Method for refining titanium tetrachloride by removing vanadium through aluminum powder

A technology of titanium tetrachloride and crude titanium tetrachloride, which is applied in the direction of titanium halide, etc., can solve problems such as unsafety, aluminum powder consumption, vanadium residue removal, and complicated process, so as to achieve high safety and reduce the amount of aluminum powder and the effect of removing vanadium residue and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

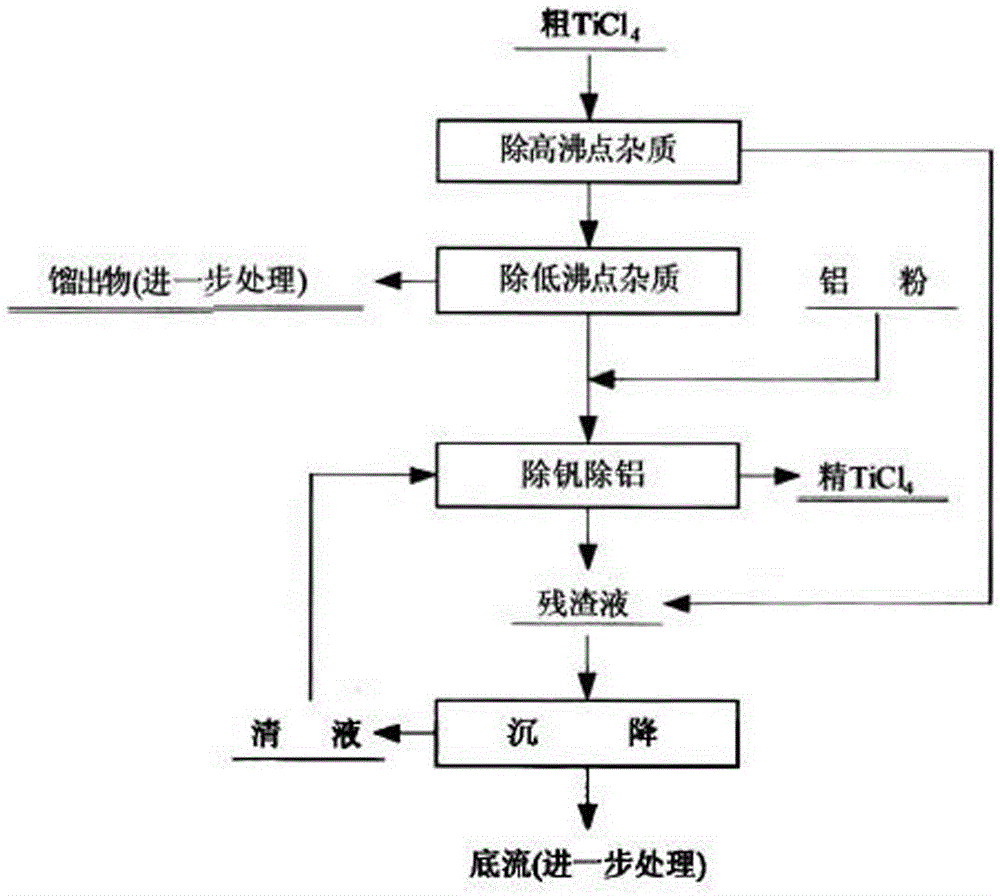

[0014] The method for refining titanium tetrachloride by removing vanadium from aluminum powder of the present invention comprises the following steps:

[0015] ① The crude titanium tetrachloride test solution removes high-boiling impurities, and the generated impurities flow into the residue liquid container;

[0016] ② The crude titanium tetrachloride test solution removes low-boiling impurities, and the resulting distillate is further processed;

[0017] ③ Add aluminum powder and clear liquid to the crude titanium tetrachloride test liquid, remove vanadium and aluminum to obtain refined titanium tetrachloride, and the residue liquid enters the residue liquid container;

[0018] ④The residue liquid is settled to obtain a clear liquid and an underflow, the clear liquid is used for vanadium and aluminum removal, and the underflow can be further purified;

[0019] The method for removing vanadium and refining titanium tetrachloride from aluminum powder of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com