Patents

Literature

49results about How to "Chemical reaction stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

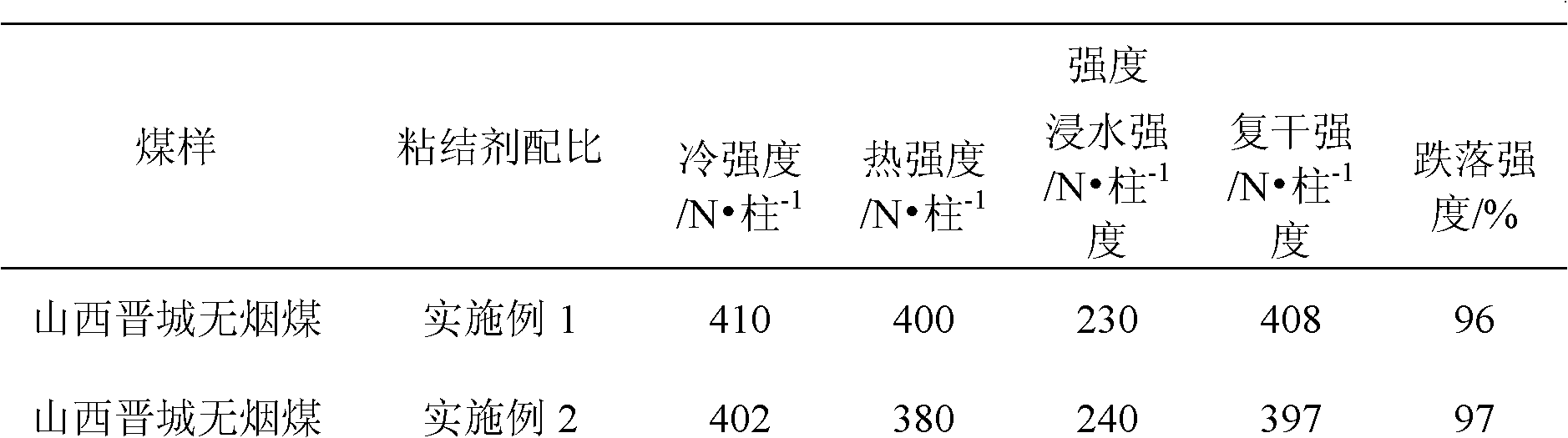

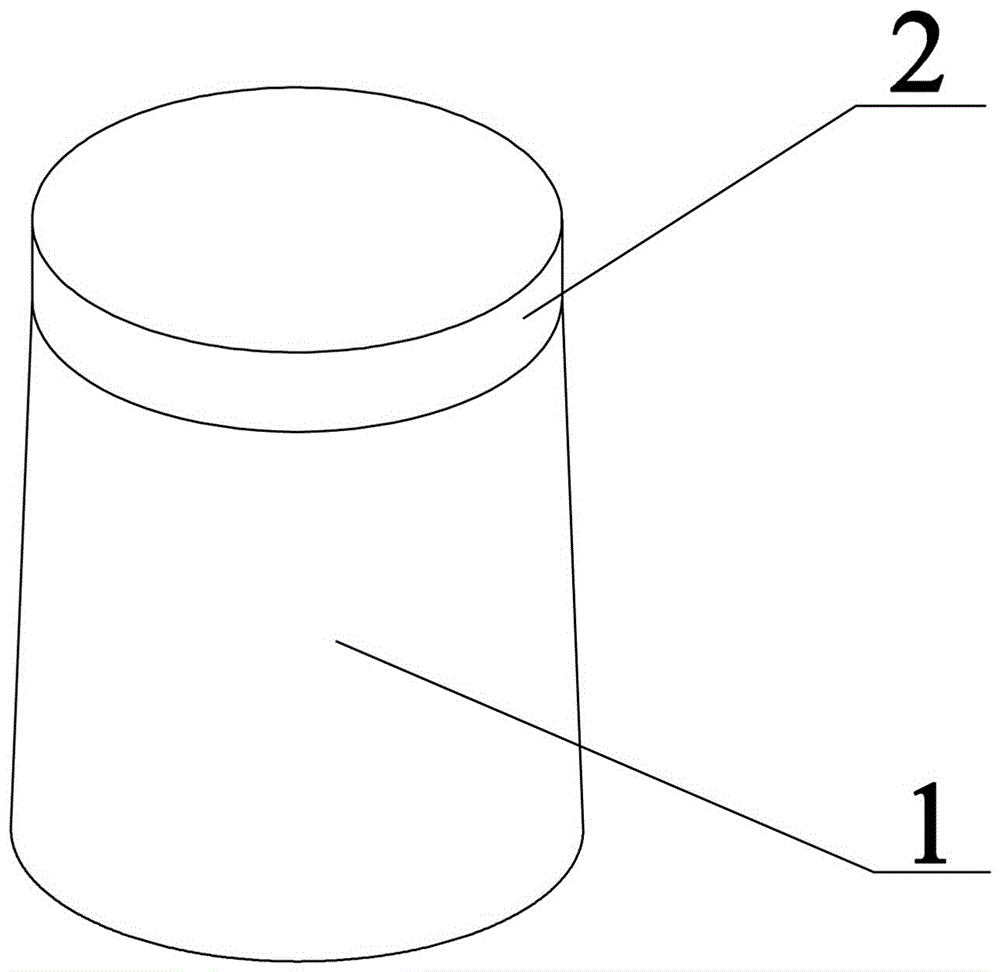

Briquette binder and briquette preparation method based on binder

The invention provides a briquette binder and a briquette preparation method based on the binder. The binder comprises 45 to 75 mass percent of humic acid, 8 to 20 mass percent of bentonite, 5 to 18 mass percent of kaolin, 1 to 5 mass percent of quartz sand, 2 to 8 mass percent of quicklime, 0.1 to 2 mass percent of sodium chloride, 0.1 to 2 mass percent of potassium permanganate and 0.05 to 0.1 mass percent of polyacrylamide. The binder has a simple preparation process, low cost, convenient use and no any secondary pollution and is applicable to various types of coal. The process for preparing the briquette by using the binder comprises the following steps of: only making little pretreatment on raw material coal and the binder, mixing the raw material coal and the binder in proportion, adding water into the mixture, uniformly stirring, pressing the mixture into a cylindrical briquette by using a press machine, and air-drying or drying the cylindrical briquette. The briquette prepared by using the binder of the invention has the characteristics of high cold strength, high water resistance, low cost, low ash increment, high thermal strength, high sulfur retention rate and wide source of raw materials.

Owner:SHAANXI UNIV OF SCI & TECH

Zero-power consumption steel-making method using electric-arc furnace

ActiveCN103205529AIncrease profitPromote rapid formationProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a zero-power consumption steel-making method using an electric-arc furnace. The zero-power consumption steel-making method specially comprises the following steps of: controlling the proportion of steel scrap in a furnace burden structure at 20%-30% and the proportion of molten iron at 70%-80%; pushing the steel scrap in a vertical shaft into the furnace by a hydraulic device, wherein the pushing speed is 1-3t / min; adding the molten iron to the furnace at twice through a molten iron adding chute for the furnace wall, wherein the primary molten iron accounts for 40%-80% of the total amount of the molten iron, the iron addition speed is 15-30t / min, the secondary molten iron accounts for 20%-60% of the total amount of the molten iron, and the iron addition speed is 4.5-6.5t / min; simultaneously adding lime to the furnace for slagging, and blowing oxygen for smelting; and when the temperature and components of the molten iron meet the technological requirements, finishing smelting in the electric-arc furnace. The zero-power consumption steel-making method can prevent the molten iron and furnace slag from overflowing from a furnace gate, thus reducing the consumption of slag charges and steel in the smelting process.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for producing dehydroepiandrosterone

The invention discloses a production method for dehydroisoandrosterone, which comprises the steps of ketoxime reaction, Bering reaction, hydrolysis reaction, and obtaining a finished product after refining and is characterized in that: in the hydrolysis reaction, potassium carbonate and methanol are used for reacting with a Bering reactant; filtering, crystallization, centrifugalization and drying are carried out to the solution after reaction, thus obtaining the finished product. In the hydrolysis reaction, since the alkalinity of the potassium carbonate is moderate, the reaction has relatively slow speed, stable chemical reaction and little produced heat and is safe. After refining, the melting point, the content and the yield of the product are respectively increased by 2 DEG C, 1.5 percent and 3.4 percent; the color and luster and the appearance of the product are improved; various indexes of the product are placed in the front ranks of the same industry in China; the method is also proved to have safety, effectiveness and quality controllability; meanwhile, the method increases output and lowers production cost, the product quality not only meets the requirements of customers but also increases market competitive power.

Owner:HUBEI DANAO PHARMA CO LTD

Electrode material for disposable alkaline batteries

InactiveCN102856529AReduce transfer speedPrevent hindering reaction speedPrimary cell electrodesDry cellsNickel oxide hydroxideZinc alloys

The invention relates to an electrode material for disposable alkaline batteries. The electrode material comprises an anode material, a cathode material, a septum, alkaline electrolyte, an anode collector and gel, wherein the septum is positioned between an anode and a cathode, the cathode material comprises manganese dioxide and nickel oxide hydroxide which serve as cathode activity materials as well as conductive carbon grains, and the anode material refers to zinc or zinc alloy and graphite.

Owner:黄宣斐

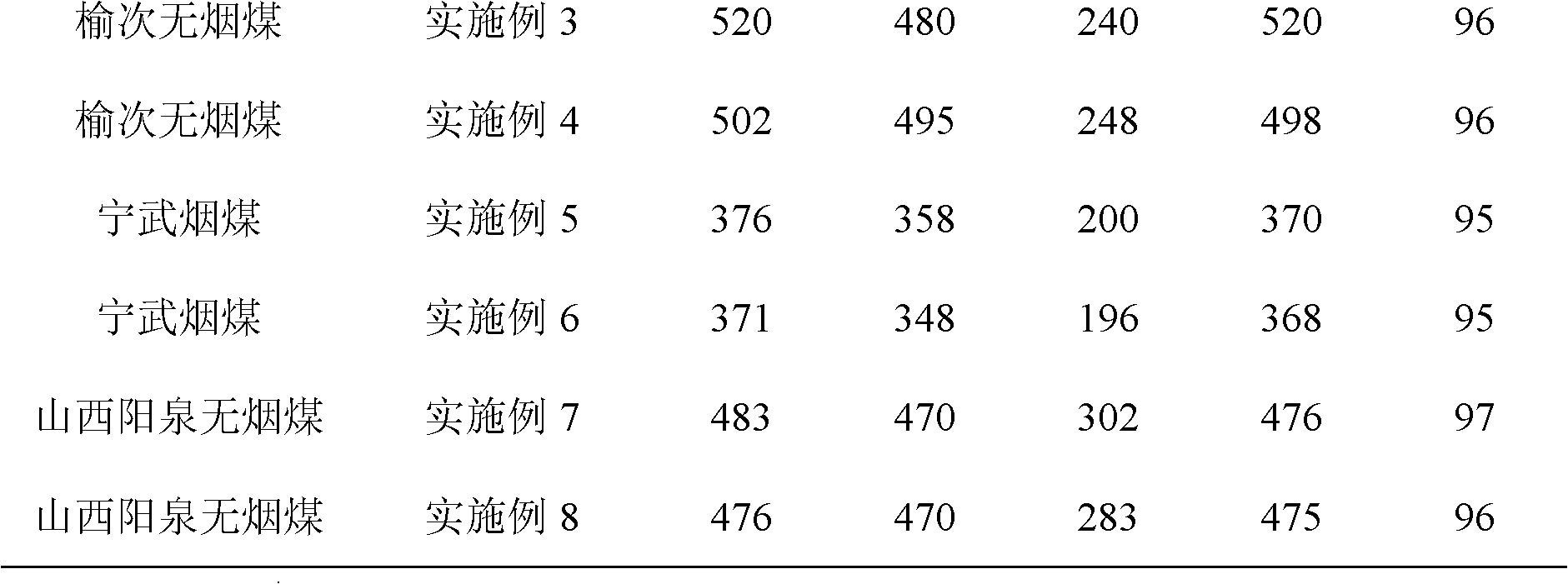

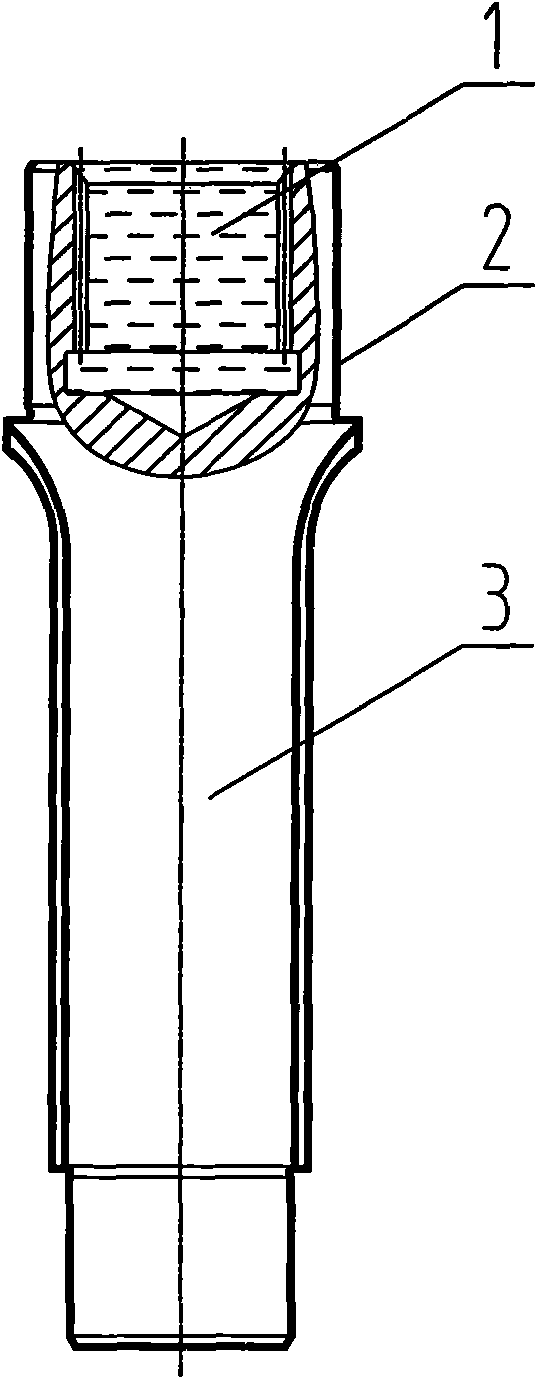

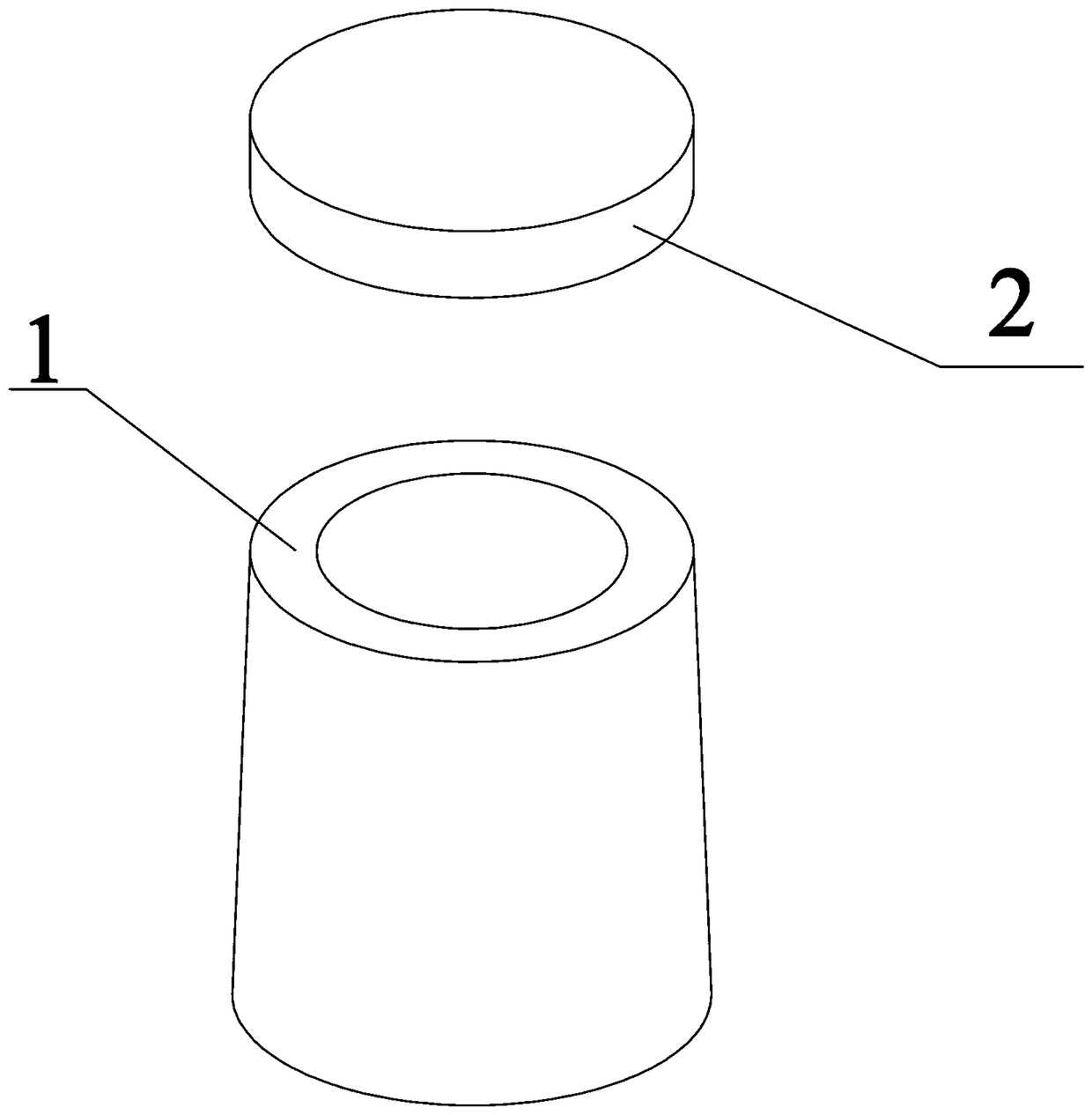

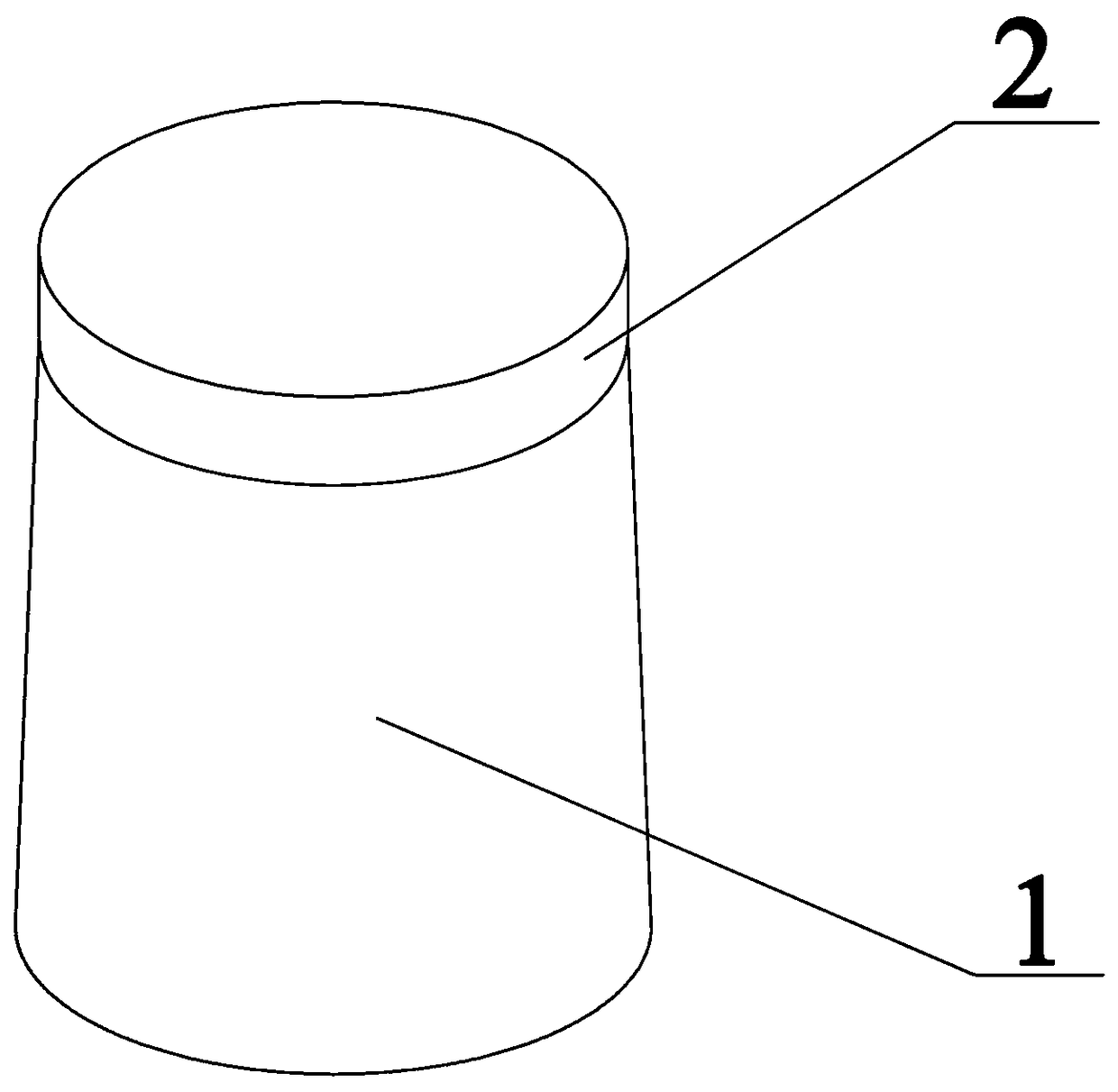

Cast steel exothermic riser sleeve

The invention relates to a casting riser sleeve, in particular to a cast steel exothermic riser sleeve. The two ends of the exothermic riser sleeve are opened. A top cover is arranged at the top end of the exothermic riser sleeve. The top cover is made of precoated sand. The exothermic riser sleeve is adopted for replacing a sand mold overflow riser in the prior art, the setting time is prolonged, heat supply is uniform, and the interior of an exothermic riser is free of defects, deformation and expansion; and the surface of a casting is bright and clean, the appearance is tidy, the technology yield is increased by 4.6%, and the production cost is reduced.

Owner:西峡飞龙特种铸造有限公司

Restoration method for eliminating heat treatment deformation of metal internal teeth

The invention discloses a restoration method for eliminating heat treatment deformation of metal internal teeth, which comprises the following steps: performing covering protection on a quenched metal internal teeth workpiece according to required corrosion resistant materials, and only exposing parts needing restoring; contacting the metal internal teeth workpiece after the covering protection with acid corrosive liquid to generate chemical reaction; when the corrosive dissolution amount of the chemical reaction on the parts of the metal internal teeth workpiece needing restoring is equal to the swelling amount of the heat treatment deformation of the metal internal teeth workpiece, taking the metal internal teeth workpiece out; and cleaning the metal internal teeth workpiece, and performing rust-proof treatment. The invention provides a chemical processing method for the metal inner teeth surface with simple process, convenient operation, reasonability and high efficiency, which can quickly solve the problem of shrink deformation of the internal teeth of a metal workpiece after heat treatment without adopting the conventional cutting method.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Production technology of ignition charge specially used for digital electronic detonator

InactiveCN106831276AGuaranteed reliabilityImprove performanceAlkali metal salt explosive compositionsDetonatorAdhesive

The invention discloses a production technology of ignition charge specially used for a digital electronic detonator. The ignition charge is prepared from the following raw materials in parts by weight: 8-12 parts of potassium chlorate or potassium perchlorate, 6-10 parts of lead thiocyanate and 2-4 parts of nitrocotton. The production technology comprises the following steps: (1) putting nitrocotton, butyl acetate or ethyl acetate and polyvinyl acetate emulsion adhesive into a glue preparation barrel, and uniformly stirring, so that adhesive solution with the mass percent concentration of 3-10% is obtained; (2) mixing potassium chlorate or potassium perchlorate and lead thiocyanate with the adhesive solution obtained in the step (1) according to the parts by weight, fully and uniformly stirring by adopting a bakelite rod, so that the ignition charge is obtained; and then covering with wet cloth, putting the ignition charge into a glass dryer for later use, and enabling the ignition charge to be in an environment with the humidity of 60-80%. The production technology disclosed by the invention guarantees initiation reliability and high precision of the digital electronic detonator.

Owner:QIANJIN IND EXPLOSIVES CO LTD

Polishing solution for chemically mechanically polishing germanium crystal and application method

InactiveCN104449404AImprove efficiencyReduce roughnessSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesHardnessSurface-active agents

The invention relates to a polishing solution for chemically mechanically polishing germanium crystal and an application method. The polishing solution comprises a rough polishing solution and a fine polishing solution, wherein the rough polishing solution is mainly prepared from the following raw materials in percentage by weight: 10 to 50% of hydrosol grinding material, 0.2 to 1.5% of an oxidant, 0.5 to 2% of a pH conditioner, 0.2 to 1.5% of a chelating agent, and 0.1 to 1% of a surface active agent, wherein the hydrosol grinding material is 15 to 110nm in particle size and has the concentration being not less than 40wt% (percentage by weight) and hardness being not greater than 7 Mohs; the fine polishing solution is mainly prepared from 0.1 to 0.5% of a surface active agent, and the balance of deionized water. The two-step polishing method is performed for chemical mechanical polishing and comprises two steps of selecting the rough polishing solution and then second the fine polishing solution; the two polishing can be performed through one polishing machine. The polishing solution has the beneficial effect that the problems of low rate, high roughness and pollution of metal ions and particles in chemical mechanical polishing of germanium crystal materials can be solved.

Owner:HEBEI UNIV OF TECH

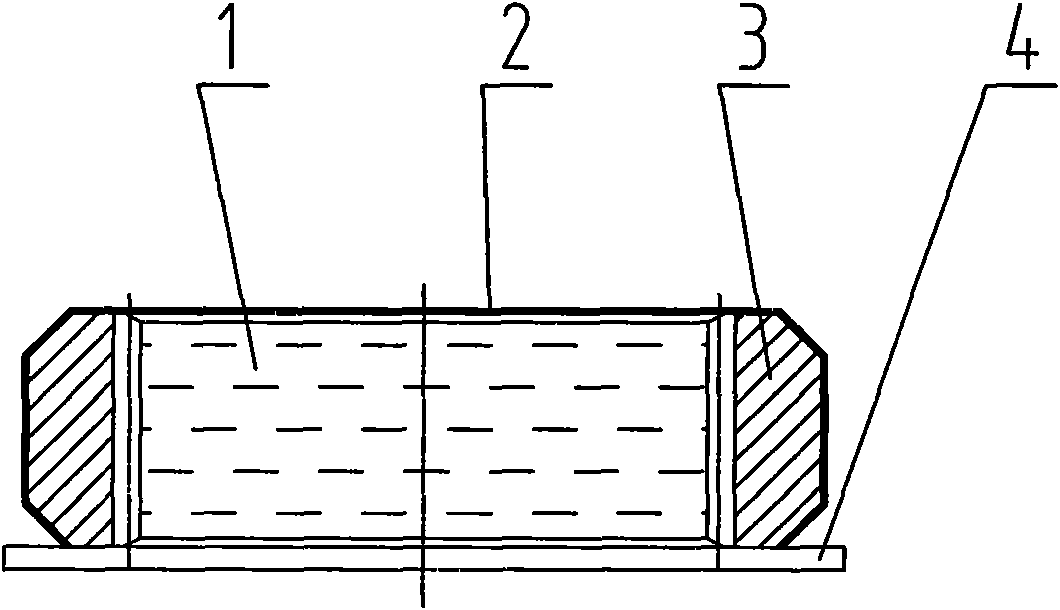

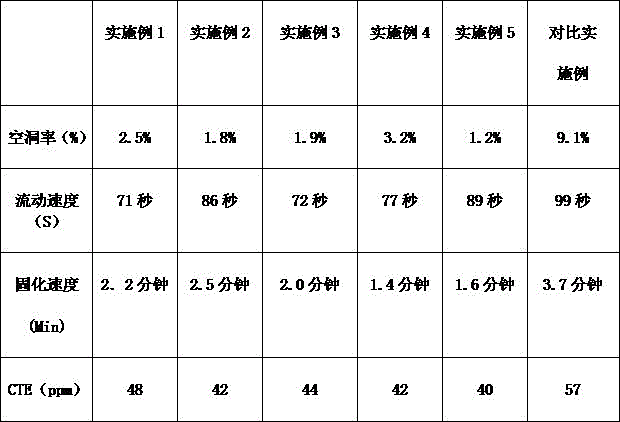

Bottom filling adhesive having good compatibility with scaling powder and preparation method thereof

ActiveCN106398617AImprove compatibilityGuaranteed reliabilityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention discloses a bottom filling adhesive having good compatibility with scaling powder and a preparation method thereof. The bottom filling adhesive is compounded by, by weight, 5-25 parts of self-synthesized compatible resin, 20-50 parts of epoxy resin, 5-20 parts of thinner, 1-3 parts of coupling agent, 0.1-1 part of dispersant, 35-50 parts of filler and 5-30 parts of curing agent, wherein the self-synthesized compatible resin is compounded by, by weight, 500-700 parts of dimer acid, 140-360 parts of hydroxyl-terminated toughened resin, 1-8 parts of methyl benzenesulfonic acid, 90-190 parts of low-viscosity bifunctional epoxy resin and 0.2-3.0 parts of triphenyl phosphine. Compared with the prior art, the compatibility with scaling powder of the bottom filling adhesive is excellent, the defects formed in the flowing and curing process are decreased, the flowing speed and the curing speed are high, the bottom filling adhesive meets the requirement for high density packaging, an expansion coefficient is small, and the reliability of packaging components is effectively guaranteed.

Owner:YANTAI DARBOND TECH

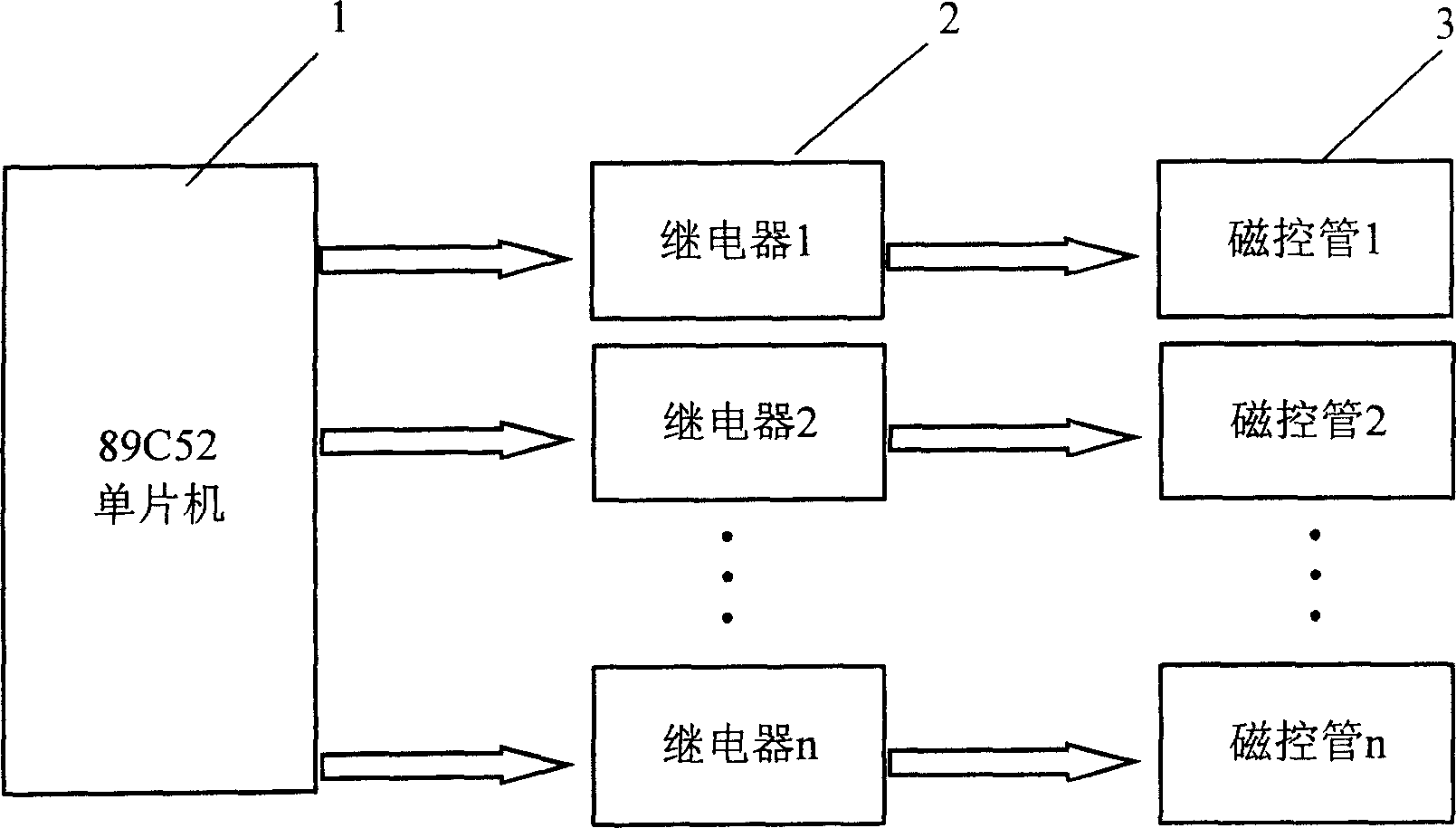

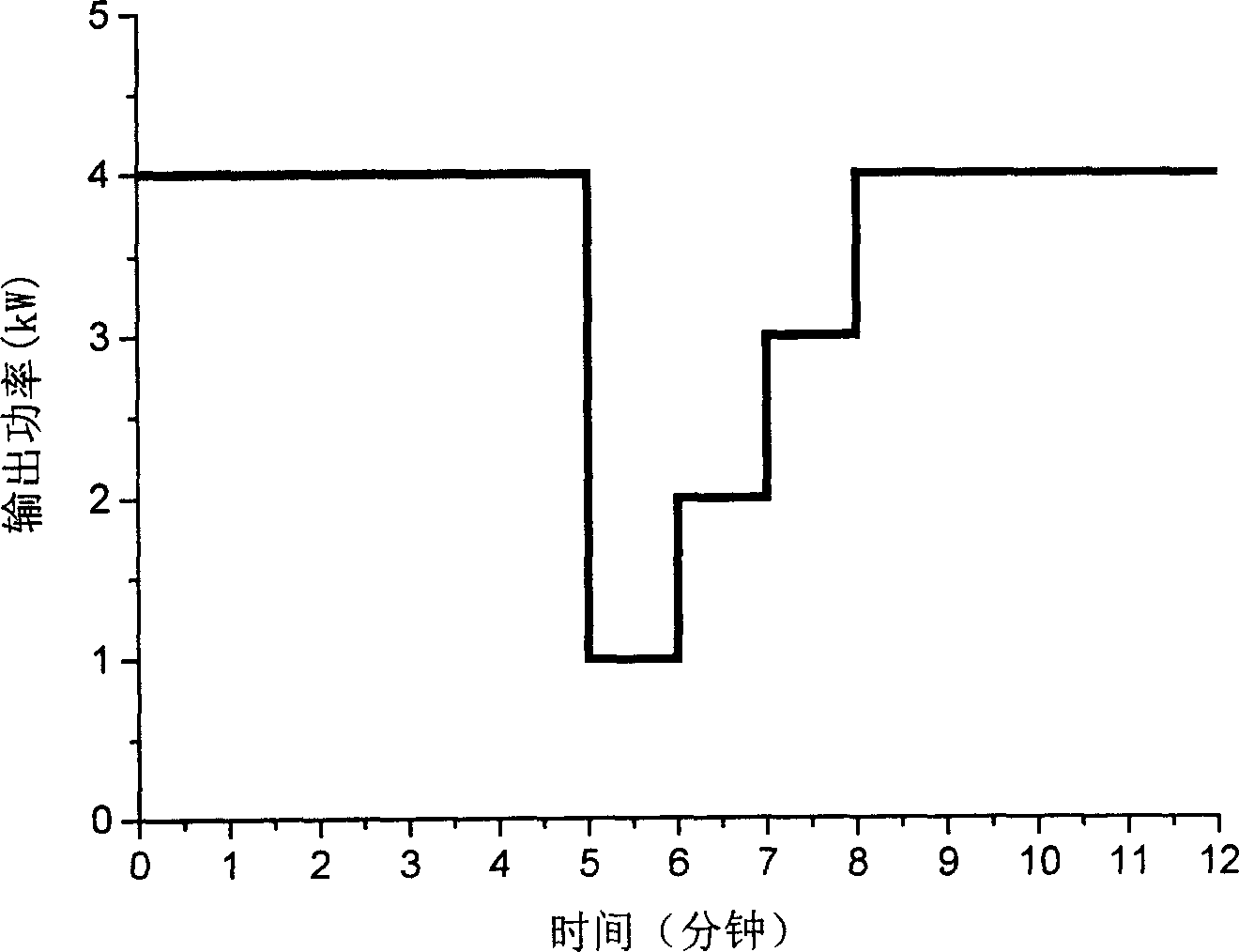

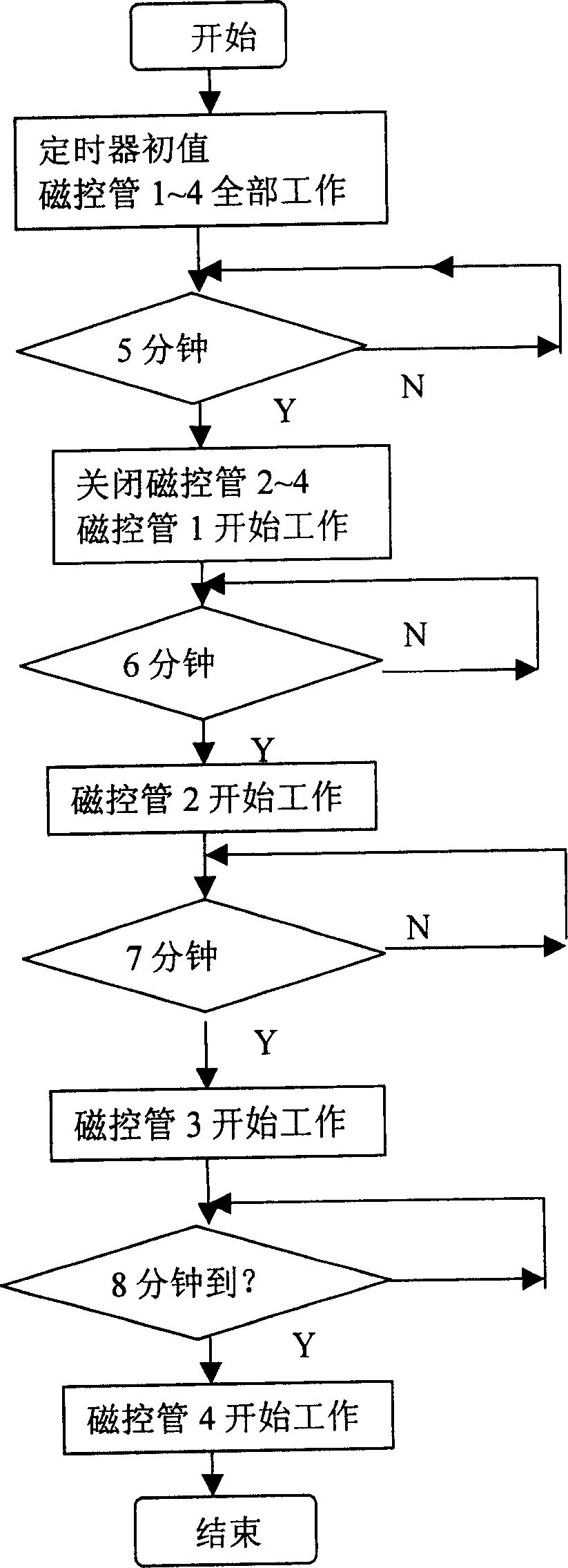

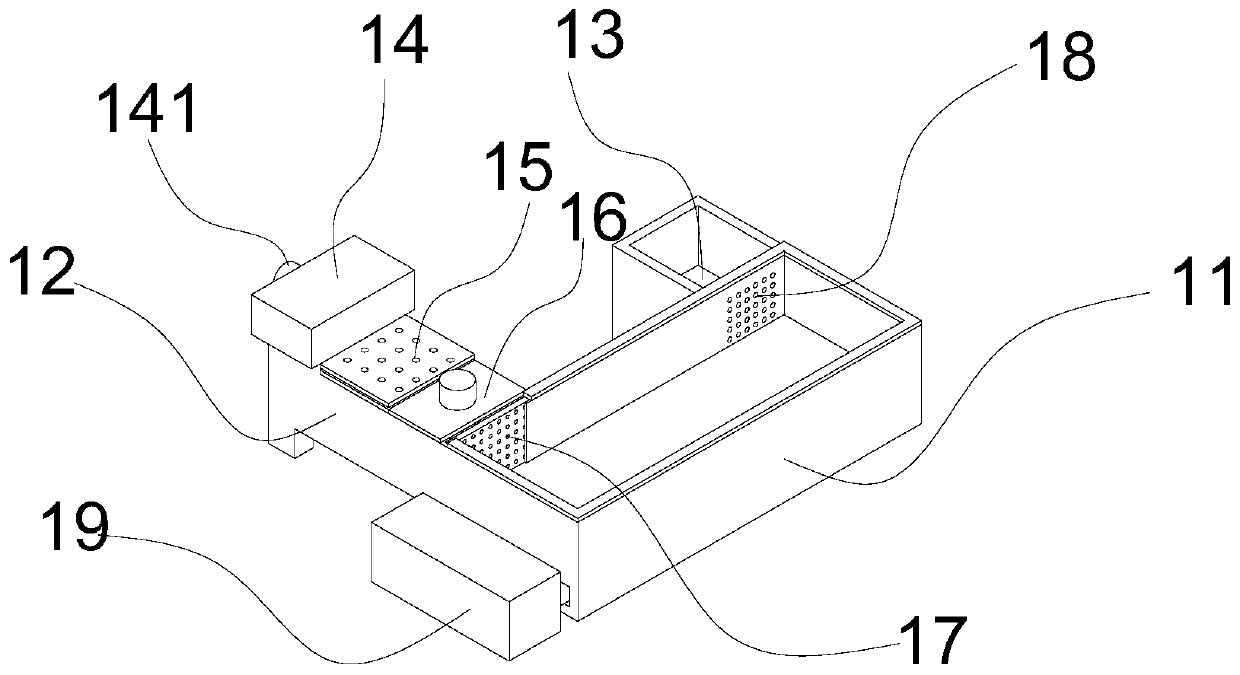

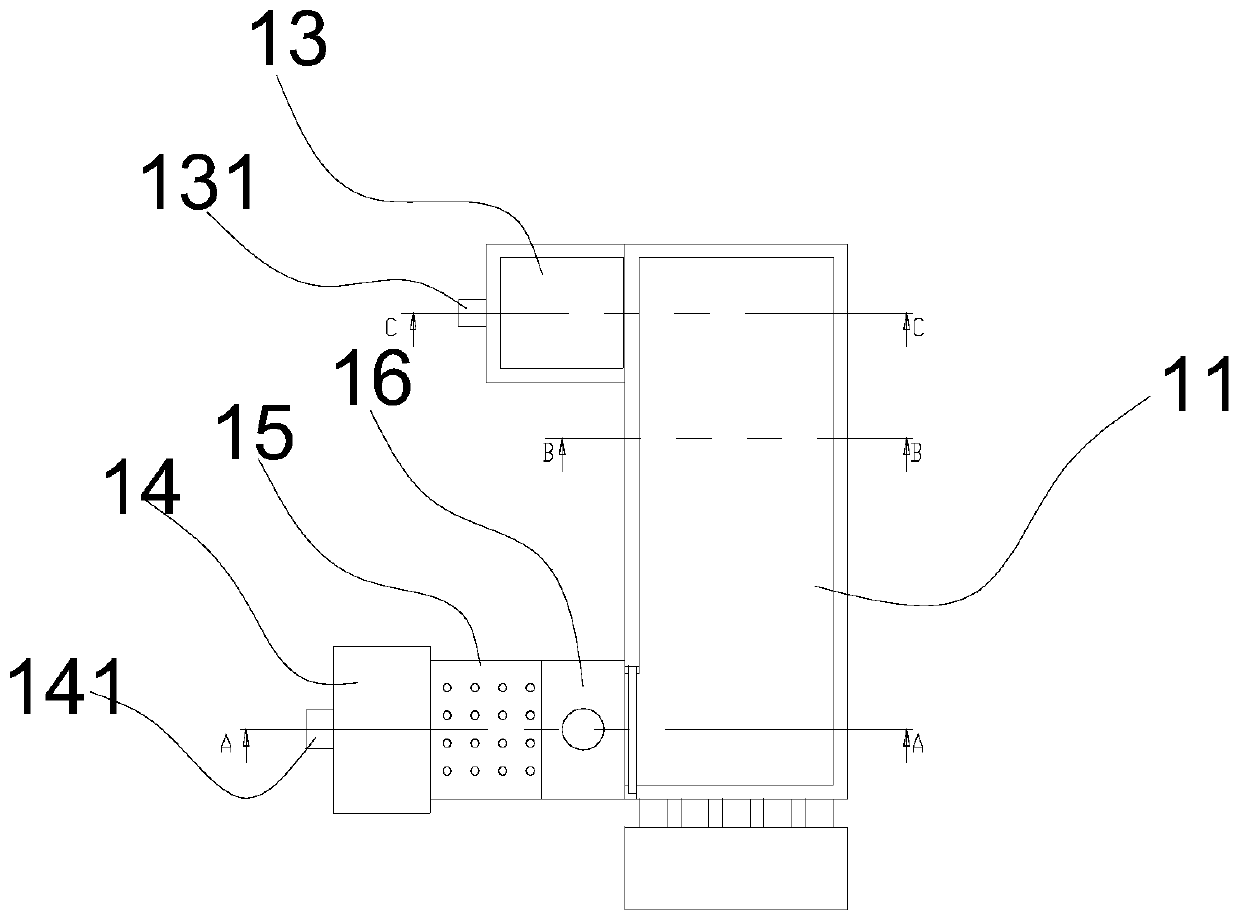

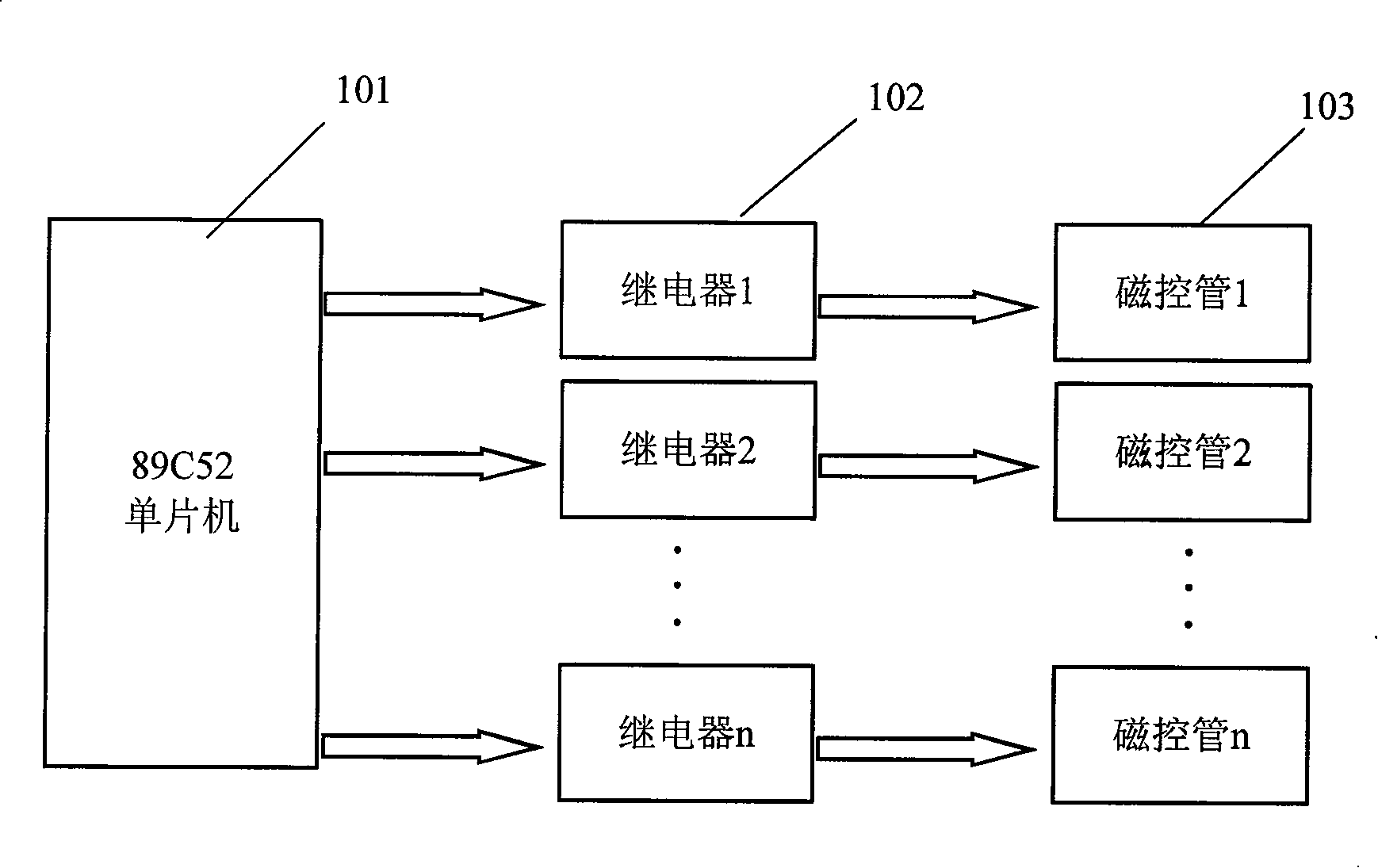

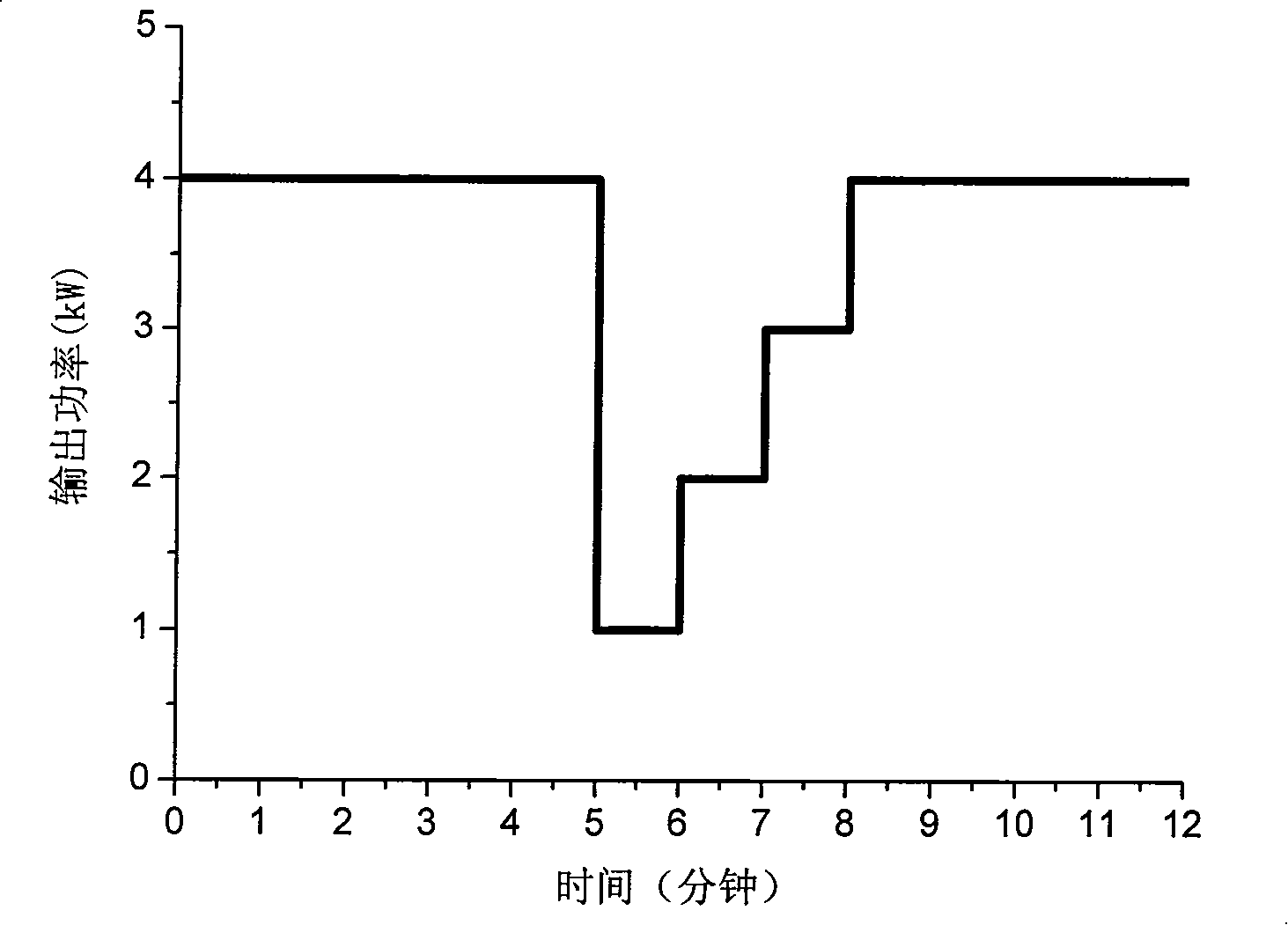

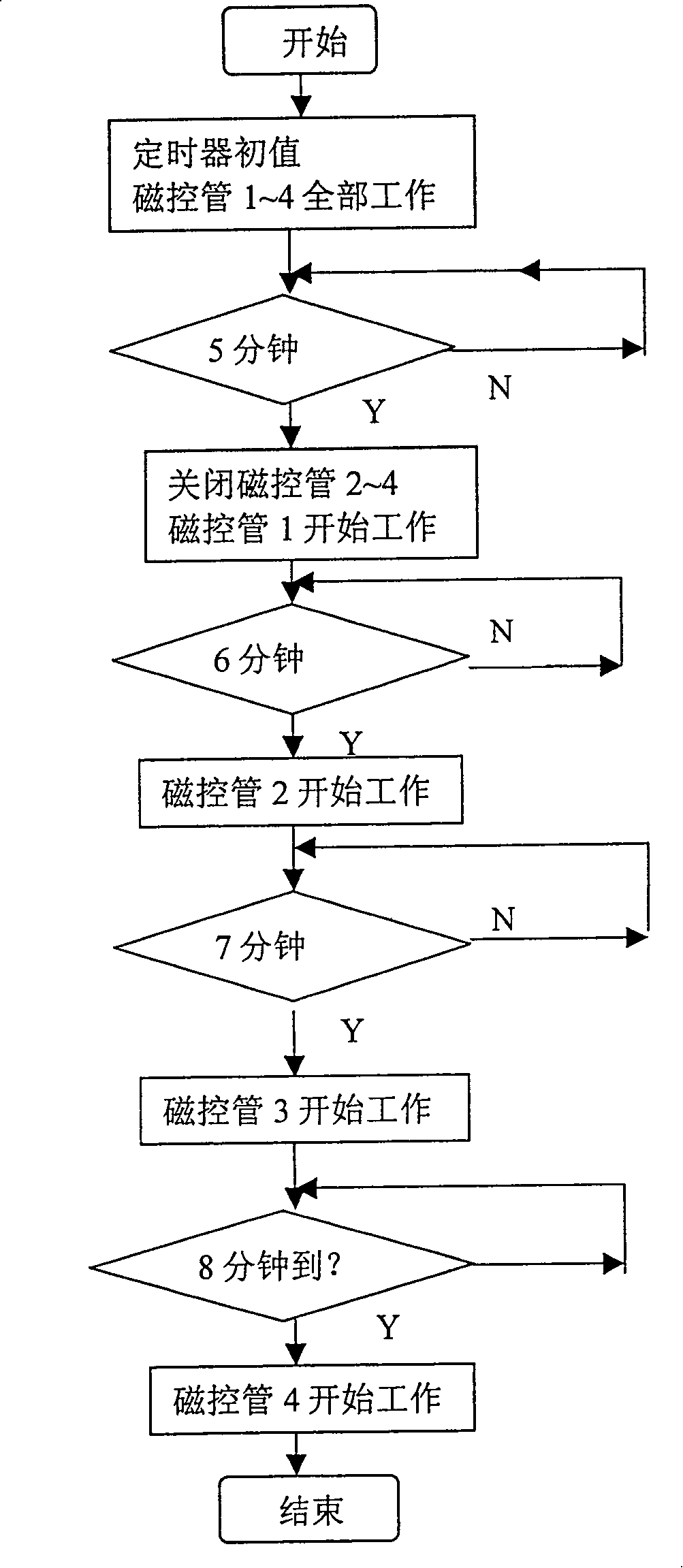

Positive power control method for multiple magnetic-control tube microwave chemical reactor

ActiveCN1836770AAdjust output powerChemical reaction safetyMicrowave heatingEnergy based chemical/physical/physico-chemical processesMicrocontrollerChemical reaction

The active power control method for multiple magnetron microwave chemical reactor features that programmable active power controller is set in the microwave chemical reactor and connected separately to the magnetrons through relays, so that the magnetrons may operate in different on-off states under the control of the chemical reaction controlling program. In the chemical reaction system and before abrupt temperature raise or suddenly changed microwave energy reflection, the number of magnetrons in use is reduced actively for safe operation of the system. After that, the number of magnetrons in use is increased gradually to raise the power of the microwave chemical reactor. In this way, the output power of the microwave chemical reactor is controlled for smooth change.

Owner:SICHUAN UNIV

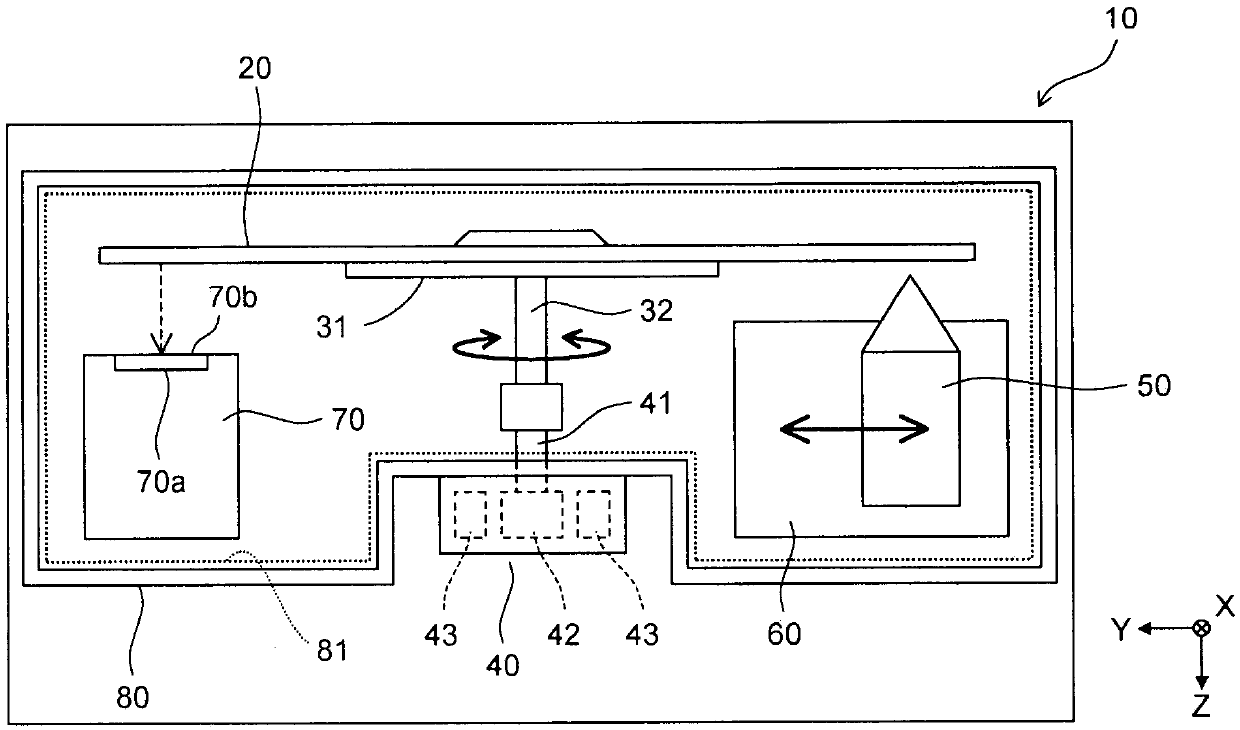

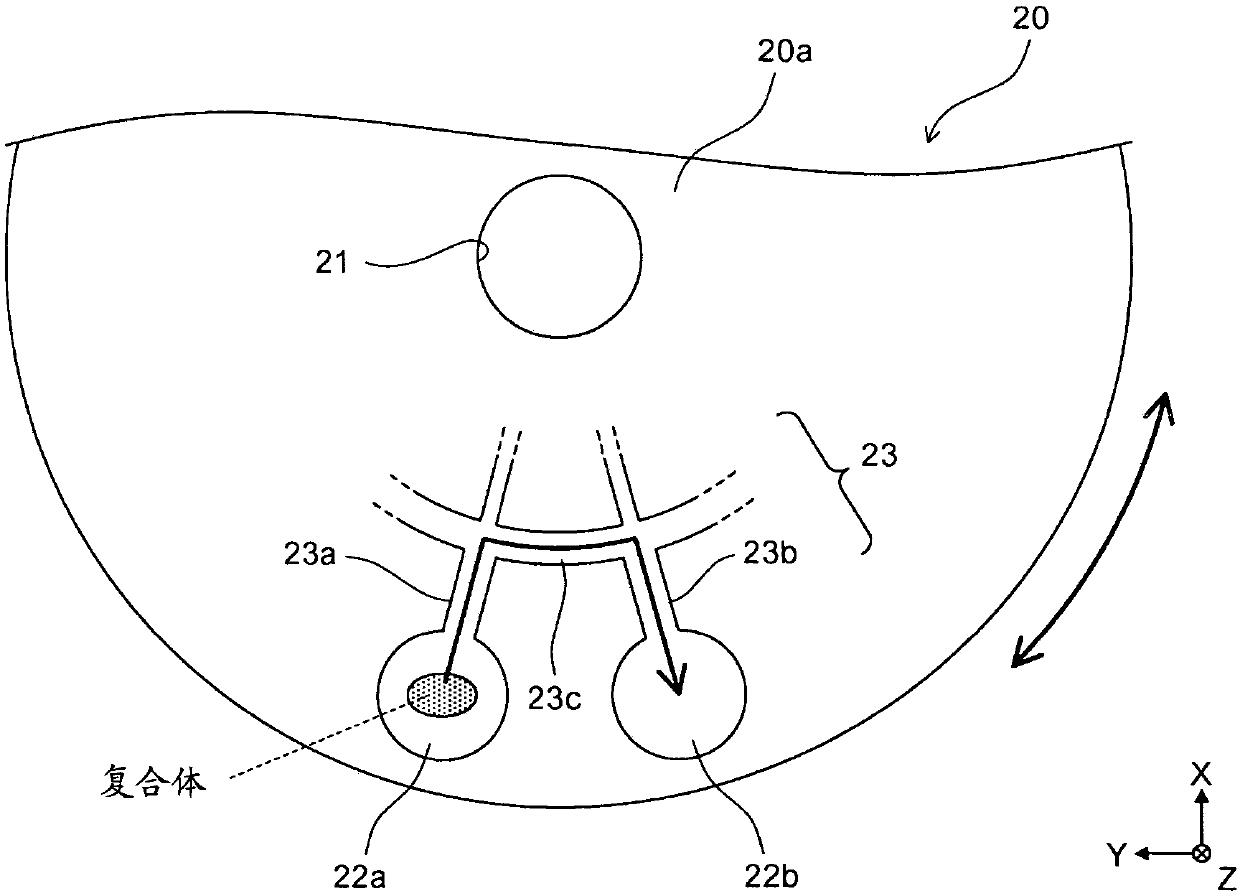

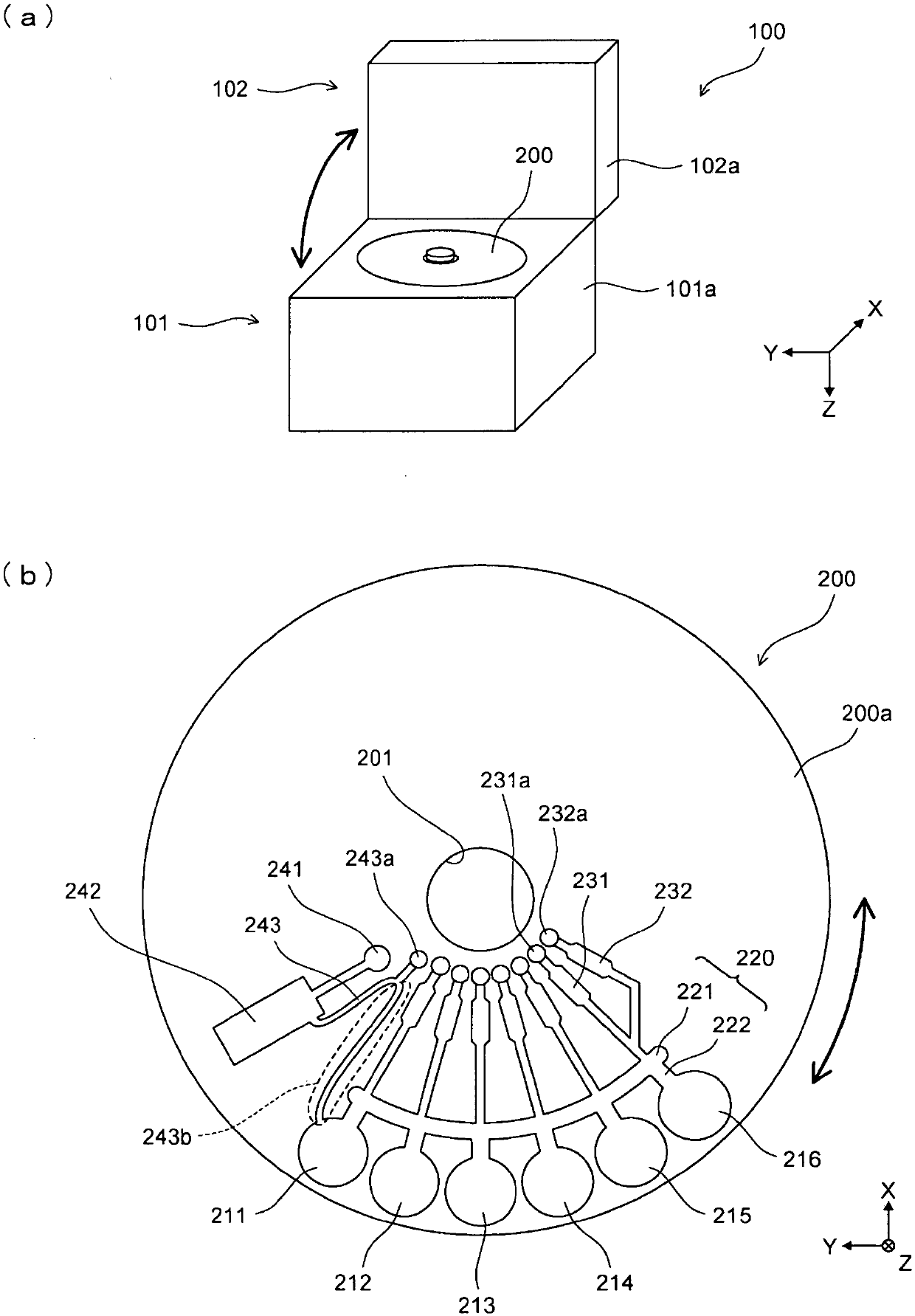

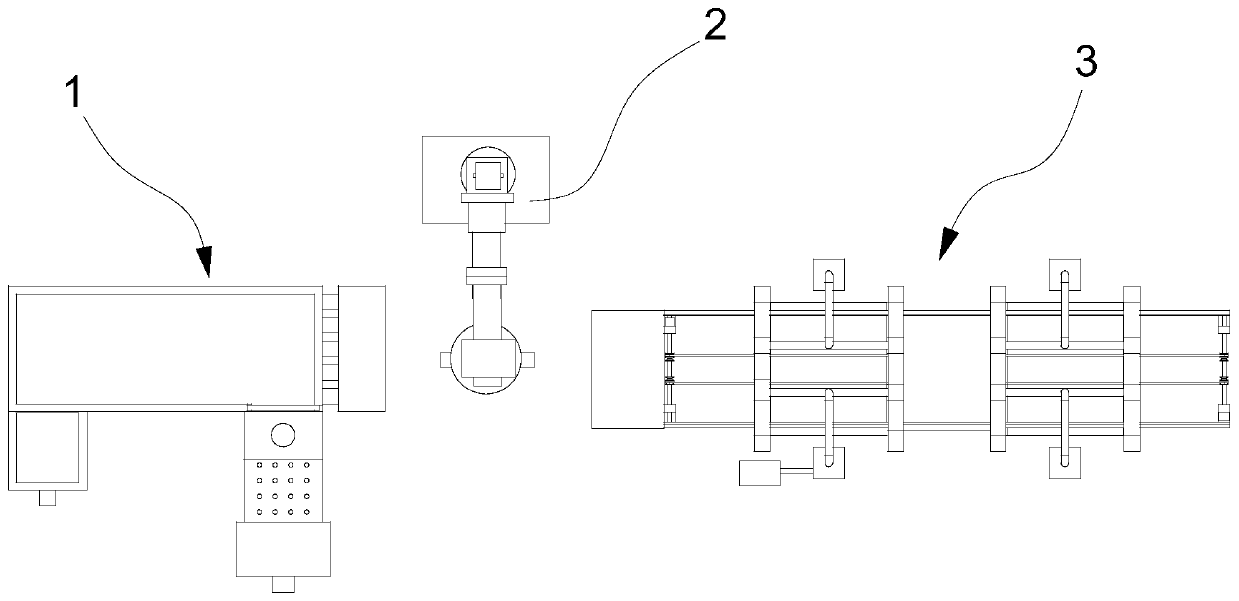

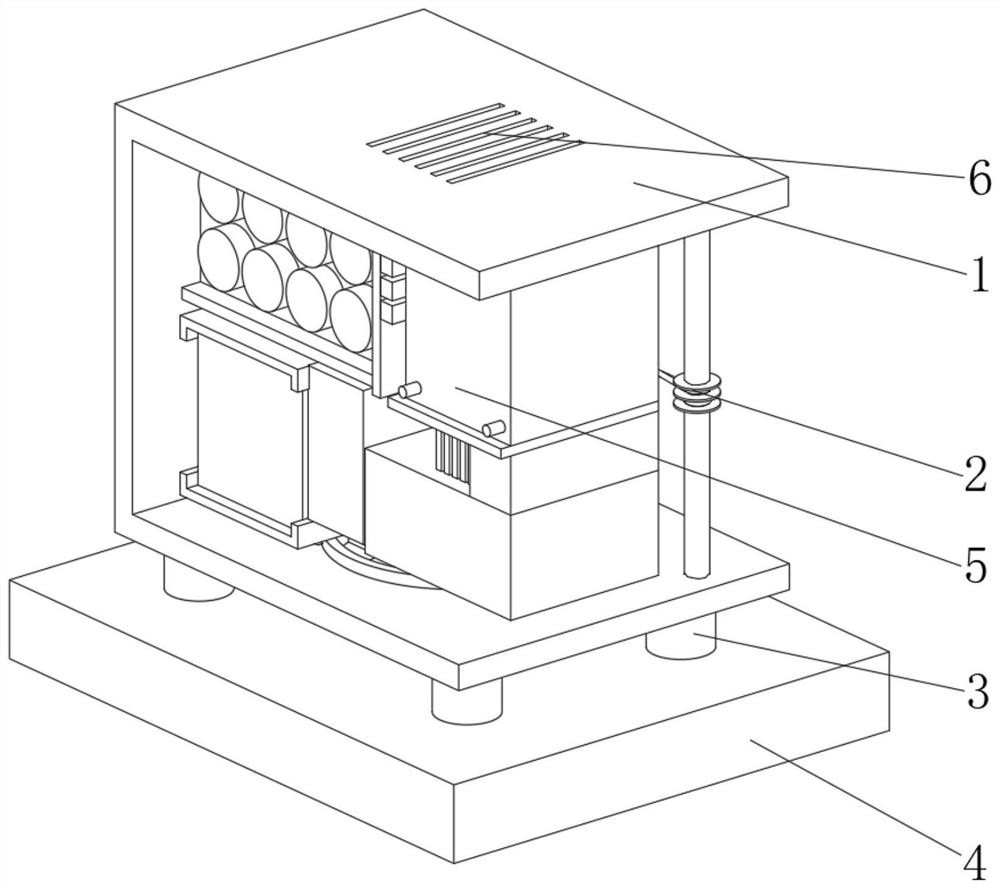

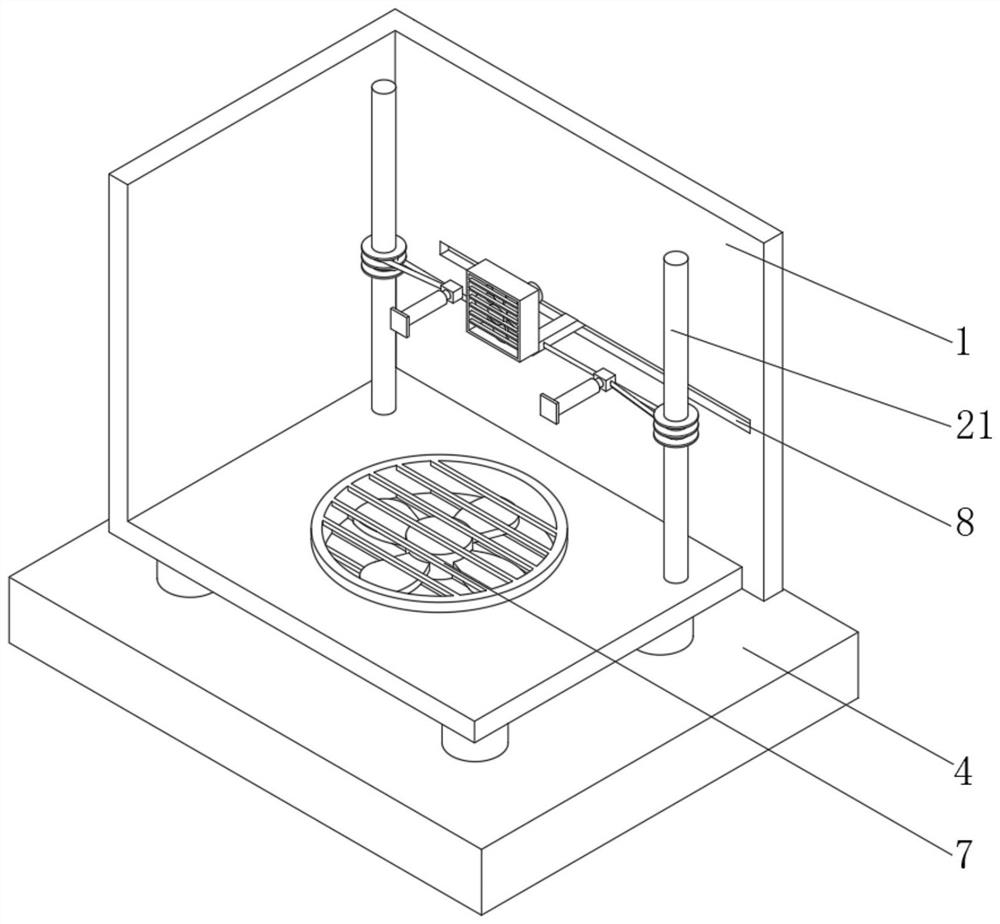

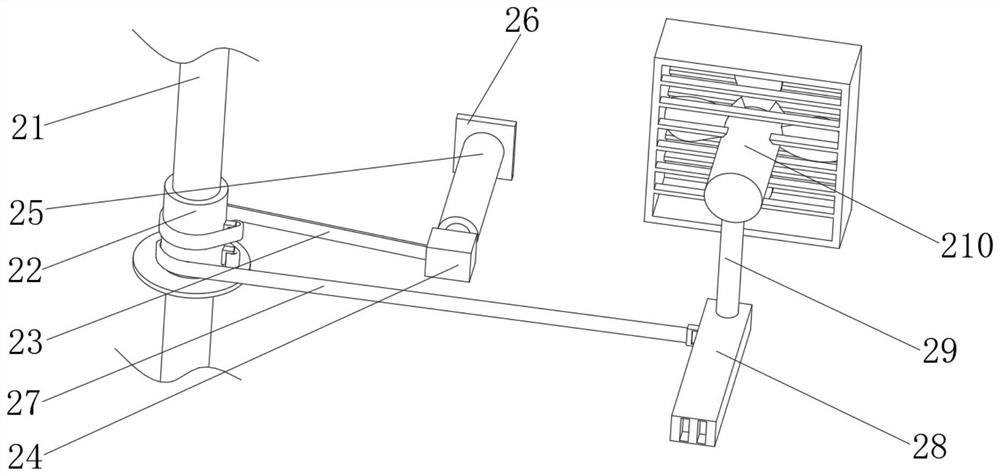

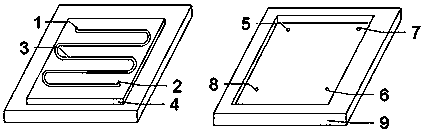

Chemiluminescence measurement apparatus and measurement method

ActiveCN107561063AChemical reaction stabilityHigh precisionShaking/oscillating/vibrating mixersTransportation and packagingChemical reactionElectric machinery

The present invention relates to a chemiluminescence measurement apparatus and a measurement method that can improve the accuracy of chemiluminescence measurement and stabilize the chemical reaction in a cartridge. The chemiluminescence measurement apparatus includes: a support member configured to support a cartridge for measuring a test substance contained in a specimen by chemiluminescence measurement; a motor configured to rotate the support member so as to rotate the cartridge such that a process required for the chemiluminescence measurement proceeds in the cartridge; and a light receiver configured to receive light generated by chemiluminescence in the cartridge that is supported by the support member rotated by the motor. The cartridge supported by the support member and a light receiving surface of the light receiver are disposed inside a dark space surrounded by a light-shielding portion, and the motor is disposed outside the dark space.

Owner:SYSMEX CORP

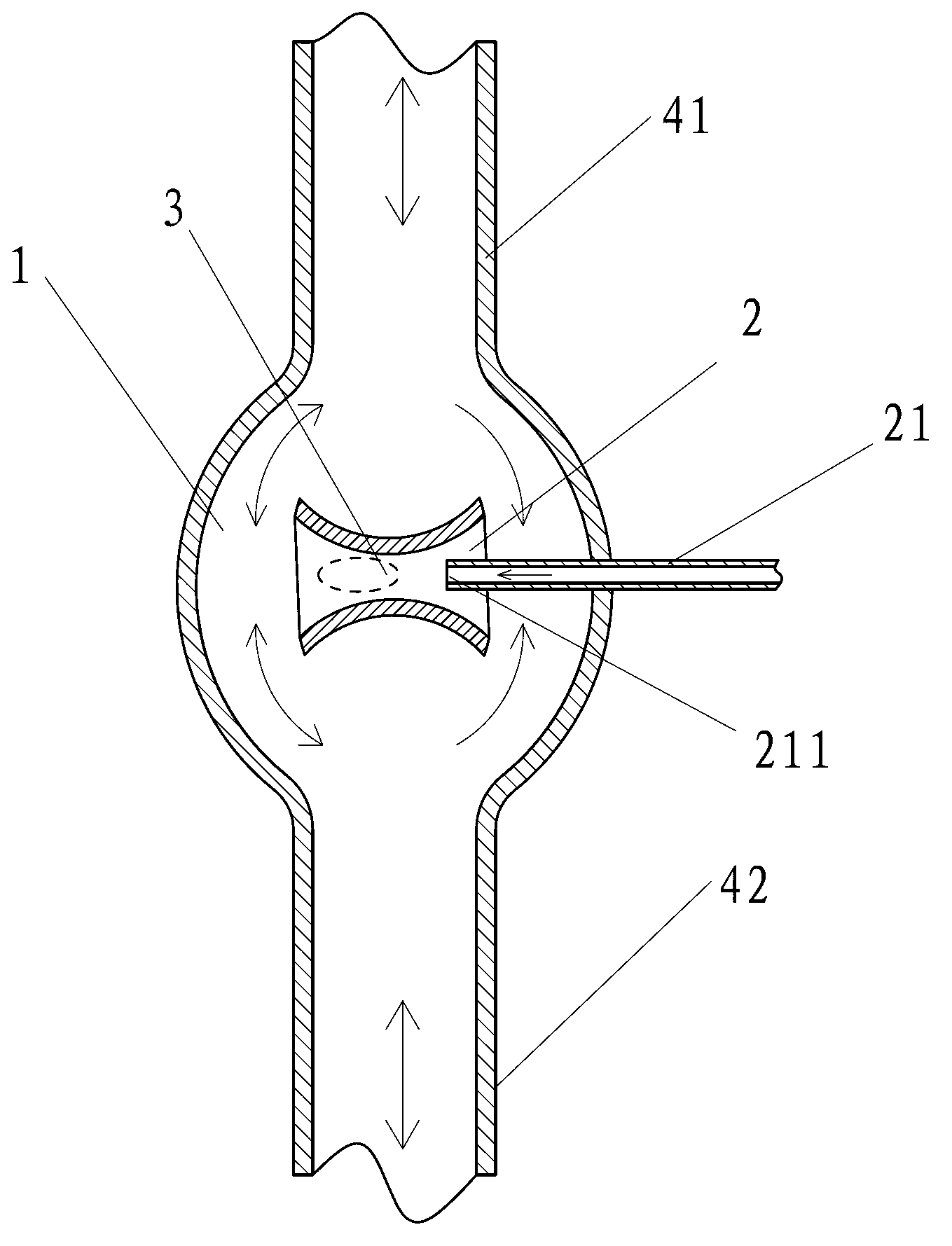

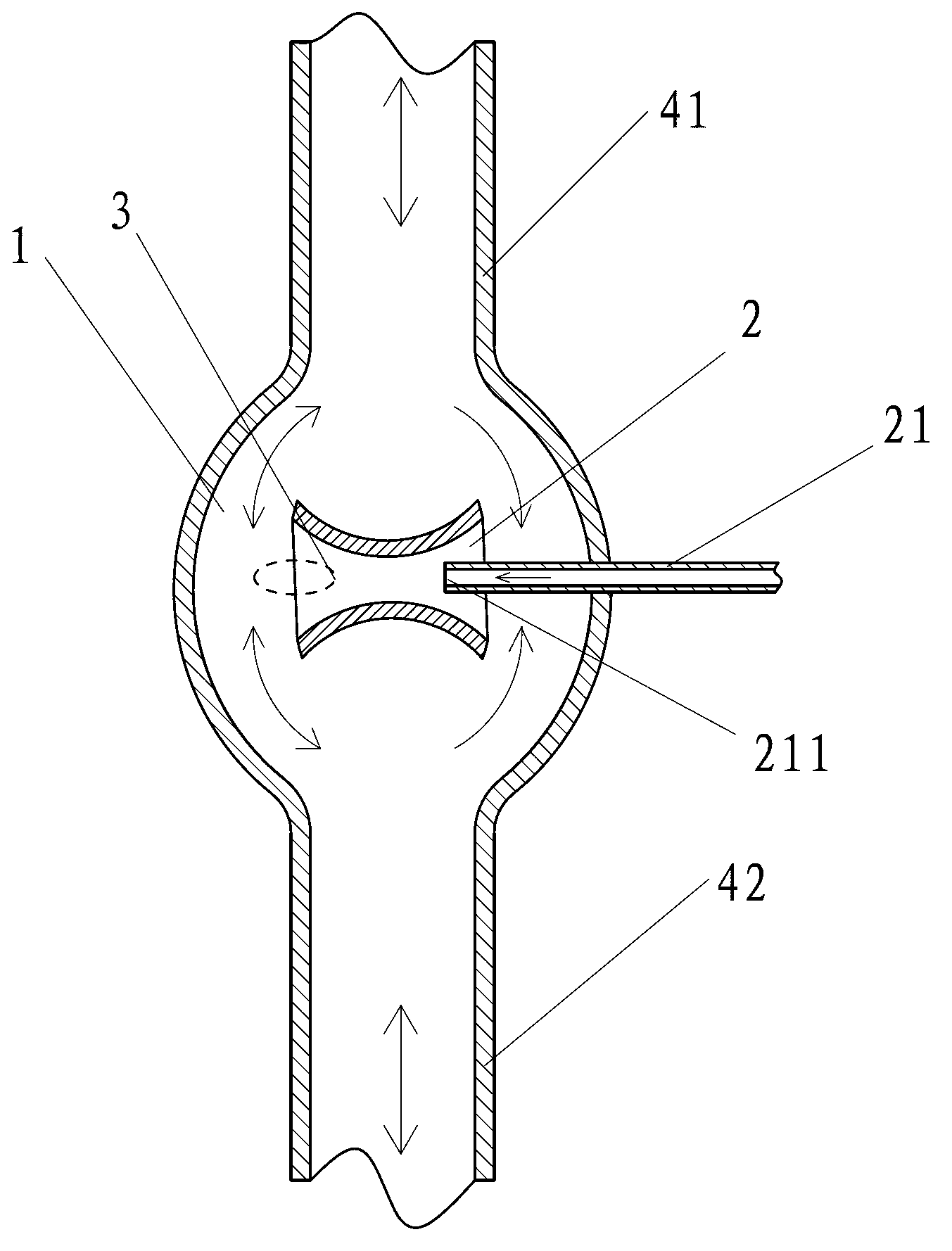

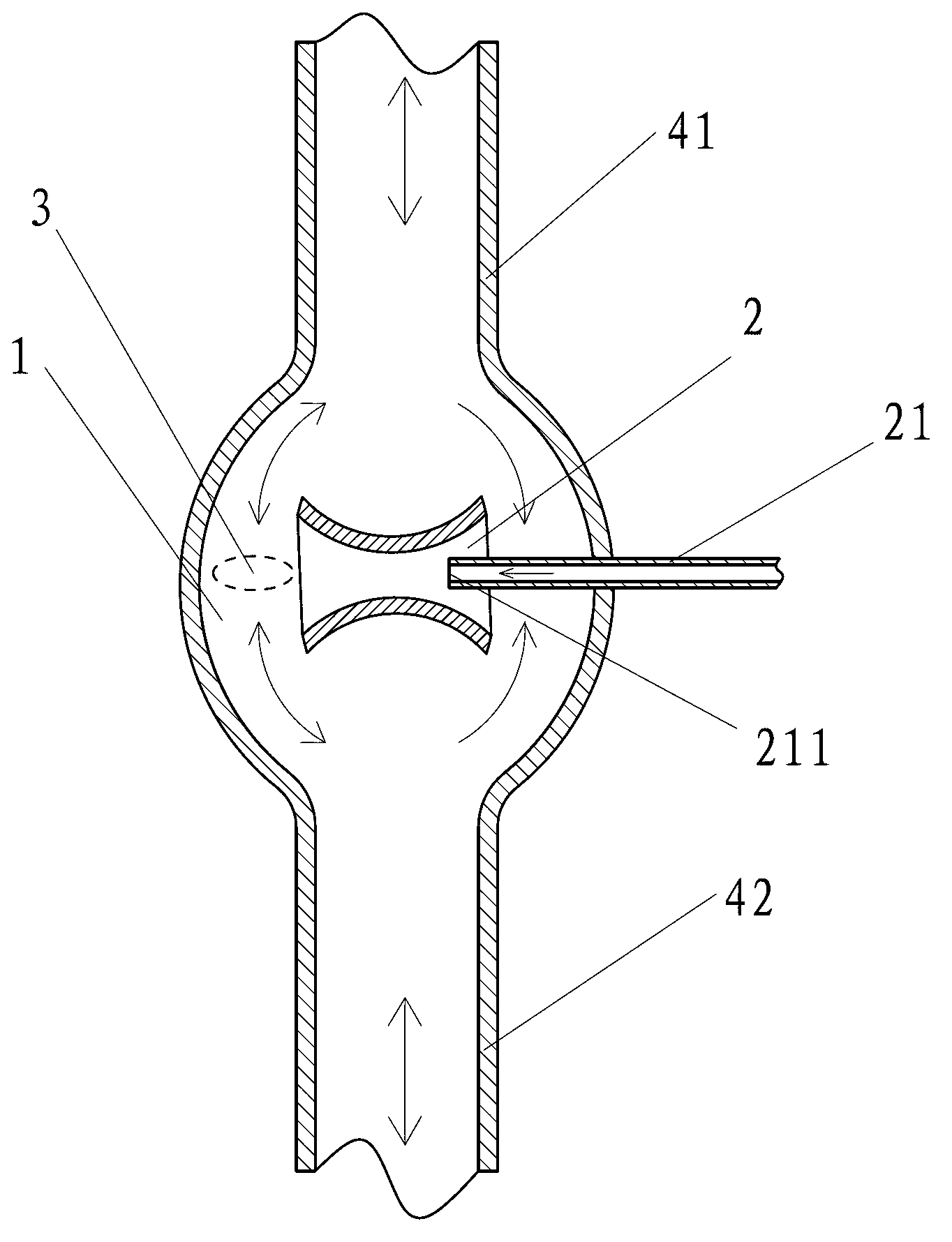

Working medium internal combustion heater

ActiveCN103174546AChemical reaction stabilityStable jobHot gas positive displacement engine plantsStable stateChemical reaction

The invention discloses a working medium internal combustion heater which comprises a working medium enveloping space, a jet pump and a combustion chamber, wherein the jet pump is arranged in the working medium enveloping space, and a high-pressure power fluid nozzle on the jet pump is communicated with an oxidizing agent source and / or a reducing agent source. The combustion chamber is arranged at a fluid outlet of the jet pump, or between the fluid outlet of the jet pump and the high-pressure power fluid nozzle of the jet pump, or outside the fluid outlet of the jet pump. By means of the working medium internal combustion heater, fluid jetted into the working medium enveloping space (for example, a space in a reciprocating passageway) is enabled to be mixed (a mixing process is contained and a chemical reaction happens) with fluid in the reciprocating passageway and to stay in a stable state, and therefore the fluid can work stably and react chemically and stably (combust fully in a mixed mode).

Owner:山东沃达纸制品有限公司

Chemical process of nickel-titanium alloy material

The chemical preparation method for nickel-titanium alloy material, which is characterized in that: 1) covering the non-working position with soft nonmetal material to form protective layer; 2) dipping the alloy piece into reaction solution contained with hydrofluoric acid, nitric acid and water to required degree; 3) taking out and clearing the alloy piece in flowing water; 4) putting the piece in dehydrogenation furnace for one hour at 300Deg. This invention solves the rapid form problem failed by traditional technique.

Owner:INNOVATIVE MATERIAL & DEVICES

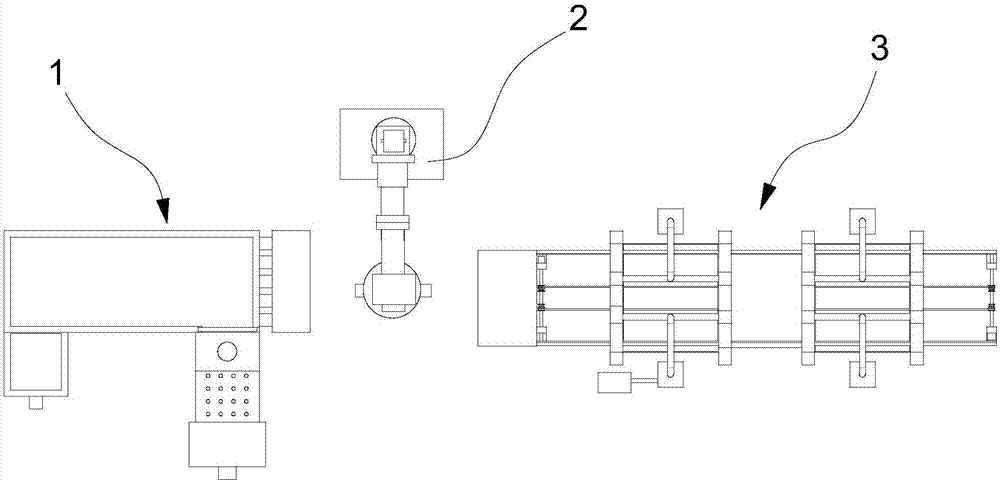

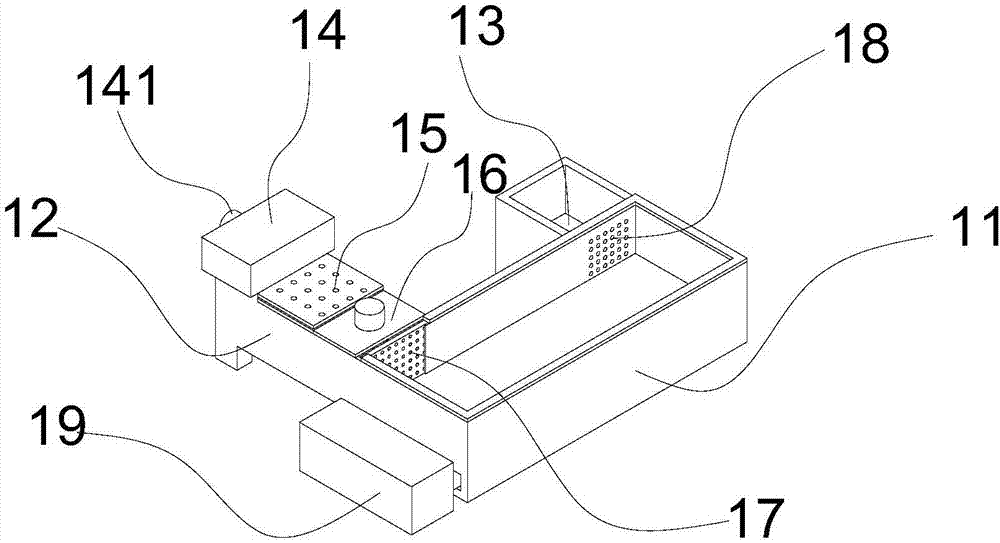

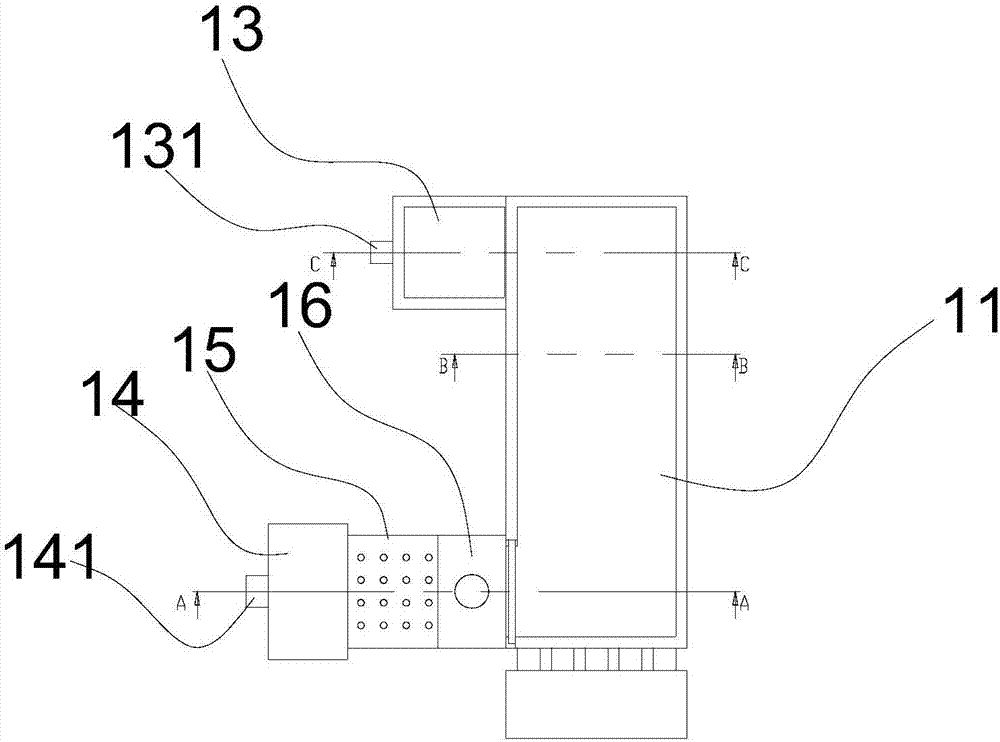

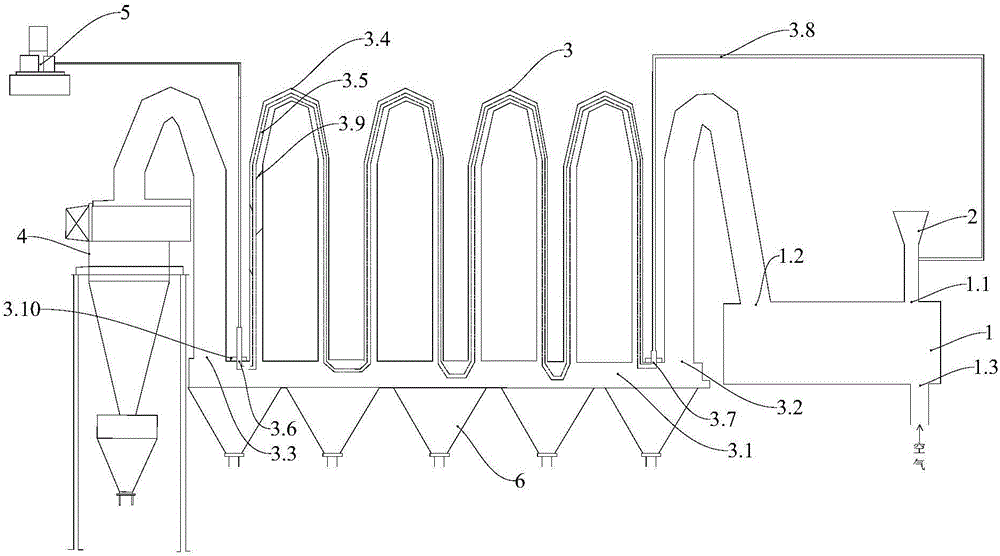

Silicon wafer cleaning and texturing device

ActiveCN107968062AHigh temperature control accuracyChemical reaction stabilityPolycrystalline material growthAfter-treatment detailsTemperature controlChemical reaction

The invention discloses a silicon wafer cleaning and texturing device, which can be convenient for texturing temperature control and ensure that a silicon wafer is always in a wet state when the silicon wafer undergoes the silicon wafer cleaning and texturing processes. The silicon wafer cleaning and texturing device comprises a silicon wafer texturing trough, a silicon wafer transfer device and asilicon wafer cleaning device, wherein the silicon wafer transfer device is arranged between the silicon wafer texturing trough and the silicon wafer cleaning device. By adopting the silicon wafer cleaning and texturing device, the texturing temperature control precision is high, the chemical reaction in the entire process tank is stable and controllable, effective control of the reaction speed and volatilization amount of a solution can be realized, and the adjustment of the process is facilitated; and the silicon wafer is sprayed during the transfer process so as to ensure that the siliconwafer always maintains a wet state during operation, thereby effectively avoiding the occurrence of ''edge scratched wafer'', and improving product quality.

Owner:LESHAN TOPRAYCELL

Preparation method of ceramic substrate for medium-free copper-coated gold-deposited light-emitting diode (LED) package

InactiveCN105489713AChemical reaction stabilityImprove thermal conductivitySemiconductor devicesVulcanizationChemical reaction

The invention discloses a preparation method of a ceramic substrate for medium-free copper-cladding gold-deposited light-emitting diode (LED) package. The preparation method comprises the following steps of sintering a ceramic wafer, in which ceramic powder is subjected to die forming and then placed in an environment at 1,000-1,020 DEG C for sintering for 8 to 10 minutes to obtain the ceramic wafer; coating copper, in which copper is coated on the upper surface of the ceramic wafer by a vacuum mist plating method to form a copper foil; etching, in which the useless copper foil is corroded with dilute sulphuric acid according to a process flow diagram to reserve the useful copper foil as a circuit; depositing gold, in which gold liquid medicine passes through the substrate with the circuit already etched so that the gold is deposited on the copper foil to obtain a finished product. According to the preparation method, a medium-free copper cladding technique is adopted, and the excellent heat conduction performance of primary copper and ceramic is maintained; and the gold is deposited on the copper, the chemical reaction of the gold is stable, the vulcanization problem is effectively solved, and the electrical property of the product and the long-term maintenance rate of light refraction are further improved.

Owner:郭垣成

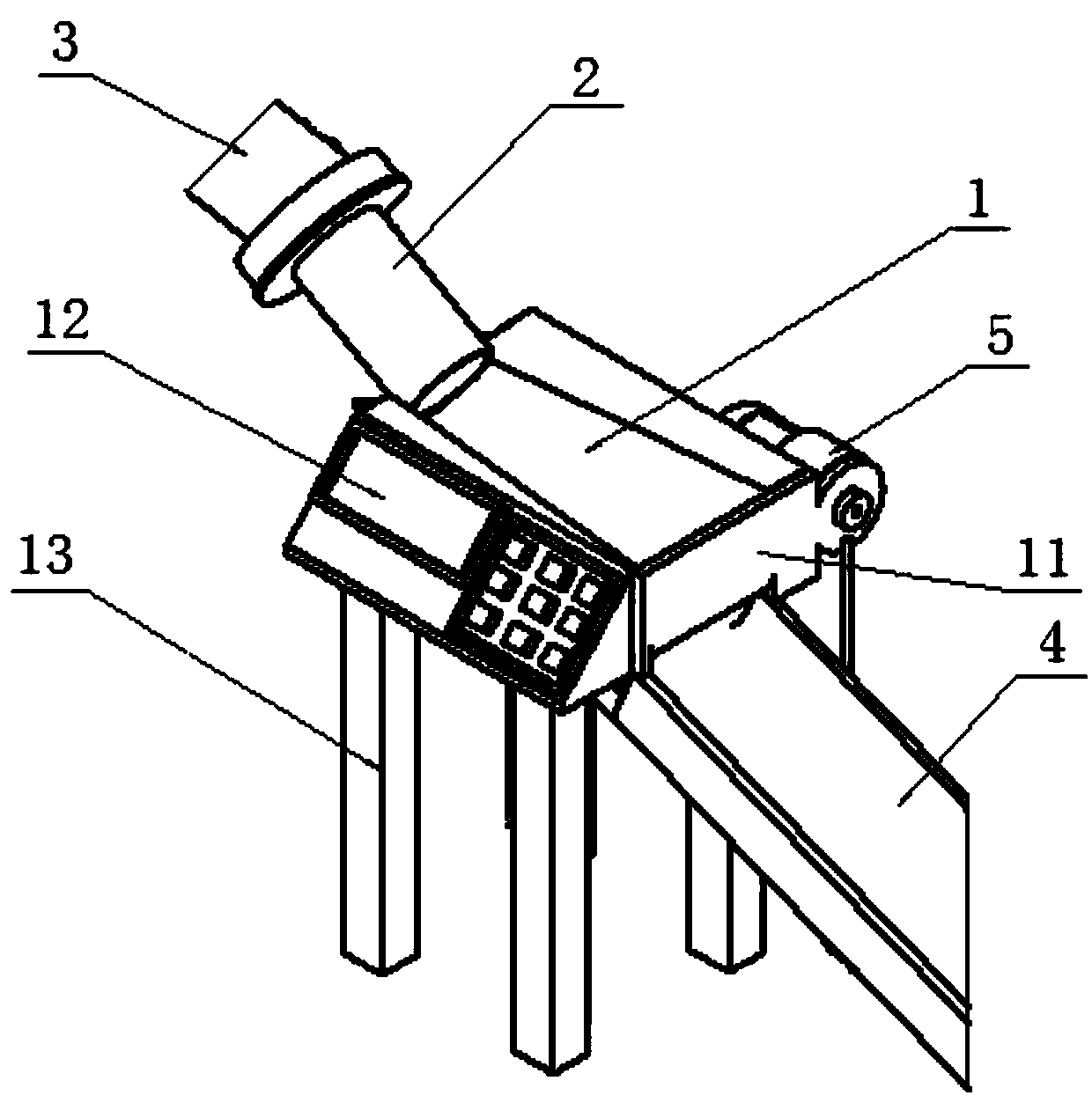

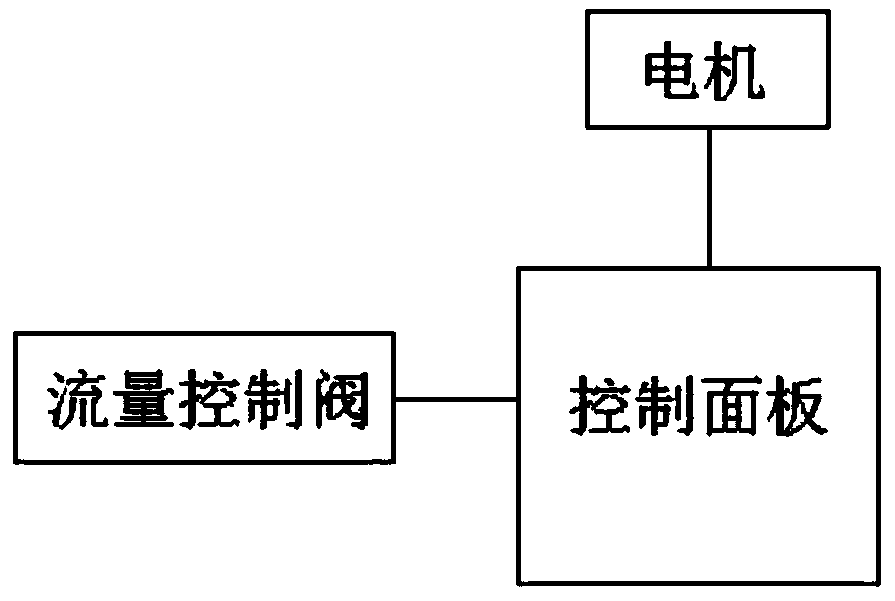

Automatic continuous feeding method

The invention discloses an automatic continuous feeding method, a flow control valve is opened, and the raw material in a storage bin flows into a storage tank from a connecting pipe. The opening andclosing degree of the flow control valve can be controlled by a control panel. According to different reaction speed and reaction flow rate requirements, the rotation of a motor is controlled by the control panel. The output shaft of the motor rotates and can drive a stopper plate to rotate to lift the stopper plate, and the solid raw material flows out from the gap between the lower edge of the stopper plate and the bottom plate of the storage tank under the action of the height difference between a feeding end and a discharging end to a feeding tank, and is added into a reaction vessel for chemical reaction, and the motor rotation angle is controlled according to different reaction speed and reaction flow rate requirements. The invention can control the flow rate of raw materials by controlling the lifting and lowering of the stopper plate by the control panel, does not need manual handling operation, can improve the working efficiency, can precisely control the amount of added solidraw materials according to the reaction need, can ensure the continuity of filling, and realizes automatic control production.

Owner:江苏糦丰科技有限公司

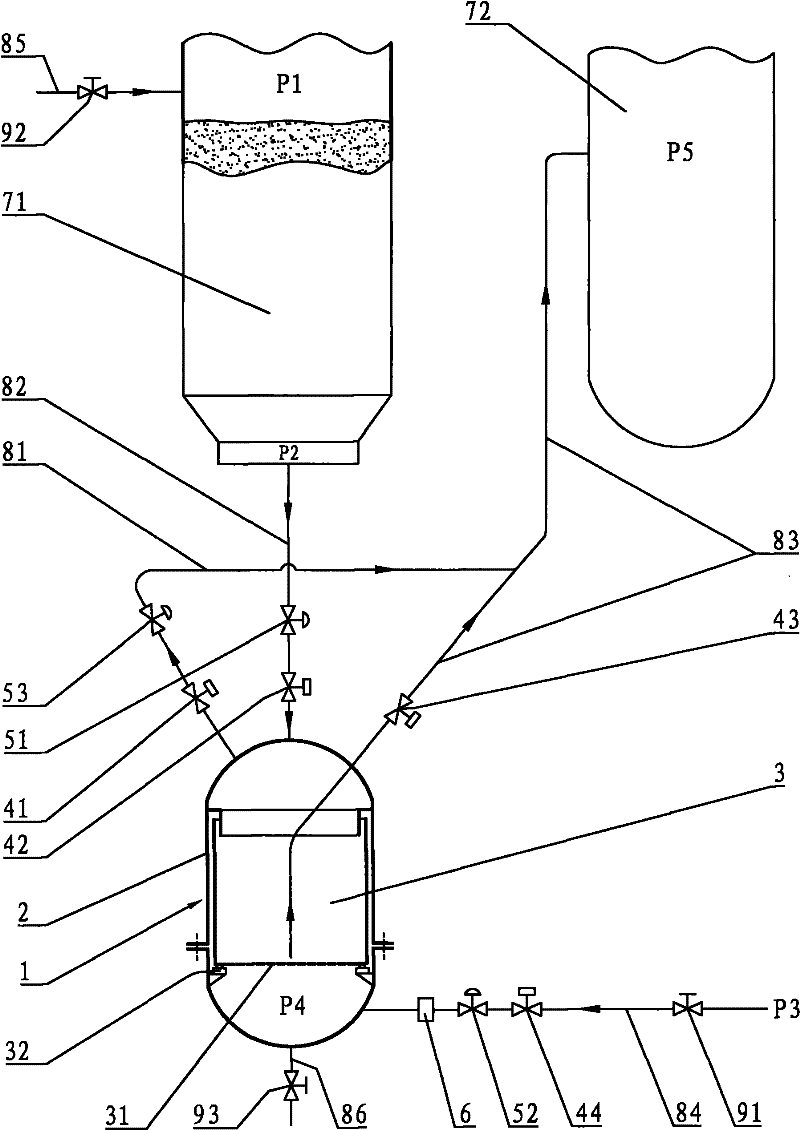

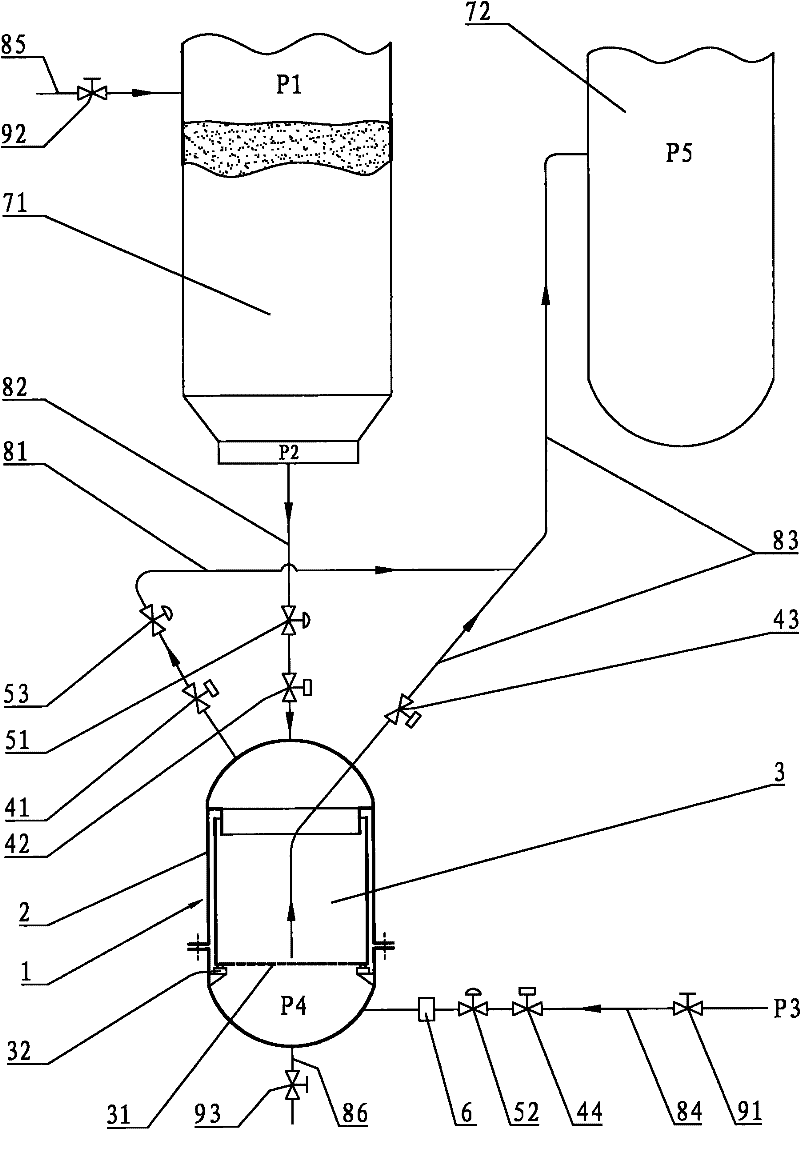

Automatic catalyst-feeding method

The invention discloses an automatic catalyst-feeding method in order to solve the problem that the feeding amount of the prior small feeder with a weighing function is small in the process of batch-by-batch feeding. In the process of operation, flow-conveying air is constantly charged into a feeder (1), and the pressure P4 of the feeder (1) is constantly lower than or equal to the pressurizing pressure P1 of a catalyst storage tank (71) and higher than the pressure P5 of a regenerator (72). The method mainly includes the following steps: (A) feeding speed regulation, (B) regulative discharge, (C) feeding, and (D) feeding standardization. The method is mainly used in the fluid catalytic cracking technique of the petrochemical industry and the methanol-to-olefins reaction technique of the coal chemical industry, and uses the small feeder (1) with a weighing function to continuously feed a great deal of catalyst in the catalyst storage tank (71) into the regenerator (72).

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Electrode material of alkaline battery

The invention relates to an electrode material of an alkaline battery. The electrode material comprises an anode, a cathode, a separation plate located between the anode and the cathode, an alkaline electrolyte, an anode current collector and gel; the cathode comprises the following cathodic active materials: manganese dioxide, nickel oxyhydroxide and conductive carbon particles; and the anode comprises zinc or zinc alloy, and graphite.

Owner:杨雯雯

Heat utilization device in dezincification process of gas ashes and method of heat utilization device

InactiveCN106636658AImprove dust removal efficiencyIncrease productivityRecycling and recovery technologiesProcess efficiency improvementEngineeringMechanical engineering

The invention relates to the technical field of gas ash dezincification and discloses a heat utilization device in a dezincification process of gas ashes. The heat utilization device comprises a rotary kiln, wherein a feeding device is arranged in a feeding hole of the rotary kiln; a smoke vent of the rotary kiln is connected with a dust collector through a cooler; the cooler comprises a transversely arranged long tube, and a smoke inlet is arranged at one end of the long tube; the smoke inlet is communicated with the smoke vent of the rotary kiln through a pipe and a smoke outlet is arranged in the outer end of the long tube; the smoke outlet is communicated with the dust collector through a pipe; and a plurality of inverted U-shaped tubes are uniformly arranged in the middle of the long tube, openings in two ends of each inverted U-shaped tube communicate with the long tube, an inner tube is arranged in each inverted U-shaped tube, one end of each inner tube communicates with air through an air pump and the other end of each inner tube sequentially passes through the corresponding inverted U-shaped tube and penetrates out of an outlet of the inner tube on the long tube, and each inner tube, which penetrates out of the outlet of the inner tube, is connected with the feeding device through a branch hose. According to the heat utilization device, raw materials of the gas ashes are heated by using the heat in the dezincification process to remove moisture.

Owner:武汉钢铁有限公司

Method for achieving direct microalloying in steel material production process

ActiveCN106498104AChemical reaction stabilityImprove securityBlast furnace detailsManufacturing convertersSolid solutionBlast furnace

The invention discloses a method for achieving direct microalloying in a steel material production process. Associated ore is adopted as an original material for material smelting production, main alloy elements are added in a blast furnace ironmaking process, microalloying elements contained in the iron ore concentrate selected from the associated ore are adsorbed and fixed therein, carriers enter molten iron with the microalloying elements under the self gravity and the molten iron scouring effect, and the microalloying elements in the carriers can be reduced to be in the elementary substance state by adding a deoxidizing agent, thereby entering steel materials in a solid solution mode for achieving a microalloying effect. A brand new train of thought is provided for direct microalloying of the microalloying elements in steel material production, the microalloying elements existing in the solid solution mode can be effectively obtained for the materials, and therefore the microalloying effect is achieved. The method has the advantages that the production process is safe, the materials are simple in source and easy to obtain, industrial production is easy to conduct, and resource configuration and utilization are reasonable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

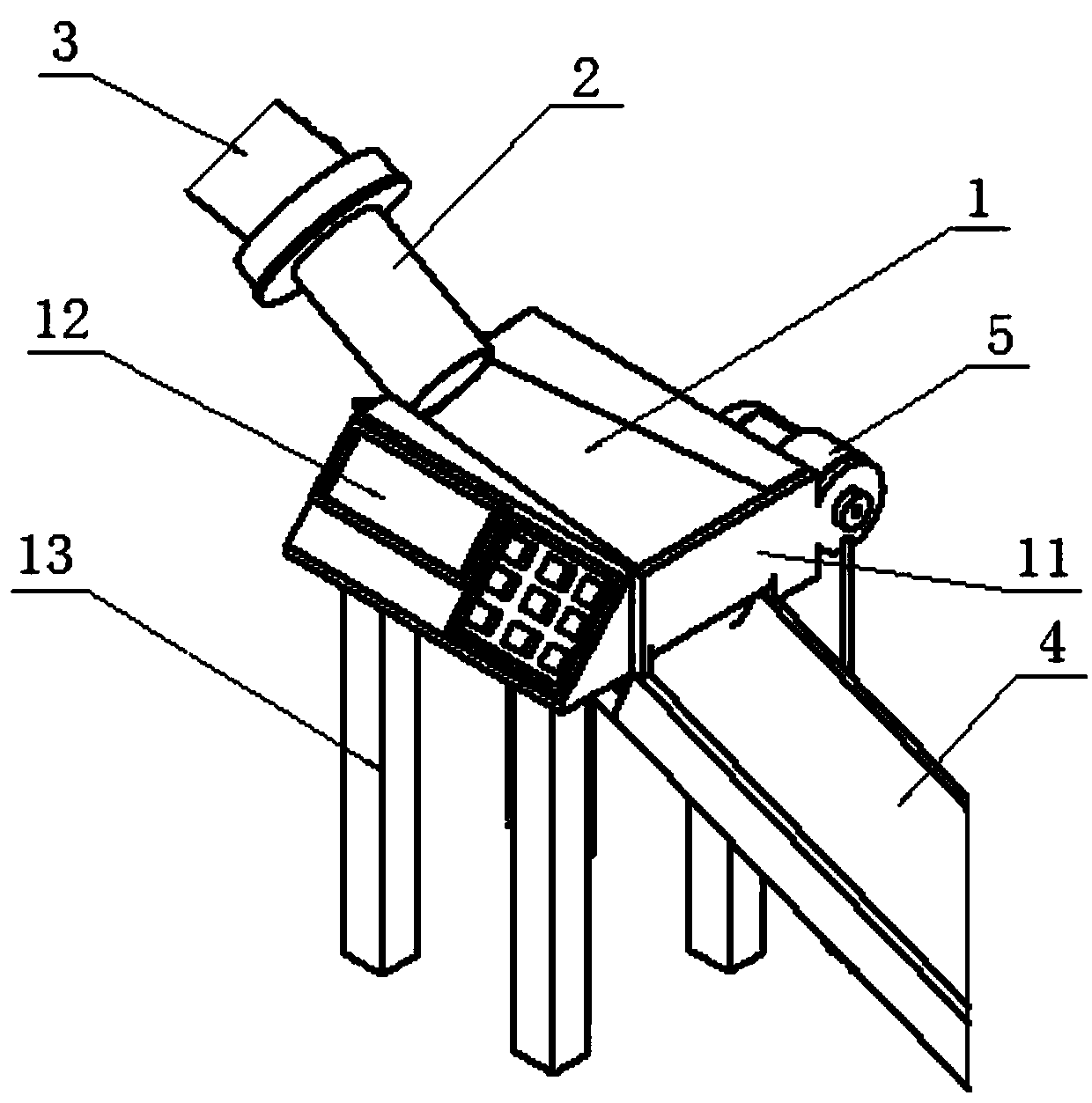

Feeding device capable of automatically and continuously running

InactiveCN109592359AImprove work efficiencyGuaranteed continuityConveyor partsChemical reactionAutomatic control

The invention discloses a feeding device capable of automatically and continuously running, which includes a storage tank, the feeding end of the material storage tank is connected with a guide outletof a material guide, the input port of the material guide is connected to a storage bin through a connecting pipe. The feeding end of the material storage tank is higher than the discharging end, thedischarging end of the material storage tank is connected with a material feeding tank, and the discharging end is provided with a material stopper plate which is driven to rise and fall by a drivingmechanism on one side of the material storage tank, and a control panel is arranged on one side of the material storage tank, and the driving mechanism and the material guide are respectively electrically connected with the output control end of the control panel. The invention can control the flow rate of the added raw materials by controlling the lifting and lowering of the stopper plate through the control panel, does not need manual handling operation, can improve the working efficiency, can precisely control the amount of the added solid raw materials according to reaction, can ensure the continuity of the filling, and can ensure the stable and normal progress of the chemical reaction. In this process, no labor is needed, and automatic control of production is realized.

Owner:江苏糦丰科技有限公司

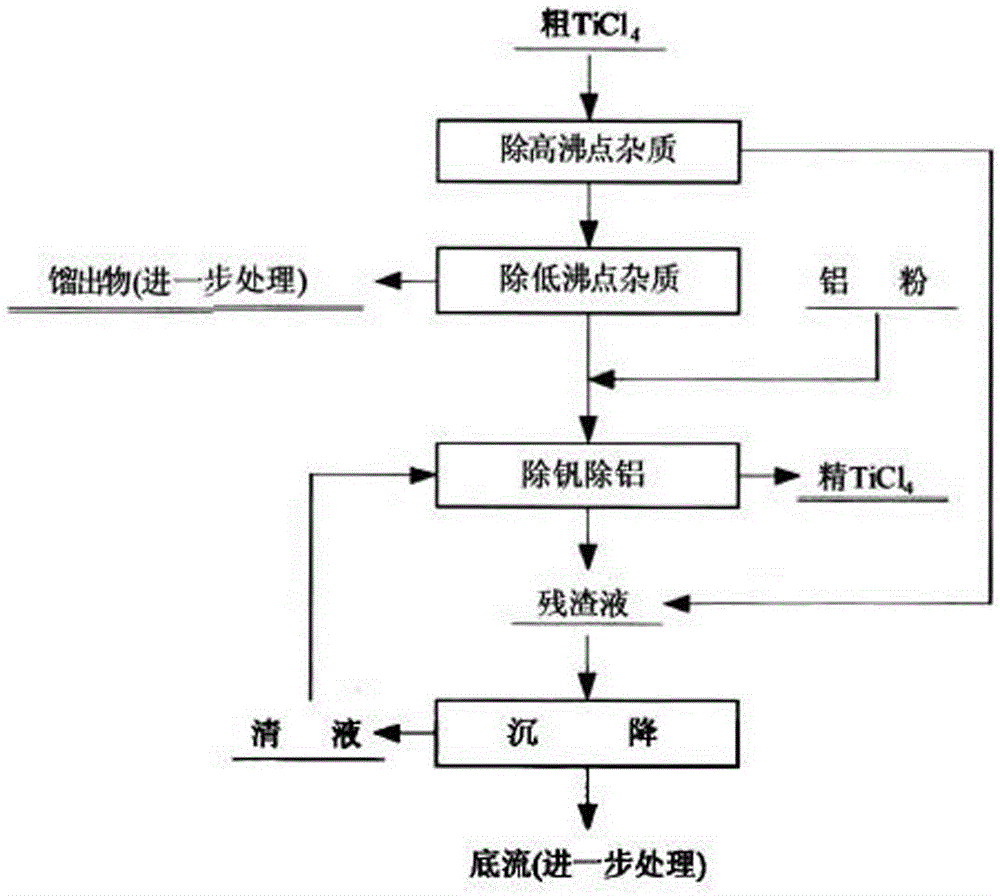

Method for refining titanium tetrachloride by removing vanadium through aluminum powder

InactiveCN104150529AChemical reaction stabilityImprove securityTitanium halidesChemical reactionBoiling point

The invention relates to the field of chemical engineering, and particularly relates to a method for refining titanium tetrachloride by removing vanadium through aluminum powder. The method comprises the following steps: removing high-boiling-point impurities from a crude titanium tetrachloride test solution, removing low-boiling-point impurities from the crude titanium tetrachloride test solution, adding aluminum powder and a clear solution into the crude titanium tetrachloride test solution, removing vanadium and aluminum to obtain refined titanium tetrachloride, and settling the residual solution to obtain the clear solution and underflow, wherein the clear solution can be used for removing vanadium and aluminum, and the underflow can be further purified. The method for refining titanium tetrachloride by removing vanadium through aluminum powder is steady in chemical reaction process, high in safety and simplified in procedures, and the amount of the aluminum powder and the amount of vanadium removal residuals can be greatly decreased.

Owner:SHAANXI ALLIANCE LOGISTICS

Silicon wafer cleaning and texturing device

ActiveCN107968062BHigh temperature control accuracyChemical reaction stabilityPolycrystalline material growthAfter-treatment detailsTemperature controlChemical reaction

The invention discloses a silicon wafer cleaning and texturing device, which can be convenient for texturing temperature control and ensure that a silicon wafer is always in a wet state when the silicon wafer undergoes the silicon wafer cleaning and texturing processes. The silicon wafer cleaning and texturing device comprises a silicon wafer texturing trough, a silicon wafer transfer device and asilicon wafer cleaning device, wherein the silicon wafer transfer device is arranged between the silicon wafer texturing trough and the silicon wafer cleaning device. By adopting the silicon wafer cleaning and texturing device, the texturing temperature control precision is high, the chemical reaction in the entire process tank is stable and controllable, effective control of the reaction speed and volatilization amount of a solution can be realized, and the adjustment of the process is facilitated; and the silicon wafer is sprayed during the transfer process so as to ensure that the siliconwafer always maintains a wet state during operation, thereby effectively avoiding the occurrence of ''edge scratched wafer'', and improving product quality.

Owner:LESHAN TOPRAYCELL

Zero-power consumption steel-making method using electric-arc furnace

ActiveCN103205529BIncrease profitPromote rapid formationProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Positive power control method for multiple magnetic-control tube microwave chemical reactor

ActiveCN100408159CAdjust output powerChemical reaction safetyMicrowave heatingEnergy based chemical/physical/physico-chemical processesMicrocontrollerChemical reaction

Owner:SICHUAN UNIV

Process for extracting tin from silver separation residues

InactiveCN109852808AFully filteredHigh purityProcess efficiency improvementChemical reactionFiltration

The invention discloses a process for extracting tin from silver separation residues. The process comprises the steps that 1, a proper amount of the silver residues are picked and subjected to crushing treatment, the silver residues obtained after crushing are mixed with a flocculating agent according to the mass ratio of 1: 10 and ground into thick liquid, and the materials are mixed uniformly, so that a mixed solution of the silver residues and water is obtained; 2, the mixed solution of the silver residues and the water is poured into a holding furnace, the temperature is raised to 560-850DEG C, stirring is conducted for 20 minutes, and after stirring is completed, the materials are left standing still for 3-6 hours; and 3, filter treatment is conducted on mixed liquor obtained after stirring is completed in step 2 four times through a high-pressure filter, wherein filtration of the first time is conducted at the speed of 40 m / h. According to the process for extracting the tin fromthe silver separation residues, filtration is conducted multiple times, and it can be guaranteed that impurities in the silver residues are filtered out completely; the purity of an obtained productis improved; meanwhile, under the atmosphere of carbon dioxide, the impurities in the silver residues can be separated out, and the purity of the obtained product is further improved; in addition, under the atmosphere of nitrogen gas, a chemical reaction can take place stably; and the preparation process is simple and low in cost, and the better application prospect is achieved.

Owner:柳州光华科技有限公司

A current reconstruction overmodulation device for an air conditioner inverter

ActiveCN113300575BImprove cooling effectImprove stabilityModifications for power electronicsVibration suppression adjustmentsConvertersTransverter

Owner:深圳粤能能源技术有限公司

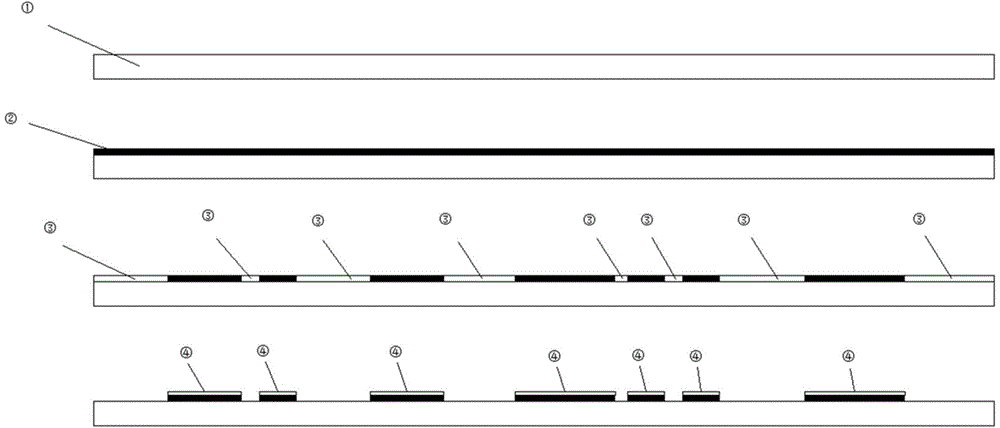

Method for preparing quartz glass microchannel core plate

InactiveCN110538621AImprove heat resistanceHigh light transmittanceChemical/physical/physico-chemical microreactorsChemical reactionHeat resistance

The invention relates to a method for preparing a quartz glass microchannel core plate. Quartz glass is used as a substrate to prepare a boss quartz glass plate substrate by machining; a quartz glasscapillary is welded on a boss surface according to a specific trend by using a hot melting technology; a groove quartz glass plate substrate is prepared by using a grooving machine; and finally the boss quartz glass plate substrate and the groove quartz glass plate substrate are combined to form the complete quartz glass microchannel core plate by using a hot melting technology. According to the invention, the quartz glass is selected as the substrate material, so that higher heat resistance and light transmittance are achieved. In the method, a common machining technology is combined with thehot melting technology, and operation is simple. Compared with a method for preparing a glass microchannel by mechanical micromachining, the method has the advantages that the surface quality of theinner wall of the microchannel is high; chemical reactions can be stably carried out; the phenomenon of reaction liquid leakage does not occur; the size of the microchannel can be accurately adjustedthrough the quartz glass capillary; and the trend and length of the microchannel can be adjusted according to requirements of the chemical reactions. The space between the microchannel and the groovecan be reserved for heating and heat exchange.

Owner:南京工业大学东海先进硅基材料研究院

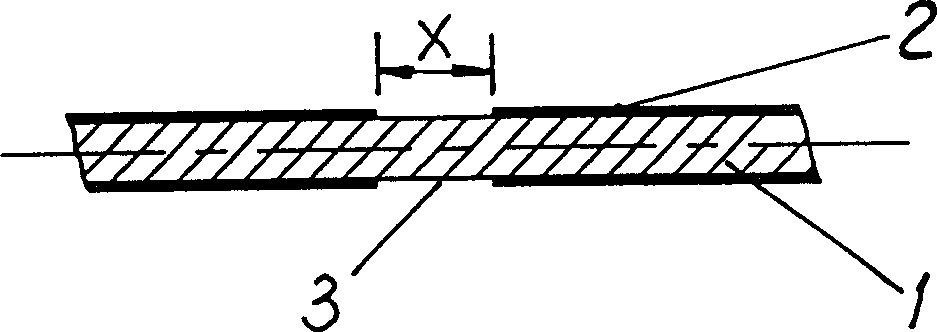

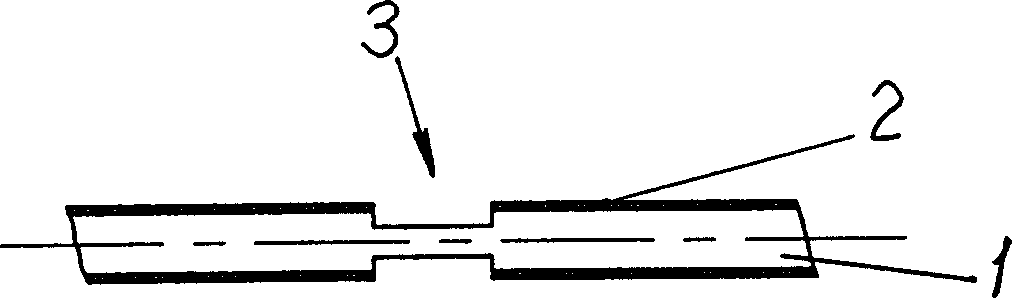

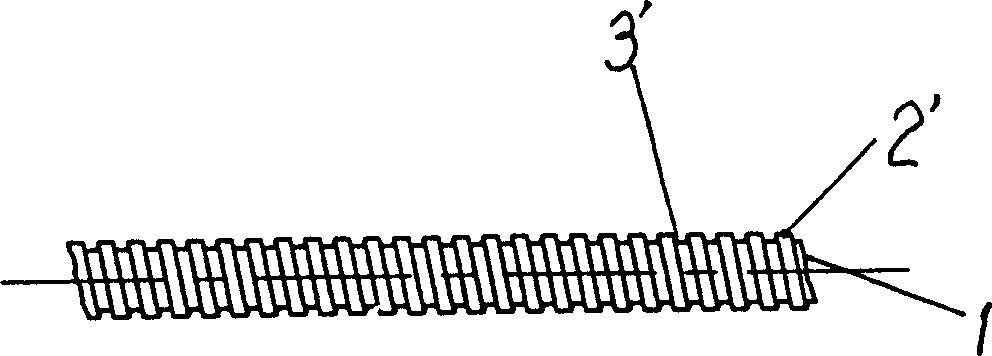

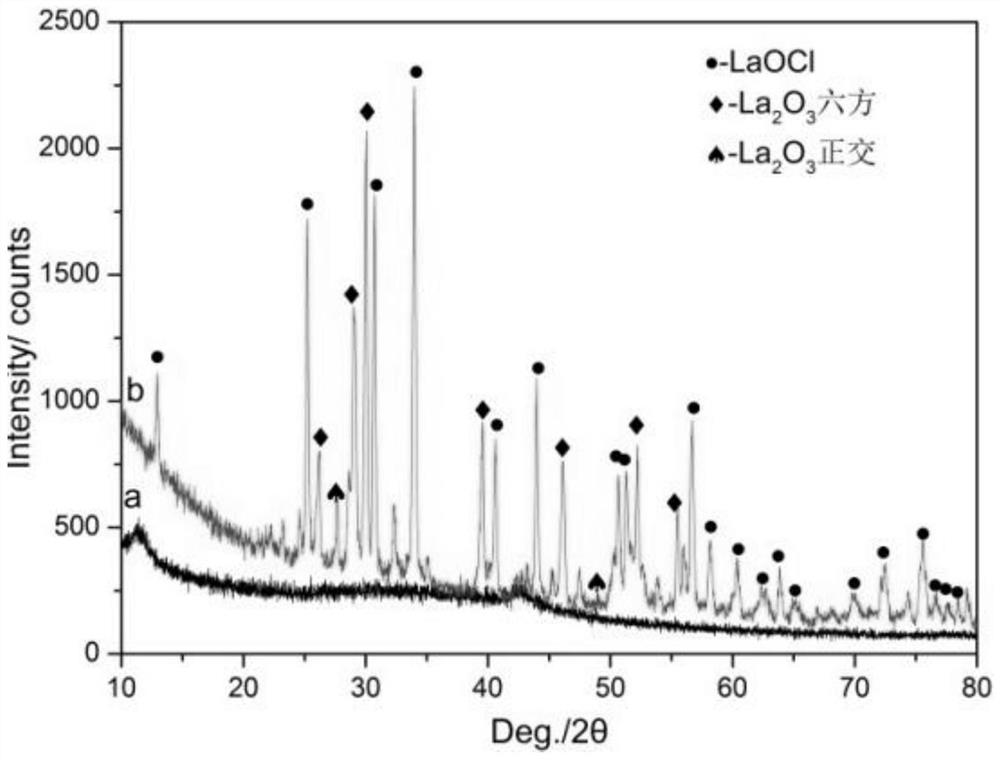

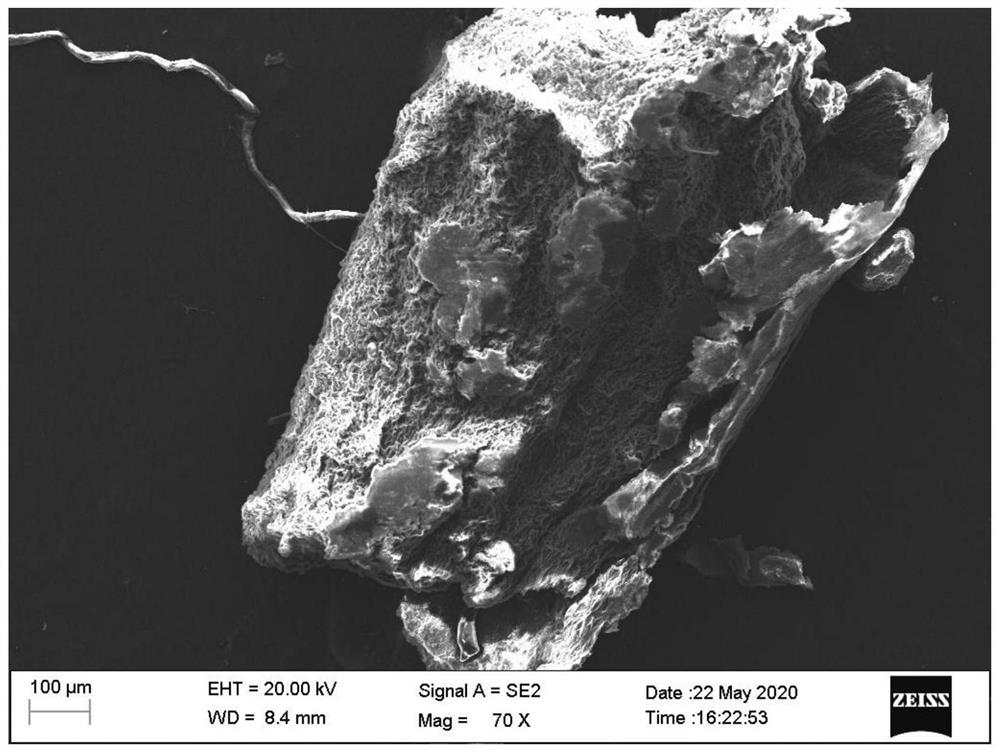

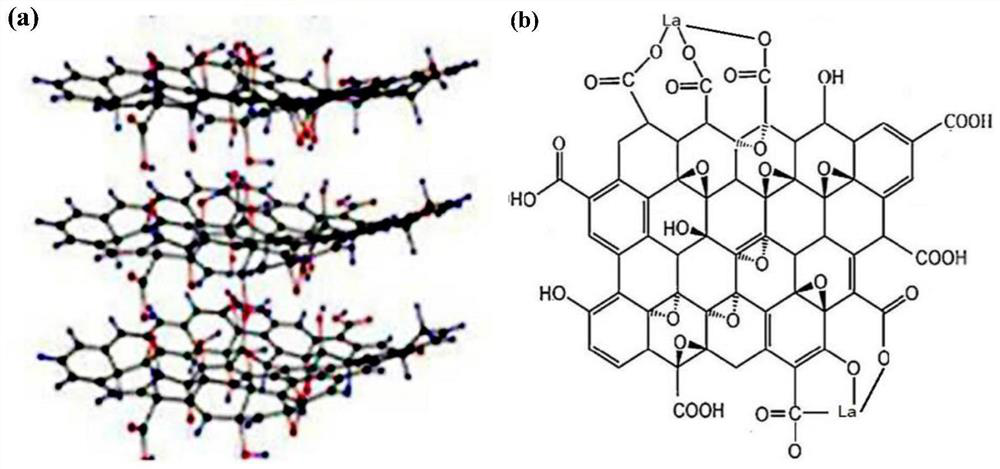

A method of microalloying in iron and steel materials based on carbon carrier adsorption of rare earth elements

The invention relates to a method for micro-alloying iron and steel materials based on carbon carrier adsorption of rare earth elements. Soluble rare earth salts are selected and dissolved to prepare rare earth salt solutions. The rare earth elements in the solution are adsorbed and fixed by carbon carriers to form The rare earth compound of the carrier is mixed with a deoxidizer to make a compact or a long cored wire. During the microalloying process, it undergoes a reduction reaction with the deoxidizer to reduce the rare earth elements and dissolve them into molten steel. , to complete the microalloying process of rare earth in iron and steel materials. The production process of the method is safe, the material source is simple and easy to obtain, the industrial production is easy to carry out, and the method is energy-saving and environment-friendly. The amount of rare earth microalloying in the obtained steel material is high, which can reach 10-100ppm, the yield of rare earth elements is high, the uniformity is good, and the remaining rare earth solution after the adsorption is completed can be reused, the resource allocation and utilization are efficient and reasonable, and have good application prospects.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A cast steel heating riser sleeve

The invention relates to a casting riser sleeve, in particular to a cast steel exothermic riser sleeve. The two ends of the exothermic riser sleeve are opened. A top cover is arranged at the top end of the exothermic riser sleeve. The top cover is made of precoated sand. The exothermic riser sleeve is adopted for replacing a sand mold overflow riser in the prior art, the setting time is prolonged, heat supply is uniform, and the interior of an exothermic riser is free of defects, deformation and expansion; and the surface of a casting is bright and clean, the appearance is tidy, the technology yield is increased by 4.6%, and the production cost is reduced.

Owner:西峡飞龙特种铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com