A method of microalloying in iron and steel materials based on carbon carrier adsorption of rare earth elements

A technology of rare earth elements and microalloying, which is applied in the field of microalloying, can solve the problems of deteriorating ladle top slag and tundish covering agent performance, rare earth elements have no time to fully diffuse, restrict the application and development of rare earths, and achieve safety in the production process , good uniformity and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method of microalloying in iron and steel materials based on carbon carrier adsorption of rare earth elements, the specific steps are:

[0033] (1) main raw material: take lanthanum chloride as raw material, be dissolved in water, be made into the lanthanum chloride solution of lanthanum ion concentration 10% (wt%), the solution pH value is controlled at 5~7;

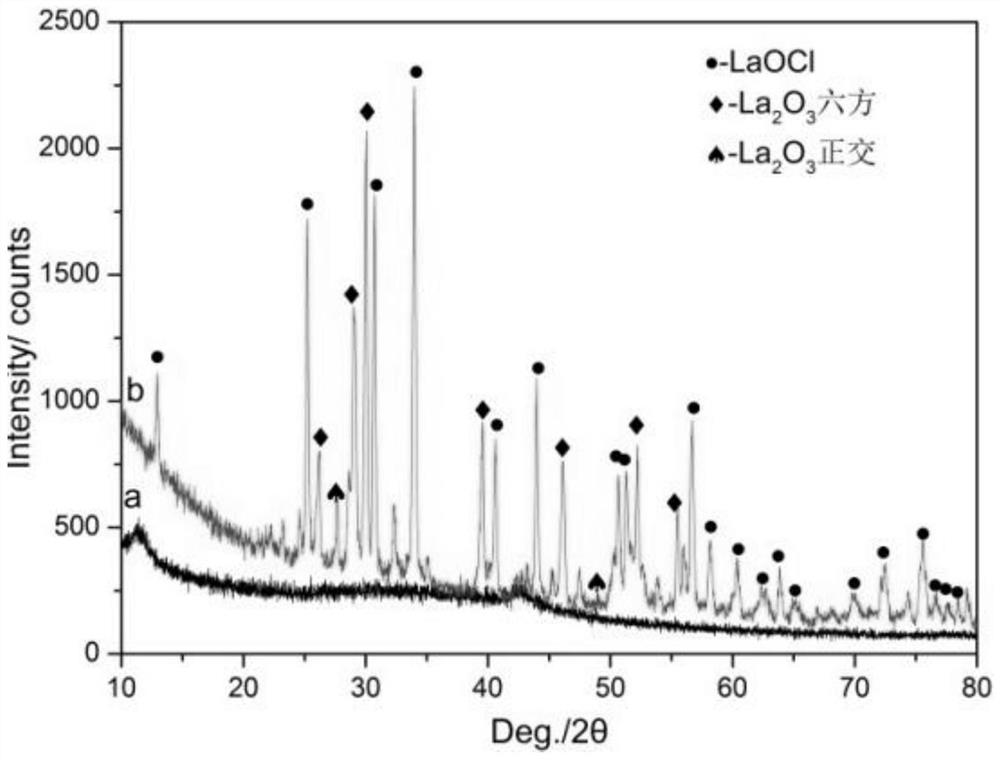

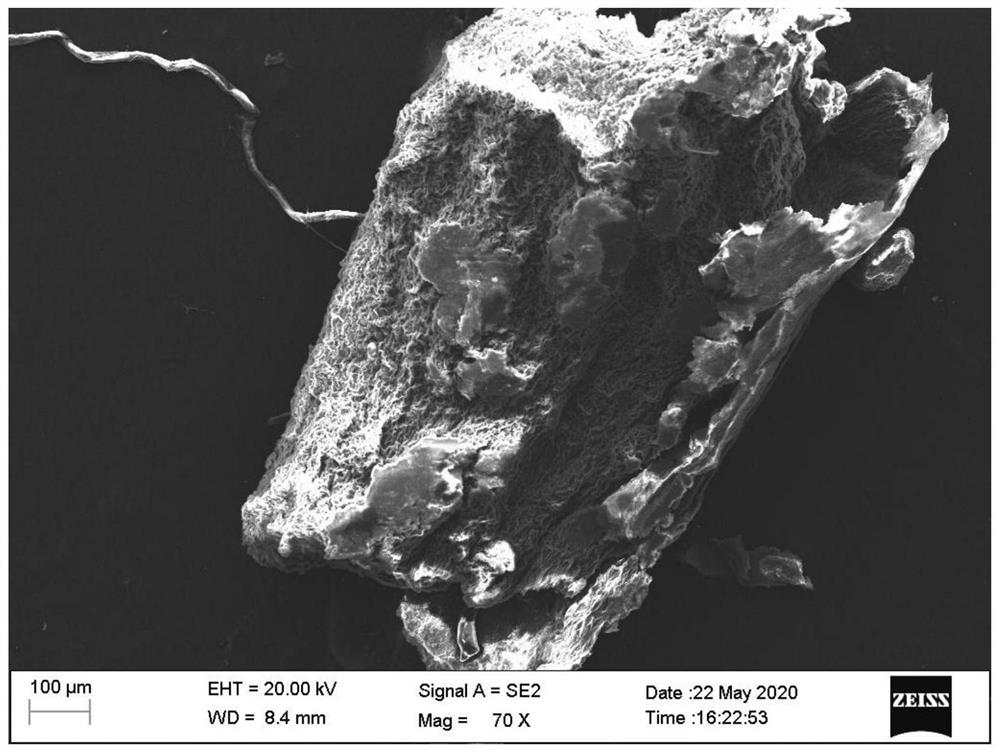

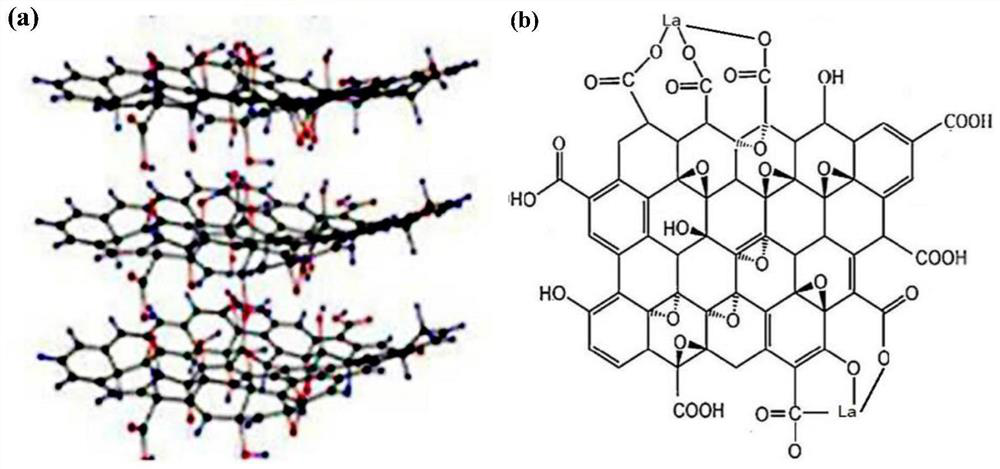

[0034] (2) Adsorption carrier: Take 50g of graphite oxide and 50mL of lanthanum chloride solution, absorb and fix the rare earth lanthanum in the solution in graphite oxide with adsorption properties, control the adsorption temperature at 60°C to 70°C, and the adsorption time for 30min, forming A rare earth lanthanum compound with carbon as a carrier; wherein after the carbon carrier is adsorbed, the mass of the lanthanum element in the carbon carrier accounts for 5.4% of the total mass of the carbon carrier (including rare earth compounds, the same below);

[0035] Recover the lanthanum chloride aqueous solu...

Embodiment 2

[0041] The method of microalloying in iron and steel materials based on carbon carrier adsorption of rare earth elements, the specific steps are:

[0042] (1) main raw material: take cerium chloride as raw material, be dissolved in water, be made into the cerium chloride solution that cerium ion concentration is 36% (wt%), the pH value of solution is controlled at 5~7;

[0043] (2) Adsorption carrier: Take 6g of coke and 100mL of cerium chloride aqueous solution, and absorb and fix the rare earth cerium in the solution to the coke with adsorption performance. The adsorption temperature is controlled at 70°C-80°C, and the adsorption time is 25min. Rare earth cerium compound as a carrier; after adsorption, the mass of rare earth cerium in the carbon carrier accounts for 39.6% of the total mass of the carbon carrier after adsorption;

[0044]Recover the adsorbed cerium chloride aqueous solution, add cerium chloride to make the mass concentration of rare earth cerium ions in the s...

Embodiment 3

[0049] The method of microalloying in iron and steel materials based on carbon carrier adsorption of rare earth elements, the specific steps are:

[0050] (1) Main raw materials: lanthanum chloride and cerium chloride obtained by wet recovery of secondary resources are used as raw materials (the mass ratio of lanthanum and cerium is 1:2, and the total amount of other impurity elements is <5%), dissolved in ethanol Solution, be made into the ethanol mixed solution of lanthanum chloride, cerium chloride (wherein the mass concentration of lanthanum ion is 10.1%, the mass concentration of cerium ion is 20.1%), the pH value of solution is controlled at 5~7;

[0051] (2) Adsorption carrier: Take 60 kg of graphite oxide, 100 L of ethanol mixed solution of lanthanum chloride and cerium chloride, and absorb and fix the rare earth lanthanum and cerium in the solution in graphite oxide with adsorption properties, and the adsorption temperature is controlled at 50 ° C ~ 60°C, the adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com