Restoration method for eliminating heat treatment deformation of metal internal teeth

A technology of heat treatment deformation and repair method, which is applied to the repair field of heat treatment deformation of metal workpiece inner teeth, can solve the problems of high cost, uneven repair, low efficiency, etc., and achieves the effects of low cost, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

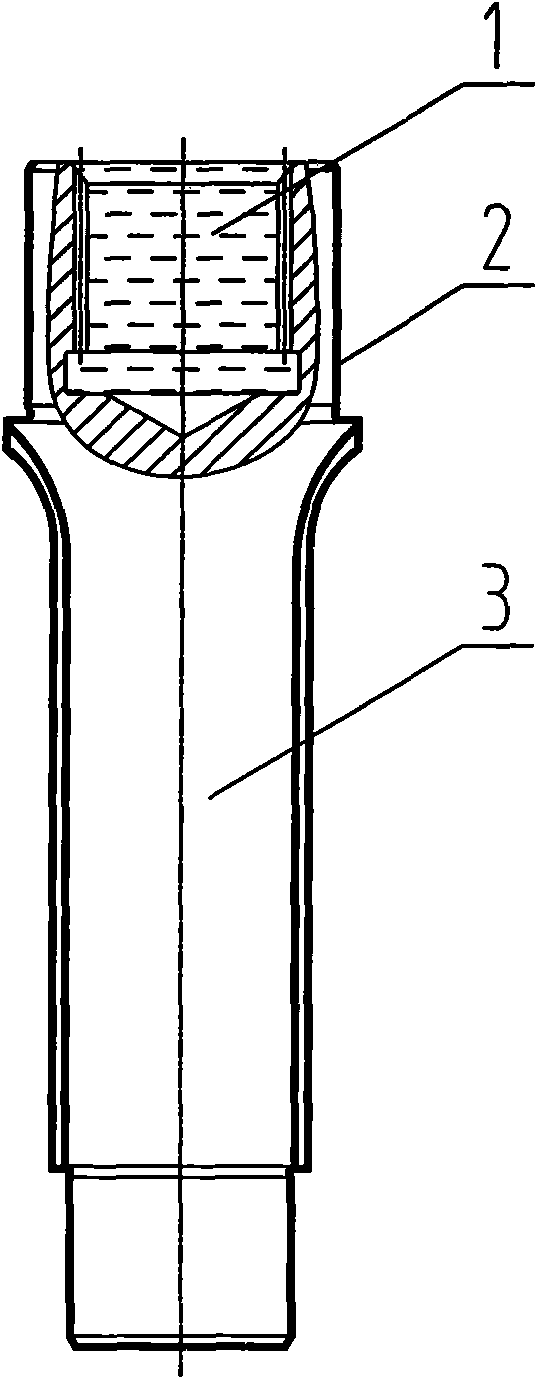

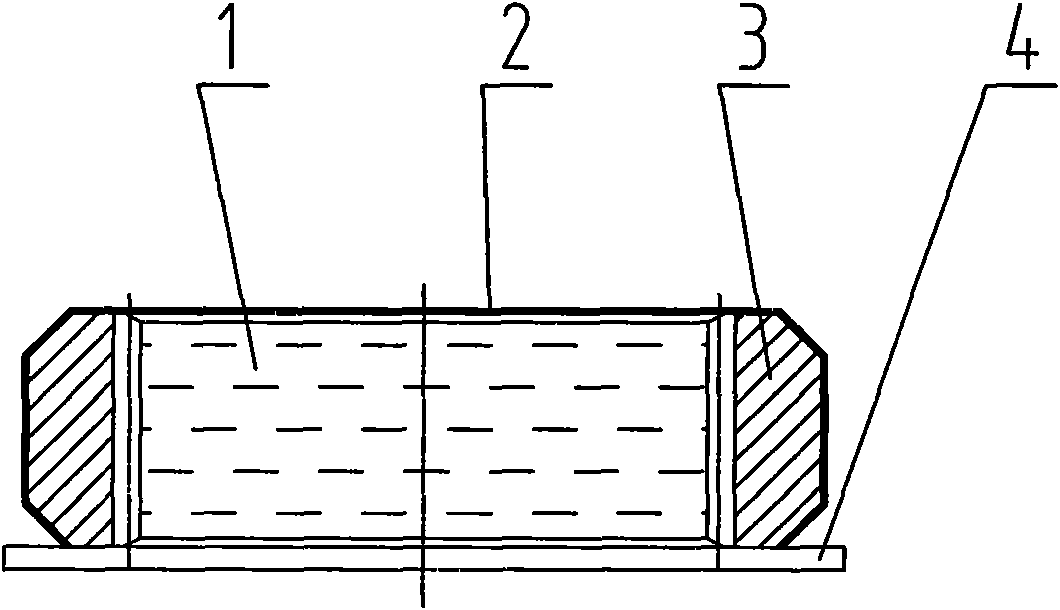

[0049] The material of the metal internal teeth in the embodiment of the present invention is a ferrous alloy metal, and its main chemical components include Fe, Cr, Ni, Mn, Mo, C, P, S, and Si. The iron and carbon contained therein can be combined with nitric acid, respectively. The principle of chemical reaction with hydrogen peroxide replaces the traditional metal cutting and forming method to quickly correct the shrinkage and deformation of the internal teeth of the metal workpiece after heat treatment, so that many problems caused by traditional metal cutting can be avoided. At the same time, in order to prevent the non-repaired part of the metal internal tooth workpiece from chemically reacting with nitric acid and hydrogen peroxide, the non-repaired part of the metal internal tooth workpiece is covered and protected to form a protective layer. The protective layer can be made of non-metallic materials (such as plastic, petrolatum, wax, etc.). If only the repaired part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com