Computer auxiliary assembly process control method facing to manual assembly

A computer-aided assembly process technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of poor system flexibility, assembly process control methods have not been reported, and product assembly process on-site control is rare. , to achieve the effect of time progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

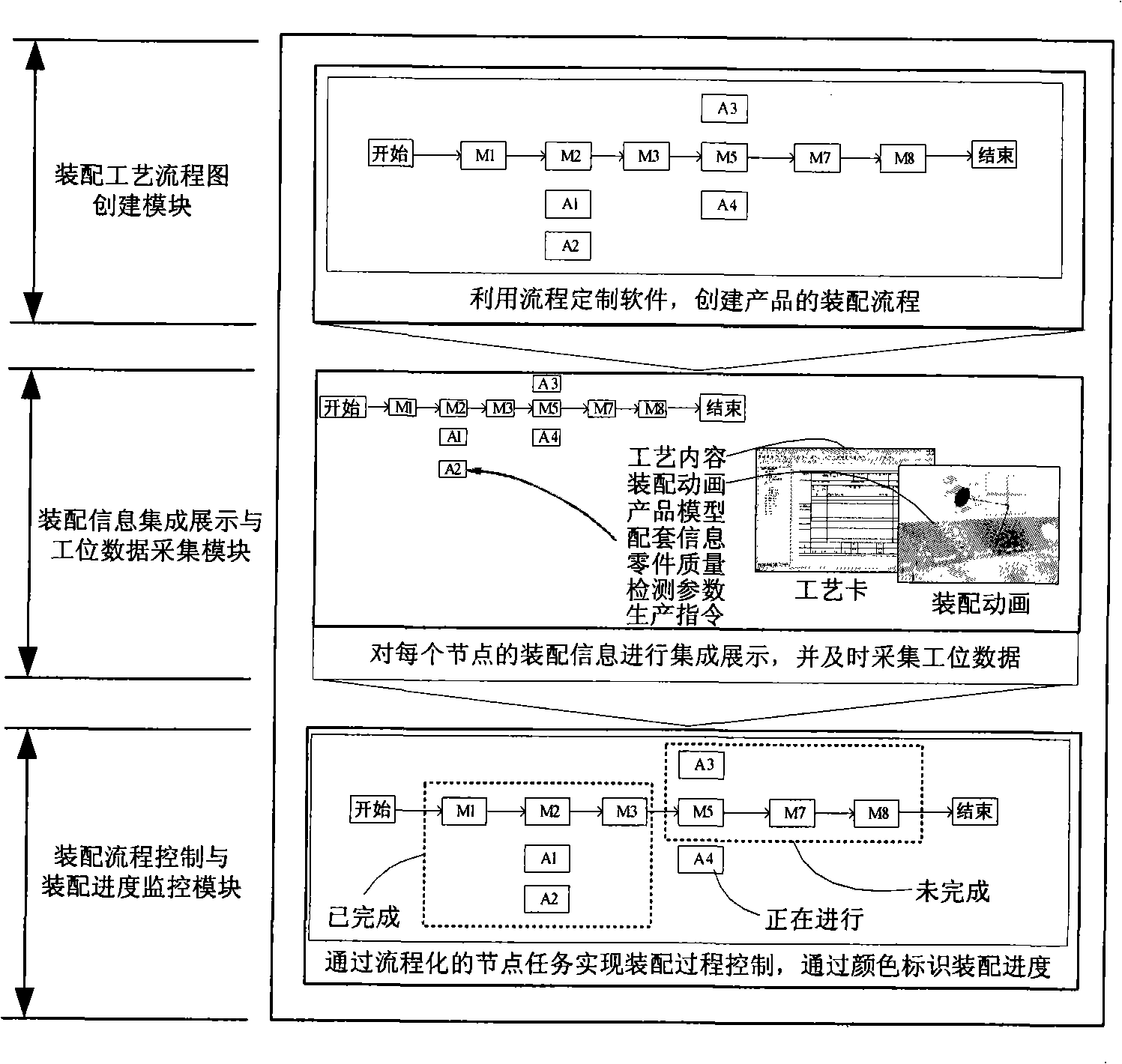

[0027] 1. Computer-aided assembly process control method for manual assembly

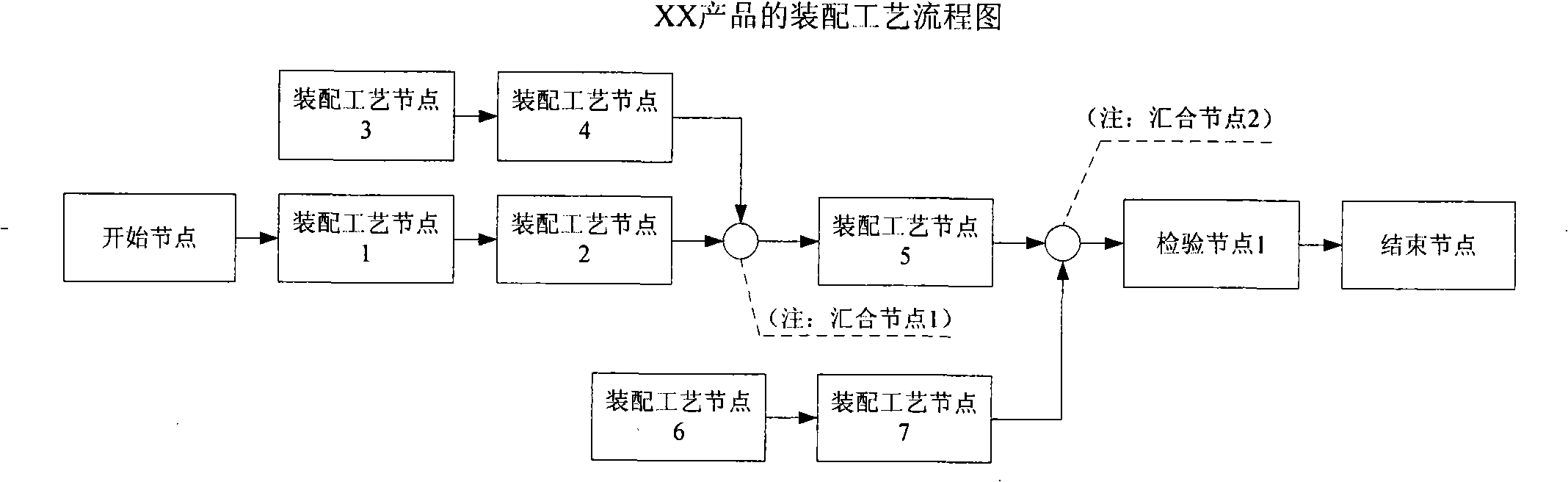

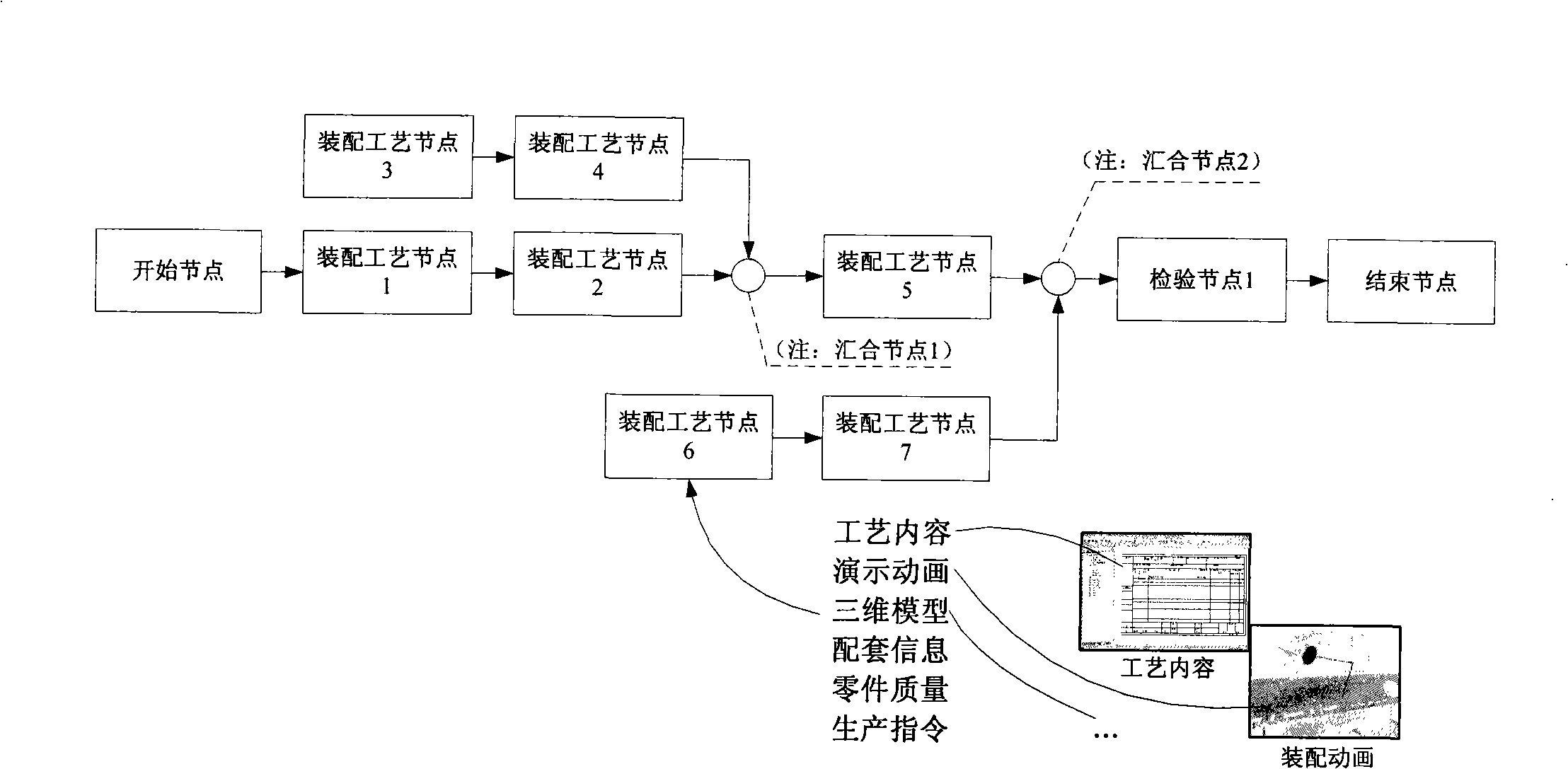

[0028] For each specific model of product, a streamlined assembly process flow chart consisting of a series of assembly nodes is generated. The manual assembly process control of the product is transformed into the control of a series of assembly nodes, and the assembly process control of the product is realized through the control of the time schedule, technical status and assembly quality of the assembly nodes. The computer-aided assembly process control method for manual assembly mainly realizes the control of the following assembly nodes:

[0029] 1) Control through the setting of key points

[0030] For the assembly of complex products, process designers always divide the whole product into several parts, and then further divide each part into several components. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com