Technique for nanometer grade super smooth processing gallium phosphide wafer

A processing technology, gallium phosphide technology, applied in metal processing equipment, manufacturing tools, grinding devices, etc., can solve the problems of complex processing technology and low processing quality of gallium phosphide, save processing time, simplify processing procedures, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

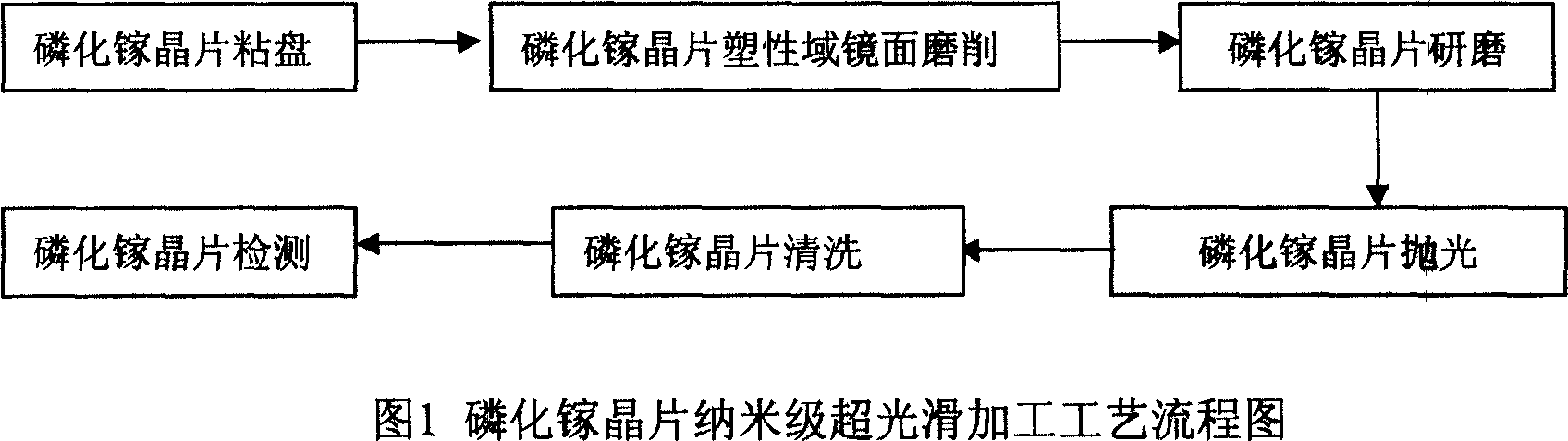

[0025] 1. First round the gallium phosphide ingot, and then slice it;

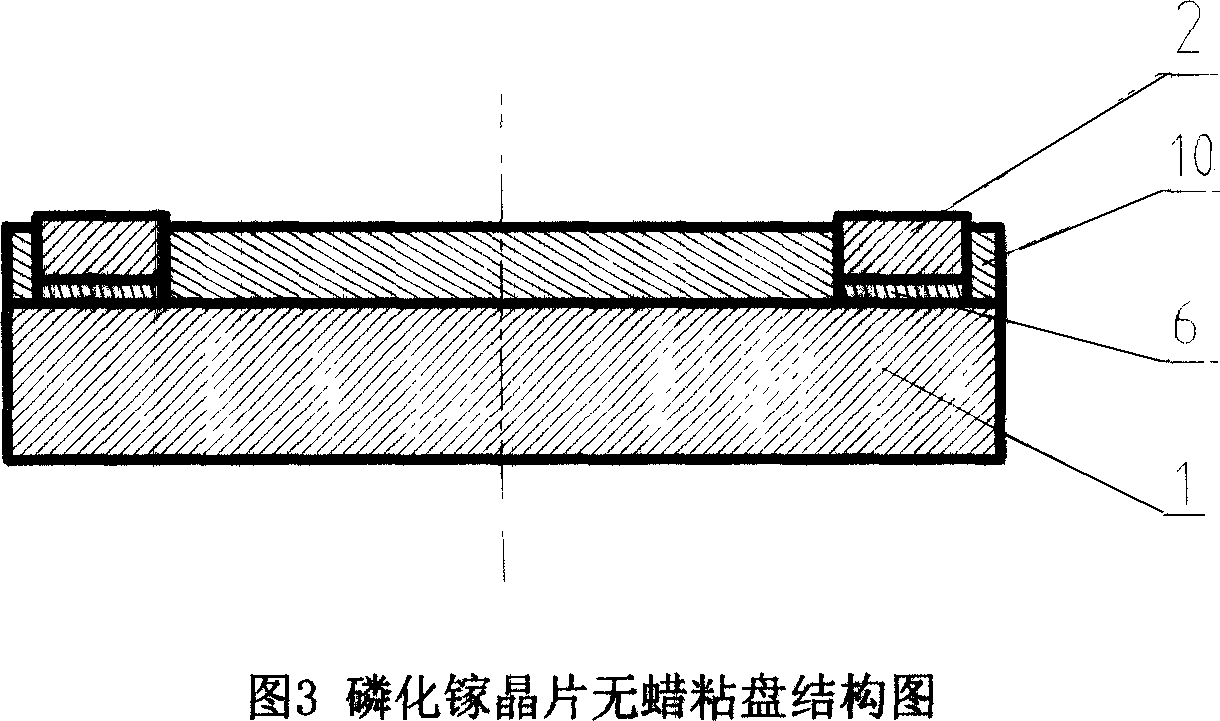

[0026] 2. Adsorb the gallium phosphide wafer into the carrier plate;

[0027] 3. On a high-rigidity grinding machine, use a low feed rate to perform plastic domain mirror grinding on gallium phosphide wafers;

[0028] 4. On a precision surface grinding machine, use a tin-lead alloy grinding disc, and use gallium phosphide micron-scale grinding liquid prepared with chromium oxide powder, olive oil, and kerosene, and grind for 10 minutes to obtain a mirror grinding effect;

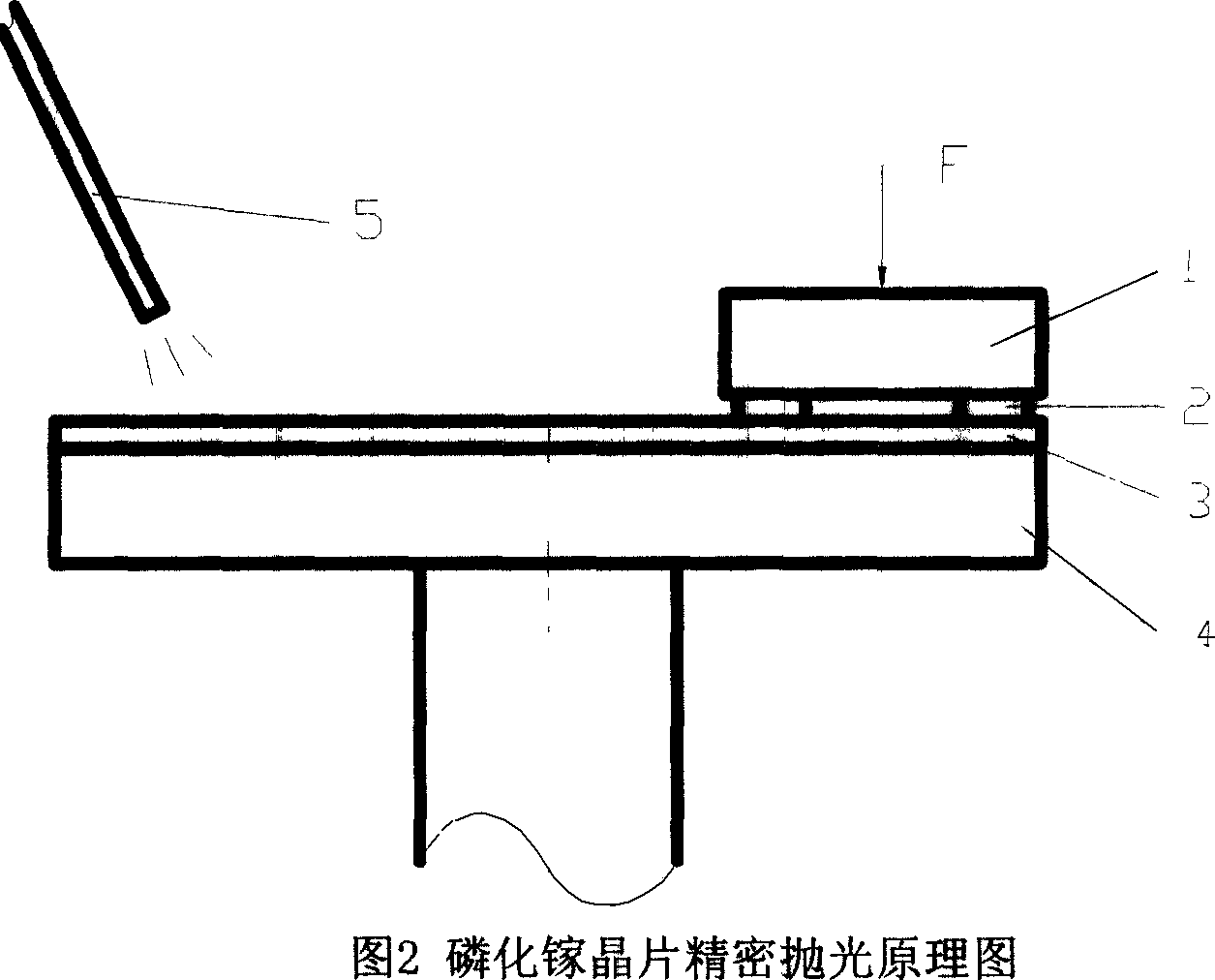

[0029] 5. On a precision surface grinding machine, use a gallium phosphide wafer nanoscale polishing solution composed of ammonium dichromate, polyoxyethylene amide, deionized water, etc. to perform global planar chemical mechanical polishing to obtain a gallium phosphide wafer nanoscale Surface roughness.

[0030] Gallium phosphide wafer polishing process parameters are:

[0031] Polishing disc speed: 70 rpm

[0032] Rotational spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com