High purity recycling and energy integration technology for different concentrations of dichloromethane wastewater

A dichloromethane and wastewater technology, applied in the direction of heating water/sewage treatment, preparation of halogenated hydrocarbons, chemical instruments and methods, etc., can solve the problems of cumbersome process, high energy consumption, waste, etc., and save the preheating system, The effect of short process route and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

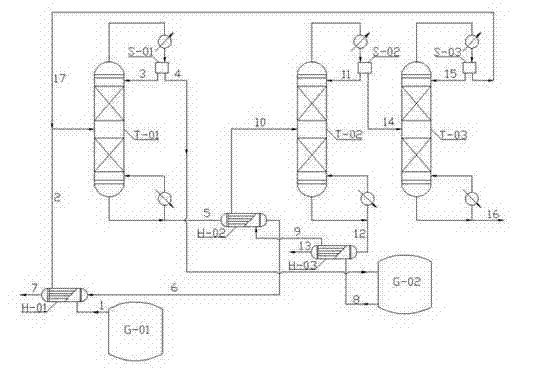

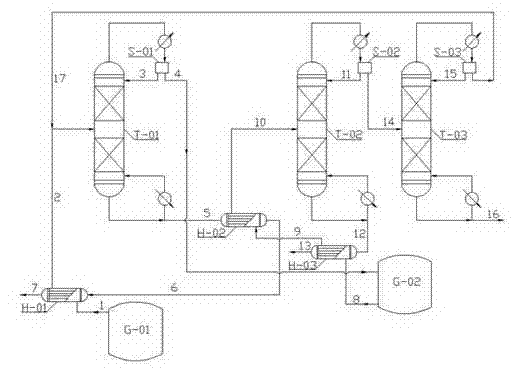

[0023] The wastewater containing 3% (wt) of dichloromethane, 96% of water, and 1% of salt residues (including other solids) at a flow rate of 5 tons / hour is preheated to 40℃ by the heat exchanger A H-01 Enter the rectification tower A T-01, the number of theoretical plates of the rectification tower A T-01 is 35, the diameter of the tower is 0.6 meters, the operating pressure is normal pressure, the kettle is heated by steam, and the top of the rectification tower A T-01 The condensate of the steam after heat exchange enters the phase separator AS-01, the light phase is refluxed, the top temperature of the rectification tower A T-01 is 80℃, the temperature of the column bottom is 101℃, and pure water and salts are obtained from the bottom of the column Residue (including other solids). The heavy phase is extracted to obtain a dichloromethane-water mixture containing 84.7% dichloromethane, which is sent to the 85% dichloromethane wastewater storage tank B G-02 for mixing. The m...

Embodiment 2

[0025] The wastewater containing 6% (wt) of dichloromethane, 93% of water, 1% of salt residues (including other solids) and a flow rate of 3 tons / hour is preheated to 40℃ by the heat exchanger A H-01 Enter the rectification tower A T-01, the number of theoretical plates of the rectification tower A T-01 is 30, the diameter of the tower is 0.8 meters, the operating pressure is normal pressure, the tower is heated by steam, and the top of the rectification tower A T-01 The condensate of the steam after the heat exchange enters the phase separator AS-01, the light phase is refluxed, the top temperature of the rectification tower A T-01 is 81℃, the temperature of the column bottom is 100℃, and the column bottom gets pure water and salt Residue (including other solids). The heavy phase is extracted to obtain a dichloromethane-water mixture containing 85% dichloromethane, which is sent to the 85% dichloromethane wastewater storage tank B G-02 for mixing. The mixture containing 85% (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com