Compressor adaptive performance curve generation method

A curve generation and compressor technology, applied in the field of compressors, can solve problems such as unfavorable operation of long-distance natural gas pipeline network optimization, deterioration of compressor performance, and wrong judgment of compressor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

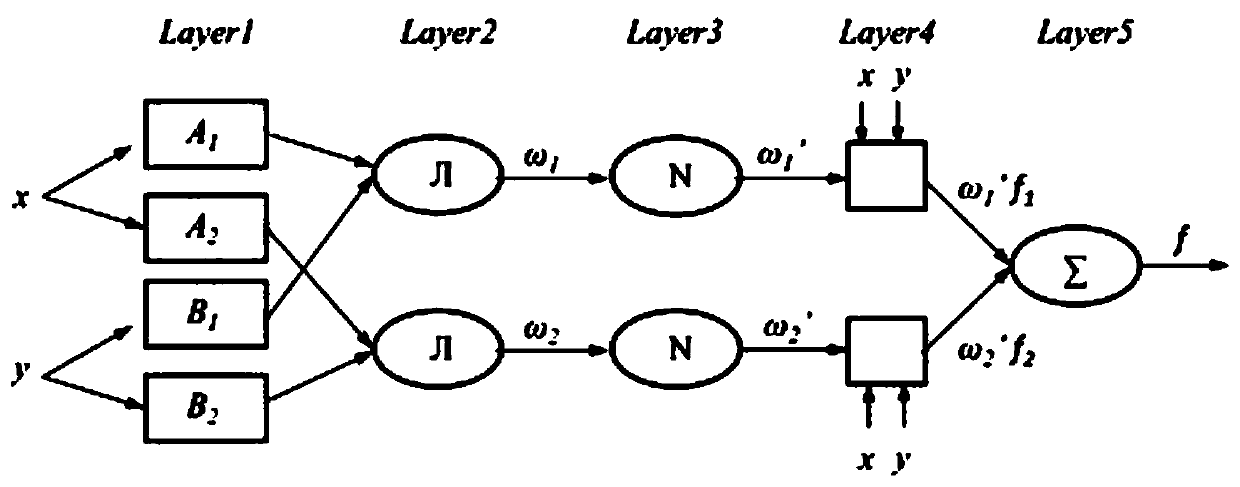

[0057] A method for generating an adaptive performance curve of a compressor of the present invention comprises the following steps:

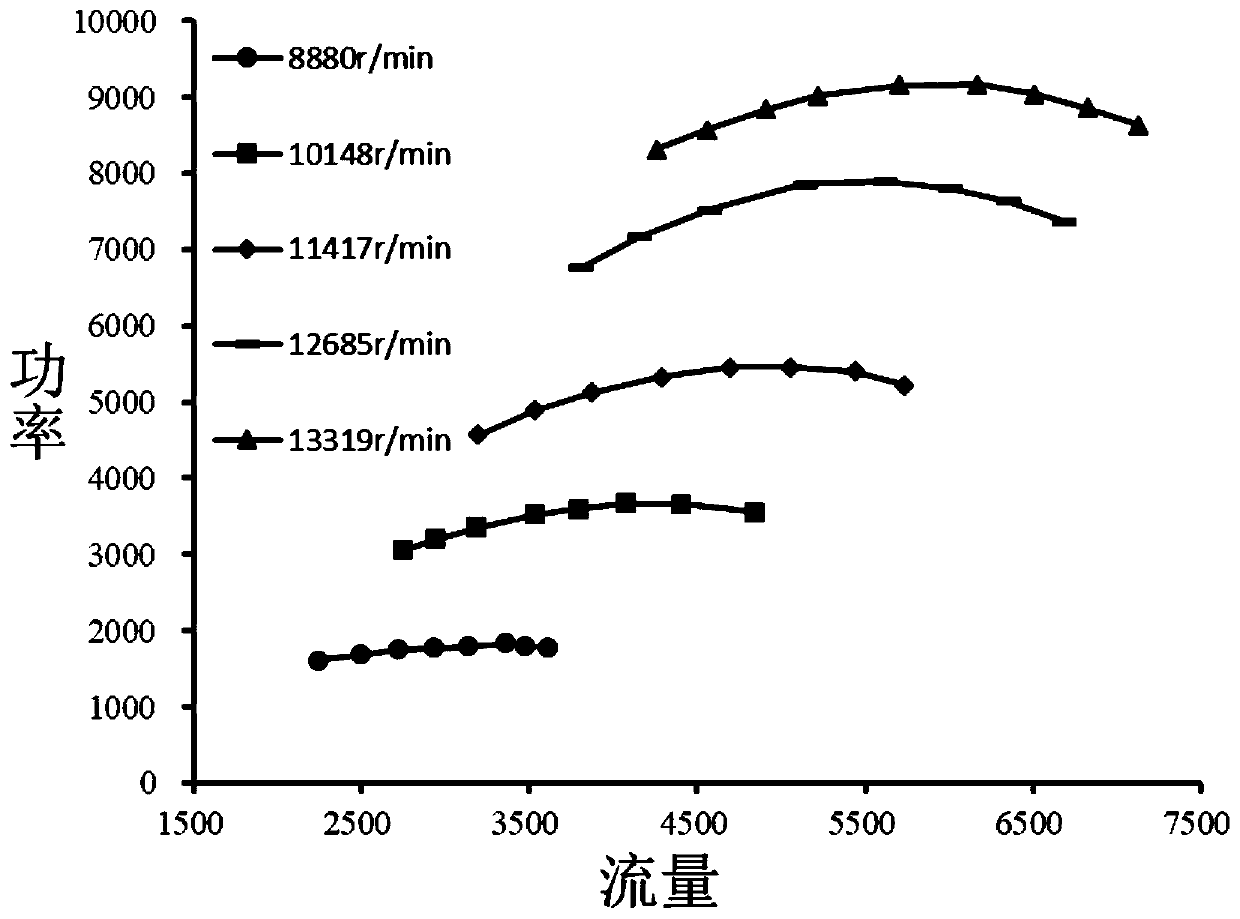

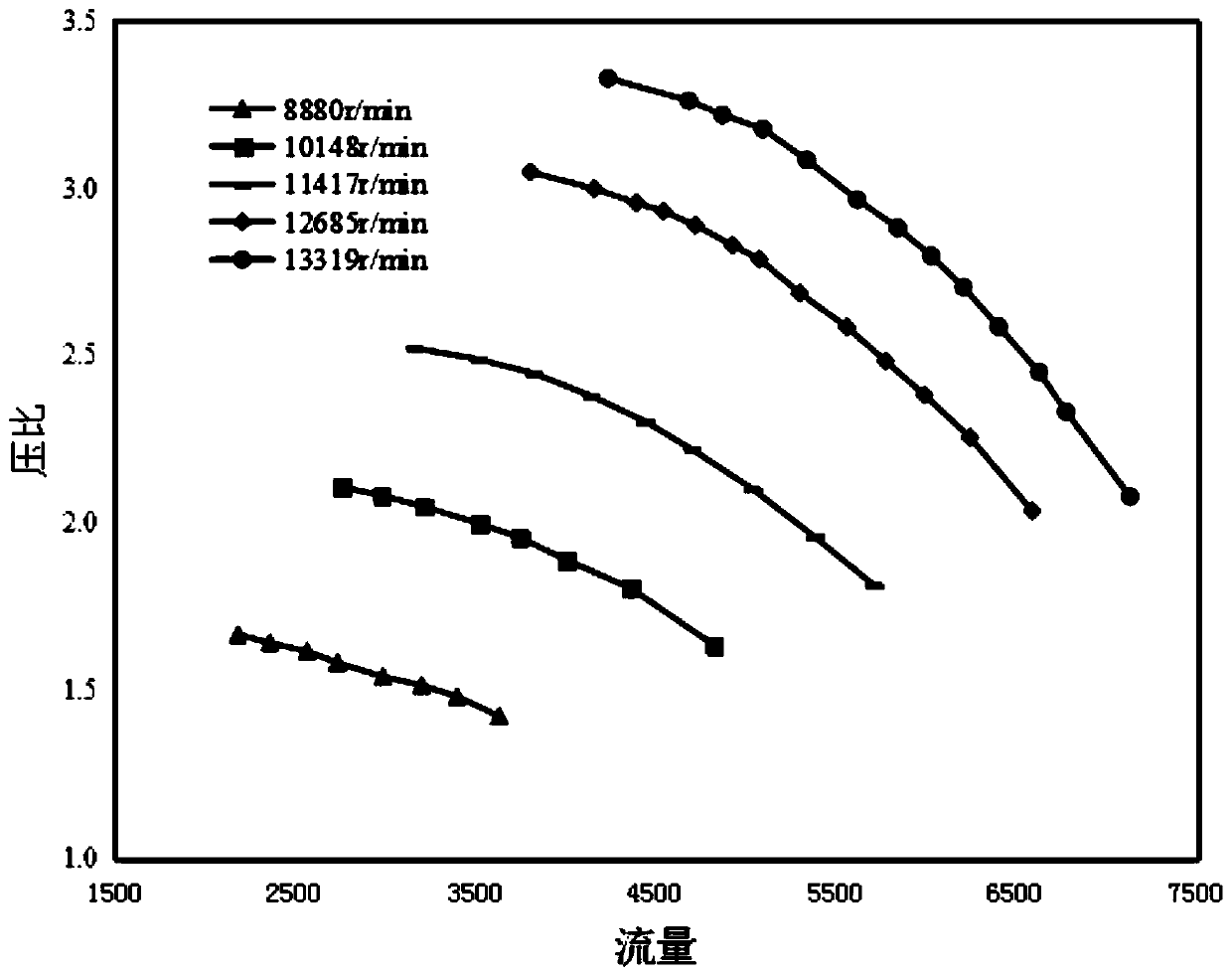

[0058] Step S1, by comparing with the actual working conditions, the rotation speeds selected in the embodiment are 13319r / min, 12685r / min, 11417r / min, 10148r / min, 8880r / min, and the relevant design performance parameters are converted into numerical forms;

[0059] Step S2, using similarity theory to obtain theoretical performance parameters under actual working conditions;

[0060] The performance conversion method adopted by the similarity theory is an approximate similarity transformation method;

[0061] The performance conversion method is divided into:

[0062] When the pressure ratio is less than 2.5, use the multi-transform algorithm;

[0063] When the pressure ratio is greater than 2.5, the half-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com