Chemical process of nickel-titanium alloy material

A nickel-titanium alloy and chemical processing technology, which is applied in the field of processing and forming of nickel-titanium alloy materials to achieve the effects of high processing efficiency, low cost and stable chemical reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

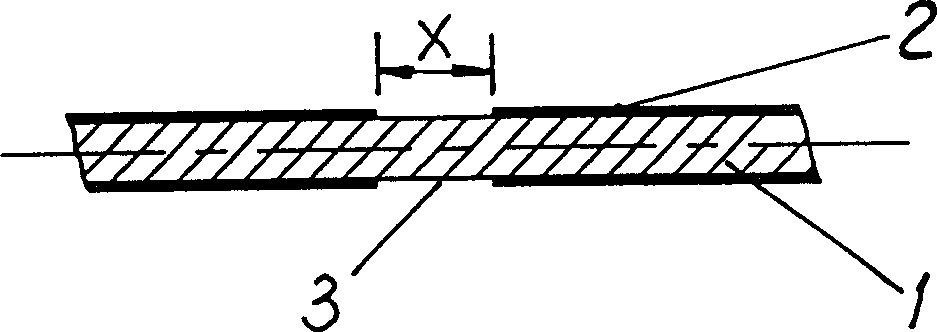

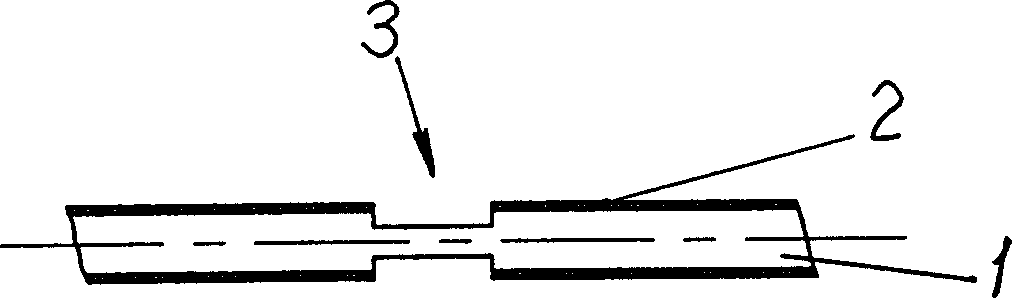

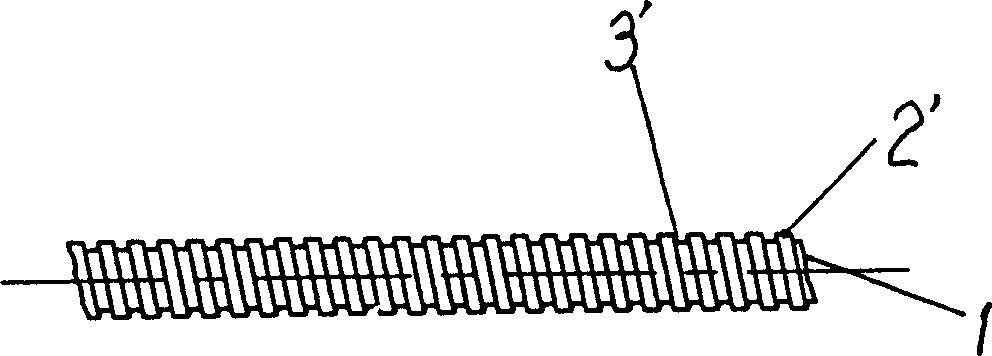

[0026] The present invention uses the principle that nickel and titanium can be dissolved in nitric acid and hydrofluoric acid respectively to replace the general metal cutting and forming method to manufacture nickel-titanium alloy products, so that it can avoid the occurrence of adhesion between nickel-titanium alloy and cutting tools during processing. Many questions came. In order to prevent the nickel-titanium alloy in the non-processed part from being dissolved in the reaction solution, the present invention should first prepare the non-processed part of the nickel-titanium alloy workpiece to cover the protective layer. The protective layer is made of soft non-metallic materials (such as adhesive tape, wax, glue, etc.). If only the processing part of the workpiece is immersed in the reaction solution, and the rest of the non-processing parts are not in contact with the reaction solution, this procedure can be exempted, and the non-processing part does not need to be cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com