RFID garment process guidance system and guidance method thereof, and production management system and method

A technology for guiding systems and processes, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of prolonging production time, lengthening delivery time, forgetting operation steps, etc., to improve production efficiency and reduce rework rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

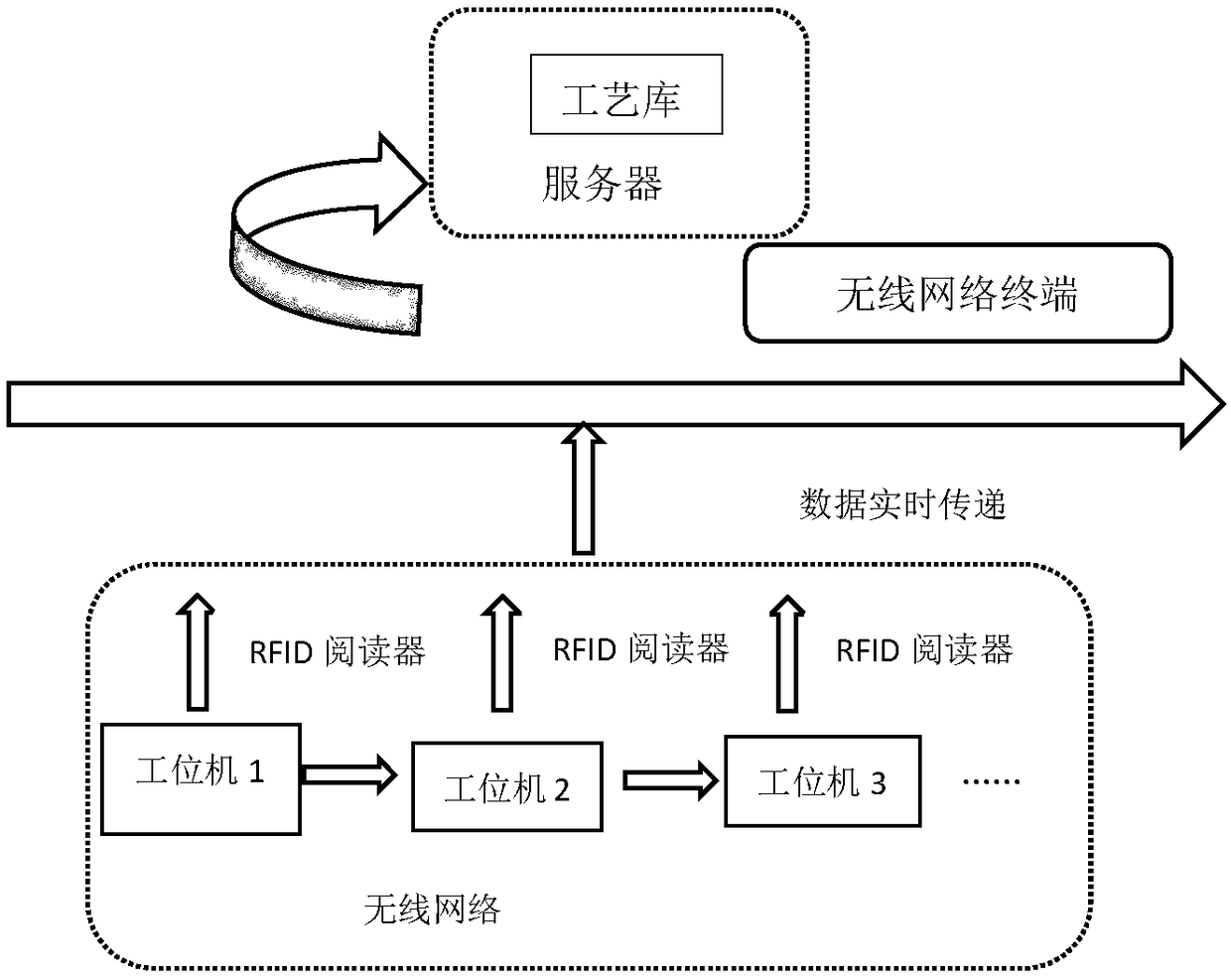

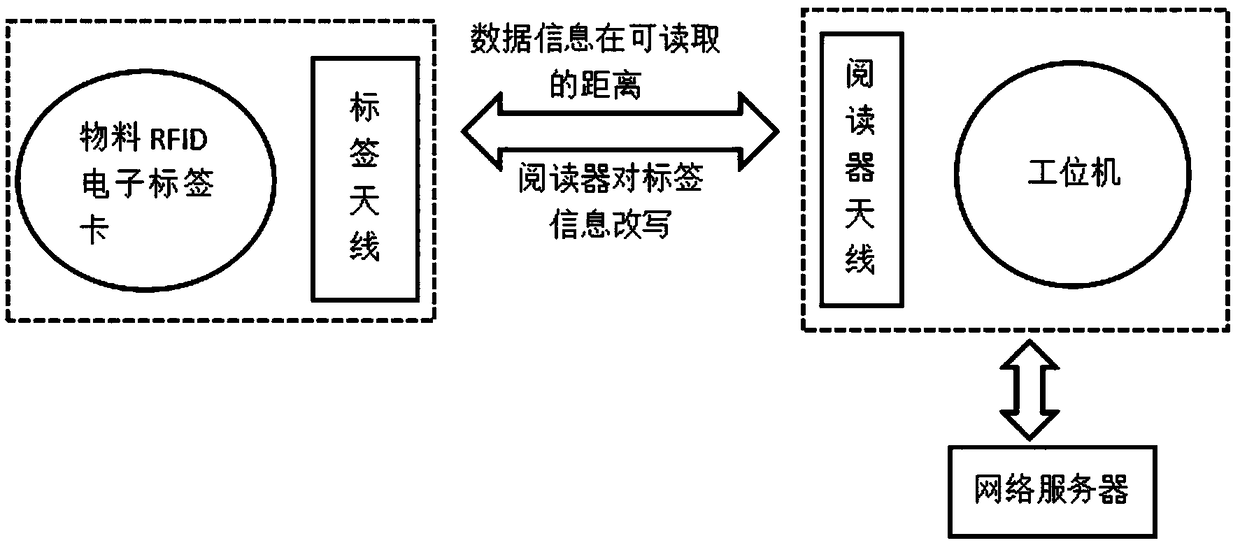

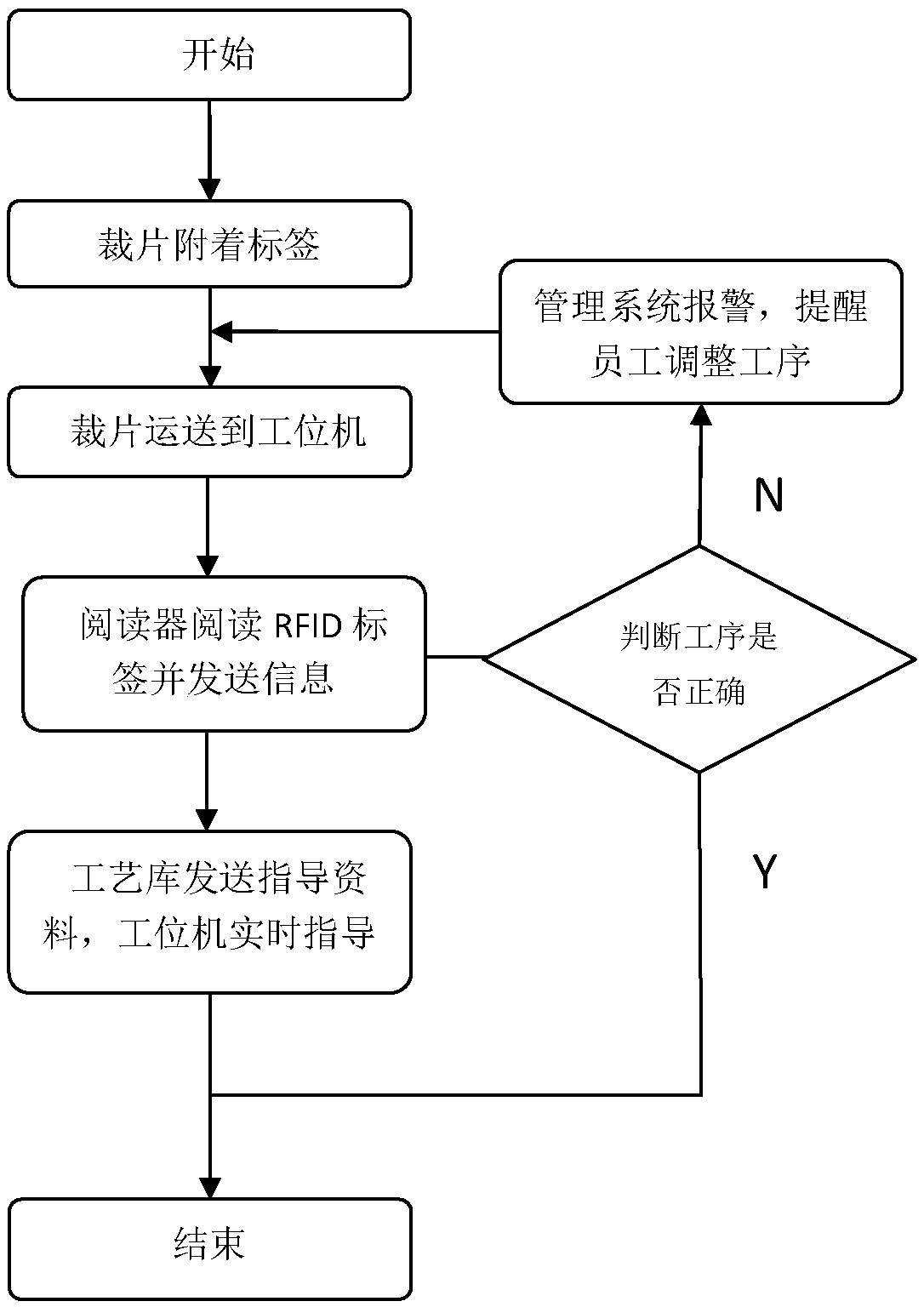

[0037] refer to figure 1 , figure 2 As shown, a clothing process guidance system based on RFID technology proposed by the present invention includes RFID electronic tags (ie, material RFID electronic tags), a workstation network server, and information transmission between various components is realized through the network environment of the workshop. Yes, the network environment described above is divided into wired or wireless. For the sake of cleanliness and safety in the workshop, generally wireless networks are widely used.

[0038] The RFID electronic tag adopts a composite IC card with faster recognition speed, higher recognition reliability, larger data capacity, repeated erasure and simultaneous batch recognition, and is attached to each qualified cut piece. Information about the pieces is written in the RFID electronic tag, such as order number, name of the piece, process parameters, inspector of the piece, etc., and the RFID electronic tag has a unique code.

[0...

Embodiment 2

[0046] This embodiment provides a production management system that adopts the garment process guidance system based on RFID technology described in Embodiment 1. This production management system combines the garment process guidance system based on RFID technology with the MES system of the enterprise to generate The management system used for enterprise production management realizes the sharing of information and resources and the real-time connection of information. The MES system obtains production data through form entry or external file import; or ERP / APS interface capture and other methods. The RFID reader described in this embodiment can not only transmit label information, guide the process operation of the current operation point, but also record production tasks, connect external PLC communication, and collect data from the current station equipment. The network server also includes a production data analysis module and an information query module. The production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com