Positive power control method for multiple magnetic-control tube microwave chemical reactor

A chemical reactor and power control technology, applied in the field of active power control of multi-magnetron microwave chemical reactors, can solve problems such as uneven changes, burning of reactant products, and limiting the stable change of microwave output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

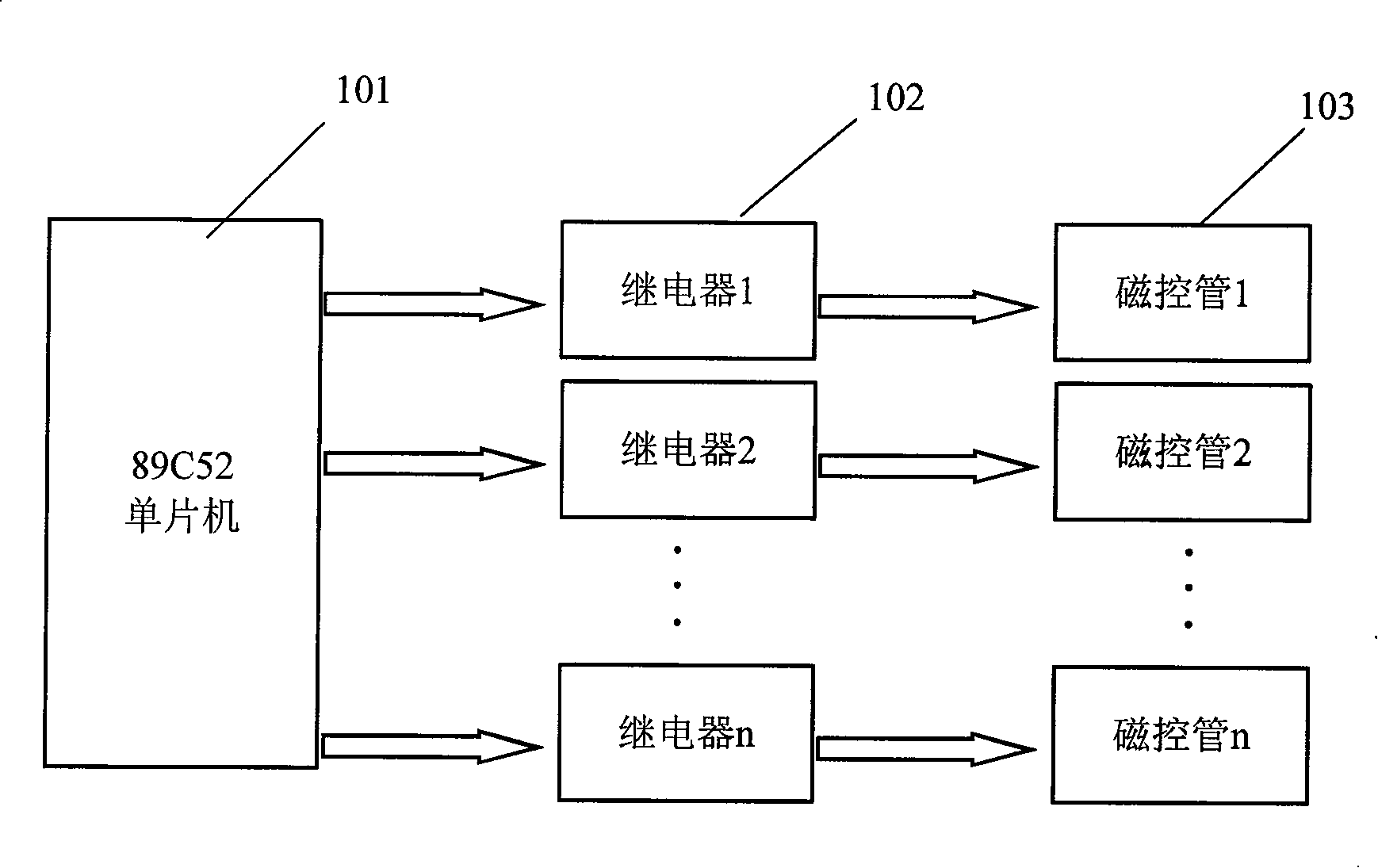

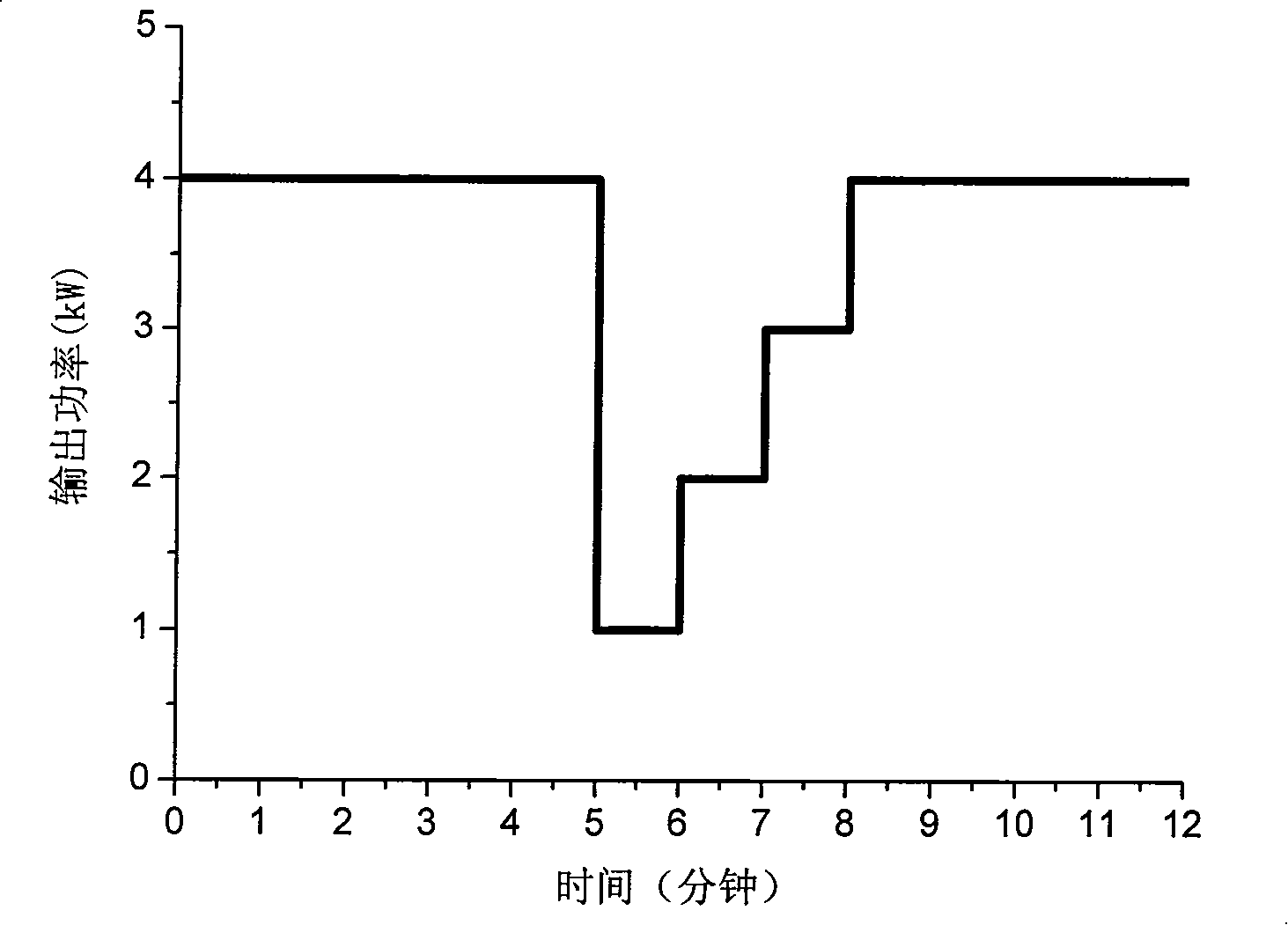

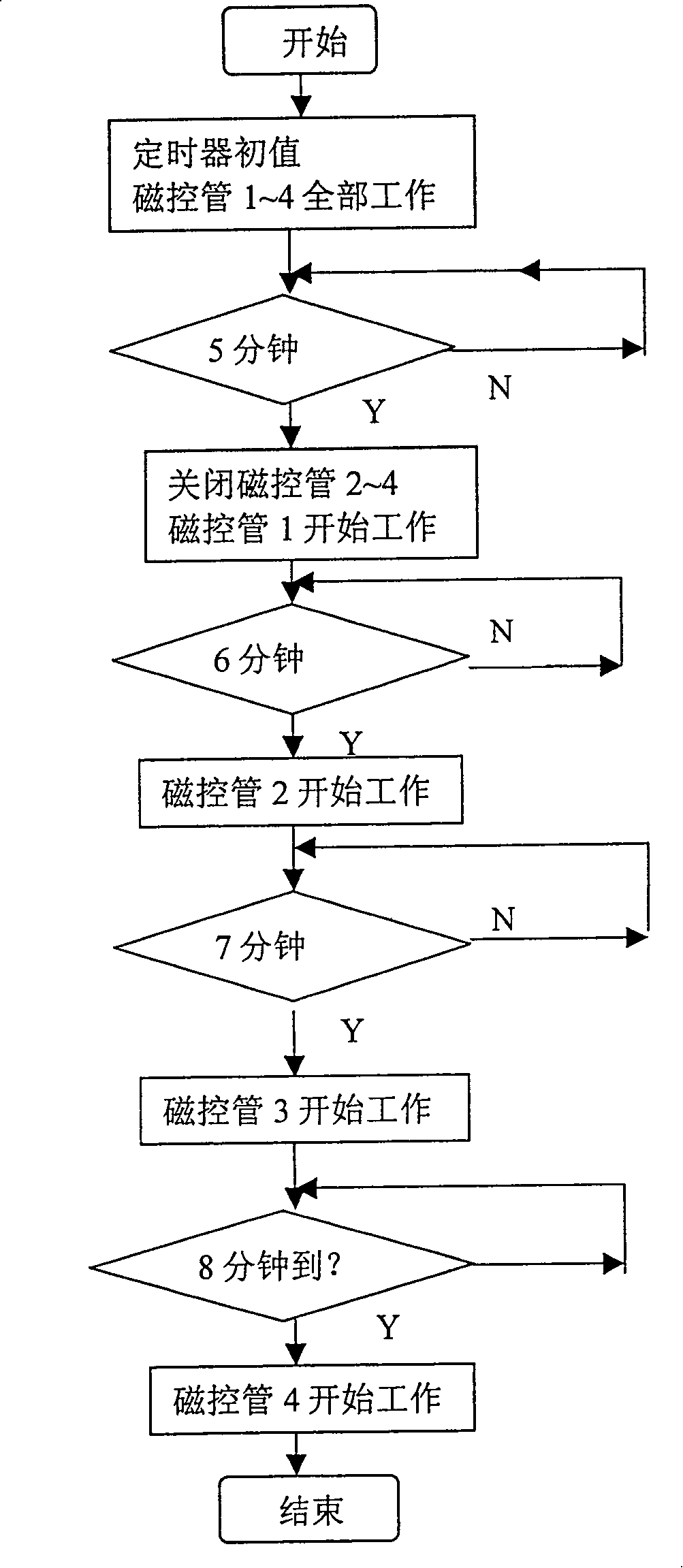

[0028] Such as figure 1 As shown, a programmable active power control device is installed in the microwave chemical reactor of n magnetrons, and the single-chip microcomputer 101 is respectively connected to n magnetrons 103 through n relays 102, and the control parameters of the chemical reaction can be written into Program the single-chip microcomputer program. The single-chip microcomputer makes n relays work in different combinations of "on" and "off" through the control circuit, and controls n magnetrons to be in different working states. When the temperature of the chemical reaction system rises sharply or microwave energy Before the reflection mutation comes, actively reduce the number of working magnetrons to m, m

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com