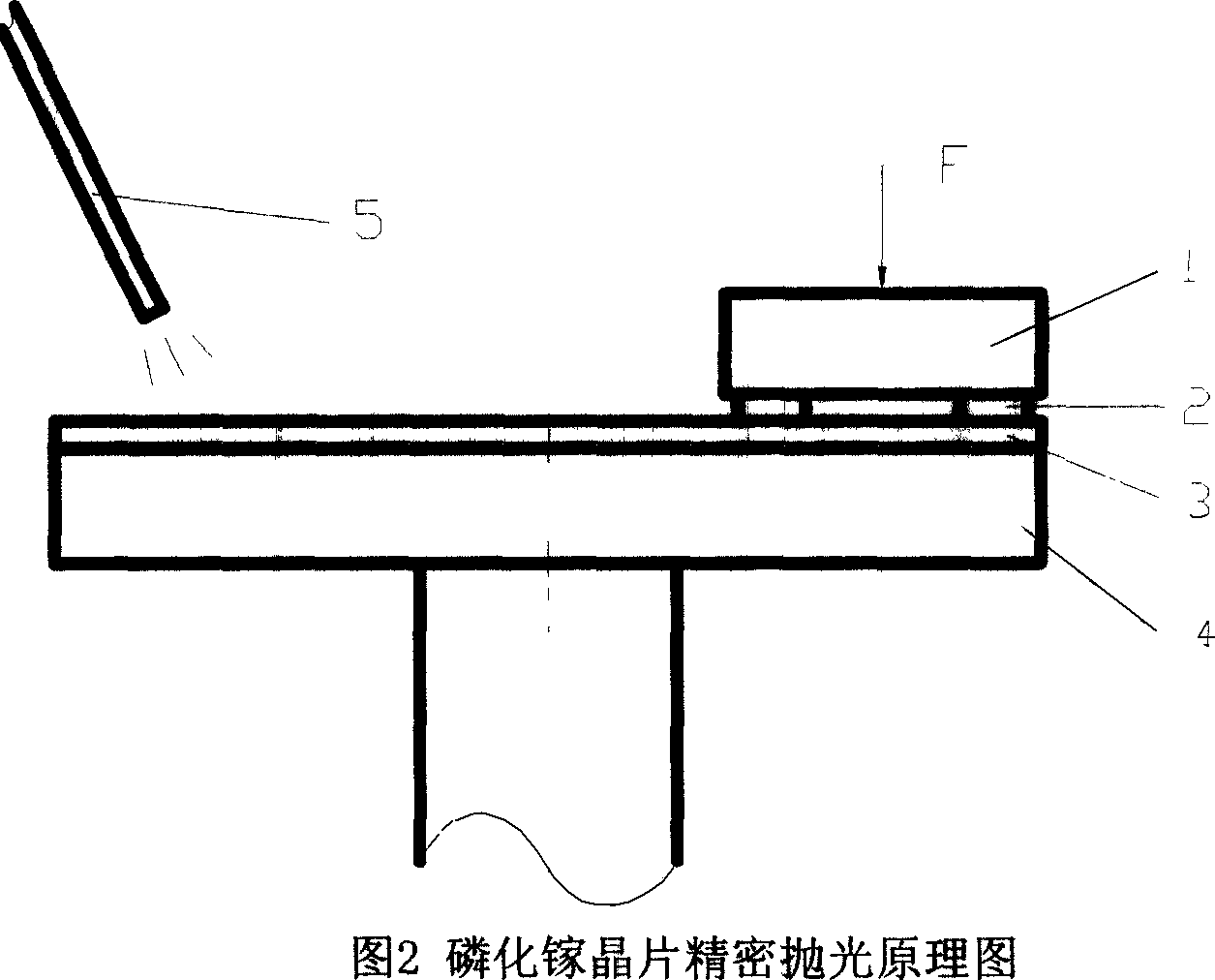

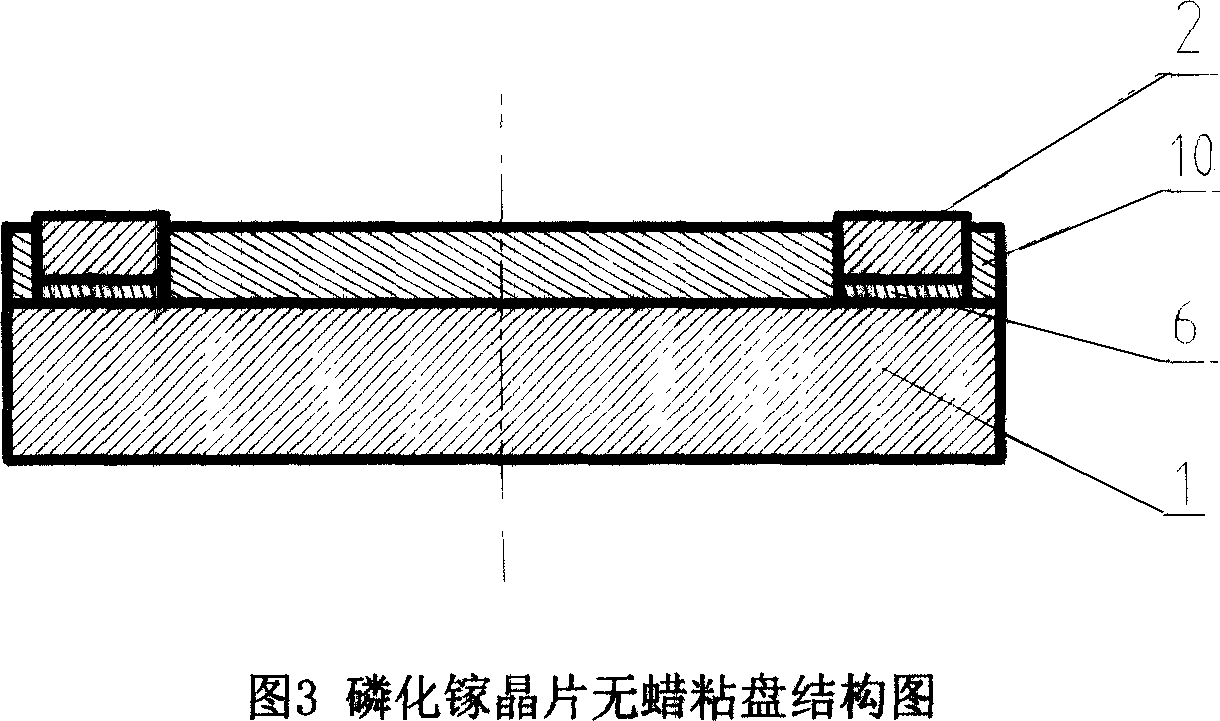

Technique for nanometer grade super smooth processing gallium phosphide wafer

InactiveCN1947944AEasy to processQuality improvementSemiconductor/solid-state device manufacturingLapping machinesProduction rateSurface roughness

A nano-class super-smooth technology for processing the GaP wafer used to prepare blue and red LEDs includes such steps as adsorbing the GaP wafer on the bearing disc by water, plastic abrading, grinding, polishing and cleaning. Its dedicated grinding liquid, polishing liquid, cleaning liquid and their components are also disclosed.

Owner:周海

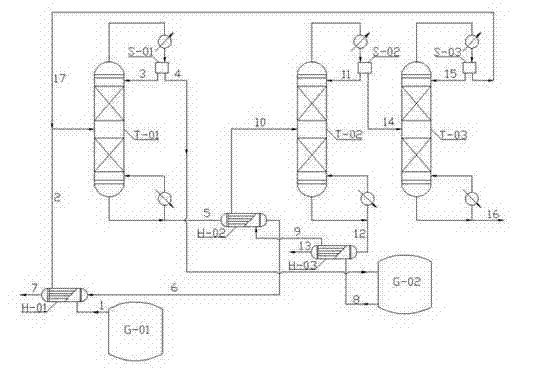

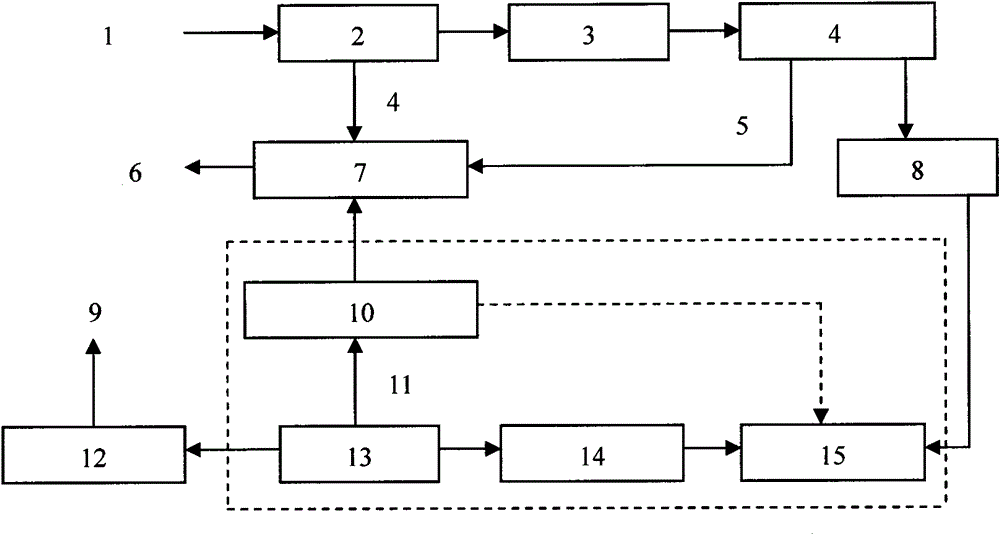

High purity recycling and energy integration technology for different concentrations of dichloromethane wastewater

InactiveCN102126917AHigh puritySolve the azeotropic problemWater/sewage treatment by heatingHalogenated hydrocarbon preparationWastewaterEnergy integration

The invention relates to a high purity recycling and energy integration technology for different concentrations of dichloromethane wastewater. The process flow diagram is shown in the figure 1. The technology is as follows: different concentrations of dichloromethane wastewater performs rectification three times, water is removed from the three fractions and dichloromethane of which purity is 99.95% can be obtained finally. In the technological process, the waste heat of the discharged material in the tank bottom can be fully utilized to preheat the material to be distilled, thus the energy can be fully utilized. The technology can be suitable for all the occasions of the high purity recycling of dichloromethane wastewater.

Owner:NANJING UNIV

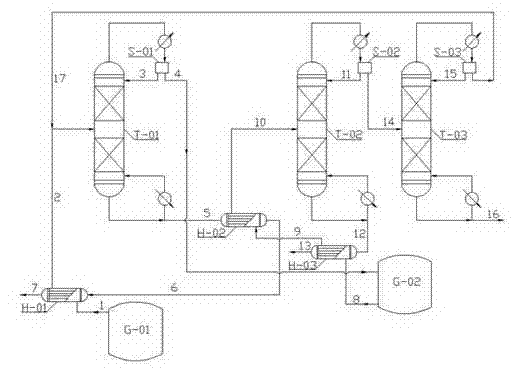

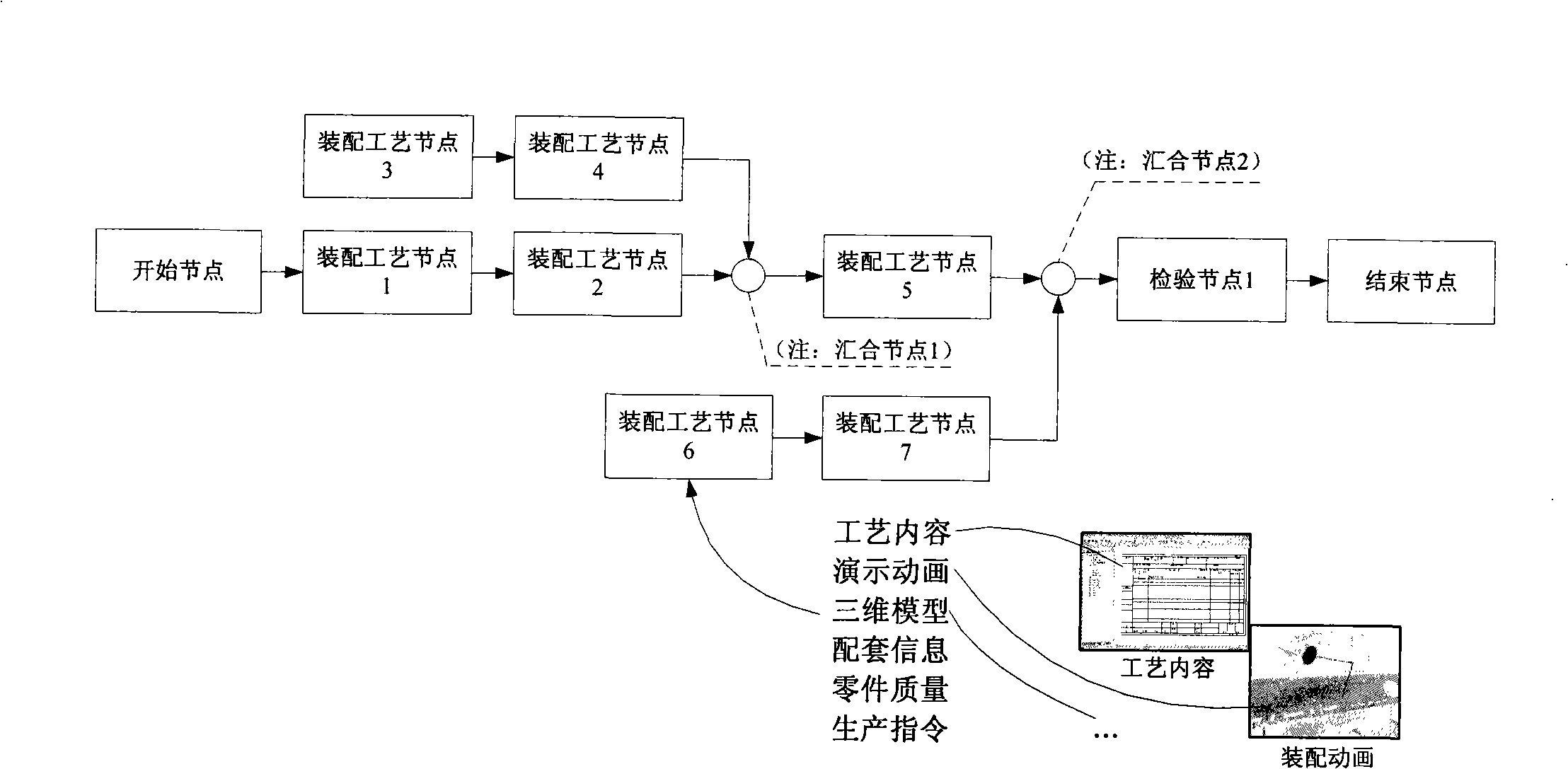

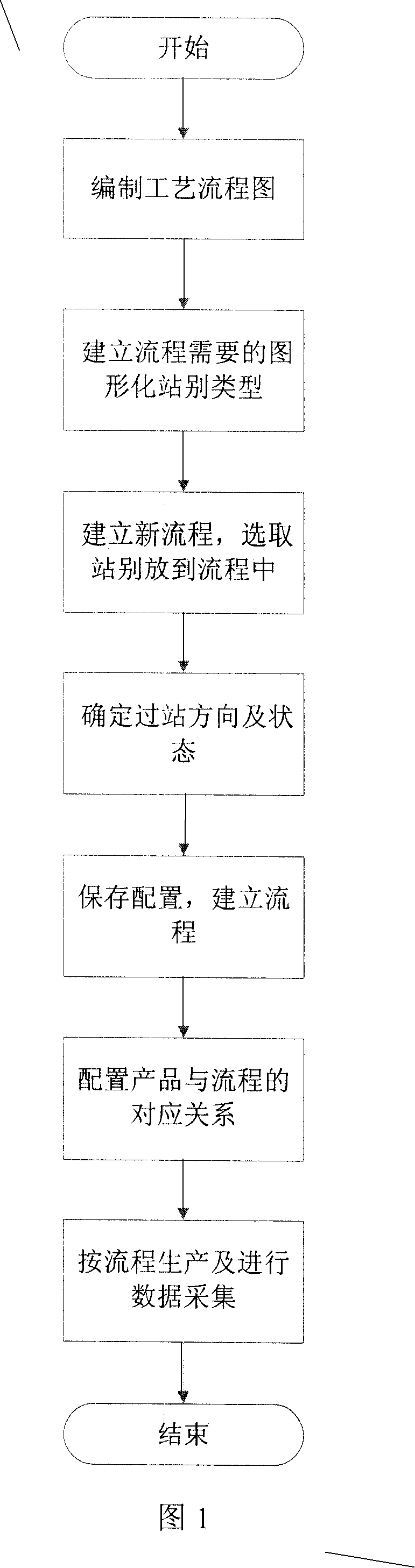

Computer auxiliary assembly process control method facing to manual assembly

InactiveCN101299153ATime controlRealize unified data managementTotal factory controlProgramme total factory controlManufacturing technologyData acquisition

A novel method for controlling the auxiliary assembling process of the computer which is manually assembled belongs to the digital design and manufacturing technique category in the advanced manufacturing field, and especially relates to the method for controlled the assembling process of product. The invention aims at the problems of larger randomness of the assembling process based on the product assembled manually, no evident producing beat and no effective technical facility and method for controlling the assembling process of product, and presents a novel control method which orients the auxiliary assembling process of the computer assembled manually. The method is composed of three modules of establishing a process chart of assembling technique, integratedly displaying the assembling information and collecting the station data, and controlling the assembling process flow and monitoring the assembling process. The invention provides an effective path and method for settling the difficulty for controlling assembling process of the product assembled manually through the effective control to the time progress, technical state and assembling quality in the assembling process of product and centralized-managing the data based on the assembling flow path.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

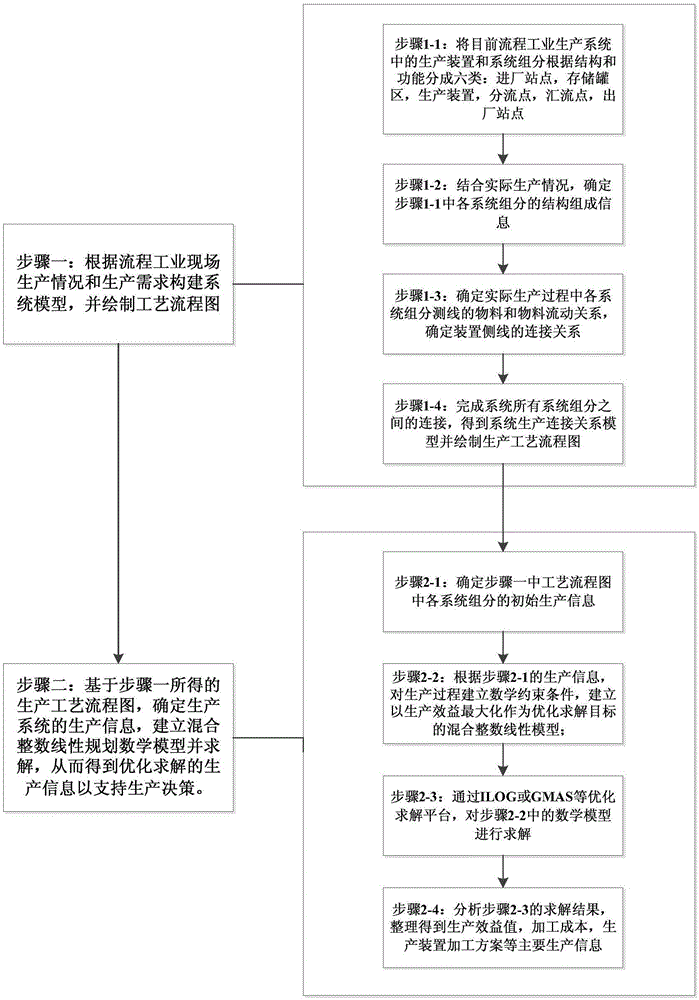

Control method of process industry production system

InactiveCN105096008AConvenient structureMaximize production efficiencyForecastingLogisticsLogistics managementEngineering

The invention discloses a control method of a process industry production system. The control method comprises the following steps: according to the site production situation and the production requirements of the process industry production system, constructing a system model, and drawing a production technological process chart; on the basis of the production technological process chart, determining the production information of the production system, and establishing a target function based on mixed integer linear programming; and taking system production benefit maximization as an optimization object to carry out optimization solution on the target function, and obtaining optimal production information used for controlling the process industry production system. The invention provides a feasible control method of the process industry production system, the control method realizes the combination of the unified modeling and the logistics optimization of the process industry production system, is effective and universal and can provide effective reference information for a production plan of the process industry for controlling.

Owner:ZHEJIANG UNIV

Treatment of natural gas feeds

The present invention provides a process for treating a natural gas stream comprising sending a natural gas stream to at least one membrane unit to produce a permeate stream containing a higher concentration of carbon dioxide and a retentate stream containing a lower concentration of carbon dioxide. Then the retentate stream is sent to an adsorbent bed to remove carbon dioxide and other impurities to produce a natural gas product stream. The regeneration gas stream is sent through the molecular sieve adsorbent bed to desorb the carbon dioxide. In one process flow scheme, the regeneration stream is combined with the permeate stream from the membrane unit. Then the combined stream is sent to an absorbent column to remove carbon dioxide from the permeate stream to produce a second natural gas product stream. In the alternative flow scheme, a second membrane unit is used to improve efficiency.

Owner:UOP LLC

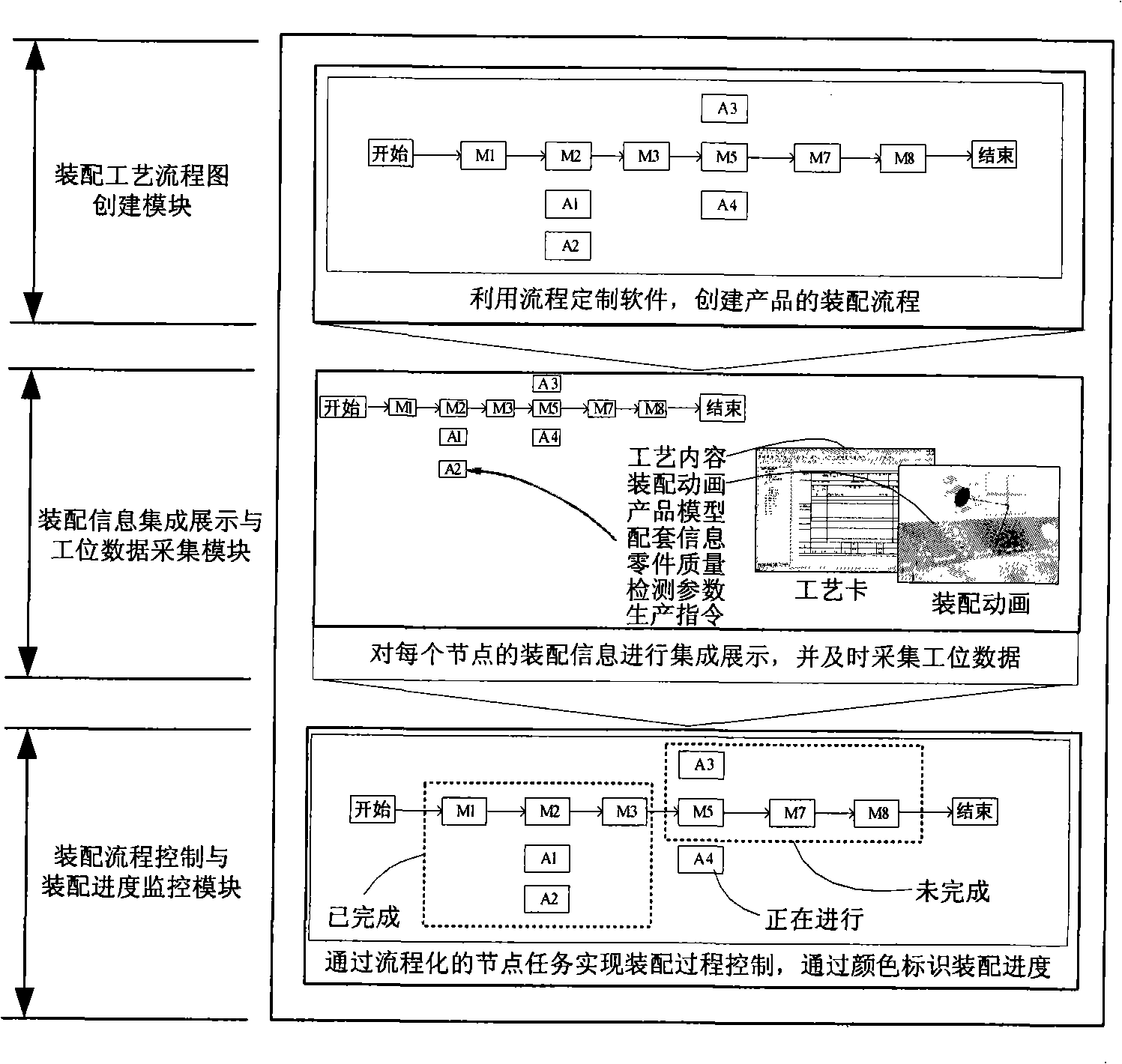

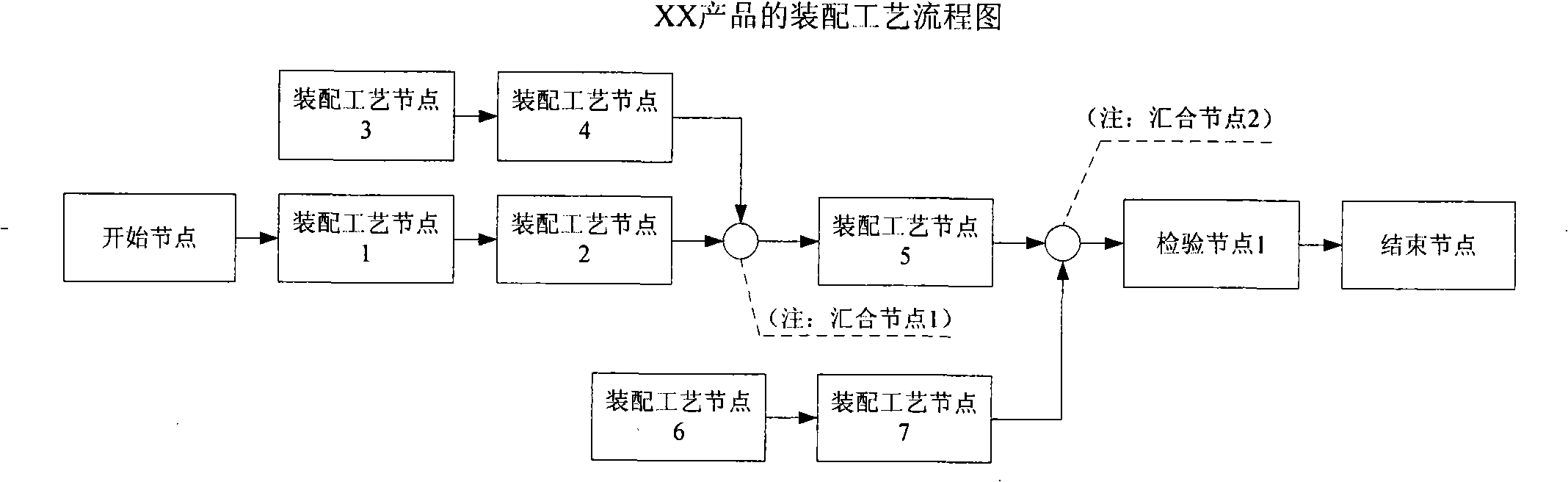

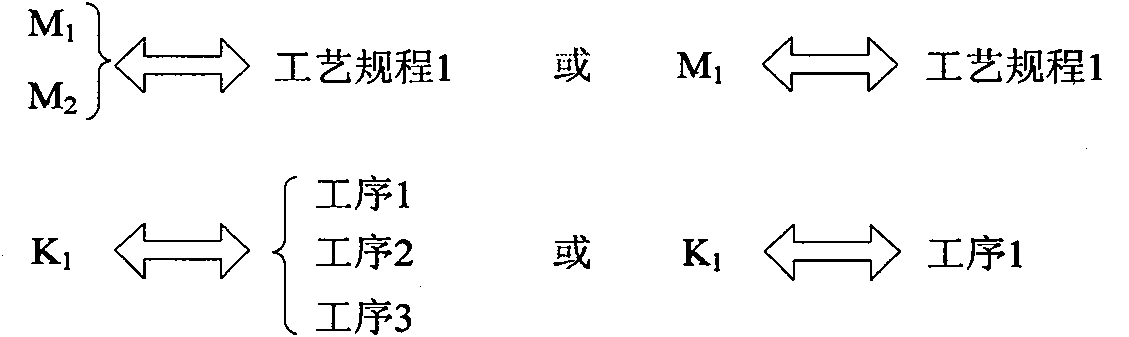

Design method of production flow

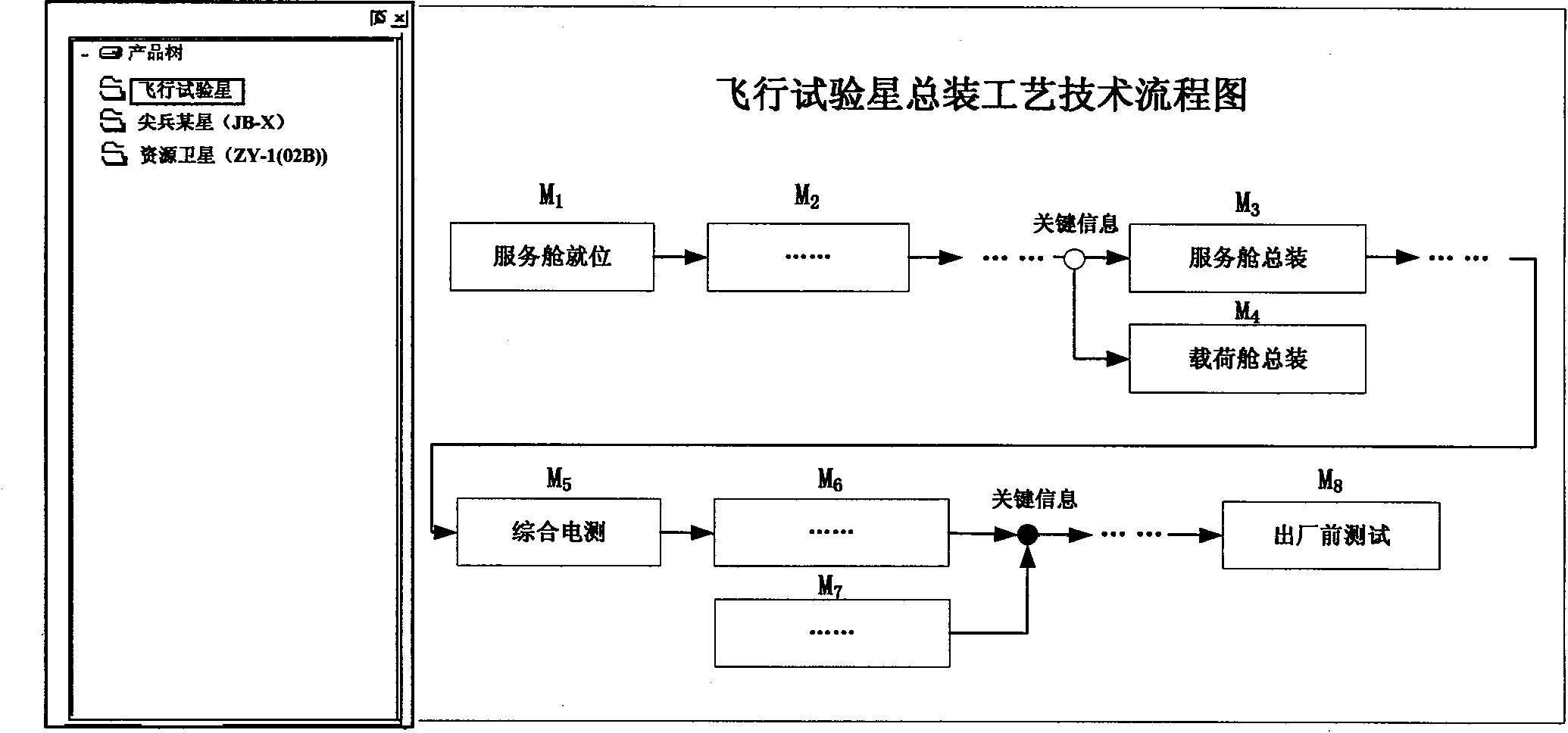

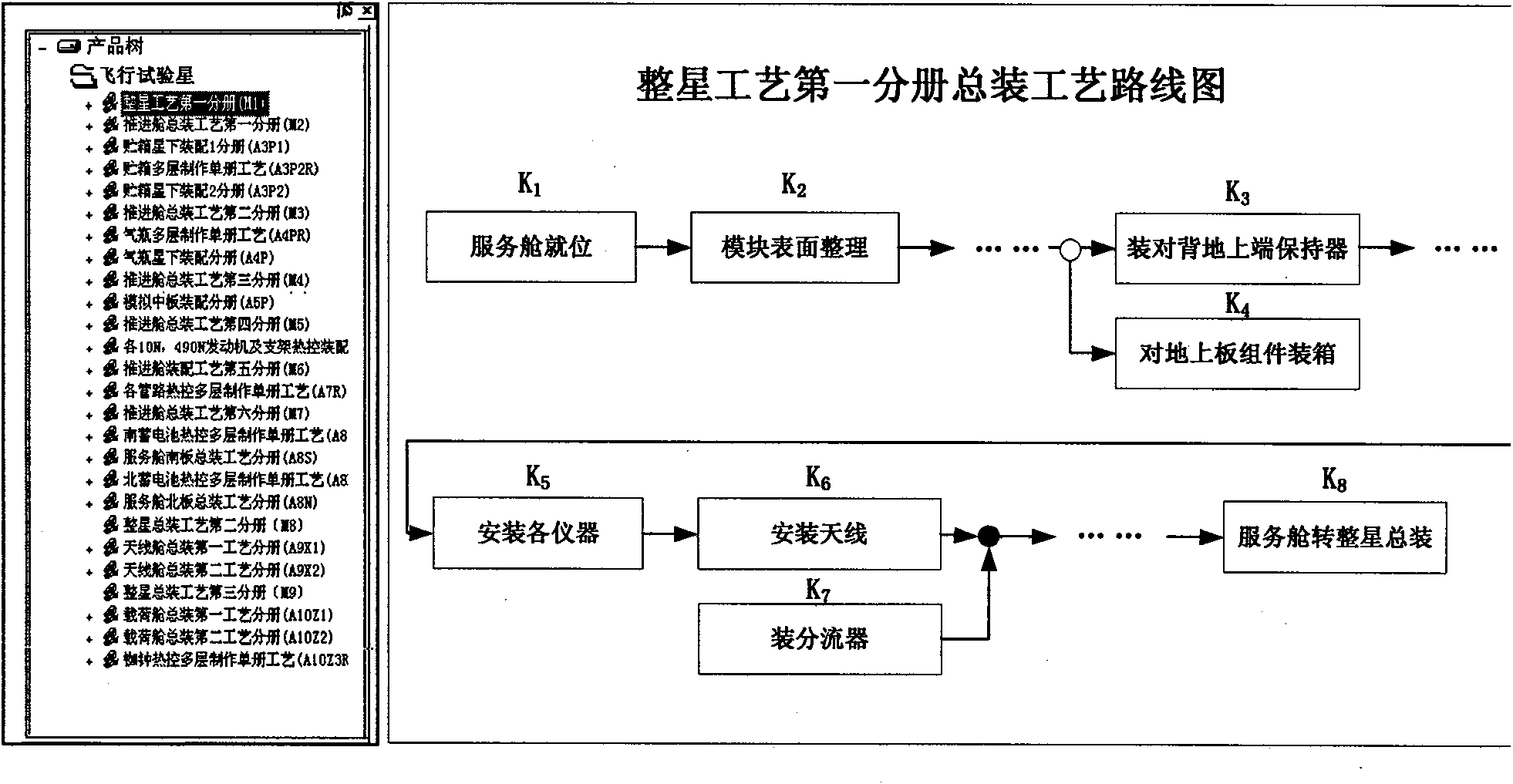

InactiveCN101770523ARealize guided productionEasy to useSpecial data processing applicationsGraphicsTheoretical computer science

The invention relates to a design method of a production flow. In the method, a final assembly (FA) process technique flowchart is drawn: firstly, selecting that the FA process technique flowchart of which spacecraft needs to be generated under a product tree, wherein the FA process technique flowchart comprises parallel operation nodes (M3, M4) and key nodes (M6, M7), and the next node is drawn after the key nodes (M6, M7) are finished; an FA process route chart is drawn: firstly, selecting to generate a process route chart of the FA process, wherein the process route chart comprises parallel operation nodes (K3, K4) and key nodes (K6, K7), the next node is drawn after the key nodes (K6, K7) are finished, the meeting position of arrows of parallel nodes is represented by a hollow or solid circle, and a numeric ordinal (K1) is generated automatically after a geometric figure is increased at one time; the incidence relation between the nodes in a graph is defined: establishing the congruent relationship M-K of the node M in the process flowchart and the node K in the process route chart and adding the corresponding process and the nodes K in the corresponding process in each pixel in the graph after drawing the FA process technique flowchart; a procedure information K-procedure is added in the process route chart: each node in a procedure route chart does not correspond to each procedure in a procedure list, each node in the process route chart can correspond to a plurality of procedures in the procedure list, but one procedure in the procedure list only belongs to one node in the procedure route chart; graphs are browsed: the graphs are managed by adopting the product tress mode; when one type on a structural tree is selected, the corresponding process technique flowchart can be displayed; sub-nodes in the process technique flowchart form the process route chart, and each pixel in the process route chart can display the corresponding.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

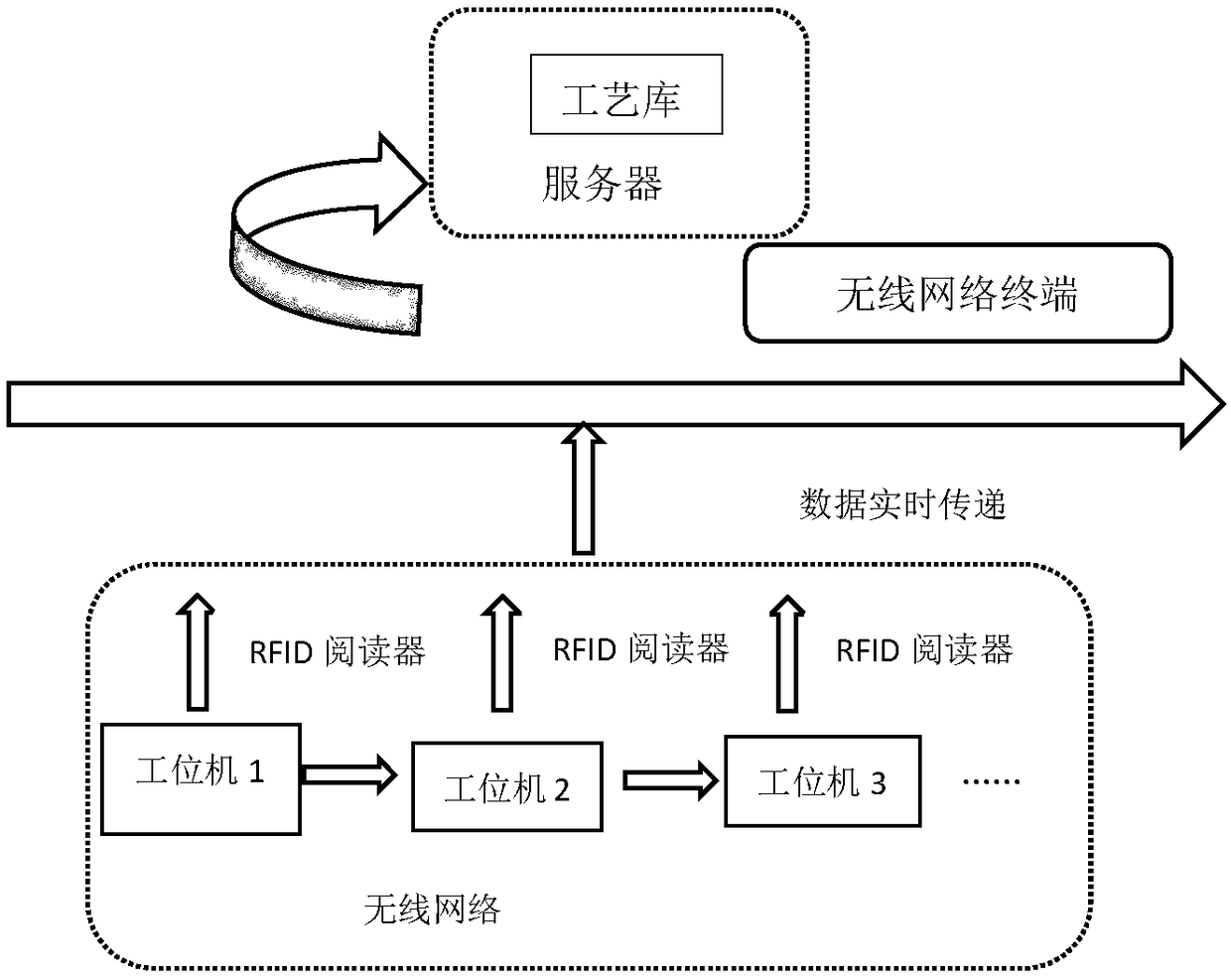

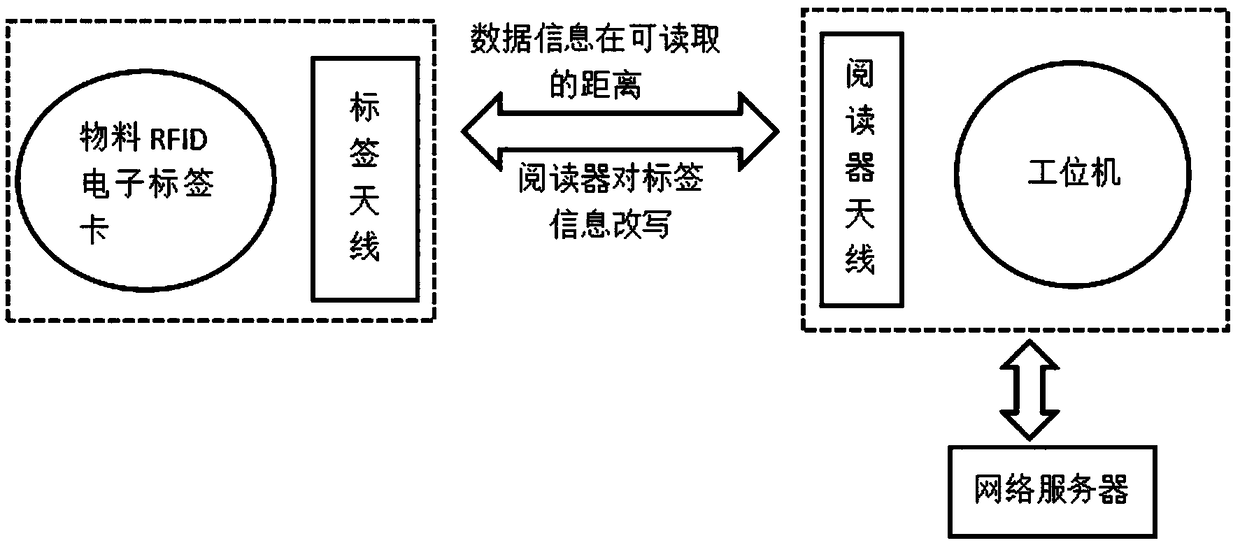

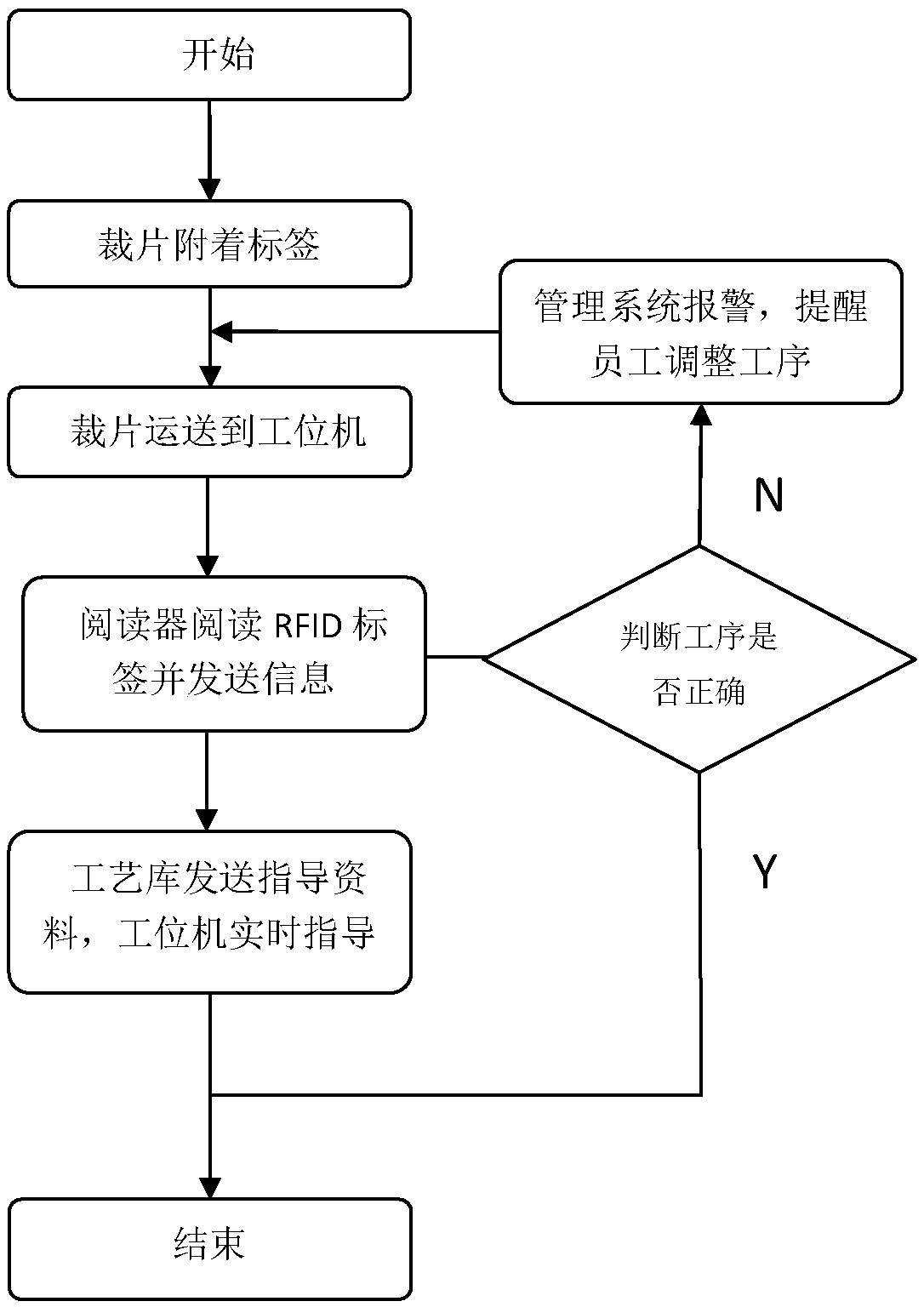

RFID garment process guidance system and guidance method thereof, and production management system and method

InactiveCN109359895AShort memorySolve the production difficulties of wrong sequence and missing sequenceResourcesManufacturing computing systemsProcess guidanceWorkstation

A RFID garment process guidance system and a guidance method thereof, a production management system and method are provided. The RFID garment process guidance system includes RFID electronic tags, workstations, network servers; information can be transmitted between the components; RFID electronic tags are attached to the pieces, the information of the pieces is written therein; the station machine includes an RFID reader and a display screen. The RFID reader reads the information on the RFID electronic tag and transmits the read piece information to the network server. Features: The networkserver includes a database and a process library, and the process library determines the process flow chart according to the style type, and performs the process division on the clothing style, and stores produce process guidance materials in the data base. When receiving the piece piece information, the process library transmits the corresponding process guidance materials to the employee's station machine for guiding the employees to operate to instruct employees to produce in real time, avoid sewing errors, better guide employees to sew, and improve production efficiency.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

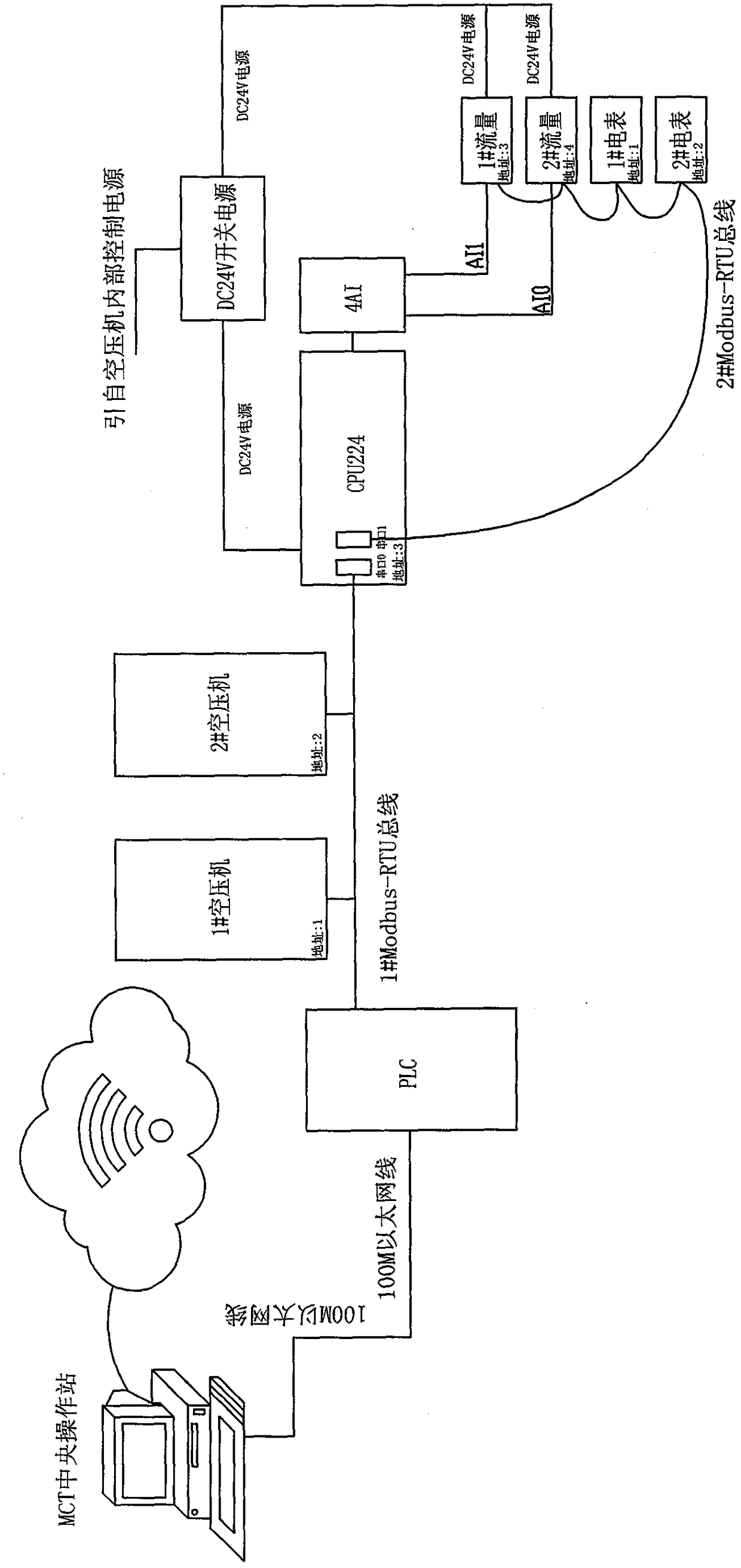

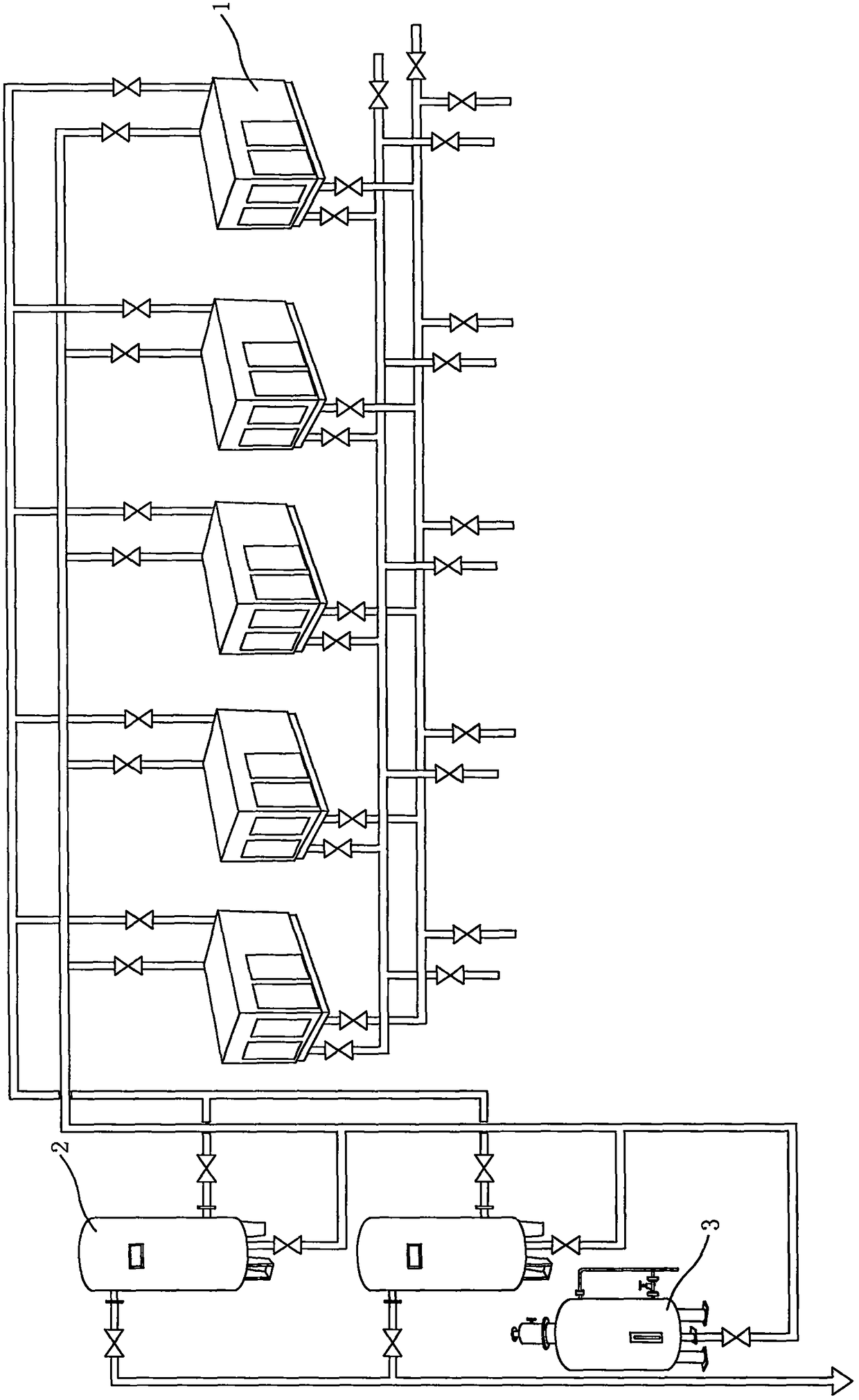

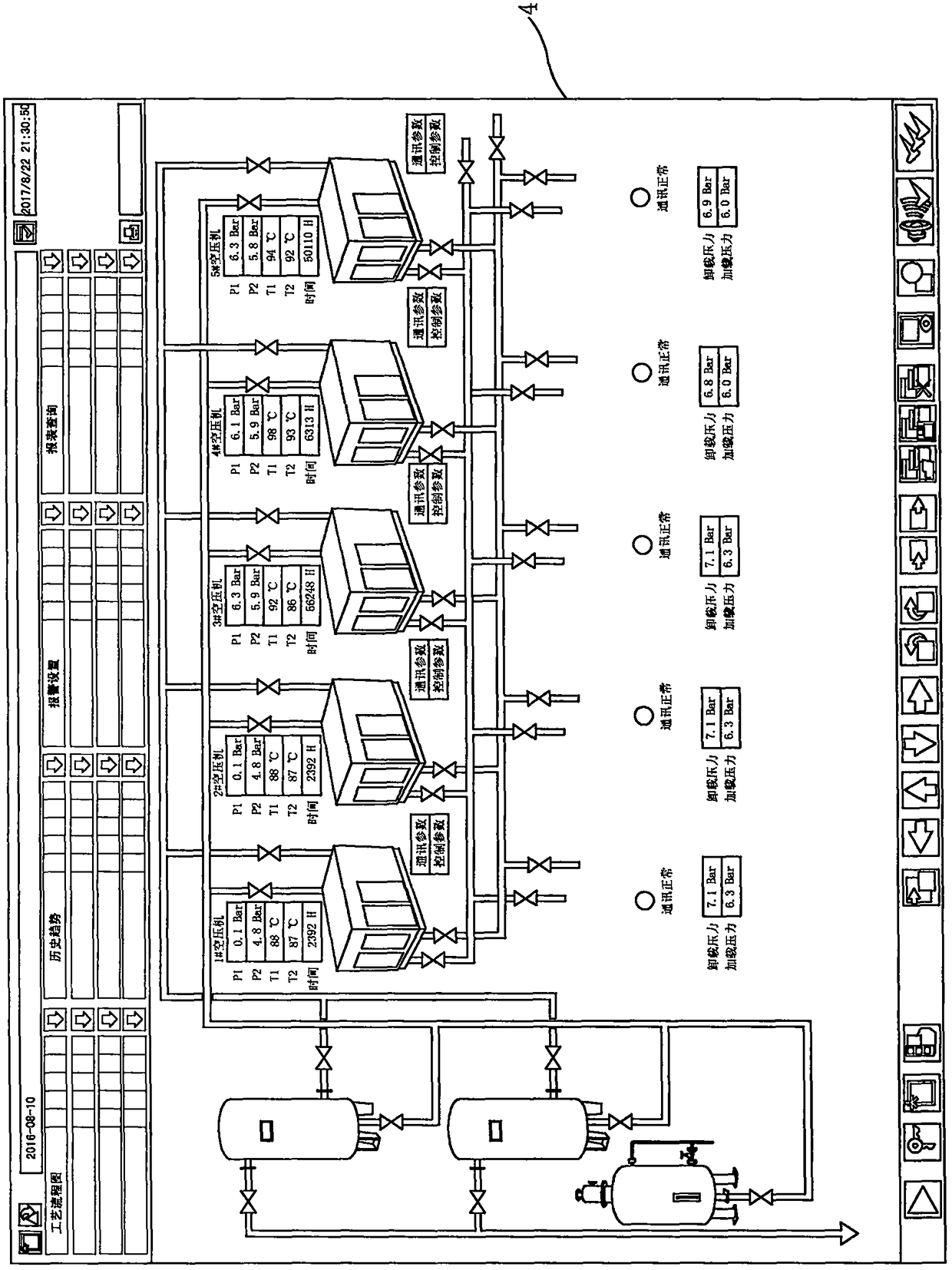

Remote monitoring system of air compressor

ActiveCN108916019AEasy to monitor remotelyRemote Monitoring AccuratePump testingPositive displacement pump componentsEngineeringAir compressor

The invention relates to a remote monitoring system of an air compressor. The system is designed regarding the technical problems that remote monitoring operations of similar products are inconvenient, and the energy saving effect is poor. The system is characterized in that a system navigation composed of grouping pull-down menus is arranged on the upper portion of a system flow main page on an air compressor automatic monitoring system of the system and comprises a process flow diagram, a historical trend, an alarming setting and a statement querying button, the process flow diagram is arranged on the lower portion of the system flow main page, and an air compressor icon of the process flow diagram is provided with a remote control operation panel of the air compressor; a dryer and a pipeline of an air storing tank are arranged on an air pipe hanging frame railway in a workshop, an air-operated connecting control cabinet is arranged above the air pipe hanging frame railway of a workarea, and the air pipe hanging frame railway is provided with a work radio frequency sensing area; an interface pressure sensor and an interface temperature sensor of the air-operated connecting control cabinet are connected with an MCT central operation station through wireless transmitters, and a connecting pipeline of an air-operated screw driver is connected with a pipe joint of the air-operated connecting control cabinet.

Owner:杭州裕达自动化科技有限公司

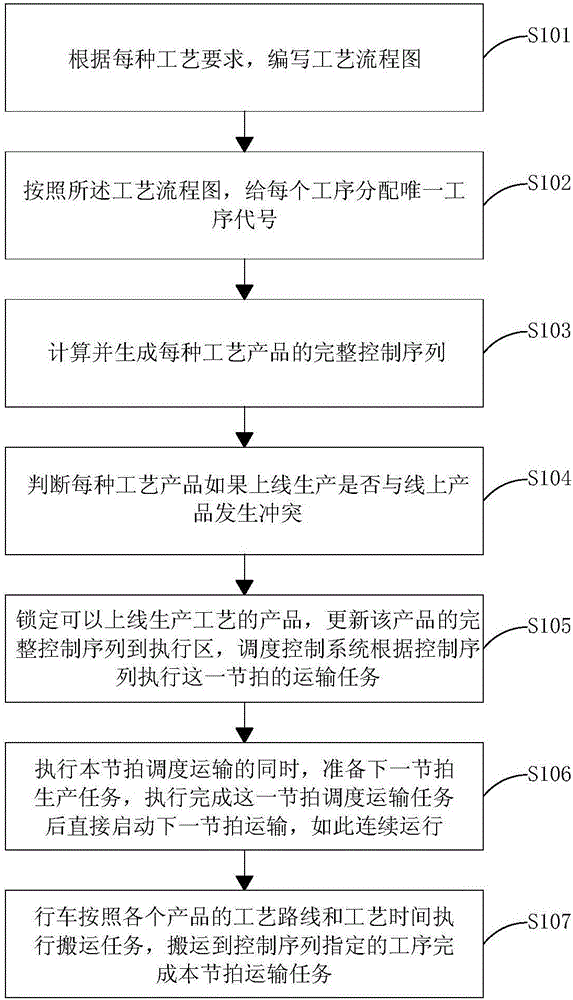

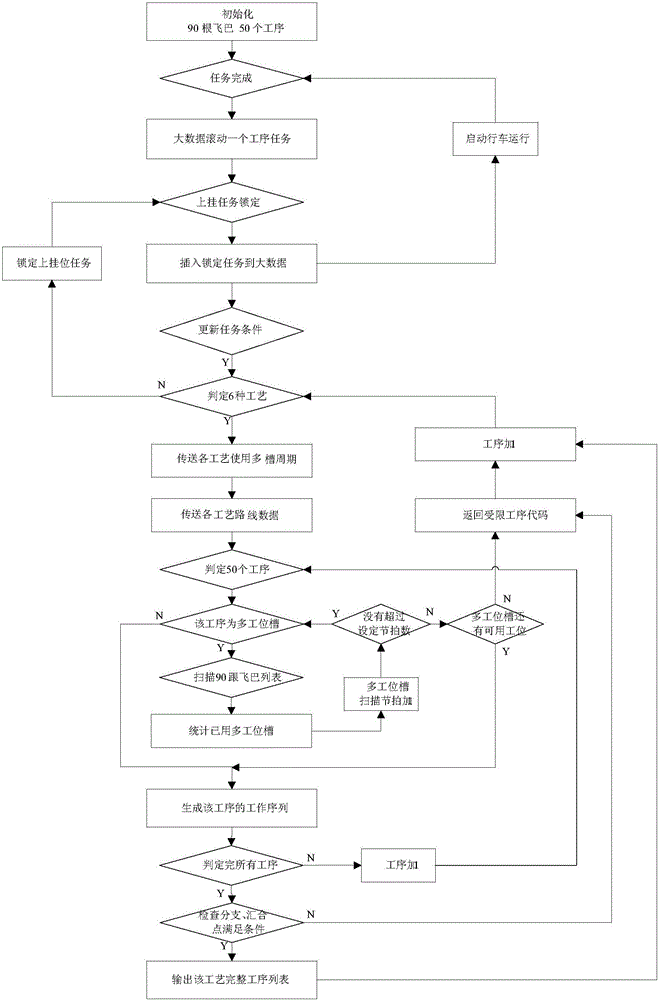

Travelling crane pre-judging, scheduling and controlling method for electroplating production line

ActiveCN105821468AIncrease productivityGuarantee product qualityCellsProduction lineComputer science

The invention discloses a travelling crane pre-judging, scheduling and controlling method for an electroplating production line. The method comprises the steps that a process flow diagram is compiled according to each process requirement; a unique procedure code is distributed to each procedure according to the process flow diagram; a complete control sequence of each process product is calculated and generated; whether each process product conflicts with an on-line product during on-line production or not is judged; products capable of being subjected to an on-line production process are locked, the complete control sequences of the products are updated to an execution area, and the transporting task of the takt is executed according to the control sequences; scheduling and transporting of the takt are executed, meanwhile, the production task of the next takt is prepared, and transporting of the next takt is directly started after the scheduling and transporting task of the takt is executed; and a travelling crane executes carrying tasks according to the process paths and process time of all the products, and the products are carried to procedures specified by the control sequences to complete the transporting task of the takt. According to the method, multiple process products can be produced in a mixed manner at the same time, the production efficiency is improved, and the product quality is guaranteed.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

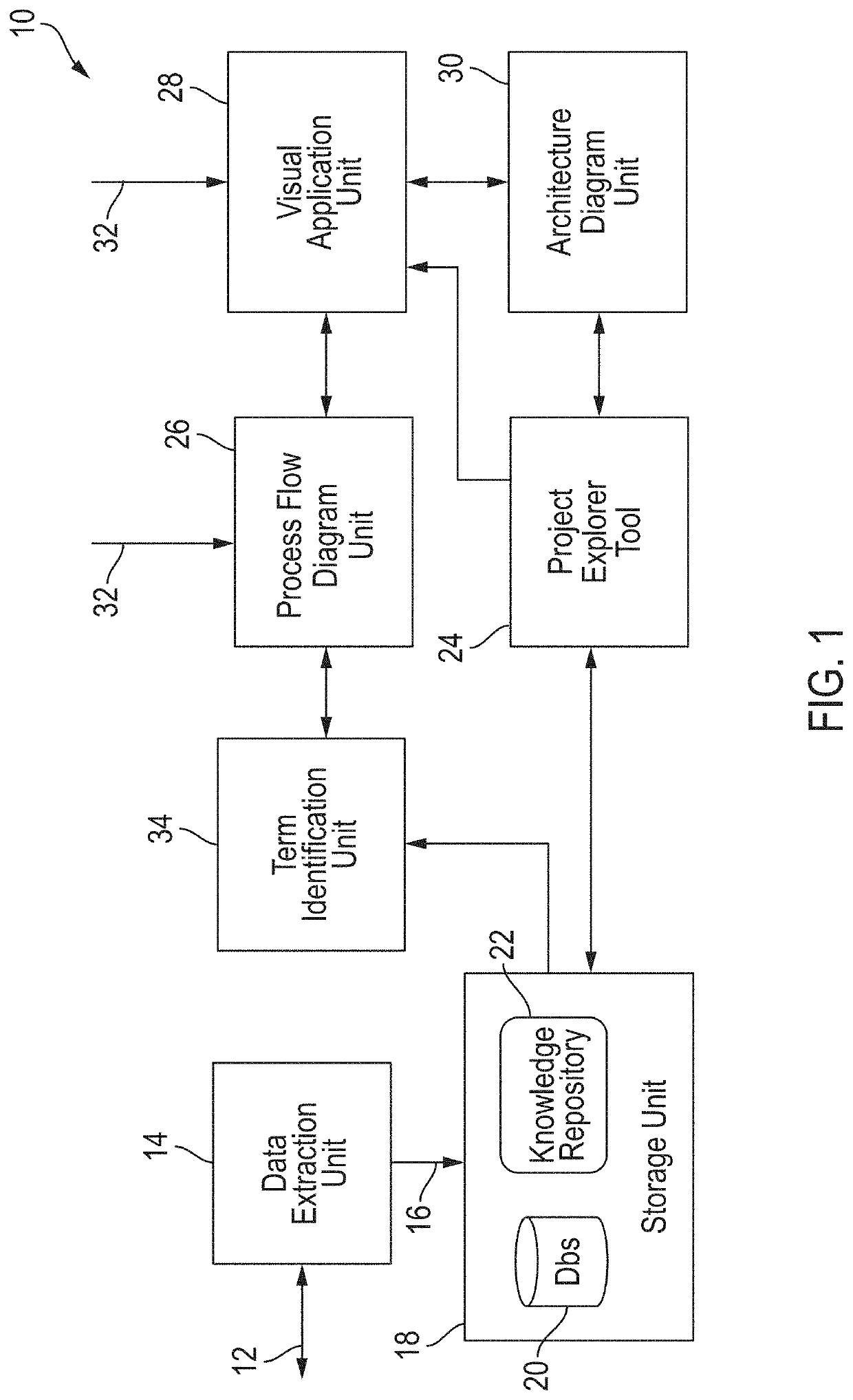

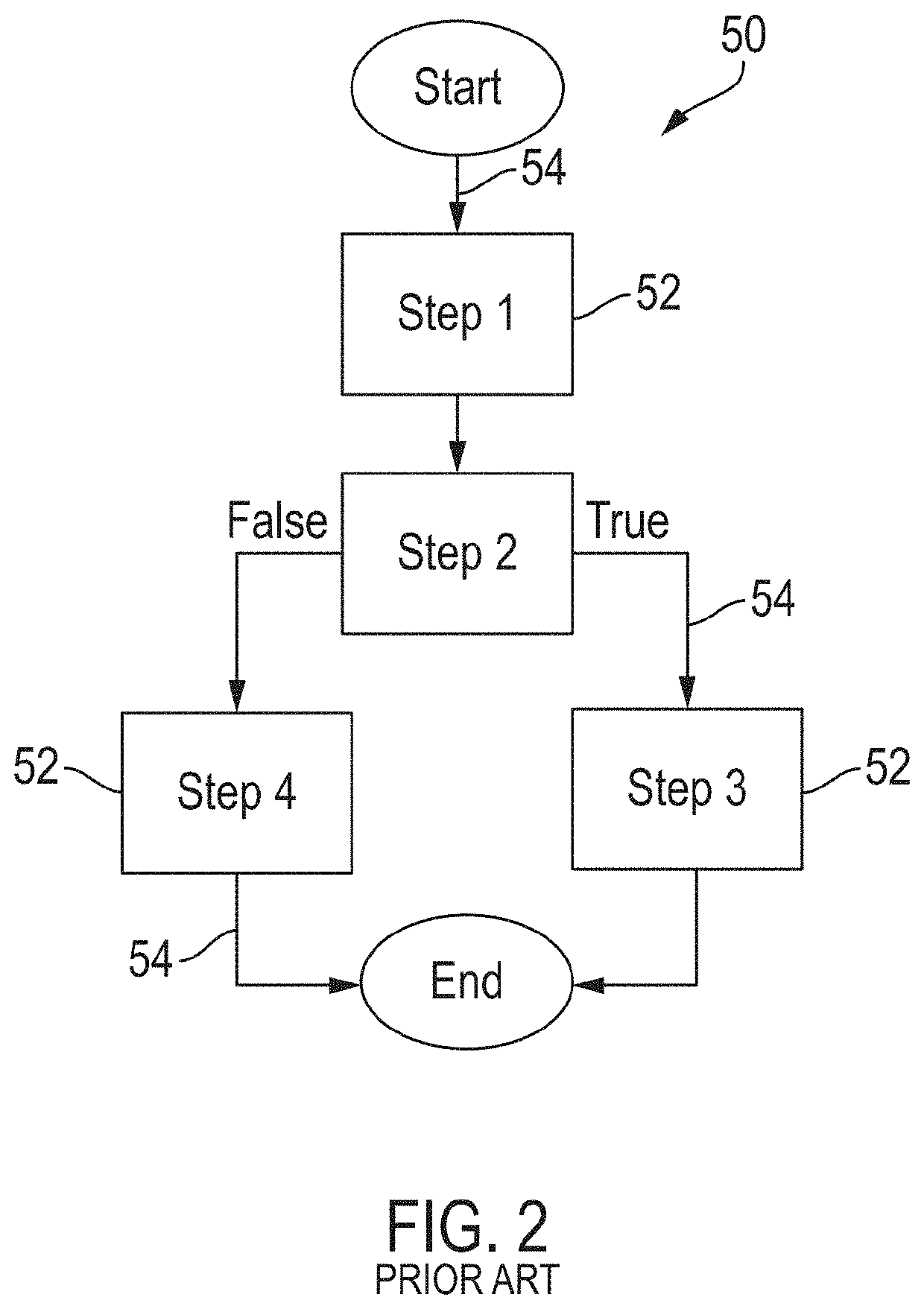

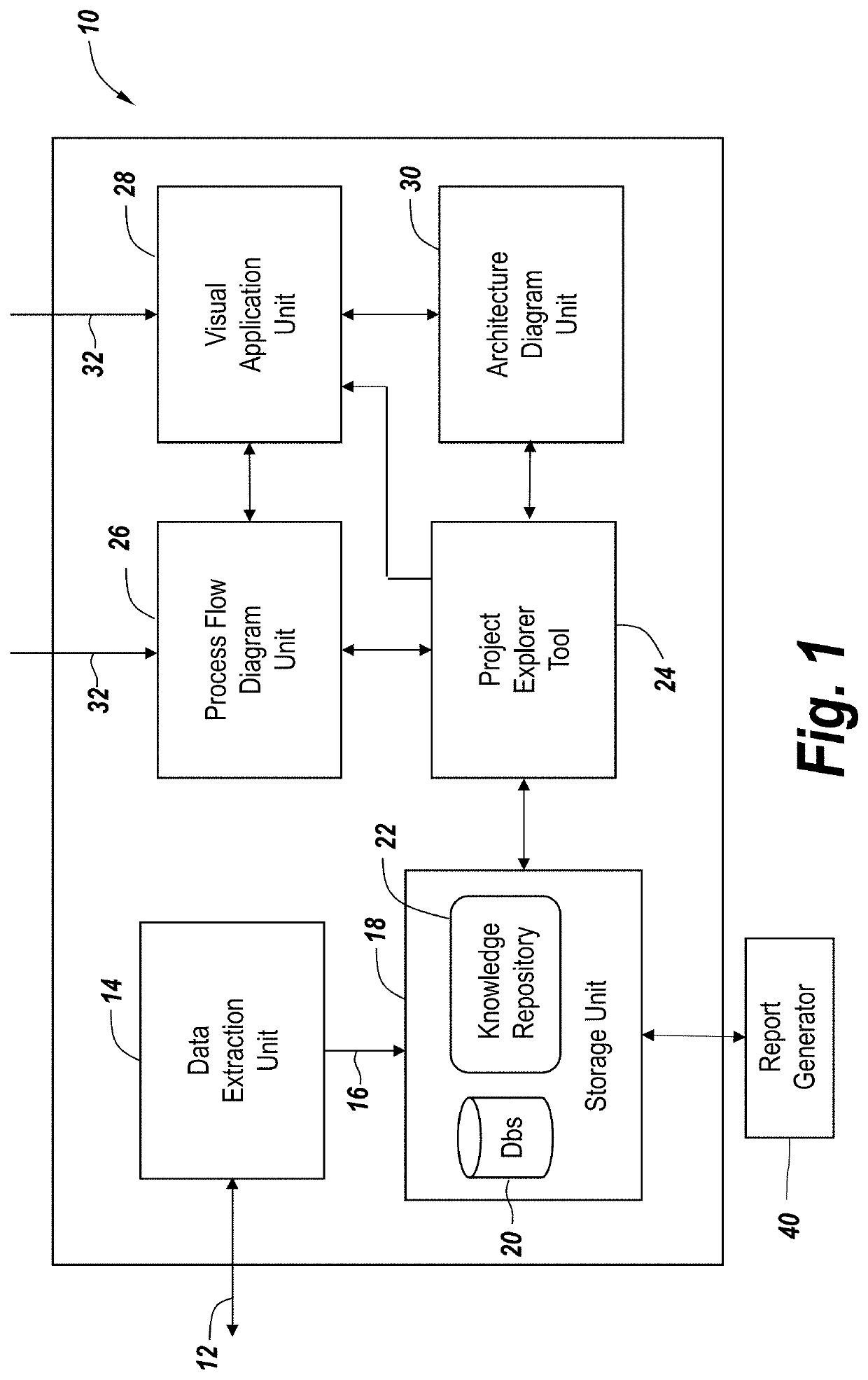

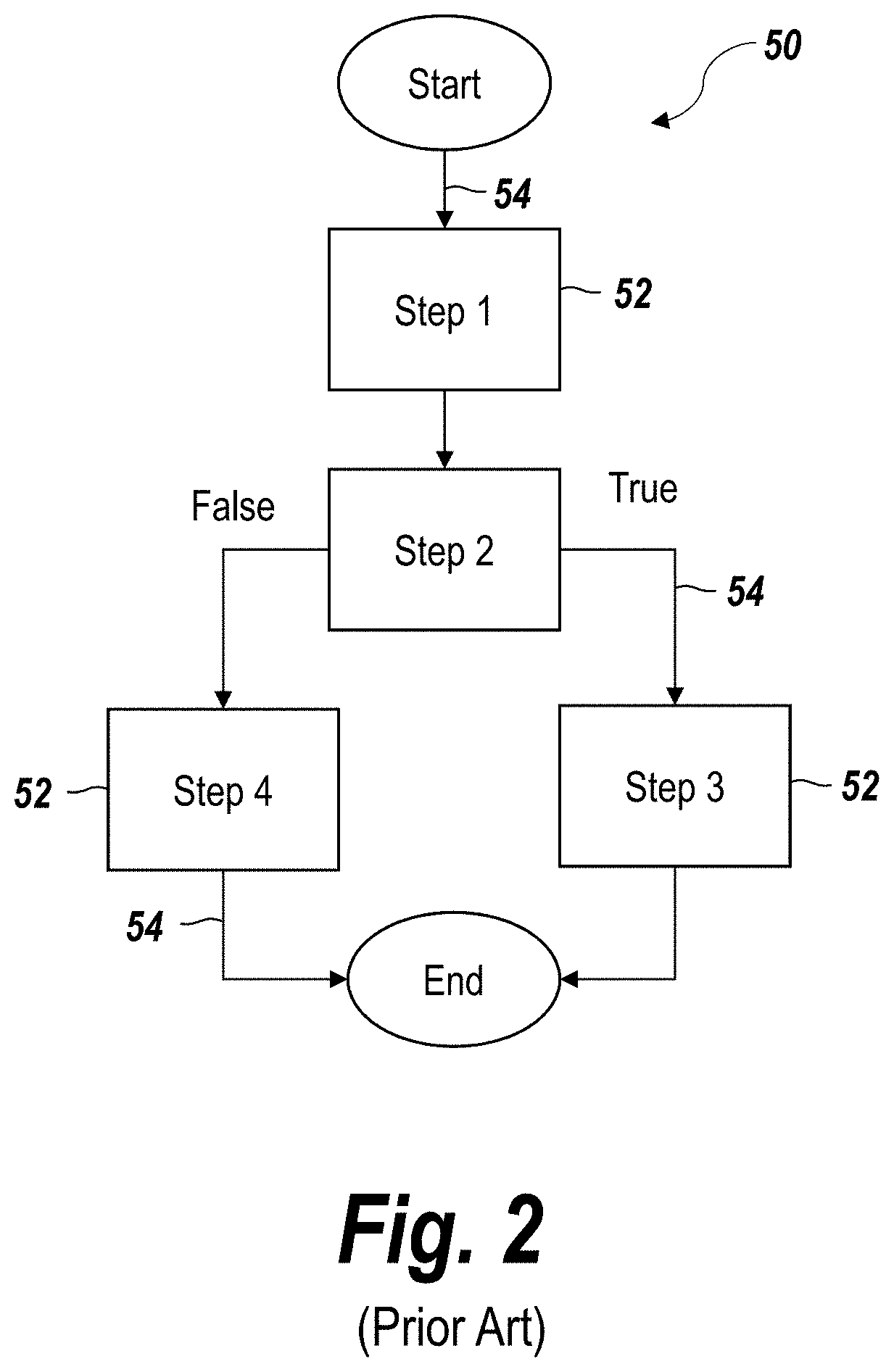

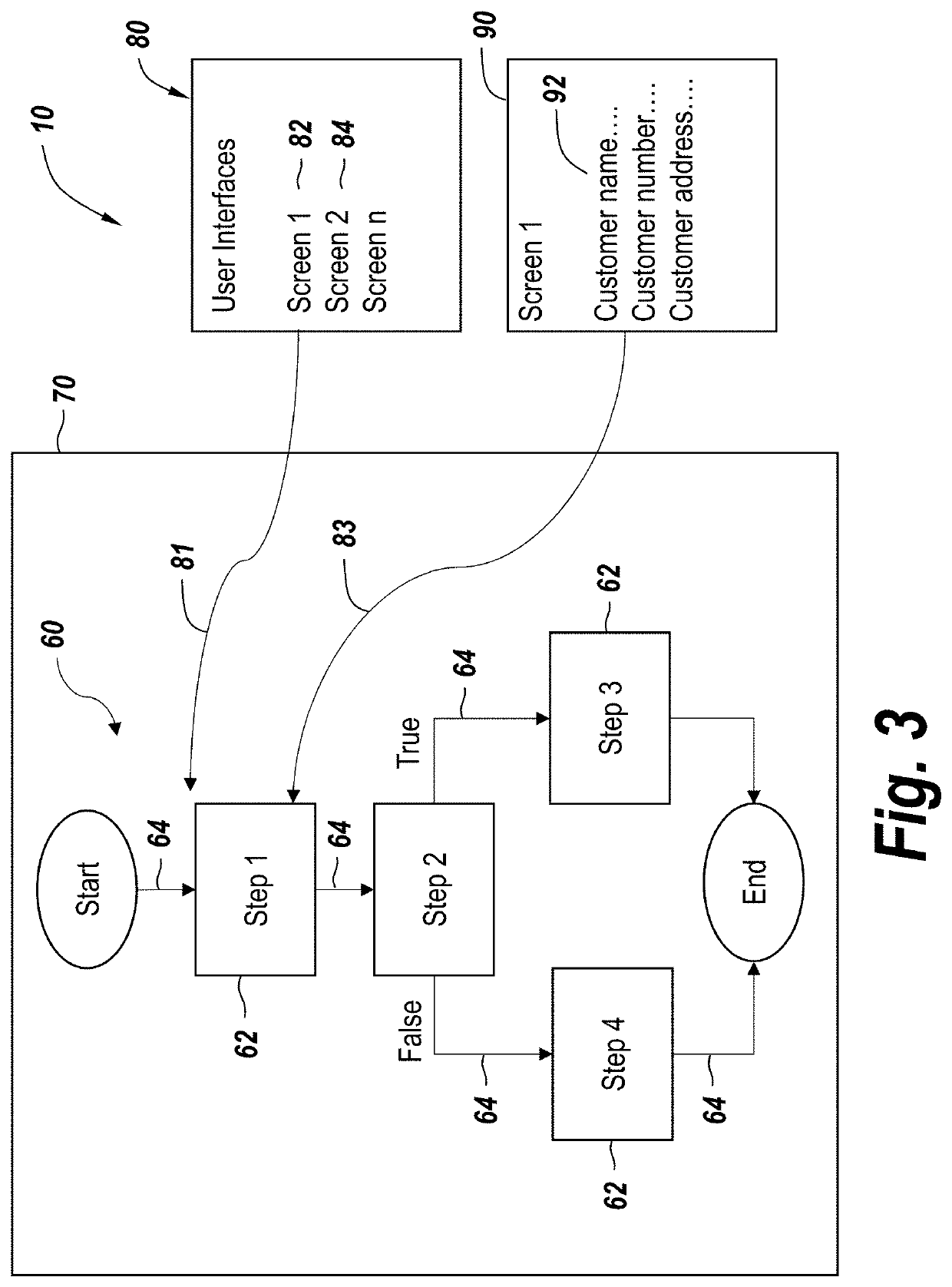

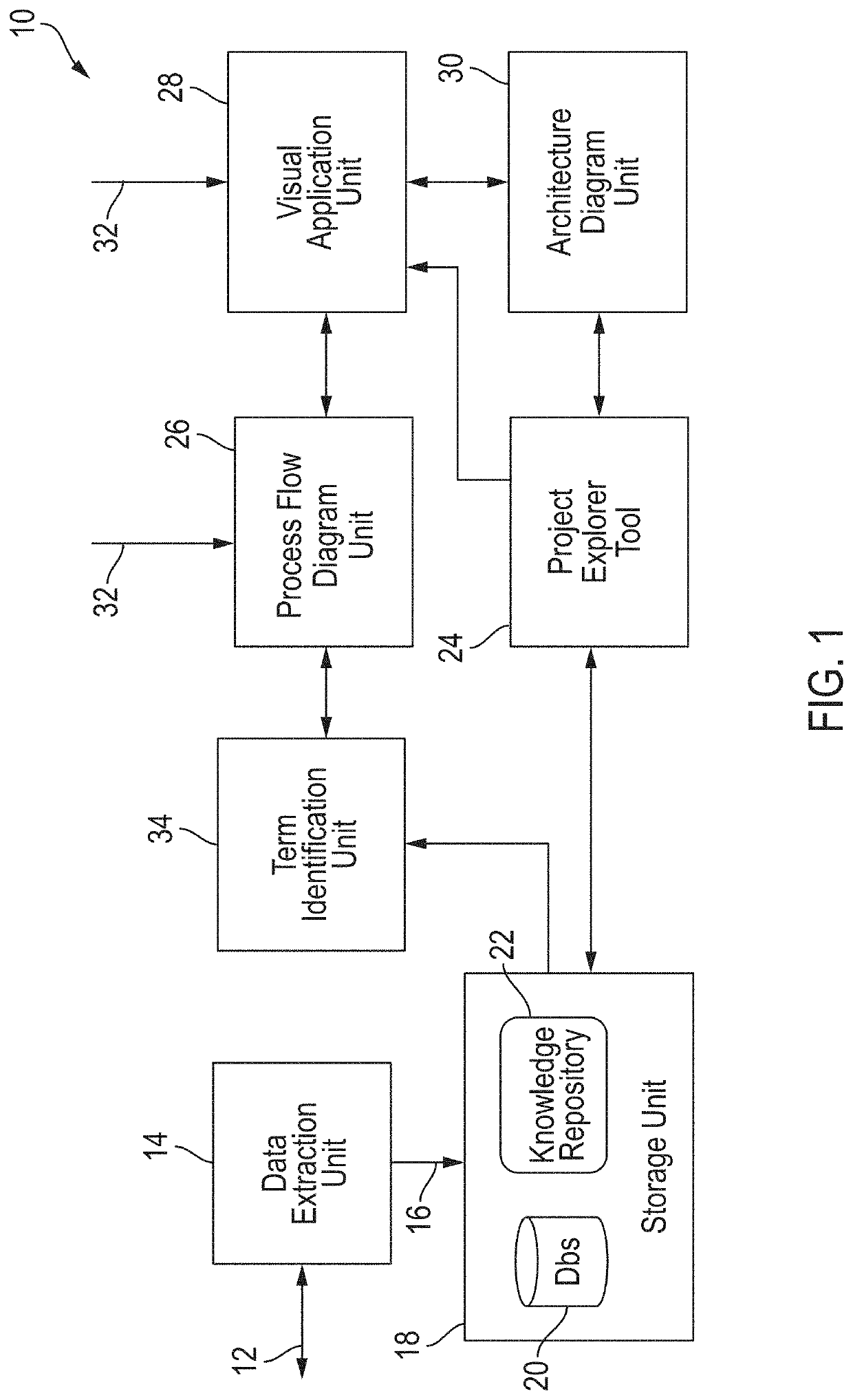

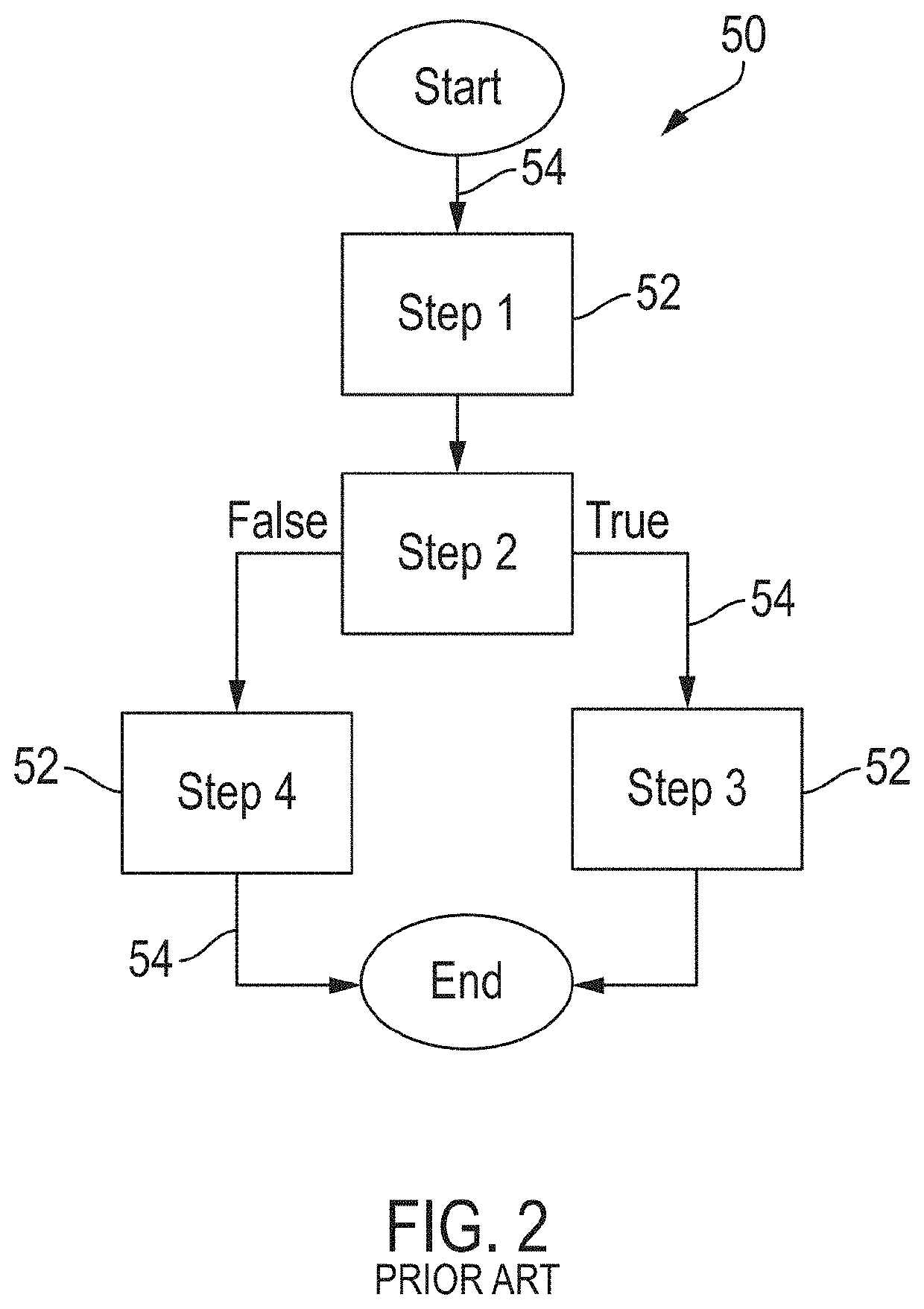

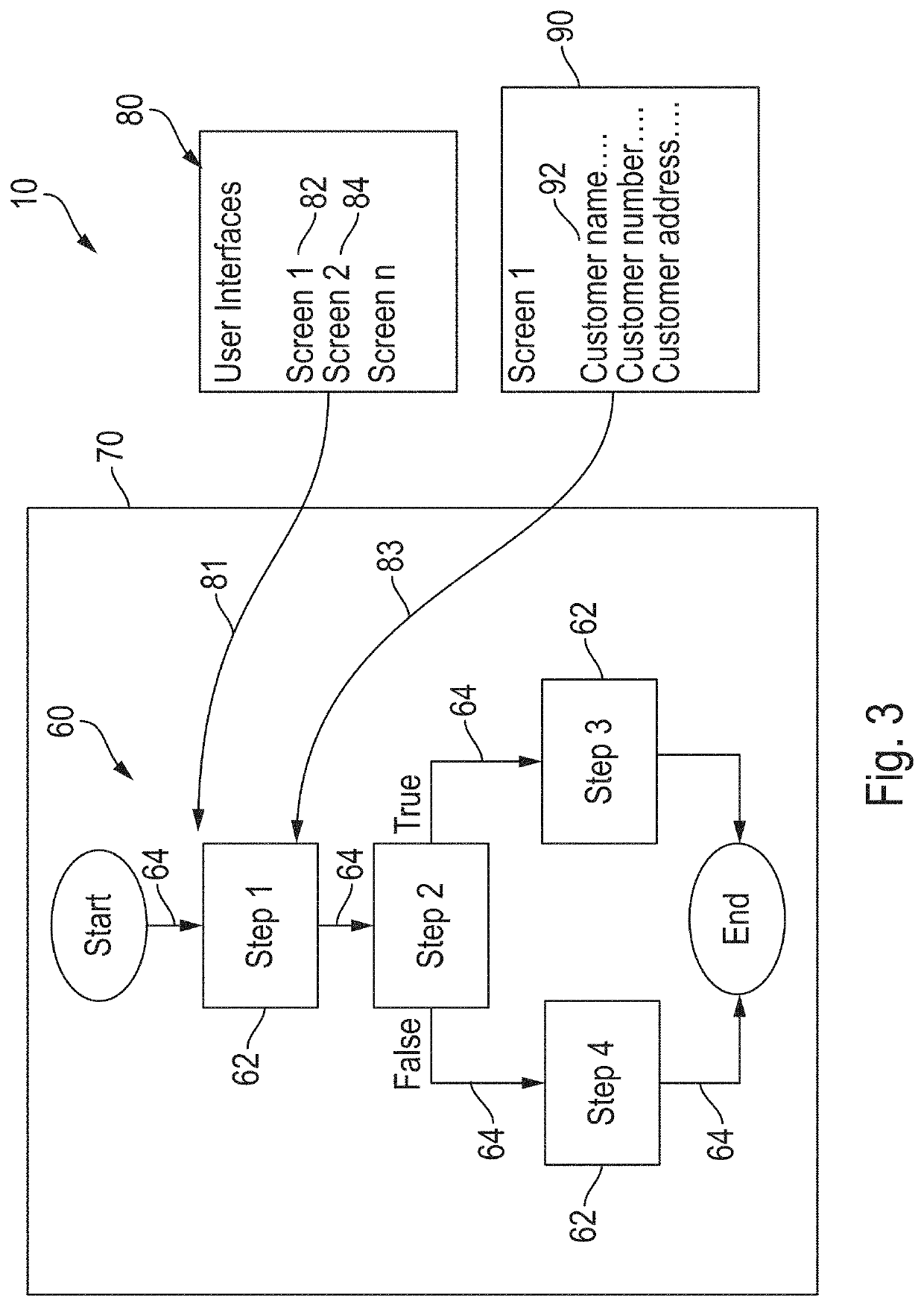

System and method for creating a process flow diagram which incorporates knowledge of business terms

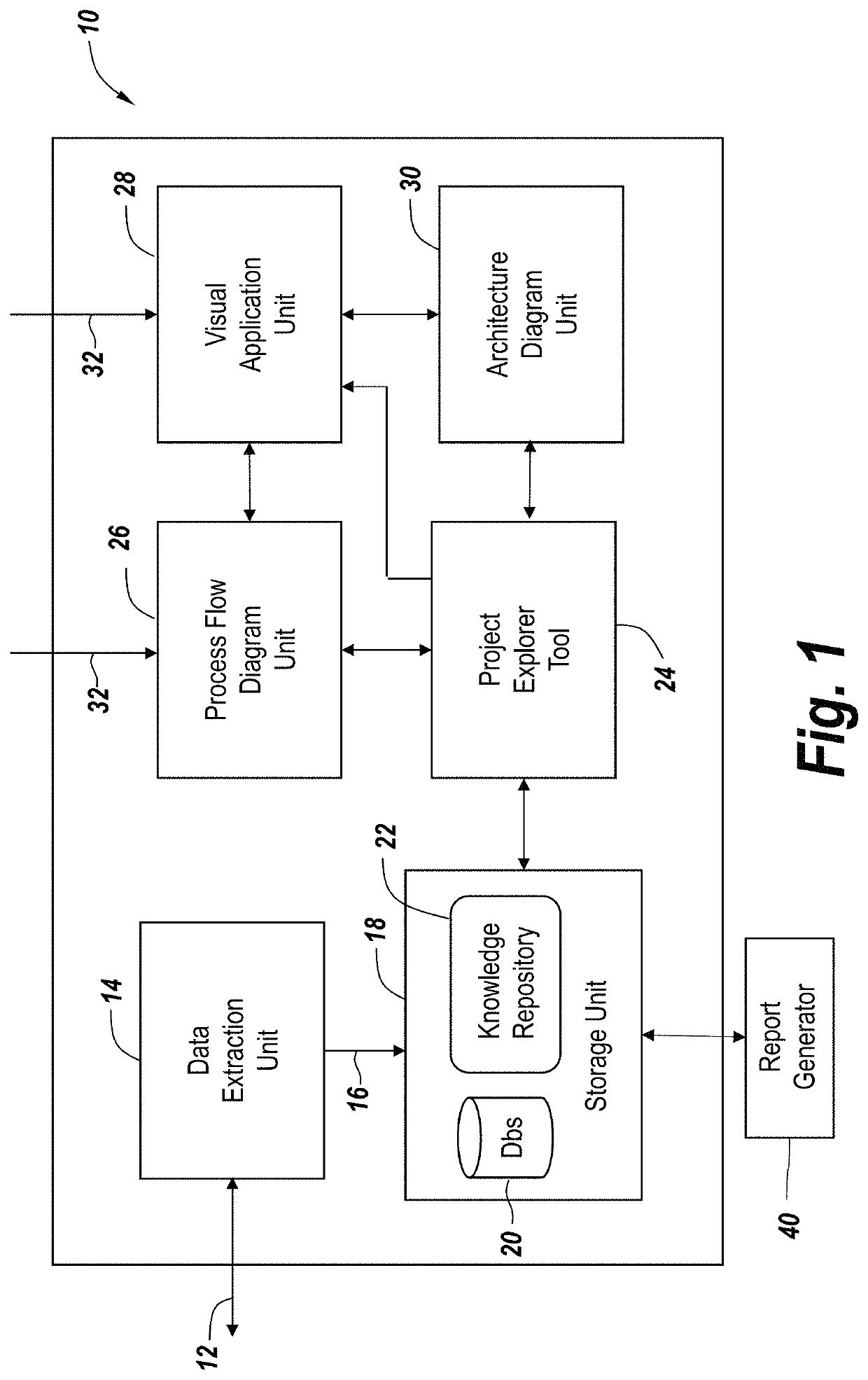

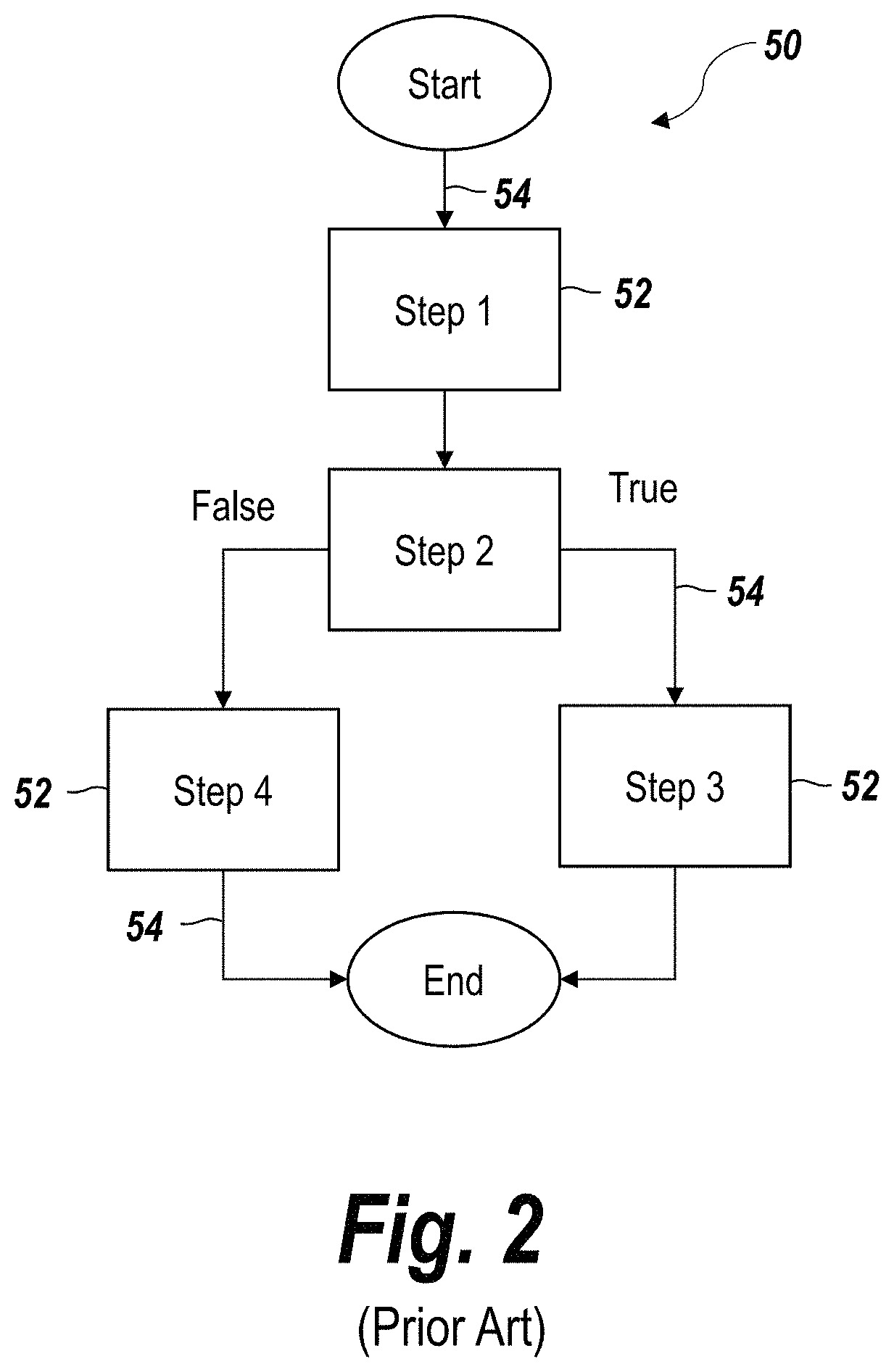

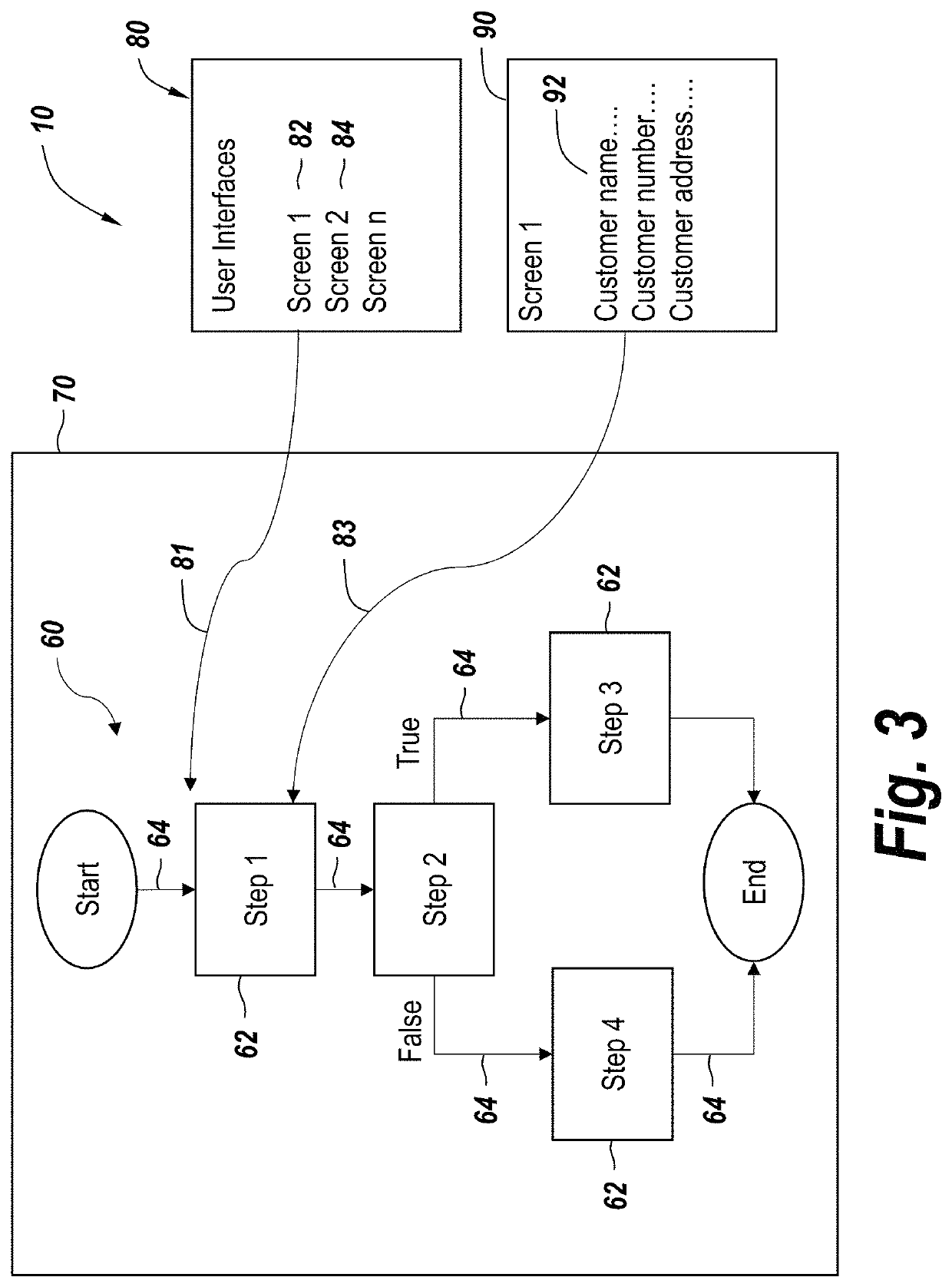

ActiveUS20210241191A1Sure easyOffice automationVisual/graphical programmingSoftware engineeringData mining

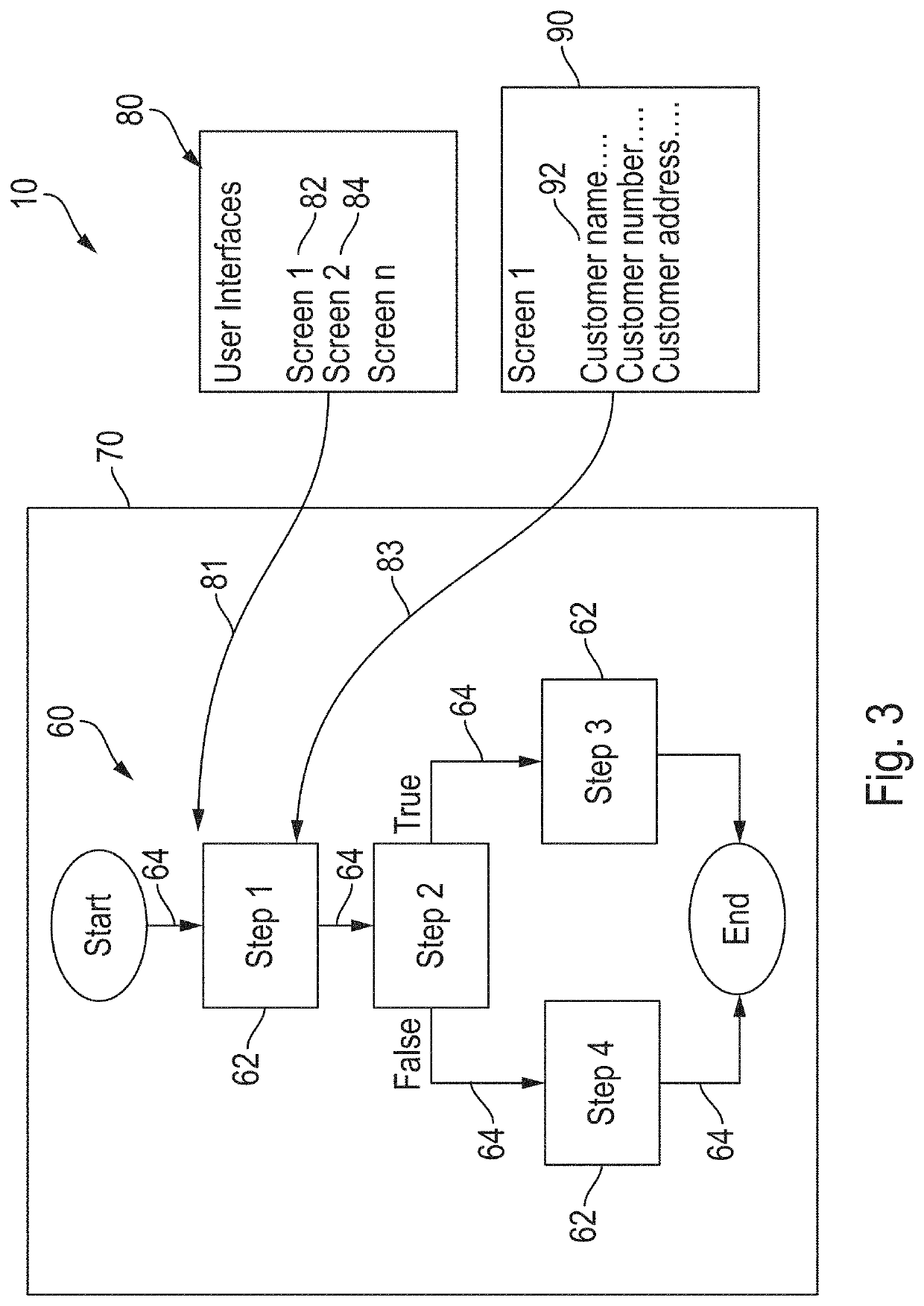

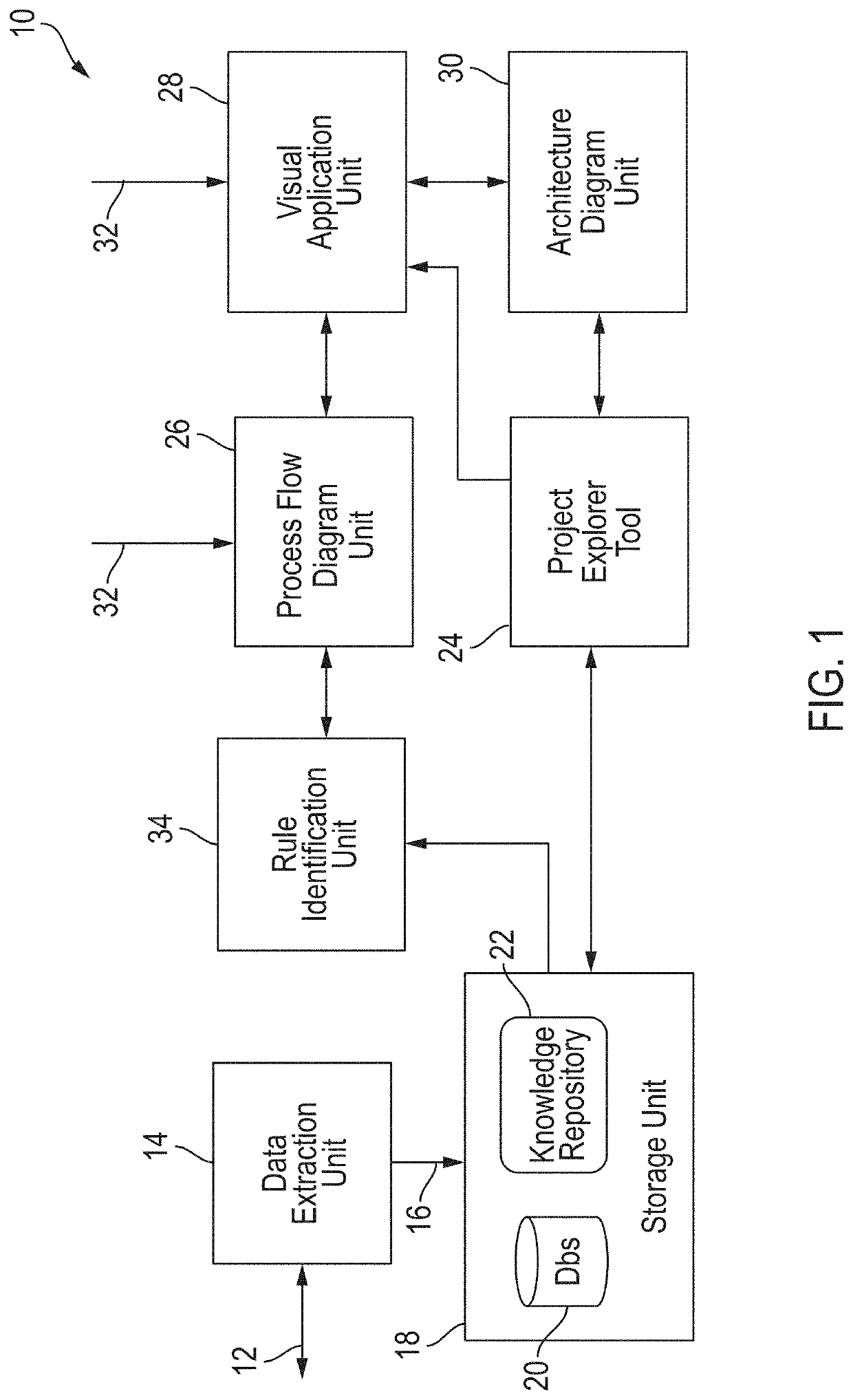

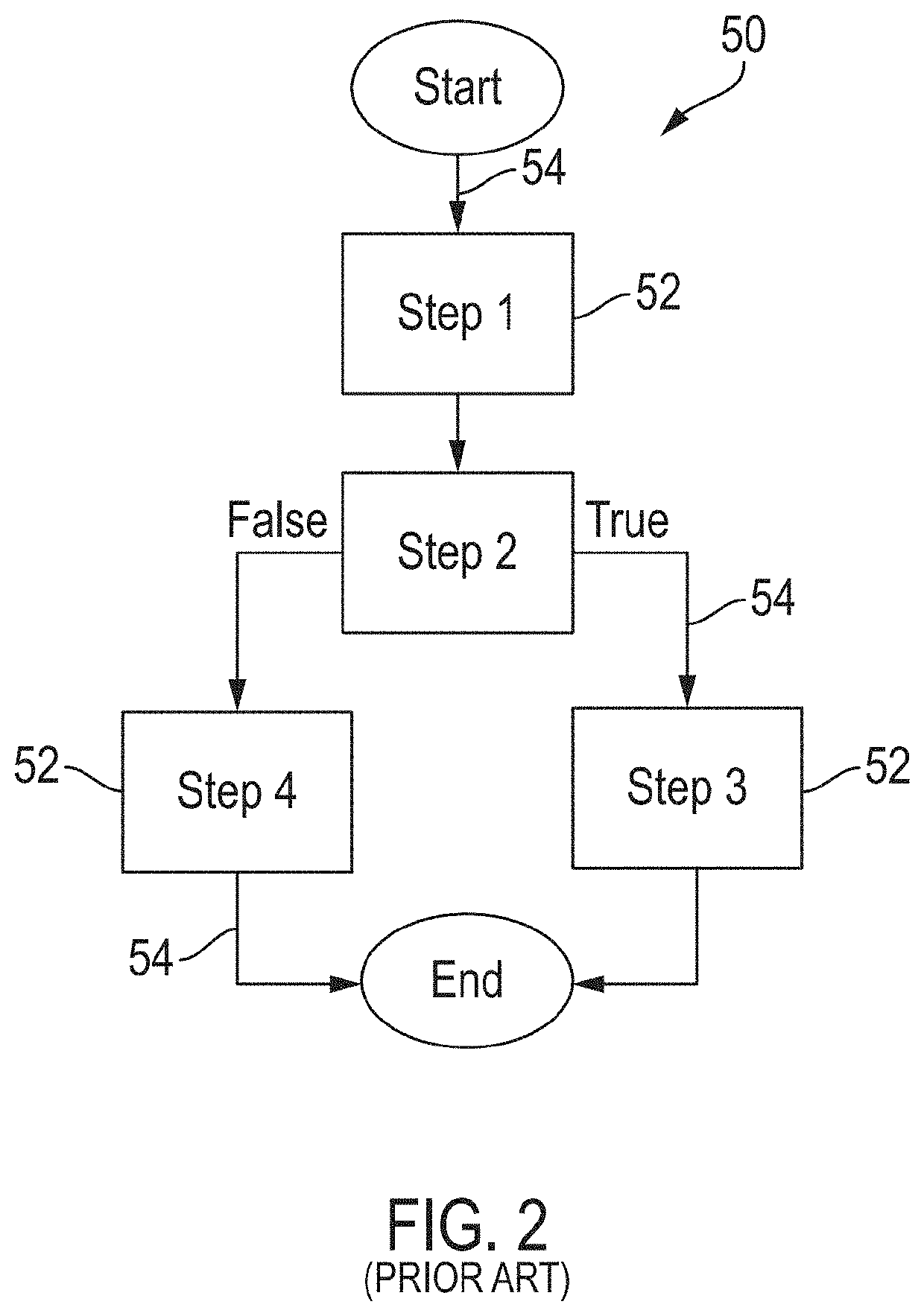

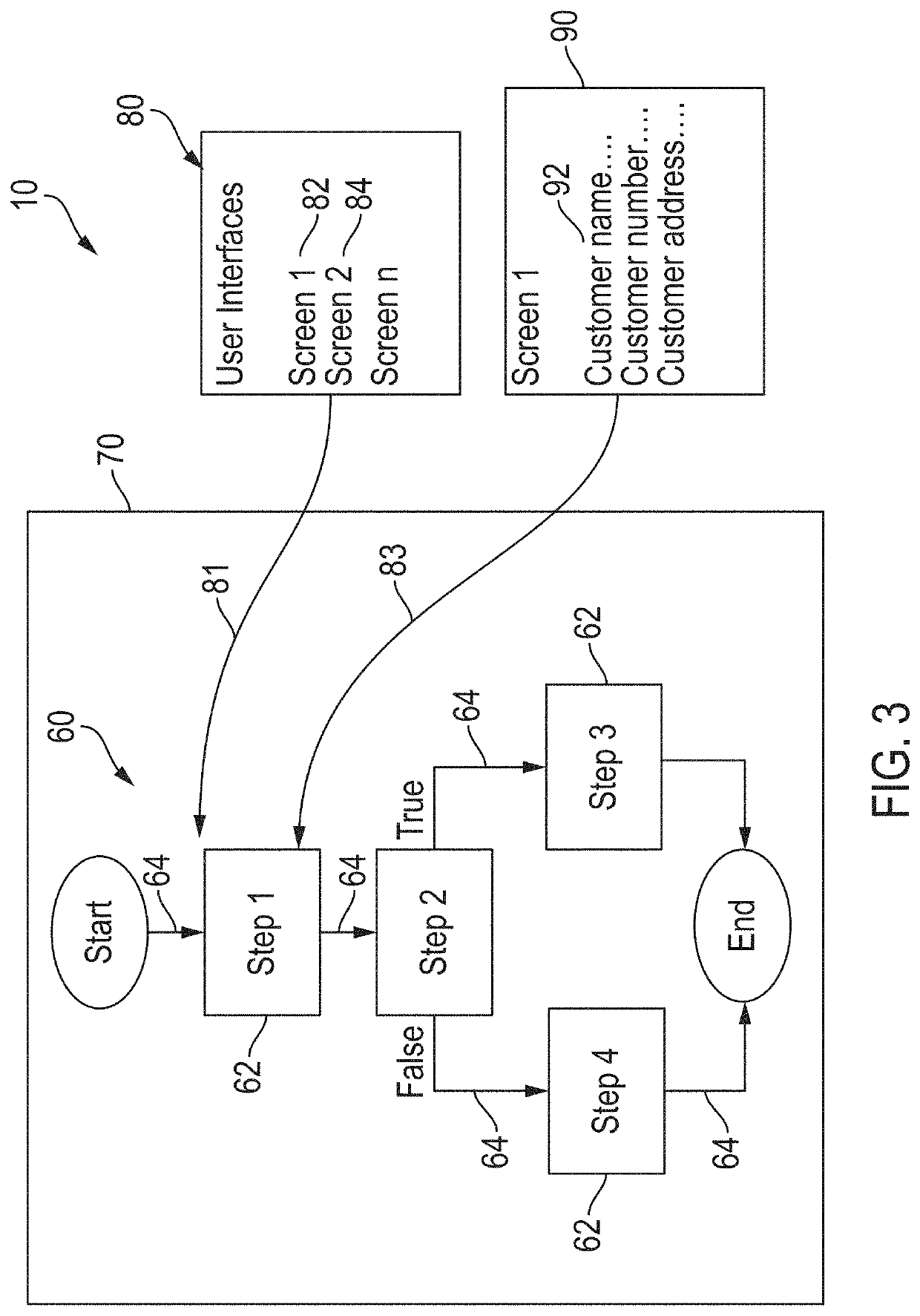

A system and method for associating a technical artifact and one or more business terms with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

System and method for creating a process flow diagram which incorporates knowledge of business rules

ActiveUS20210240449A1Sure easyDatabase management systemsSoftware designSoftware engineeringData mining

A system and method for associating a technical artifact and one or more business rules with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

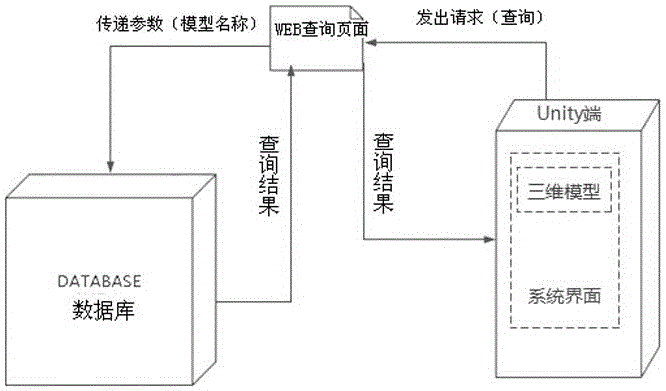

Three-dimensional in-station pipe network and device information three-dimensional display method for unite station

InactiveCN106095840ASolve the problem of equipment information displayReduce training timeWebsite content managementSpecial data processing applicationsPoint cloudData acquisition

The invention discloses a three-dimensional in-station pipe network and device information three-dimensional display method for a unite station. The method comprises the steps of performing data acquisition and arrangement on the unite station once, enabling outdoor workers to carry a professional camera and a three-dimensional laser scanning device, performing non-contact scanning measurement and shooting on supported pipelines of the unite station under the cooperation of oil field unity station technicists, and making sure underground pipeline directions by utilizing pipeline marks and a process flow diagram and querying an oil field worker; performing supported pipeline modeling according to scanned point cloud by utilizing 3D MAX software, and then importing a pipeline model into unity 3D to realize pipeline information display; and finally publishing the unity 3D on a webpage to realize online access. The method has the beneficial effects that three-dimensional in-station pipeline and device three-dimensional display of the unite station is realized through a Unity 3D engine, database access is realized through mouse click event triggering, and pipeline information is displayed on a screen, so that the difficult problem in device information display in the past is solved.

Owner:SHANDONG TIANYUAN INFORMATION TECHNOLOGY CO LTD

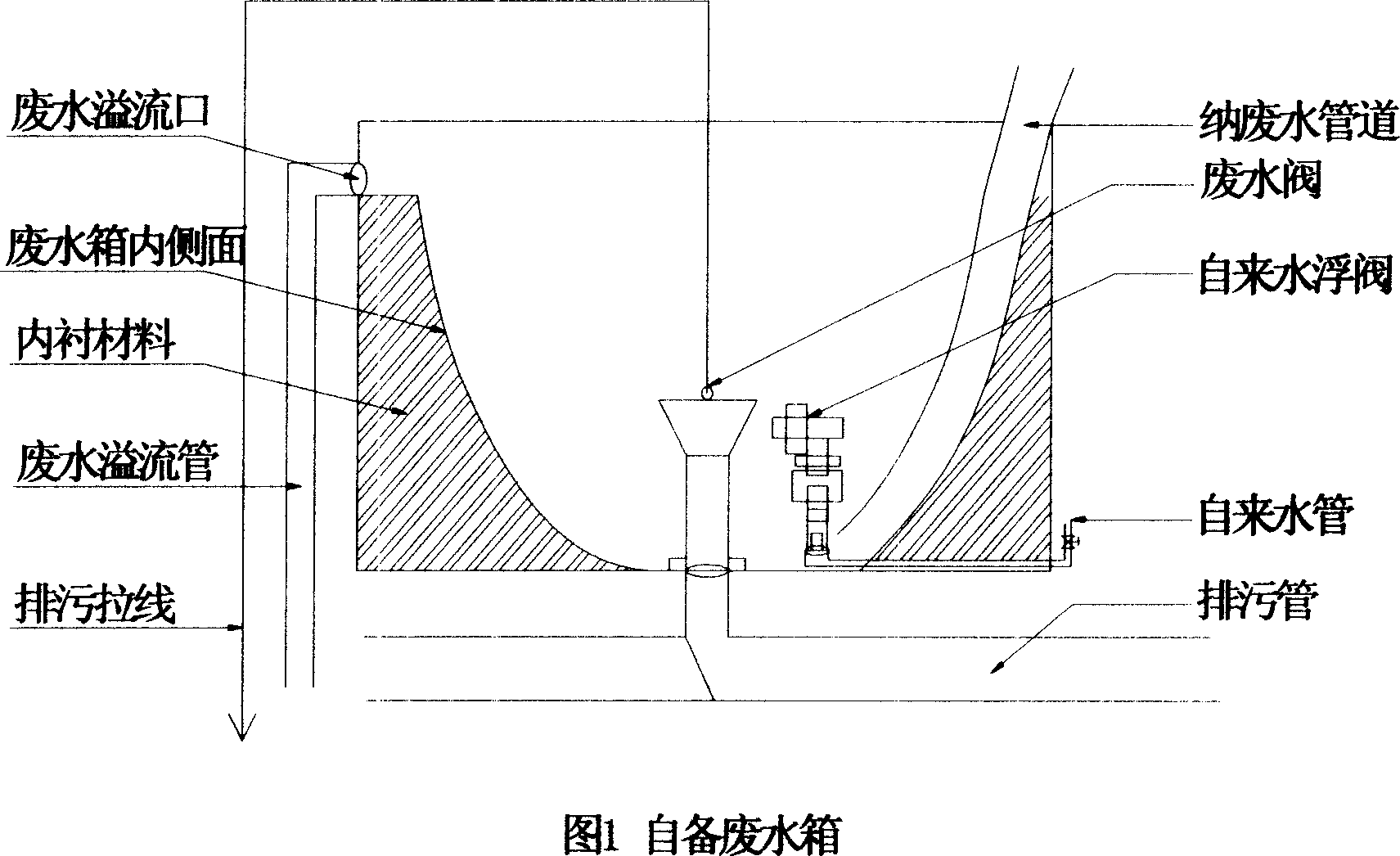

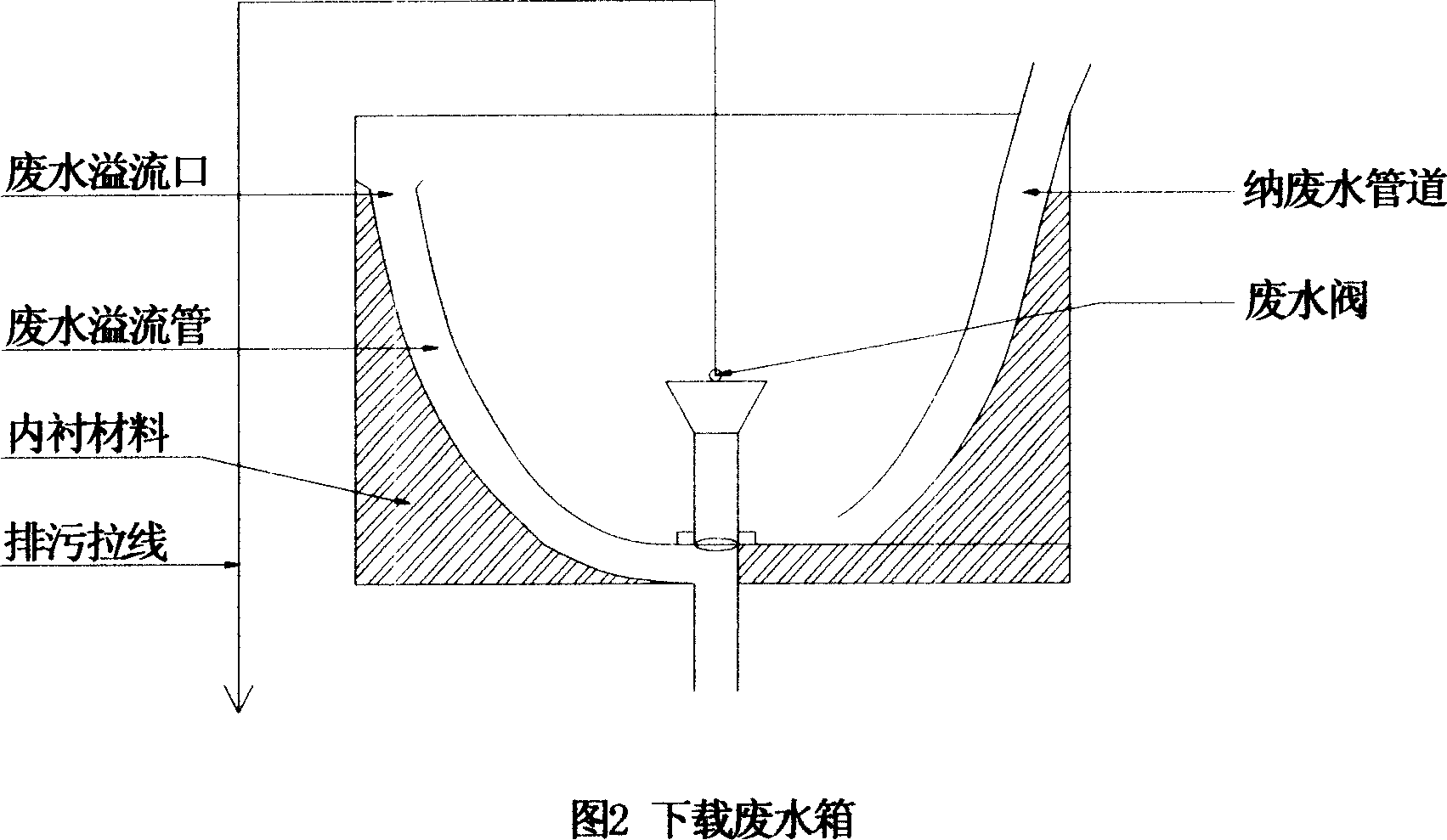

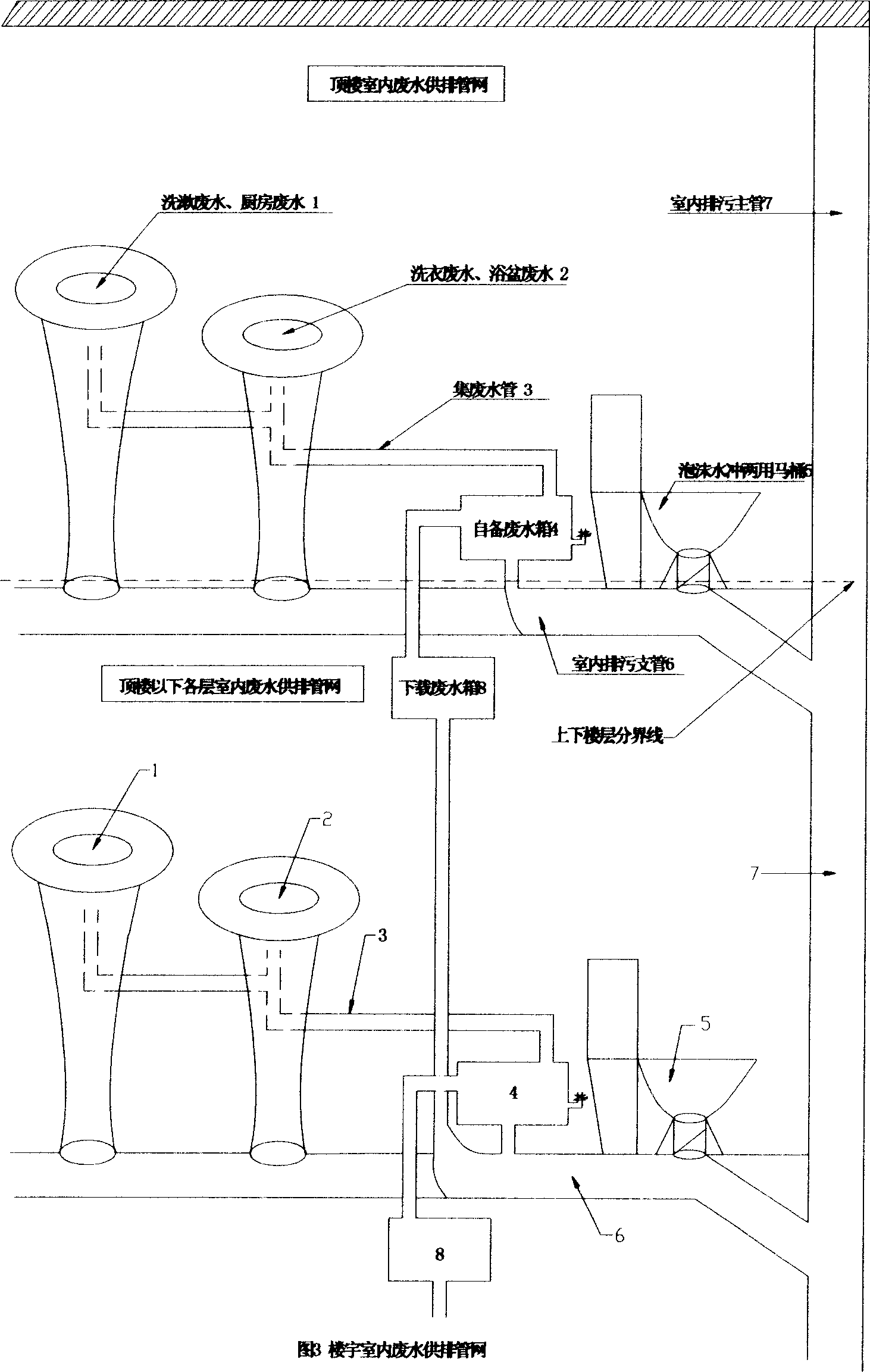

Technique for building water saving, fertilizer production cleaning, reducing domestic sewage discharge and promoting agriculture organification

InactiveCN101063314AProcess design is simple and convenientWorkmanship is feasibleBio-organic fraction processingSludge treatmentOrganificationEngineering

The invention discloses building water saving, fertilizer producing cleaning, domestic sewage and agriculture organic technology. The invention adopts the foam blocking, water flush dual purpose toilet seat, the interior supply discharge net and its sewage box mutually to largely save the tap water, secondly, high quality fertilizer is generated to realize building sewage discharge via the fertilizer producing clearing anaerobic device replacing the traditional septage disposing building sewage, thirdly, the agriculture is drove to develop to the organic technology via collecting organic fertilizer. The invention simultaneous discloses the construct graph of the interior sewage box and the engineering flow sheet of the building water saving, fertilizer producing cleaning and propelling of the organic technology.

Owner:北京市唐杰城市节能环保科技发展有限公司

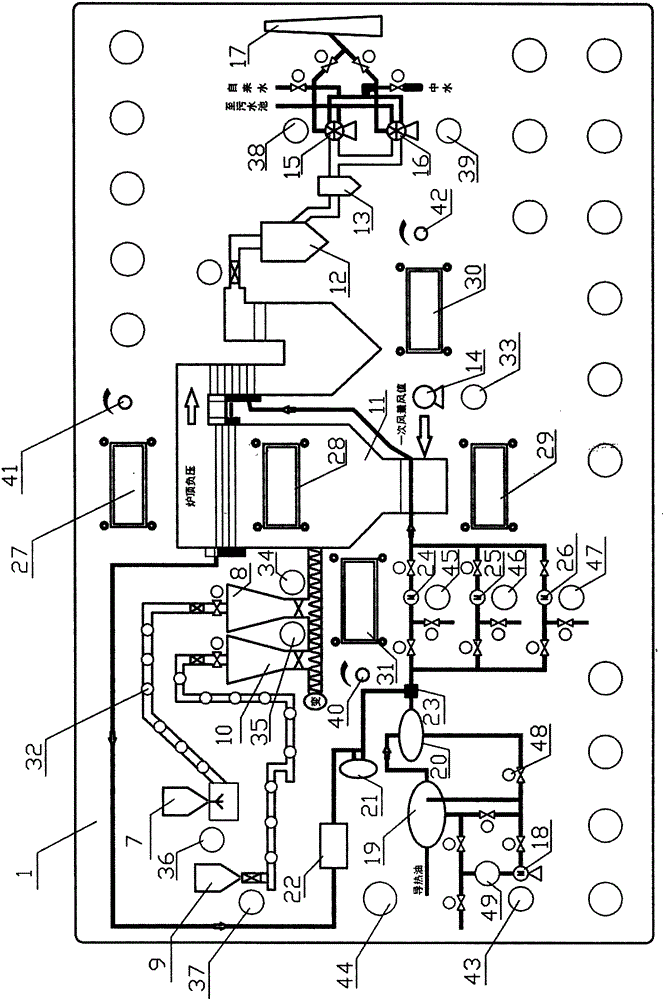

Practical training operating platform for sludge incinerator in sewage treatment plant

ActiveCN105096684AAvoid security issuesHigh technology contentCosmonautic condition simulationsSimulatorsElectricitySludge

The invention discloses a practical training operating platform for a sludge incinerator in a sewage treatment plant. The practical training operating platform comprises a bottom plate and a controller running practical training management software, wherein a touch screen, a material layer pressure difference simulation display meter, a top negative pressure simulation display meter, a draught fan A value simulation display meter and a draught fan B value simulation display meter which are electrically connected with the controller are embedded into the upper part of the front side of the bottom plate; a process flow diagram of the incinerator is drawn at the lower part of the front side of the bottom plate, and a digital display meter, an operating button, a tuning button and a simulation pipeline indicating lamp which are electrically connected with the controller are embedded into the lower part of the front side of the bottom plate; and the controller is arranged on the back of the bottom plate. During practical training operation of a trainee, the operation steps of the trainee are automatically recorded into the software system, and after the operation is completed and a submission button is clicked, all the operation steps of the trainee are automatically displayed on the system interface of the touch screen and compared with an answer database to automatically obtain a practical training result. The practical training operating platform is suitable for teaching and examination of sludge incinerator operation.

Owner:TAOPU SEWAGE TRAEATMENT PLANT OF SHANGHAI CHENGTOU SEWAGE TREATMENT

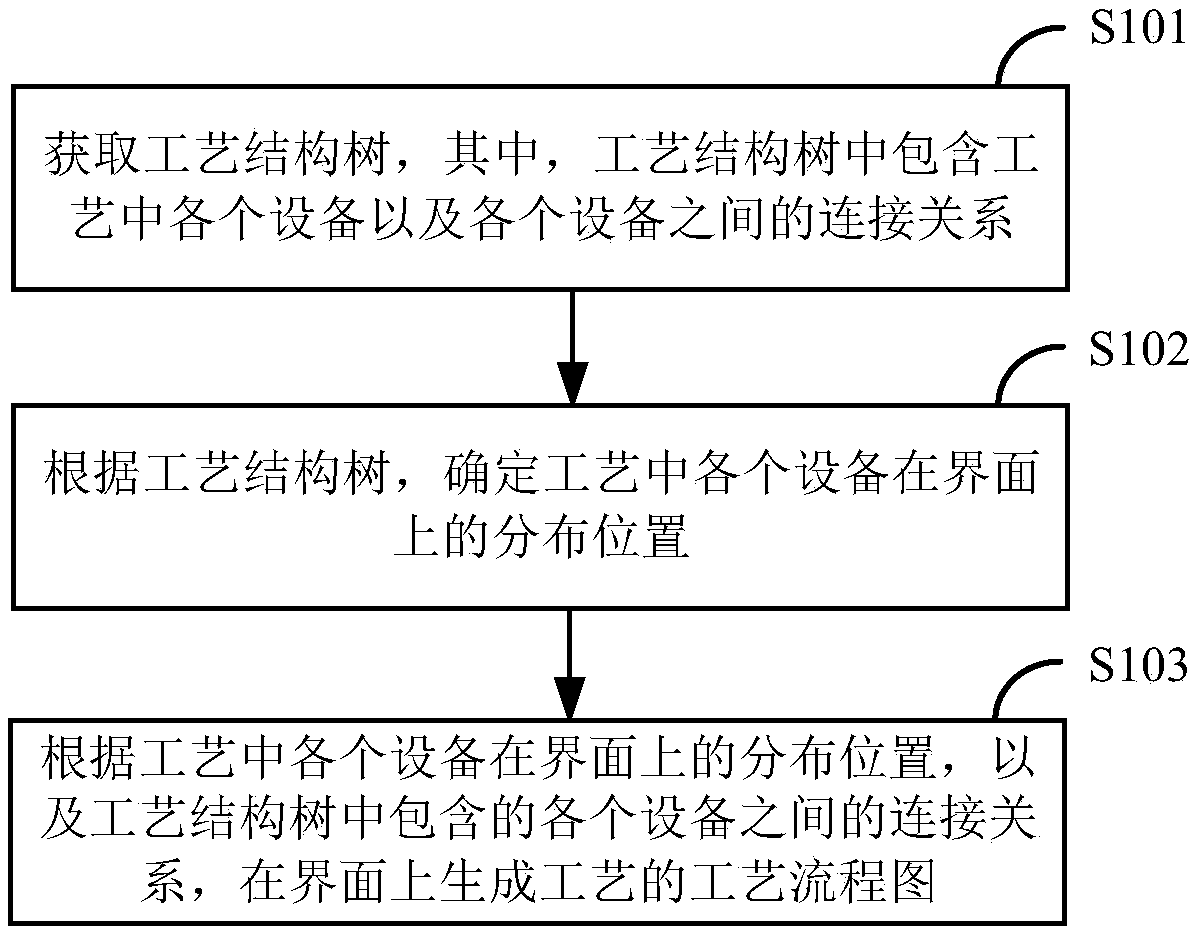

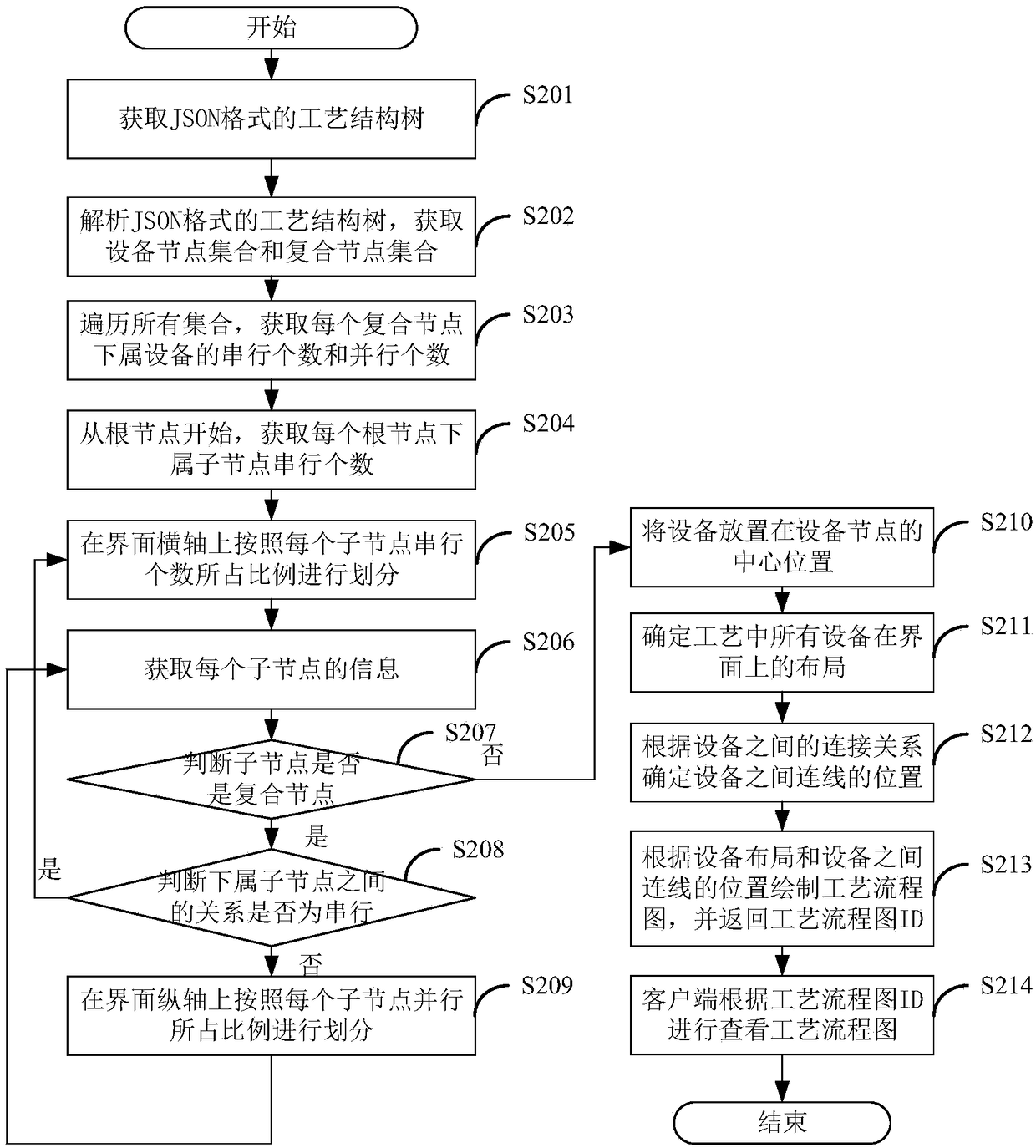

Method and device for generating process flow diagram

PendingCN109190326AImprove drawing efficiencyImprove accuracyComputer aided designSpecial data processing applicationsSoftware engineeringProcess flowsheeting

The invention discloses a method and a device for generating a process flow diagram. The method comprises the following steps: obtaining a process structure tree, wherein, the process structure tree comprises each device in the process and a connection relationship among the devices; according to the process structure tree, determining the distribution position of each device in the process on theinterface. According to the distribution position of each device in the process interface and the connection relationship between each device contained in the process structure tree, the process flowchart of the process is generated on the interface. The invention can automatically generate a process flow diagram according to the process structure tree, thereby improving the drawing efficiency of the process flow diagram and the accuracy of the drawing result.

Owner:NANJING XINLIAN ENERGY CLOUD SERVICES CO LTD

Production executive system

This invention offers a sort of manufacturing executive system, and its actualizing course is in that: Weave the corresponding craftwork flow chart, Collocate the producing channel, ensure the bill or the corresponding relation of the production and the producing flow, and process the collection and the statistic analysis of the producing data and the testing data by the bar-code scan. It is characterization in that this collocation producing channel approach, and it uses the computer page to show the position which is expressed by the visualize graphics mode and it uses the over-stage aspect to collocate the producing channel. The flow collocation of this manufacturing executive system is more visual, intuitionistic. It is propitious to identify and avoid the needless error.

Owner:伟创力电子科技(上海)有限公司

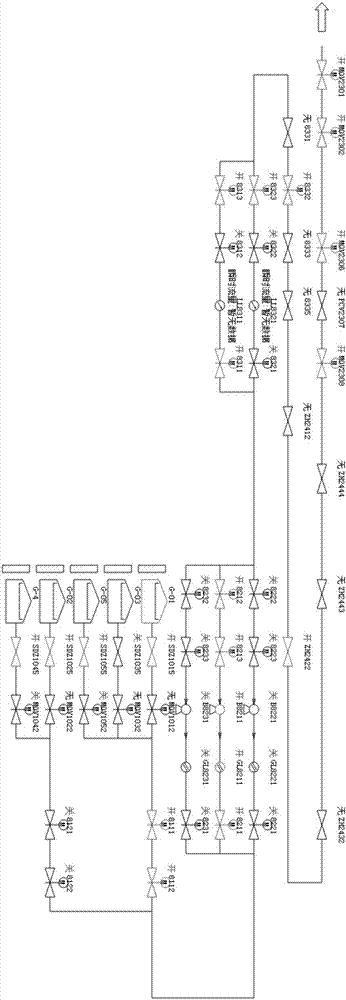

Online configuration method for gas station SCADA system process flow diagrams

ActiveCN105959157AReduce duplication of workReduce workloadData switching networksTotal factory controlSCADAFlow sheet

The invention provides an online configuration method for gas station SCADA system process flow diagrams. The method comprises the following steps: S1, drawing process flow diagram templates for various station types, and initializing the templates in a company level data storage server; S2, during station level process flow diagram configurations, according to a corresponding template file acquired by each gas station type, carrying out S3 when the actual process flow of each station is identical to the corresponding template, and carrying out S4 when the actual process flow of each station is different from the corresponding template; S3, saving the acquired corresponding template file in a station level data storage server to complete station level configurations; and S4, carrying out operations on the corresponding process flow diagram template file according to the actual situations of each gas station to complete the station level configurations, saving each updated process flow diagram in the station level data storage server of the corresponding station, uploading each updated process flow diagram in a real time manner to the company level data storage server for storage through the WCF / TCP communication mode, and releasing received data on the Ethernet through the WEB page mode. The method provided by the invention can greatly reduce the workload and cost.

Owner:中国石化销售股份有限公司 +2

System and method for creating a process flow diagram which incorporates knowledge of the technical implementations of flow nodes

A system and method for associating a technical artifact with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

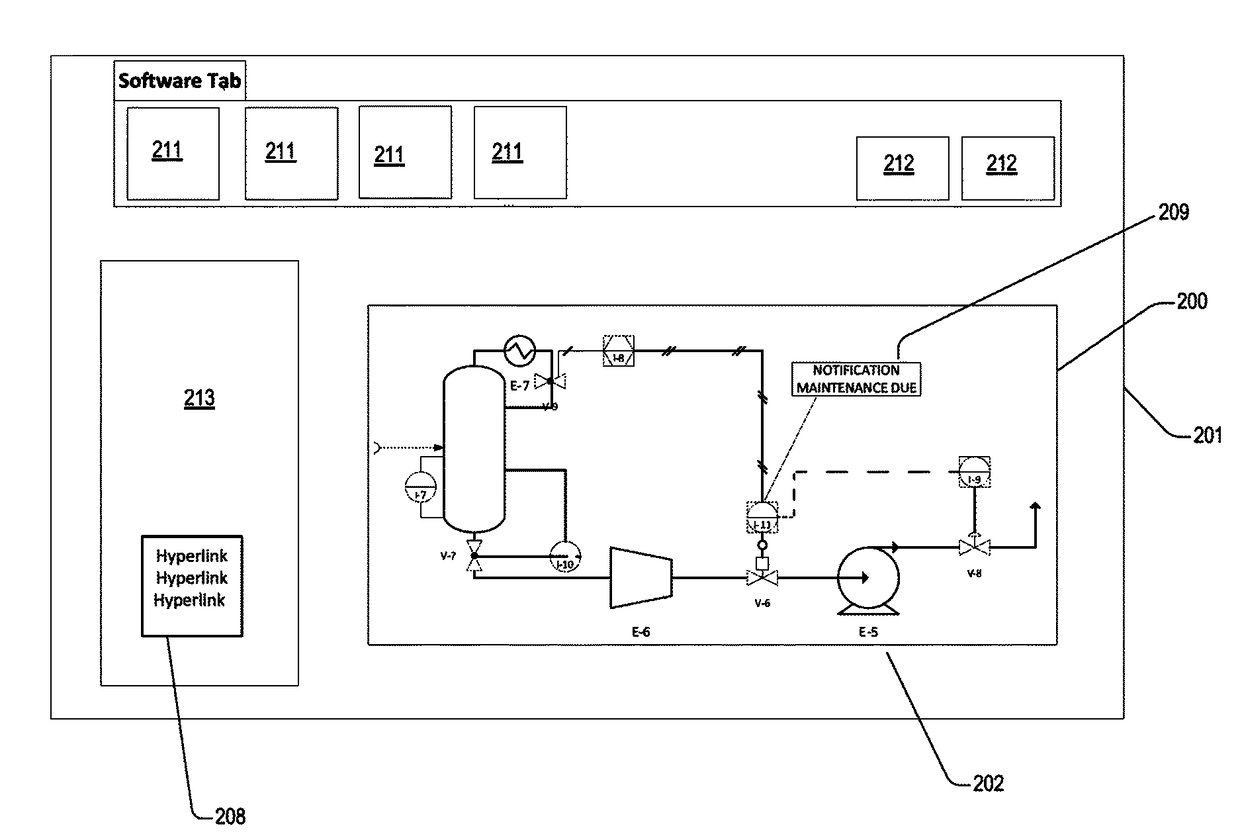

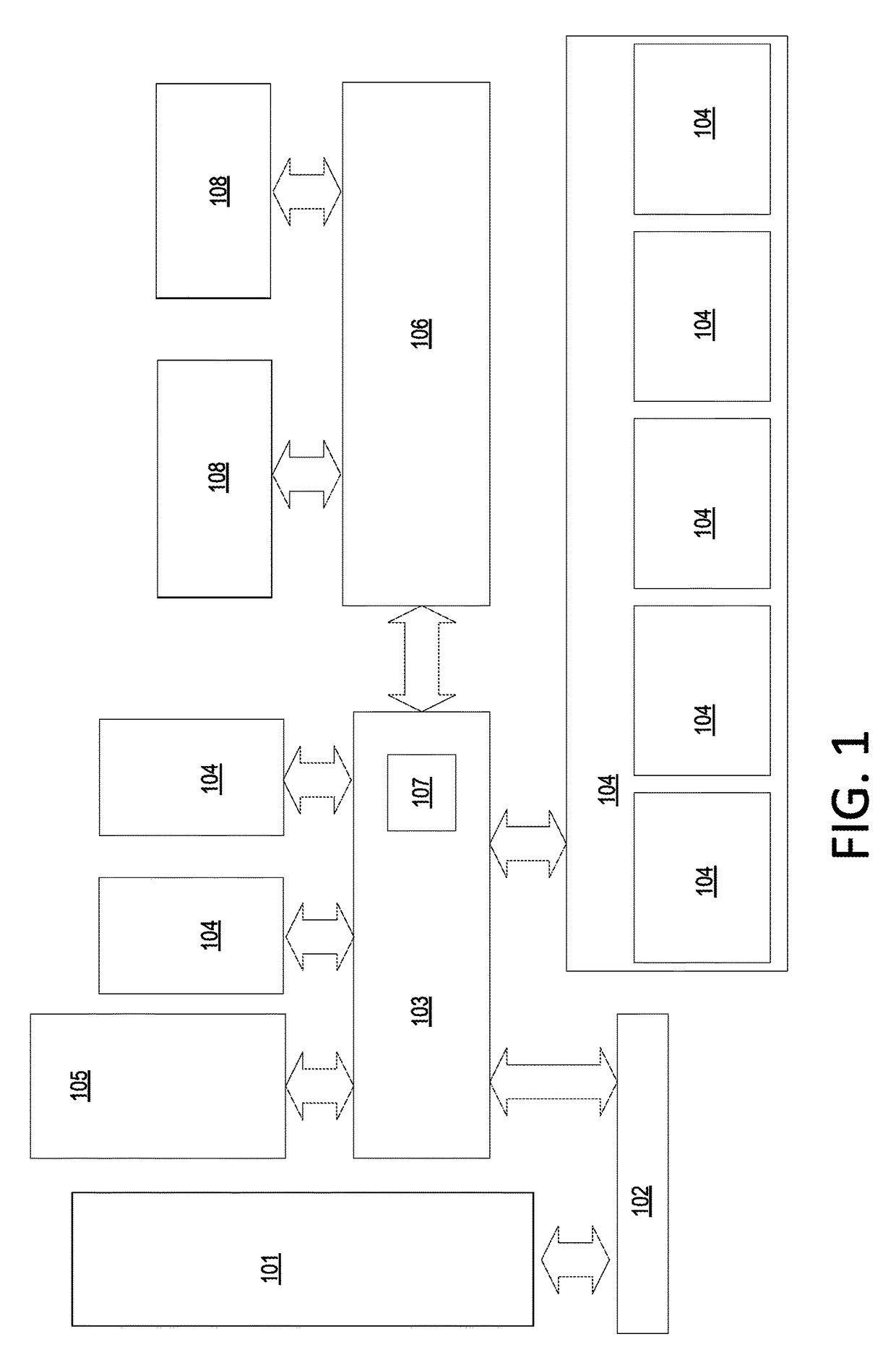

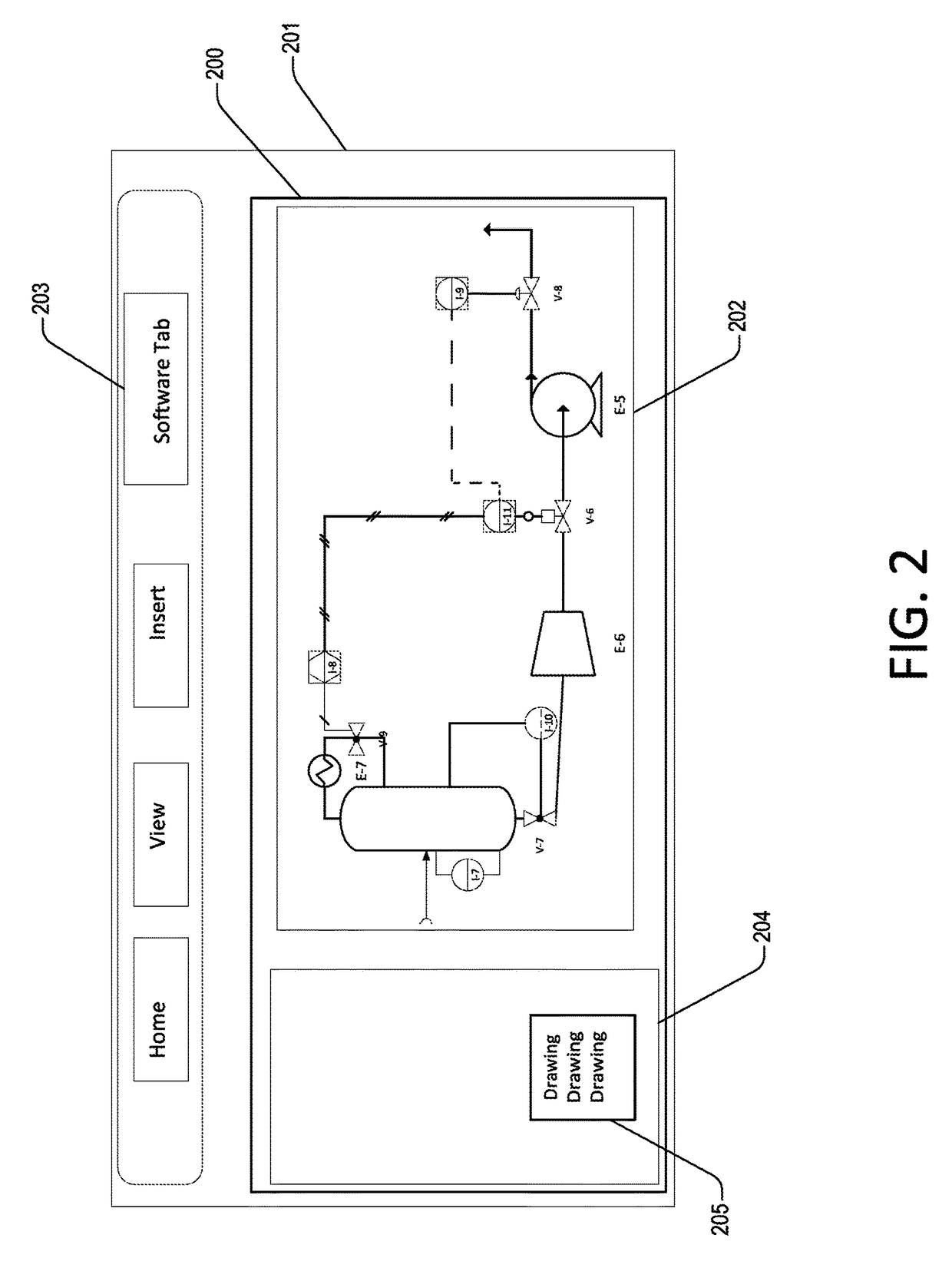

Graphical user interface systems and methods for data integration with data-driven engineering drawings

ActiveUS9811251B2Database management systemsSpecial data processing applicationsData systemUser interface

Described is a system and methodology, in which information is exchanged and / or updated within data-driven engineering schematics and various data management systems within an operating facility. The integration of plant data management systems with data-driven engineering schematics, such as piping and instrumentation diagram (P&ID), process flow diagrams (PFDs) and isometric drawings is an innovation that provides numerous benefits to multiple plant disciplines, including but not limited to Engineering, Operations, Maintenance, Procurement, Environmental, and Safety personnel. In addition to data exchange, described methods and systems within the graphical user interface are capable of generating alerts and initiating to changes to resolve data inconsistencies for a particular component represented in two or more data systems.

Owner:ENVIRONMENTAL INTELLECT INC

System and method for creating a process flow diagram which incorporates knowledge of the technical implementations of flow nodes

A system and method for associating a technical artifact with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

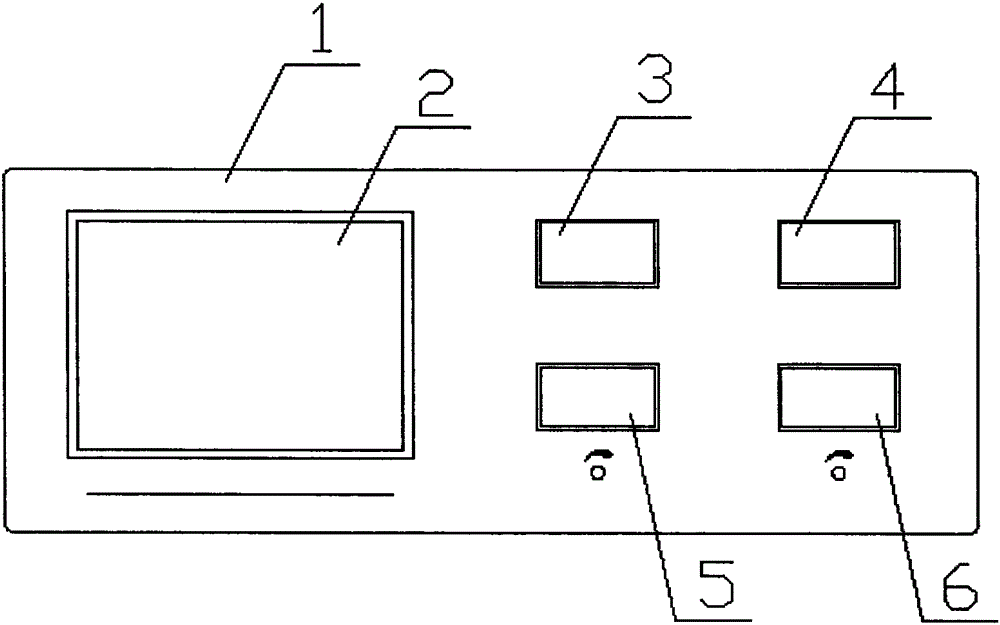

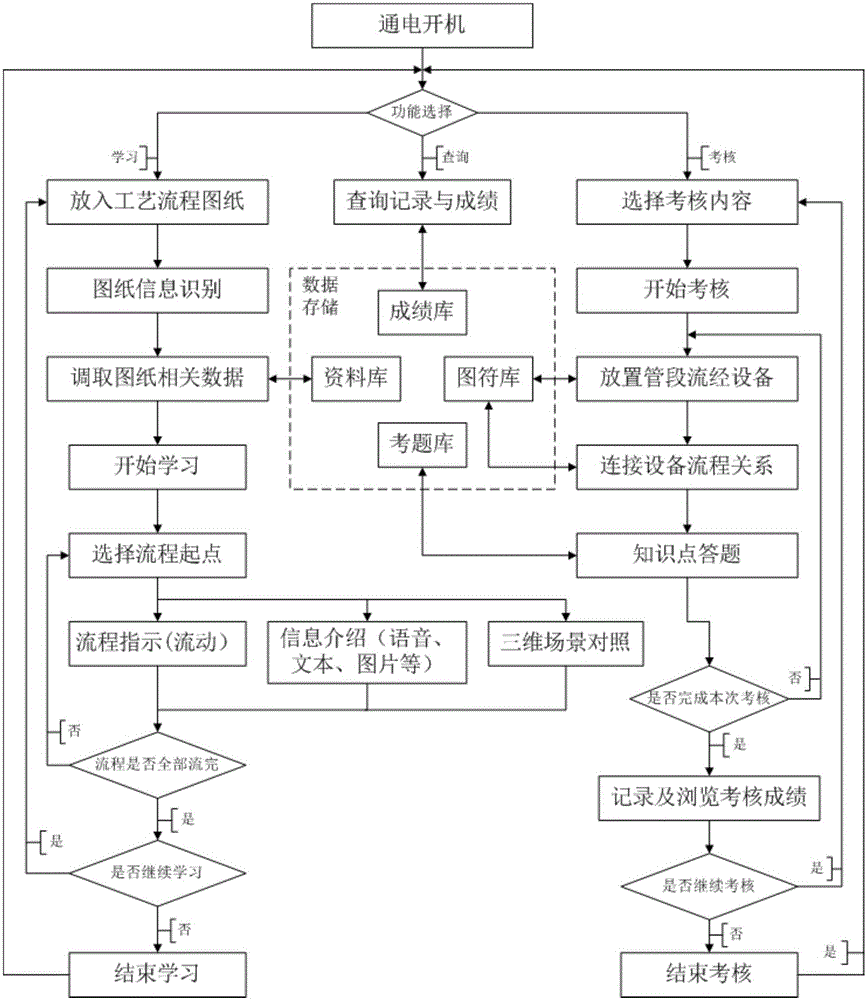

Auxiliary learning apparatus for chemical process flow chart

ActiveCN105138221AImprove learning efficiencyShorten the time periodElectrical appliancesInput/output processes for data processingSide informationComputer science

The present invention relates to an auxiliary learning apparatus for a chemical process flow chart, which mainly solves the problems of relatively long learning period, single form and low efficiency in the prior art. The auxiliary learning apparatus for the chemical process flow chart is adopted. The apparatus comprises a transparent display screen, a drawing placement and positioning mechanism, a master microprocessor system and a fixed button operation panel. The left side of the transparent display screen is connected to the fixed button operation panel; the master microprocessor system is located at the lower right side of the transparent display screen; and the drawing placement and positioning mechanism is located at the lower left side of the transparent display screen. The transparent display screen is divided into a control drawing display area and an auxiliary information display area. Panel buttons on the fixed button operation panel are connected to the master microprocessor system by data lines. The right side of the drawing placement and positioning mechanism is connected to the master microprocessor system; and the left upper end of the drawing placement and positioning mechanism is connected to the fixed button operation panel. According to the technical scheme, the apparatus better solves the problems and can be used in auxiliary learning of a chemical process flow chart.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Oil depot oil product moving path automatic planning method

InactiveCN107451696ASimple moving path automatic planningAutomatic planning is simpleForecastingElement modelWeb service

The invention discloses an oil depot oil product moving path automatic planning method comprising the steps that S1, a data model and a graphical element model are established for various types of equipment on the oil product moving path within the range of the oil depot and saved in a database; and S2, an oil product moving path process flow diagram is drawn for different oil products in the oil depot on a Web interface through the configuration mode, and the process flow diagram data are combined into the Json format to be uploaded to a Web server after completion of configuration and saved in the database. The oil product moving path planning operation is enabled to be simpler, the path planning efficiency is higher, the path planning result is more accurate and more visual, and on / off and start / stop control can be accurately performed on the involved equipment in the path according to the specified order so that the problems of negligence or error of manual planning can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP

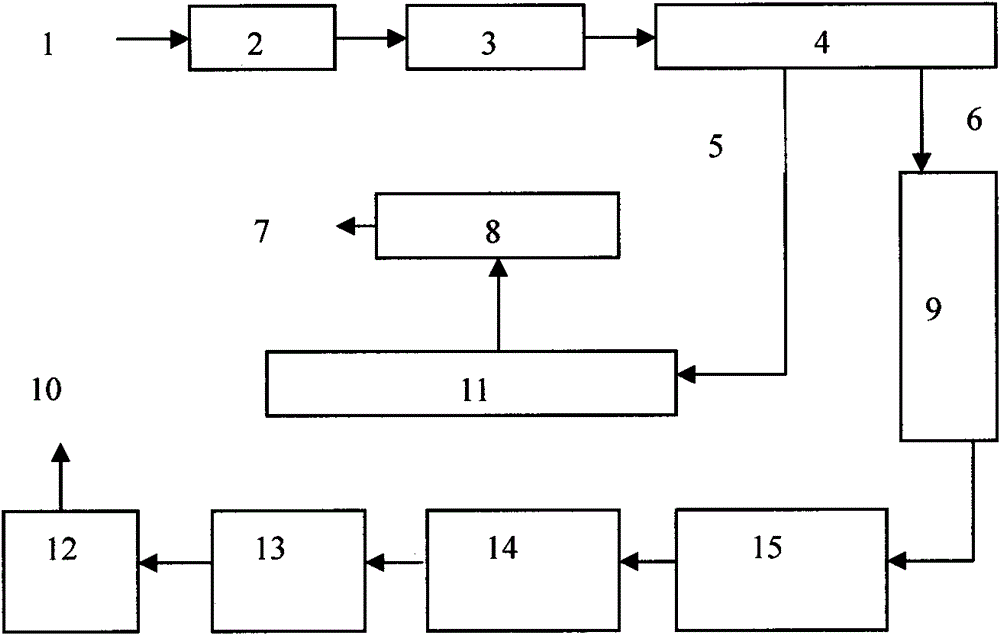

Resource recovery-based automatic corrugated board glue making system

InactiveCN102796467AEasy to adjustThe running screen is accurate and clearStarch adhesivesCycle controlSoftware

The invention discloses a full-automatic glue making system for improving corrugated board glue making performance and resource recovery. The system mainly comprises two aspects, namely a full-automatic corrugated board glue making system and a resource recovery-based corrugated board glue making recycle process (a domestic wastewater recovery process flow diagram is shown as figure 1). The full-automatic corrugated board glue making system mainly comprises software and hardware equipment of the glue making system, and matched large and small cycle control systems; by high process control over pasting temperature, viscosity, solid content and glue temperature, unstable glue quality caused by human factors is radically avoided, the high quality of products is ensured, and high efficiency and low consumption in the production process are ensured. The resource recovery-based corrugated board glue making recycle process mainly comprises steps of using the treated domestic wastewater as production water for the automatic glue making process and treating and recycling glue making wastewater. By the two aspects, water for the whole production system is organically cycled, so that cyclic production is realized, water resources are recycled, the full-automatic glue making system accords with low-carbon production and environmental protection concepts supported by China, and a green idea is combined into the glue making system.

Owner:黄遂兢

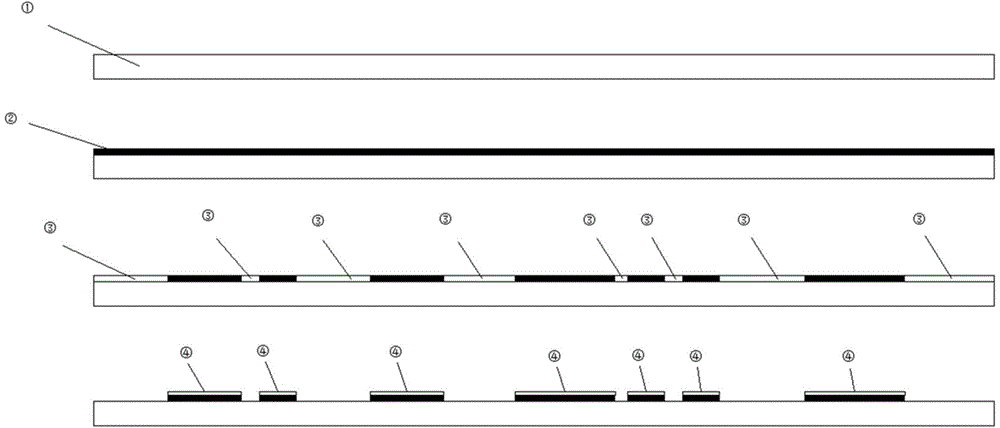

Preparation method of ceramic substrate for medium-free copper-coated gold-deposited light-emitting diode (LED) package

InactiveCN105489713AChemical reaction stabilityImprove thermal conductivitySemiconductor devicesVulcanizationChemical reaction

The invention discloses a preparation method of a ceramic substrate for medium-free copper-cladding gold-deposited light-emitting diode (LED) package. The preparation method comprises the following steps of sintering a ceramic wafer, in which ceramic powder is subjected to die forming and then placed in an environment at 1,000-1,020 DEG C for sintering for 8 to 10 minutes to obtain the ceramic wafer; coating copper, in which copper is coated on the upper surface of the ceramic wafer by a vacuum mist plating method to form a copper foil; etching, in which the useless copper foil is corroded with dilute sulphuric acid according to a process flow diagram to reserve the useful copper foil as a circuit; depositing gold, in which gold liquid medicine passes through the substrate with the circuit already etched so that the gold is deposited on the copper foil to obtain a finished product. According to the preparation method, a medium-free copper cladding technique is adopted, and the excellent heat conduction performance of primary copper and ceramic is maintained; and the gold is deposited on the copper, the chemical reaction of the gold is stable, the vulcanization problem is effectively solved, and the electrical property of the product and the long-term maintenance rate of light refraction are further improved.

Owner:郭垣成

System and method for creating a process flow diagram which incorporates knowledge of business terms

ActiveUS11348049B2Sure easyOffice automationVisual/graphical programmingSoftware engineeringData mining

A system and method for associating a technical artifact and one or more business terms with one or more portions of a process flow diagram by extracting a plurality of technical artifacts from a computing system having a plurality of software applications, providing a process flow diagram having a plurality of nodes and a plurality of edges, associating one or more of the plurality of technical artifacts with one or more of the plurality of nodes of the process flow diagram, displaying the process flow diagram, and when the node is actuated, displaying the associated technical artifact.

Owner:HATHA SYST LLC

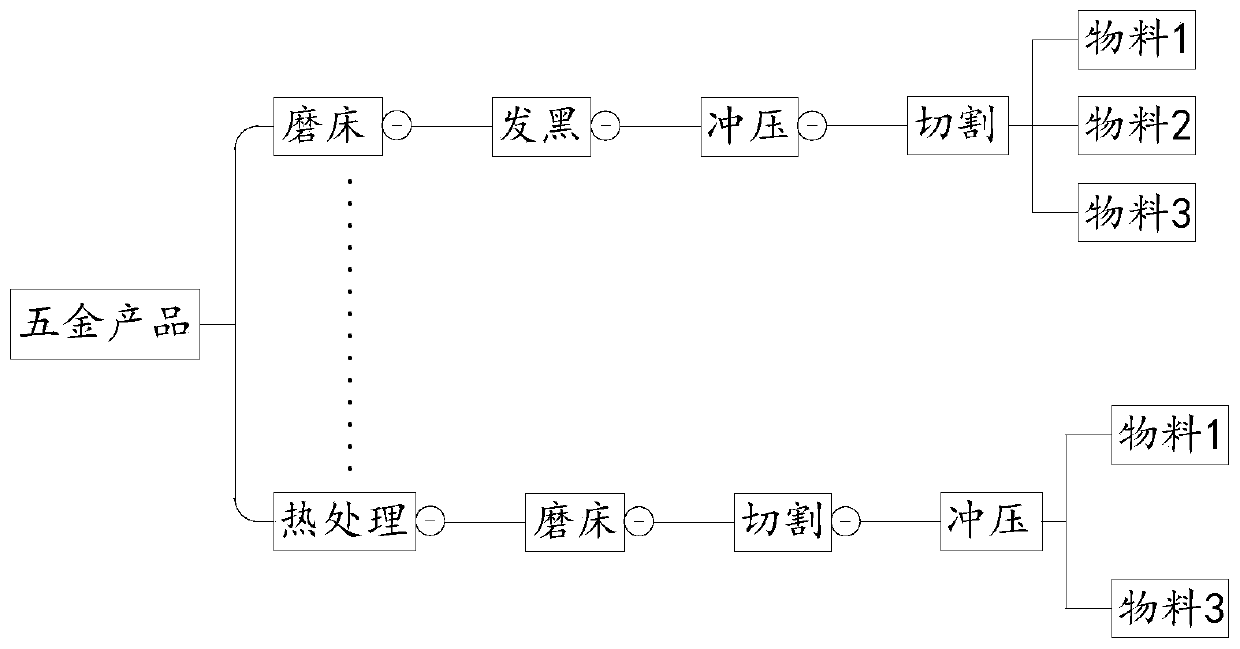

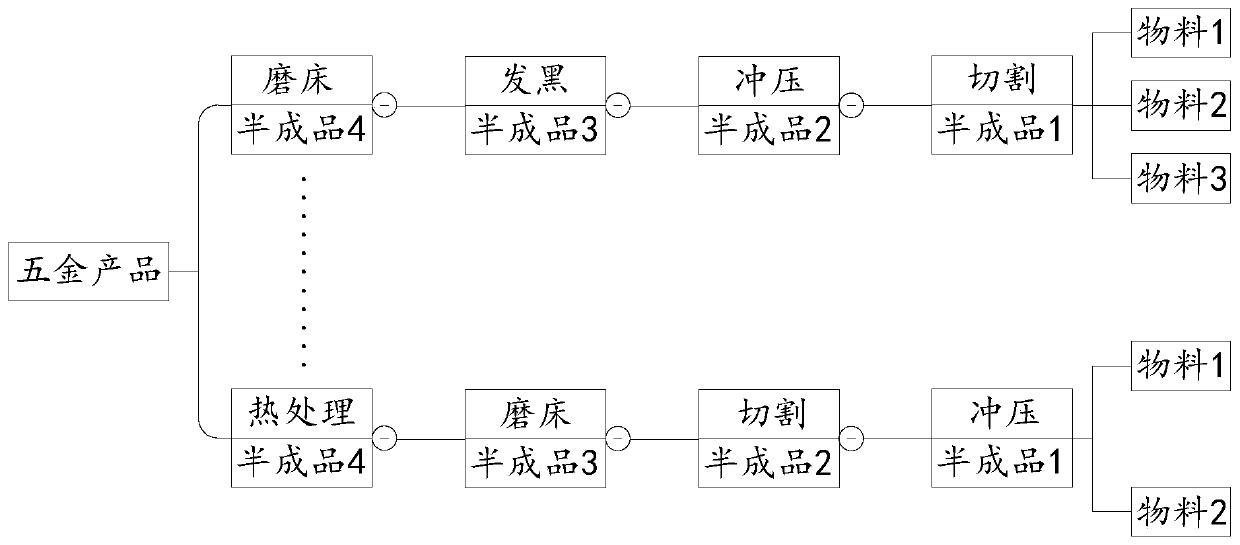

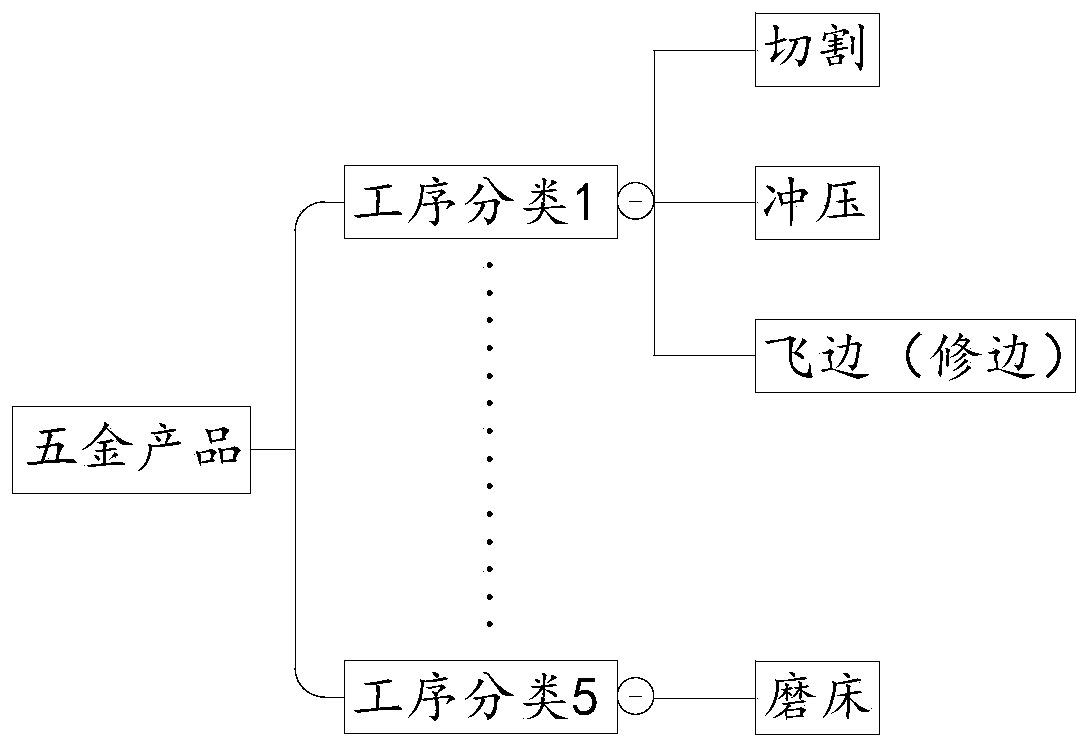

Technological process display method based on mind map, electronic equipment and storage medium

PendingCN111160862AEasy to manageQuick and easy to createOffice automationProcess engineeringProcess map

The invention provides a mind map-based process flow display method, electronic equipment and a storage medium. The method comprises the steps: drawing up a plurality of production technologies according to the features of a to-be-produced product; according to the production sequence of each production process, sequentially arranging the process steps from left to right in an inverted sequence mode, and forming a plurality of process nodes; connecting two adjacent process nodes in series to form a plurality of production process flow diagrams; taking a to-be-produced product as a root node, and connecting a plurality of production process flow diagrams in parallel to form a process flow mind map. According to the method, process nodes of the same level are connected in series to form a process flow diagram, and a plurality of process flow diagrams are associated to the same root node in a parallel connection mode to form a clear and complete process flow mind map.

Owner:广东三扬网络科技有限公司

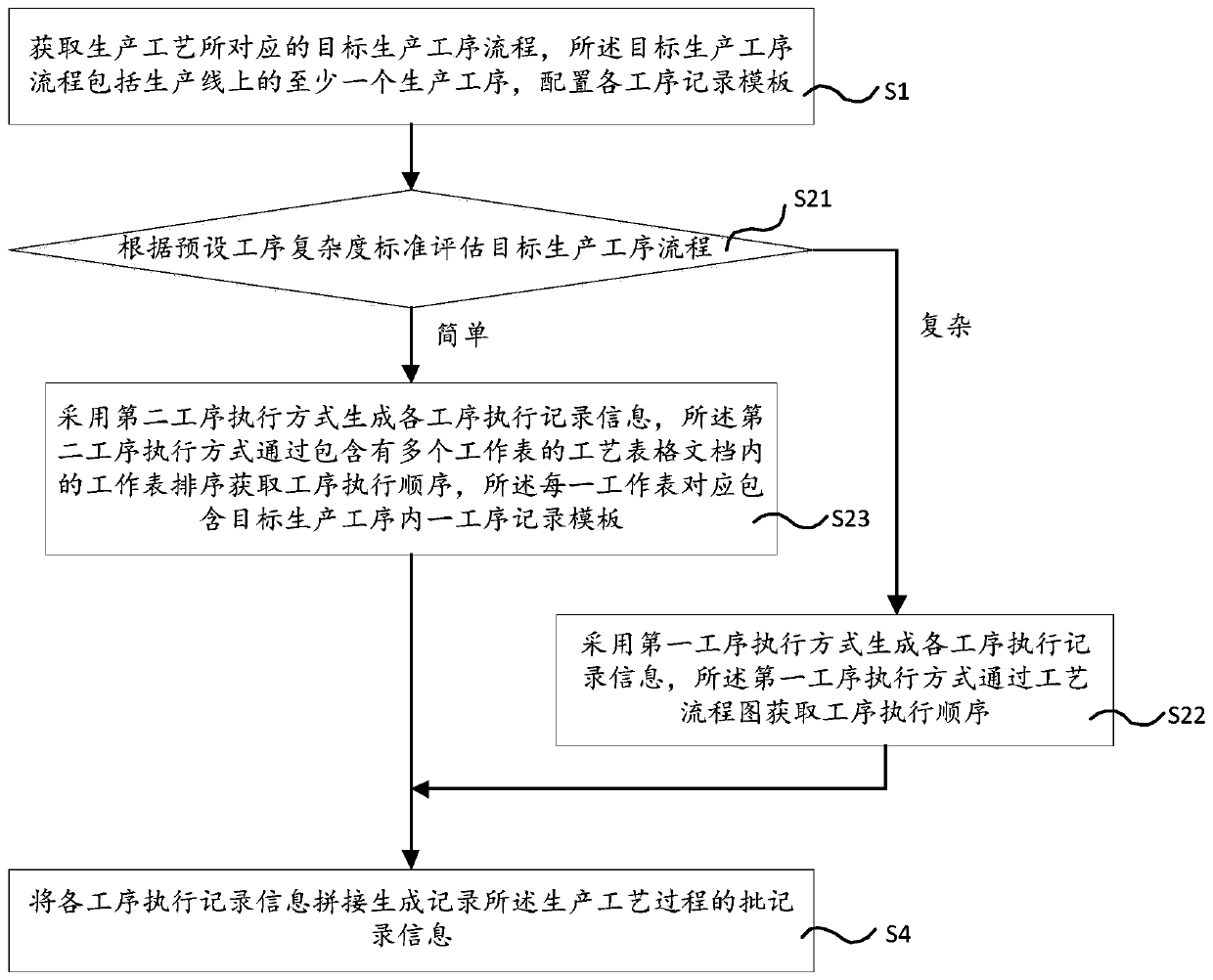

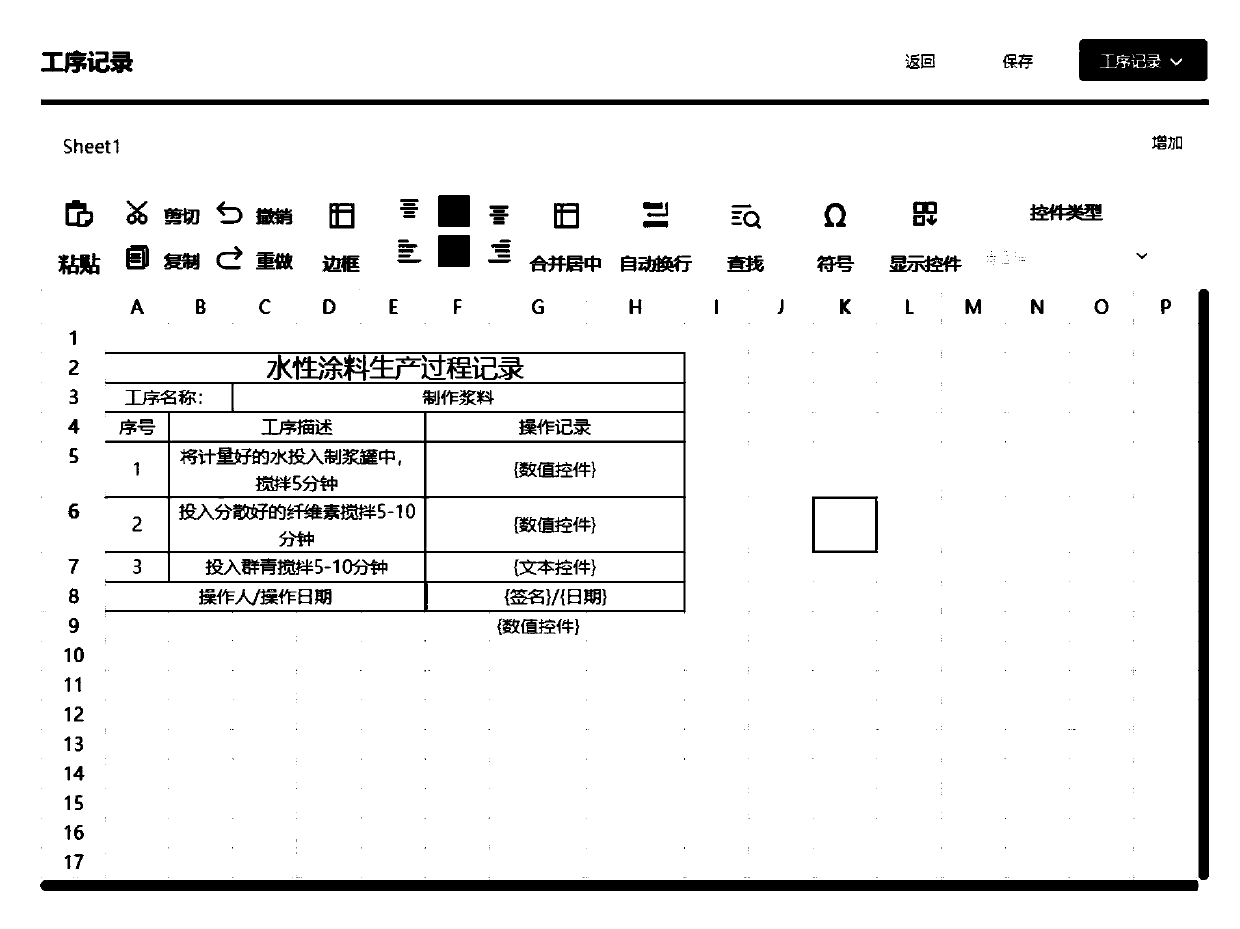

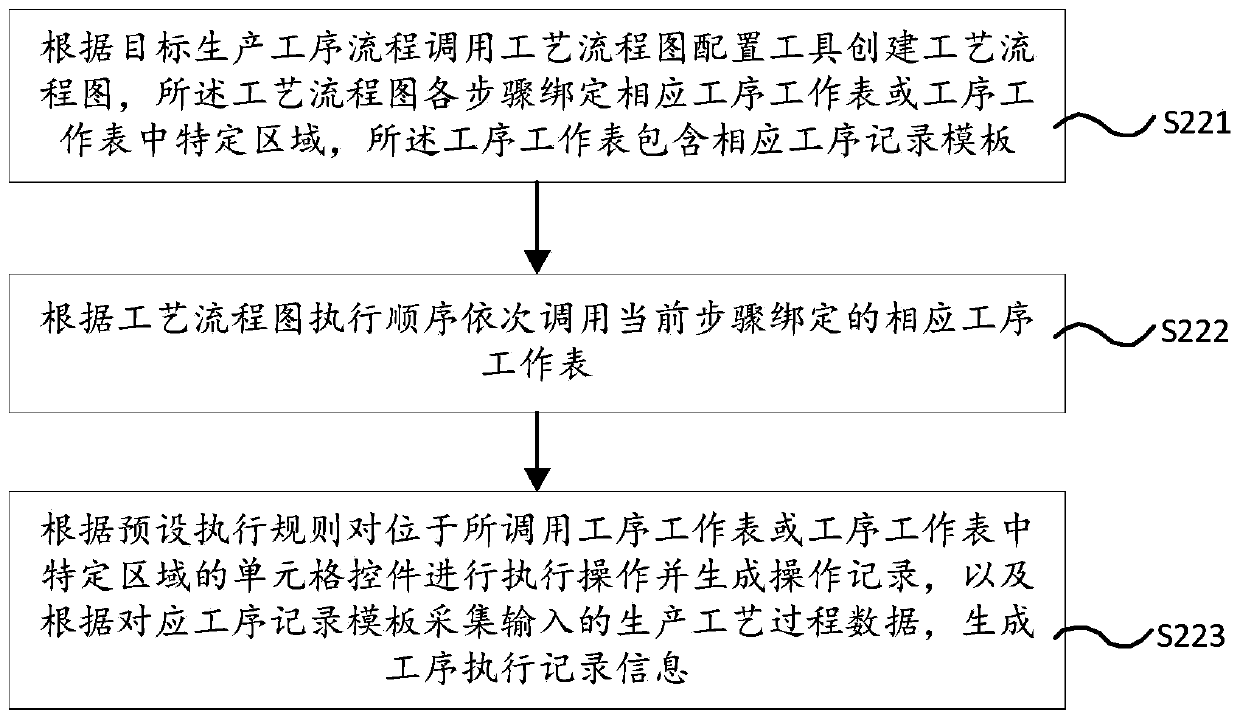

Production process recording method and device based on flow chart and table

ActiveCN110096688AFlexible adjustmentSimple processText processingSpecial data processing applicationsTechnical standardProcess complexity

The invention discloses a process recording method based on a flow chart and a table. The method comprises the steps of obtaining a target production process flow corresponding to a production process, evaluating a target production process flow according to a preset process complexity standard; if so, generating execution record information of each process by adopting a first process execution mode; otherwise, generating execution record information of each process by adopting a second process execution mode, wherein the first process execution mode obtains a process execution sequence through a process flow diagram, the second process execution mode obtains a process execution sequence through a work table sequence in a process table document comprising a plurality of work tables, each work table correspondingly comprises a process record template in a target production process; and finally, splicing the process execution record information to generate batch record information for recording the production process. When the manufacturing process which is diverse and frequently adjusted is generated, the process recording sequence and the recording content can be flexibly adjusted,and the process can be reused in similar processes and processes, so that the customized implementation period is shortened under the condition that the actual production requirements are met.

Owner:MINGDU ZHIYUN (ZHEJIANG) TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com