Device and method for measuring infiltration characteristic of vacuum air-pressure infiltration method

A technology of vacuum air pressure and vacuum pumping device, which is applied in the field of measurement and can solve the problems of fast impregnation speed and difficult measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

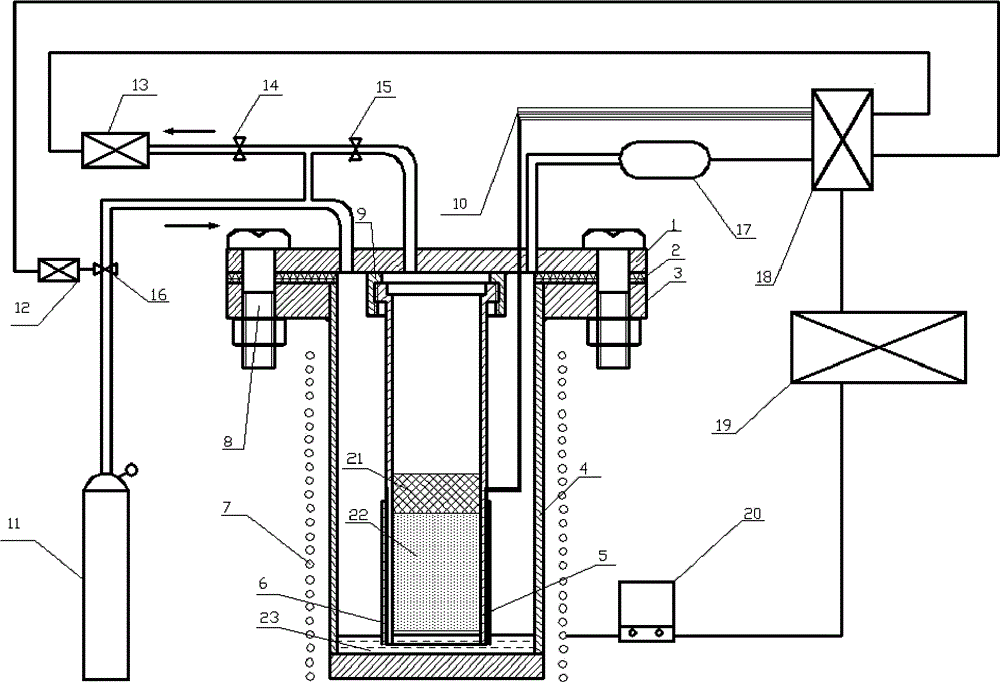

[0026] Refer to attached figure 1 , The device for measuring the infiltration characteristics of the vacuum pressure infiltration method in this embodiment includes an infiltration device, a heating control device, a vacuum device 13, a gas storage tank 11, a gas flow control device 12 and a data acquisition device.

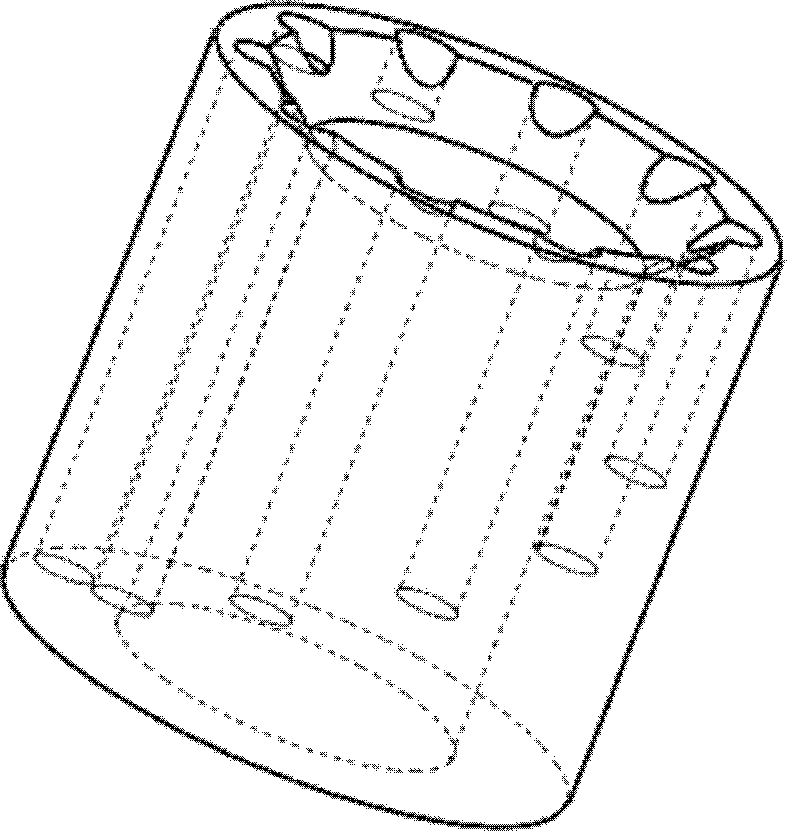

[0027] The infiltration device includes a crucible 4, a seepage chamber cover 1, an infiltration chamber 5 and a collar 6; a flange 3 is fixedly welded to the mouth of the crucible, and a metal graphite winding pad 2 is placed between the flange and the seepage chamber cover , in order to play a sealing role, the flange plate and the seepage chamber cover are fixedly connected by fastening bolts 8 . The infiltration chamber is a cylindrical shell structure with openings at both ends. The infiltration chamber is installed in the crucible. One end of the infiltration chamber is connected to the cover of the infiltration chamber through a quick joint 9. The quick jo...

Embodiment 2

[0035] In this embodiment, the device for measuring the infiltration characteristics of the vacuum air pressure infiltration method is the same as that in Example 1, and the method steps for measuring the infiltration characteristics of the vacuum air pressure infiltration method are:

[0036] Step 1: Prepare a prefabricated body whose shape can be attached to the inner wall of the infiltration chamber. In this embodiment, a cylindrical preformed body with a diameter equal to the diameter of the infiltration chamber is prepared; the preformed body is inserted into the end of the infiltration chamber near the bottom of the crucible, And the inner wall of the impregnation chamber attached to the preform is coated with graphite powder to ensure that the preform is closely attached to the inner wall of the impregnation chamber, and the position of the preform in the impregnation chamber corresponds to the installation position of the collar, so as to facilitate The thermocouple in ...

Embodiment 3

[0040] In this embodiment, the device for measuring the infiltration characteristics of the vacuum air pressure infiltration method is the same as that in Example 1, and the method steps for measuring the infiltration characteristics of the vacuum air pressure infiltration method are:

[0041] Step 1: Prepare a prefabricated body whose shape can be attached to the inner wall of the infiltration chamber. In this embodiment, a cylindrical preformed body with a diameter equal to the diameter of the infiltration chamber is prepared; the preformed body is inserted into the end of the infiltration chamber near the bottom of the crucible, And the inner wall of the impregnation chamber attached to the preform is coated with graphite powder to ensure that the preform is closely attached to the inner wall of the impregnation chamber, and the position of the preform in the impregnation chamber corresponds to the installation position of the collar, so as to facilitate The thermocouple in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com