Practical training operating platform for sludge incinerator in sewage treatment plant

A sewage treatment plant and sludge incineration technology, which is applied in the field of simulation teaching assessment system, can solve problems such as not meeting the sludge treatment requirements, and achieve the effects of light weight, high technological content, and easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: A sewage treatment plant sludge incinerator training operation platform in this embodiment includes a base plate 1 and a controller running training management software. like figure 1 As shown, the upper front of the bottom plate is embedded with a touch screen 2, an analog display meter 3 for layer pressure difference, an analog display meter 4 for furnace top negative pressure, a numerical analog display meter 5 for induced draft fan A and a numerical analog display meter 6 for induced draft fan B. An adjustment knob for adjusting the simulated induced draft fan A and the simulated induced induced draft fan B is also installed on the front upper part of the bottom plate.

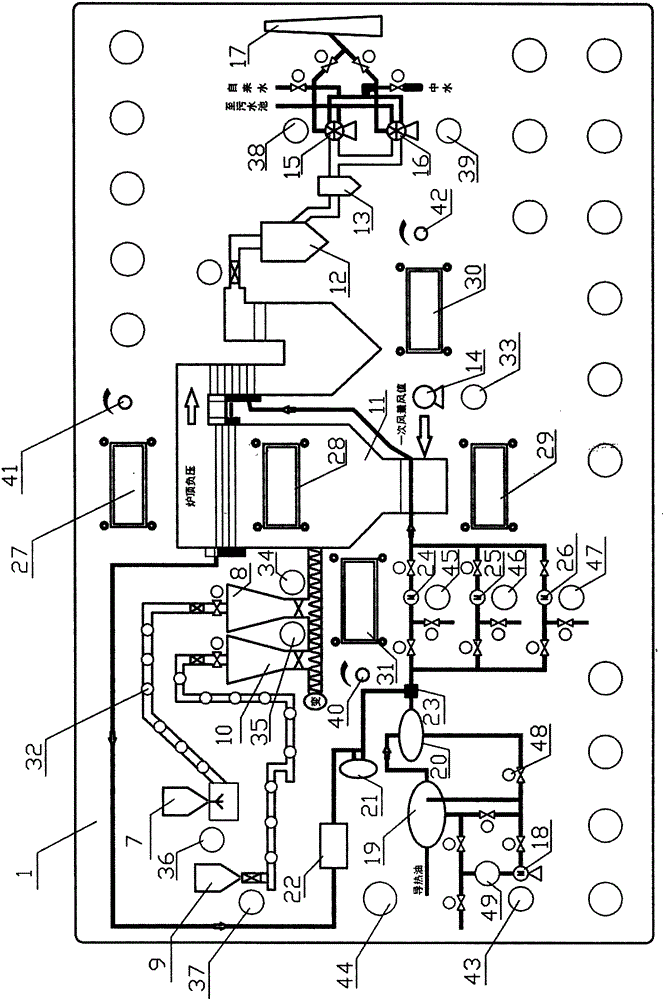

[0025] like figure 2 As shown, the process flow chart of the incinerator is drawn on the lower part of the front of the base plate and embedded with digital display meters, operation buttons, rotary buttons and analog pipeline indicators; the controller is installed on the back of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com