Automatic catalyst-feeding method

An automatic feeding and catalyst technology, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve problems such as small feeding amount, and achieve the effect of increasing feeding amount, light wear degree, and small fluctuation of device operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

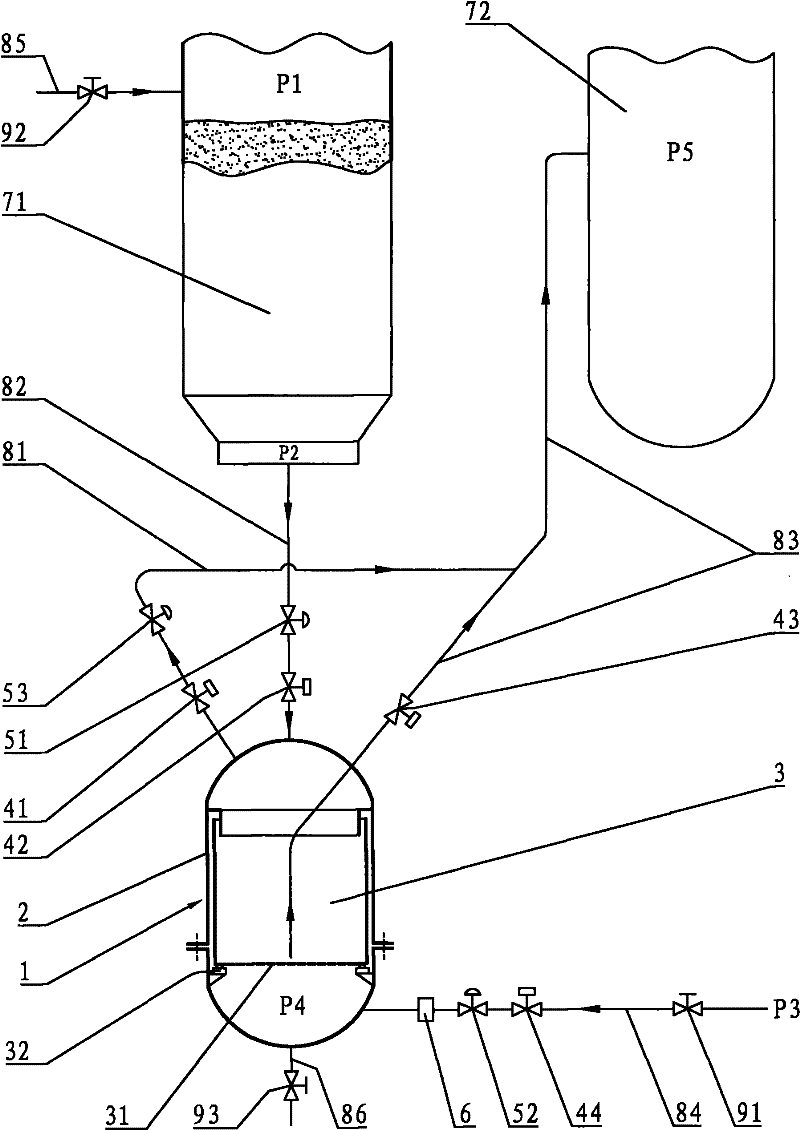

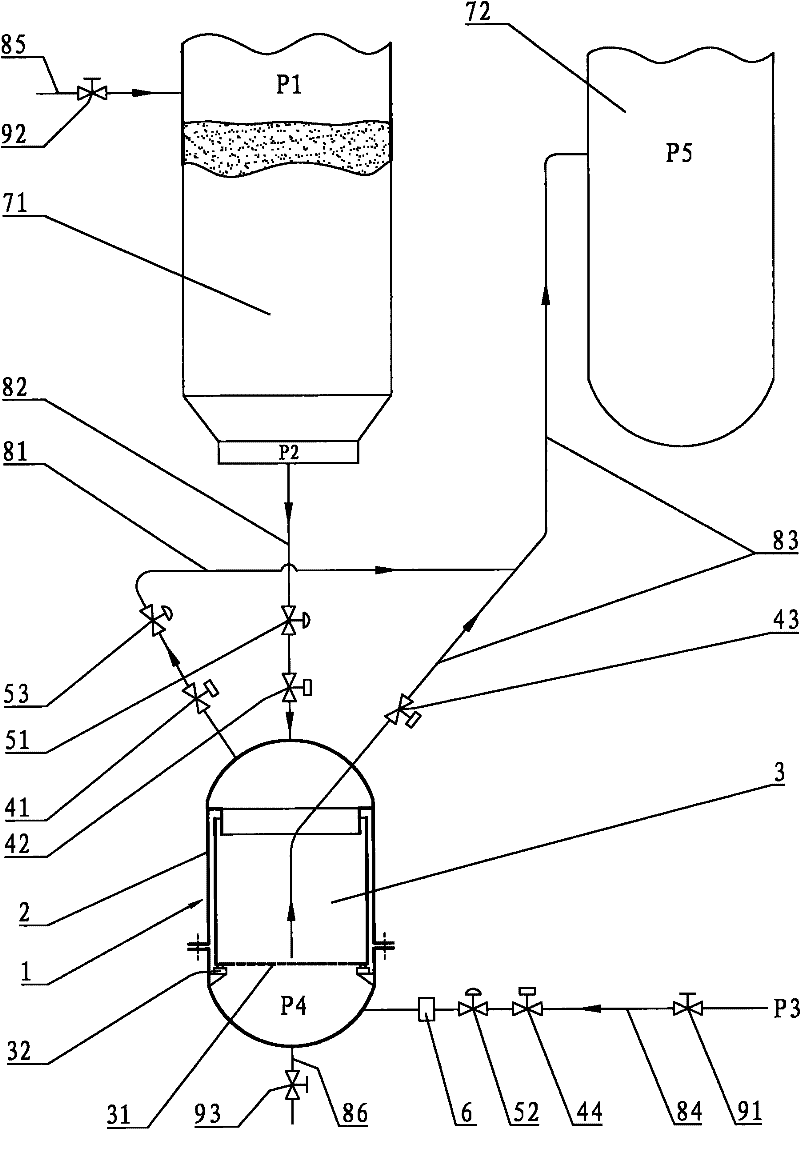

[0055] The method of the invention is adopted to continuously and automatically feed the regenerator of the FCC device of a certain oil refinery. feeding system such as figure 1 shown. The effective catalyst volume of the feeder 1 is 0.17 cubic meters, and the rated capacity of the catalyst is 153 kilograms. The weighing instrument 32 is an electronic weighing sensor, the model is BM11-200, and the accuracy is ±2‰.

[0056] The regenerator 72 is a regenerator of an FCC device, with a volume of 250 cubic meters and a pressure P5 of 0.20 MPa. The catalyst storage tank 71 has a volume of 500 cubic meters, stores 390 tons of catalyst, and has a material level height of 20 meters. The catalyst is an FCC catalyst, and the grade is GRV-C.

[0057] The nominal diameter of the feed pipe 82 and the feed valve 42 set on the feed pipe 82 and the feed regulating valve 51 is DN50 millimeters, and the length of the feed pipe 82 is 3 meters. The nominal diameter of the discharge pipe 83 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com