Cast steel exothermic riser sleeve

A heating riser and steel casting technology, which is applied in the field of casting riser sleeves, can solve the problems of easy expansion of thermal insulation material vermiculite, complex structure of thermal insulation riser sleeves, uneven heat transfer, etc., and achieve high refractoriness and prolonged solidification time , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

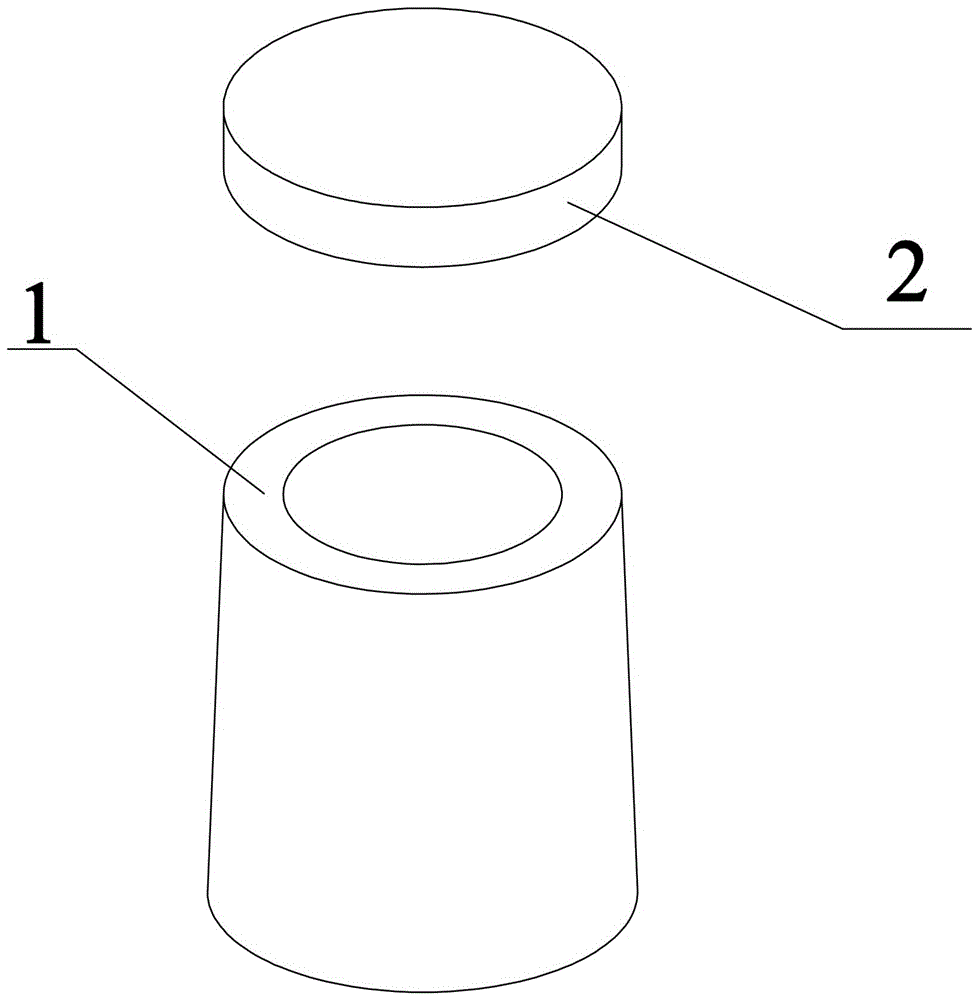

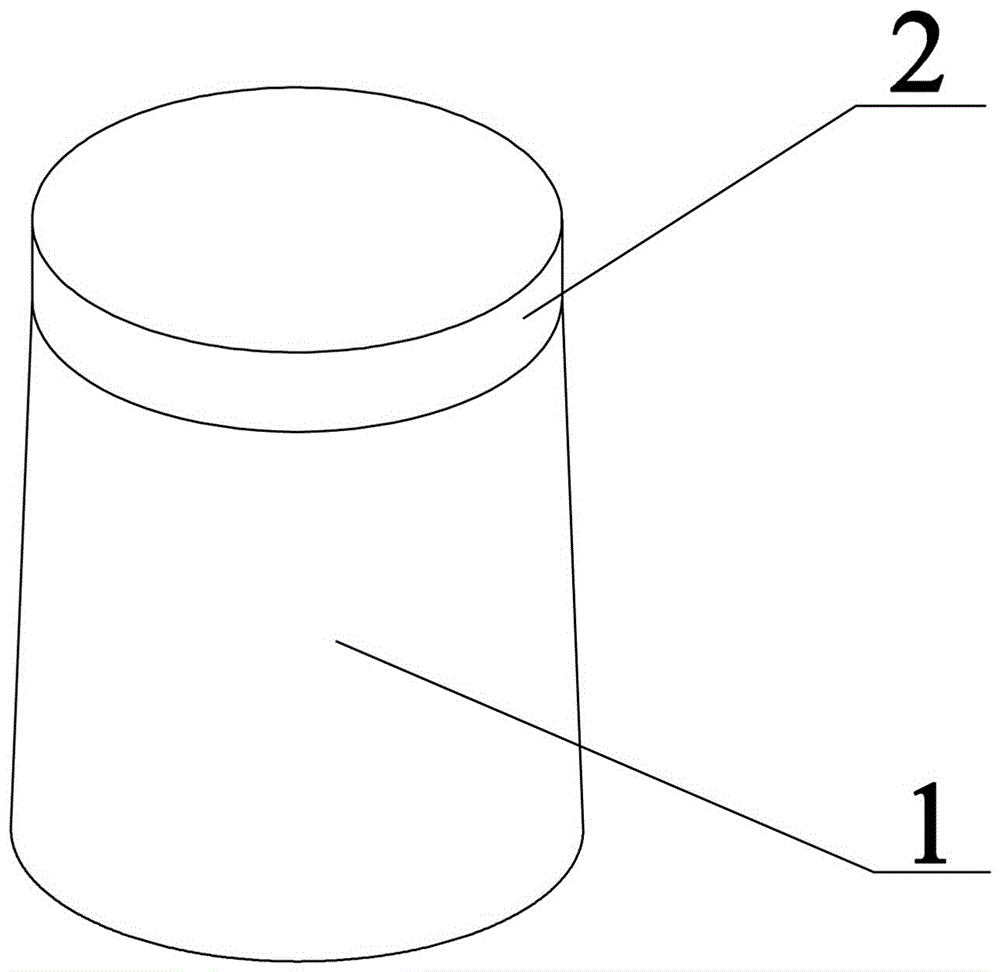

[0029] see figure 1 and figure 2 , a cast steel heating riser sleeve 1, both ends of the heating riser sleeve 1 are open, the top of the heating riser sleeve 1 is provided with a top cover 2, and the top cover 2 is made of coated sand .

[0030] The particle size of the coated sand is 40 mesh.

[0031] The raw material composition of the heating riser cover 1 is: by weight percentage,

[0032] Chromite sand 24%, hollow microspheres 13%, attapulgite clay 20%, aluminum powder 15%, ferric oxide powder 13%, graphite powder 5%, magnesium powder 3%, sodium nitrate 4%, potassium chloride 3%, plus 10% water glass and 15% water of the total weight of raw materials.

[0033] The particle size of the chromite sand is 70 mesh, Cr 2 o 3 Content ≥ 45%.

[0034] The diameter of the hollow microspheres is 100 μm.

[0035] The attapulgite clay is fibrous, and the single crystal is 50nm long and 10nm in diameter.

[0036] The particle sizes of the aluminum powder, ferric oxide powder,...

Embodiment 2

[0041] The structure and preparation method of the cast steel heating riser sleeve in this embodiment are the same as those of the cast steel heating riser sleeve in Example 1, and will not be repeated. Some differences are:

[0042] The particle size of the coated sand is 30 mesh.

[0043] The raw material composition of the heating riser cover is: by weight percentage, 25% of chromite sand, 12% of hollow microspheres, 18% of attapulgite clay, 15% of aluminum powder, 10% of ferric oxide powder, graphite powder 8%, magnesium powder 2%, sodium nitrate 6%, potassium chloride 4%, plus 11% water glass and 16% water of the total weight of raw materials.

[0044] The particle size of the chromite sand is 80 mesh, Cr 2 o 3 Content ≥ 45%.

[0045] The diameter of the hollow microspheres is 120 μm.

[0046] The attapulgite clay is fibrous, with a single crystal length of 80 nm and a diameter of 15 nm.

[0047]The particle size of the aluminum powder, ferric oxide powder, graphite ...

Embodiment 3

[0050] The structure and preparation method of the cast steel heating riser sleeve in this embodiment are the same as those of the cast steel heating riser sleeve in Example 1, and will not be repeated. Some differences are:

[0051] The particle size of the coated sand is 30 mesh.

[0052] The raw material composition of the heating riser cover is: by weight percentage, 26% of chromite sand, 13% of hollow microspheres, 17% of attapulgite clay, 20% of aluminum powder, 11% of ferric oxide powder, graphite powder 7%, magnesium powder 1%, sodium nitrate 3%, potassium chloride 2%, plus 12% water glass and 17% water of the total weight of raw materials.

[0053] The particle size of the chromite sand is 100 mesh, Cr 2 o 3 Content ≥ 45%.

[0054] The diameter of the hollow microspheres is 150 μm.

[0055] The attapulgite clay is fibrous, and the single crystal is 100nm long and 20nm in diameter.

[0056] The particle sizes of the aluminum powder, ferric oxide powder, graphite p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com