Design method of production flow

A technology for calculating regions and molecules, applied in calculations, special data processing applications, instruments, etc., can solve the problems of less information, unfavorable assembly process traceability and quality control, document distribution and production management errors, etc., and achieve the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] First of all, define the specific functions that the present invention completes:

[0022] a. Save the flow chart: save it to the database after completing the flow chart;

[0023] b. Export flow chart: export the flow chart in picture format;

[0024] c. Abandon the currently drawn flowchart: abandon the currently drawn flowchart;

[0025] d. Connecting sub-volumes: connecting between sub-volumes;

[0026] e. Delete sub-volumes or connecting lines: delete sub-volumes or connecting lines in the flowchart;

[0027] f. Insert a tag: Insert a "production process" tag in the flowchart.

[0028] The implementation method is as follows:

[0029] a. How to draw graphics

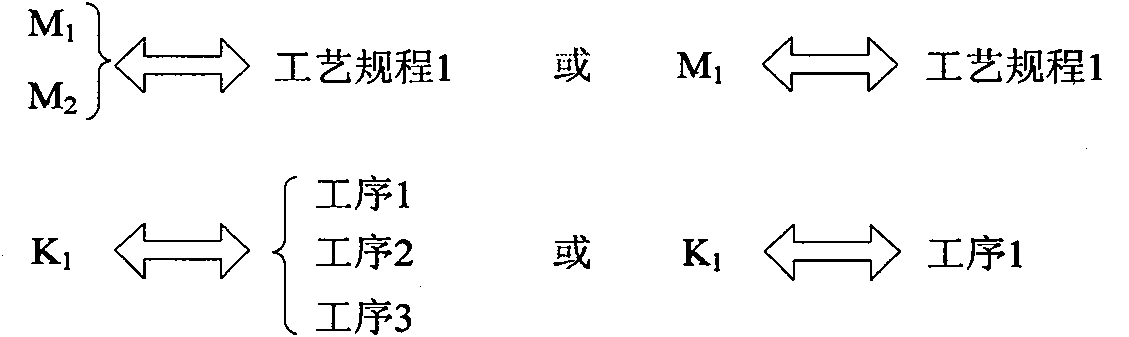

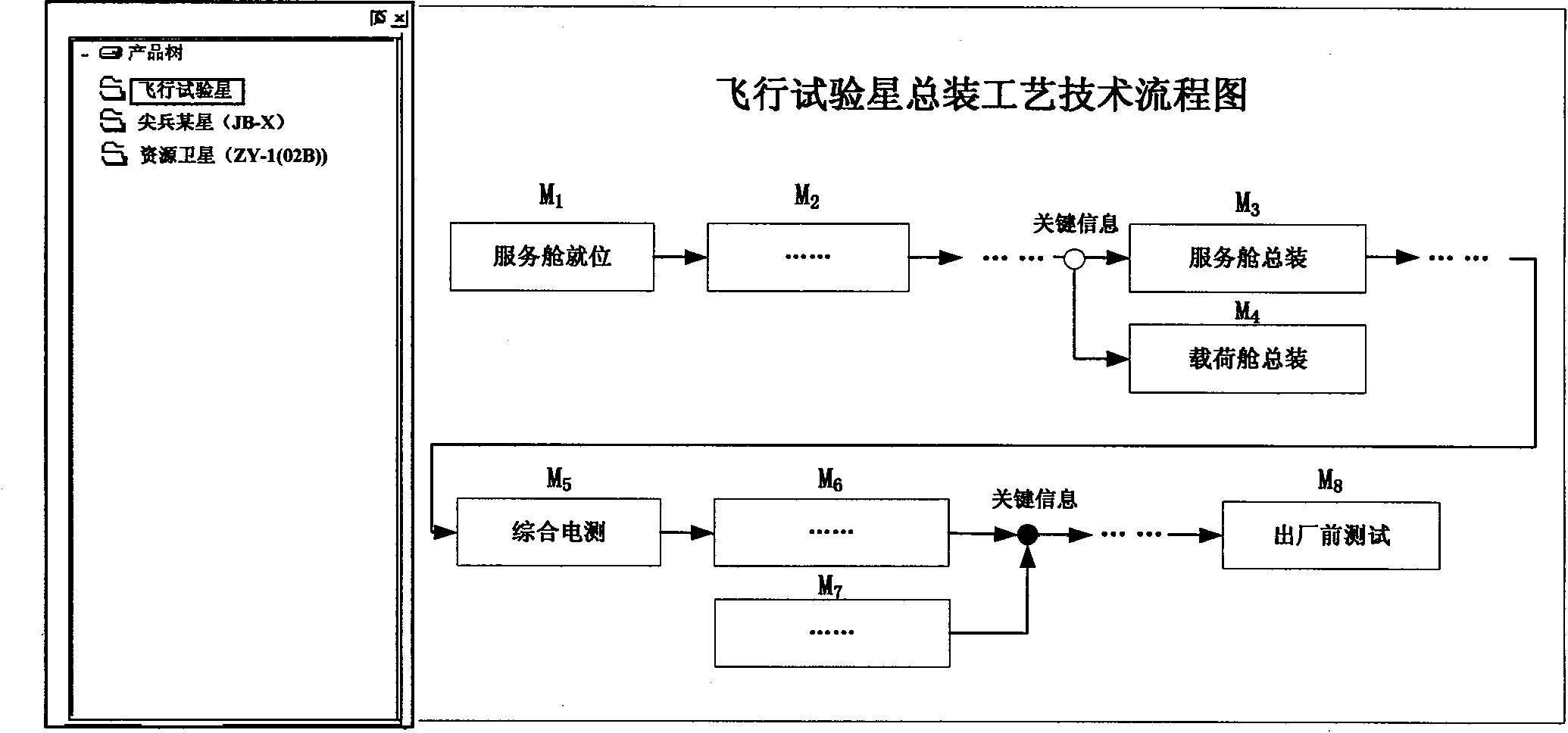

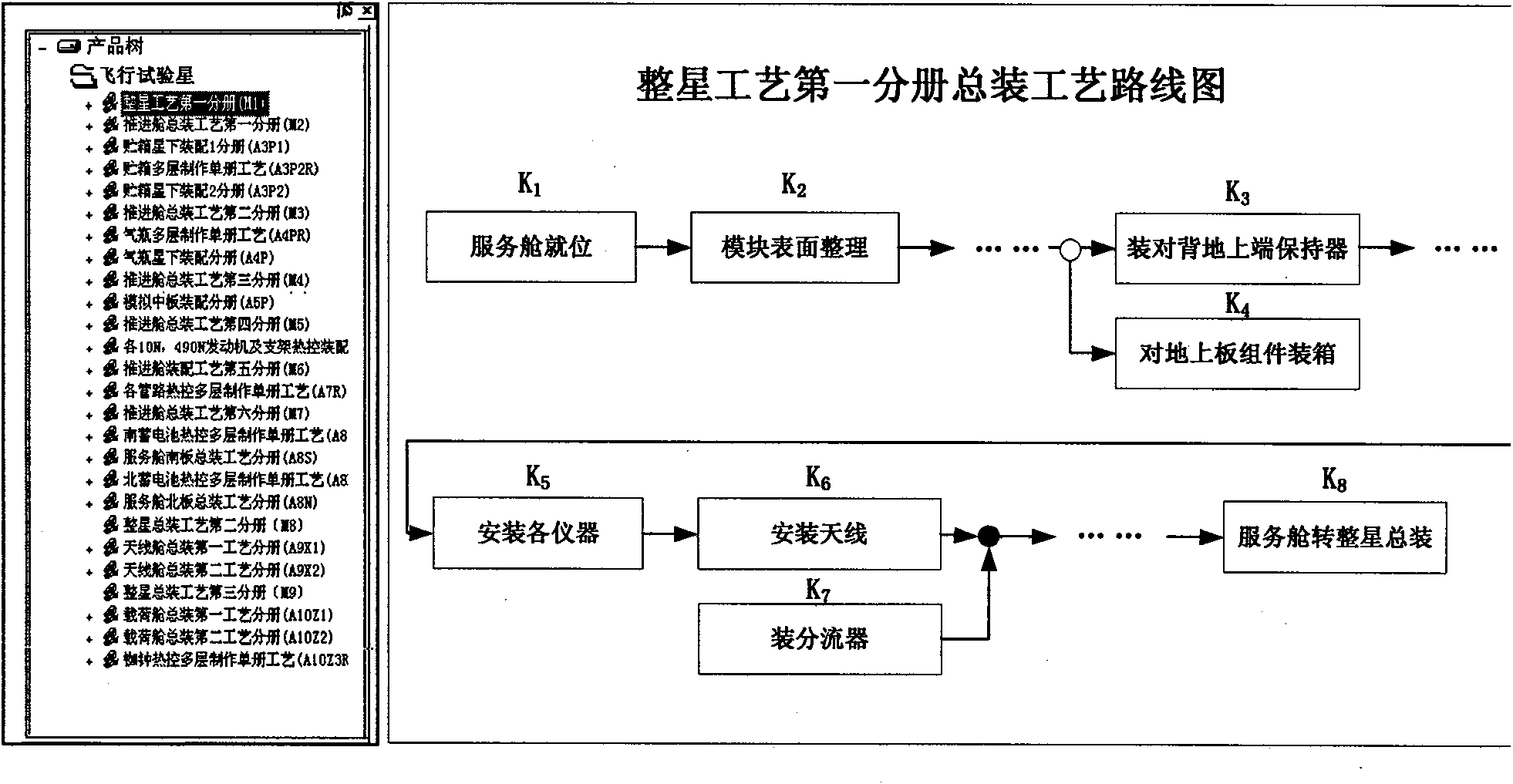

[0030] Provides basic geometry tools for drawing flowcharts (analog visio). By dragging and dropping, the drawing of a simple flow chart can be realized. There are two types of diagrams to be drawn here: the technical flow chart of the assembly process and the roadmap of the assembly process. The tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com