Bottom filling adhesive having good compatibility with scaling powder and preparation method thereof

An underfill and compatibility technology, applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve problems such as low reliability, poor flux compatibility, and small expansion coefficient, so as to ensure reliability , flow speed and solidification speed are fast, and the expansion coefficient is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

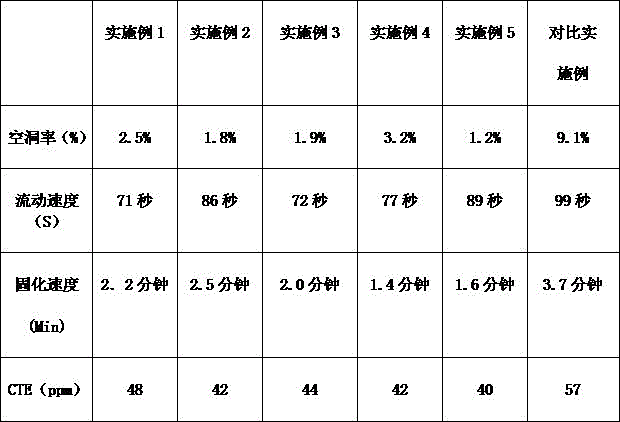

Examples

Embodiment 1

[0035] a. Add 500 parts of rosin dimer acid into the kettle, heat and melt, continue to heat to 180°C, add 140 parts of xylene formaldehyde resin Nikanol and 1.0 parts of catalyst p-toluenesulfonic acid under stirring, in a nitrogen-protected environment React for 2 hours, then add 90 parts of 1,4-butanediol diglycidyl ether and 0.2 part of triphenylphosphine, and react for another 3 hours to obtain a self-synthetic compatible resin.

[0036] b. Add 5% of self-synthesized compatible resin, 50% of cycloaliphatic epoxy resin 2021P, 5% of dodecyl to myristyl glycidyl ether, β-(3,4-epoxycyclohexyl) in the following percentages by weight 3% of ethyltrimethoxysilane, 1% of dispersant BYK-9076, 50% of silicon micropowder, and 30% of curing agent PN23 are successively dropped into a stirring tank, stirred evenly, and vacuumized for degassing to obtain the compound of the present invention and Underfill with good flux compatibility.

Embodiment 2

[0038] a. Add 700 parts of tall oil dimer acid into the kettle, heat and melt, continue heating to 220°C, add 360 parts of xylene formaldehyde resin Nikanol and 8.0 parts of catalyst p-toluenesulfonic acid under stirring, under nitrogen protection The reaction was carried out in an environment for 4 hours, then 190 parts of 1,6-hexanediol diglycidyl ether and 3.0 parts of triphenylphosphine were added, and the reaction was continued for 6 hours to obtain a self-synthetic compatible resin.

[0039] b. Add 25% of self-synthesized compatible resin, 20% of bisphenol A epoxy resin 828EL, 20% of trimethylol triglycidyl ether, and 2.0% of γ-glycidyloxypropyl trimethoxysilane in the following weight percentages %, 0.5% of dispersant BYK-W9010, 35% of silicon micropowder, and 5.0% of curing agent PN40, put them into the stirring tank in turn, stir evenly, vacuumize and defoam, and make the bottom of the present invention with good compatibility with flux Filler.

Embodiment 3

[0041] a. Add 600 parts of soybean oil dimer acid into the kettle, heat and melt, continue to heat to 200 ° C, add 260 parts of xylene formaldehyde resin Nikanol and 4.0 parts of catalyst p-toluenesulfonic acid under stirring, in a nitrogen-protected environment React in the environment for 3 hours, then add 140 parts of neopentyl glycol diglycidyl ether and 1.6 parts of triphenylphosphine, and react for another 4.5 hours to obtain a self-synthetic compatible resin.

[0042] b. Add 15% of self-synthesized compatible resin, 35% of bisphenol F epoxy resin 830LVP, 13% of 4-tert-butylphenyl glycidyl ether, and 2.5% of γ-mercaptopropyl trimethoxysilane in the following weight percentages , 0.1% of dispersant BYK-W985, 42% of silicon micropowder, and 17% of curing agent fujicure 1020 are put into the stirring tank in turn, stirred evenly, vacuumized and defoamed, and the bottom with good compatibility with flux of the present invention is obtained. Filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com