Preparation method of ceramic substrate for medium-free copper-coated gold-deposited light-emitting diode (LED) package

A technology of LED packaging and copper immersion gold, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of not meeting the requirements of high-power current passing, electrophoretic effect, poor ceramic bonding force, etc., and improve the long-term maintenance rate , solve the problem of vulcanization, the effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

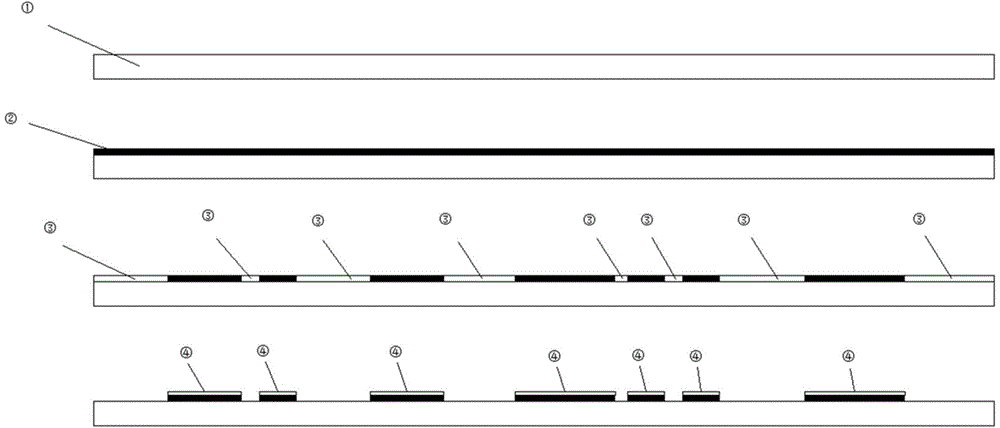

[0017] see figure 1 , in an embodiment of the present invention, a manufacturing process of a dielectric-less copper immersion gold-clad LED packaging ceramic substrate, the specific steps are as follows:

[0018] (1) Sintered ceramic sheet: the ceramic powder is molded through a mold and placed in an environment of 1000°C for sintering for 8 minutes to obtain a ceramic sheet;

[0019] (2) Copper cladding: Copper is coated on the upper surface of the ceramic sheet by vacuum plating to form copper foil, and the weight of copper on the copper foil is 28.2g;

[0020] (3) Etching: Use dilute sulfuric acid to corrode useless copper foil according to the process flow chart, leaving useful copper foil as a circuit;

[0021] (4) Immersion gold: Pass the etched circuit board through the gold potion to deposit gold on the copper foil to obtain the finished product.

Embodiment 2

[0023] A manufacturing process of a dielectric-less copper immersion gold-coated ceramic substrate for LED packaging, the specific steps are as follows:

[0024] (1) Sintered ceramic sheet: the ceramic powder is molded through a mold and placed in an environment of 1010°C for sintering for 9 minutes to obtain a ceramic sheet;

[0025] (2) Copper cladding: Copper is coated on the upper surface of the ceramic sheet by vacuum plating to form copper foil, and the weight of copper on the copper foil is 28.35g;

[0026] (3) Etching: Use dilute sulfuric acid to corrode useless copper foil according to the process flow chart, leaving useful copper foil as a circuit;

[0027] (4) Immersion gold: Pass the etched circuit board through the gold potion to deposit gold on the copper foil to obtain the finished product.

Embodiment 3

[0029] see figure 1 , in an embodiment of the present invention, a manufacturing process of a dielectric-less copper immersion gold-clad LED packaging ceramic substrate, the specific steps are as follows:

[0030] (1) Sintered ceramic sheet: put the ceramic powder into a 1020°C environment for sintering for 10 minutes after being molded to obtain a ceramic sheet;

[0031] (2) Copper cladding: Copper is coated on the upper surface of the ceramic sheet by vacuum plating to form copper foil, and the weight of copper on the copper foil is 28.5g;

[0032] (3) Etching: Use dilute sulfuric acid to corrode useless copper foil according to the process flow chart, leaving useful copper foil as a circuit;

[0033] (4) Immersion gold: Pass the etched circuit board through the gold potion to deposit gold on the copper foil to obtain the finished product.

[0034] The invention adopts the non-medium copper coating technology, which maintains the excellent thermal conductivity of the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com