Hand-held power tool

A hand-held machine tool and tool technology, applied in the direction of motor tools, manufacturing tools, wrenches, etc., can solve the problems of high measurement technology costs and adjustment technology costs, and achieve the effects of low price, reduced manufacturing time, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

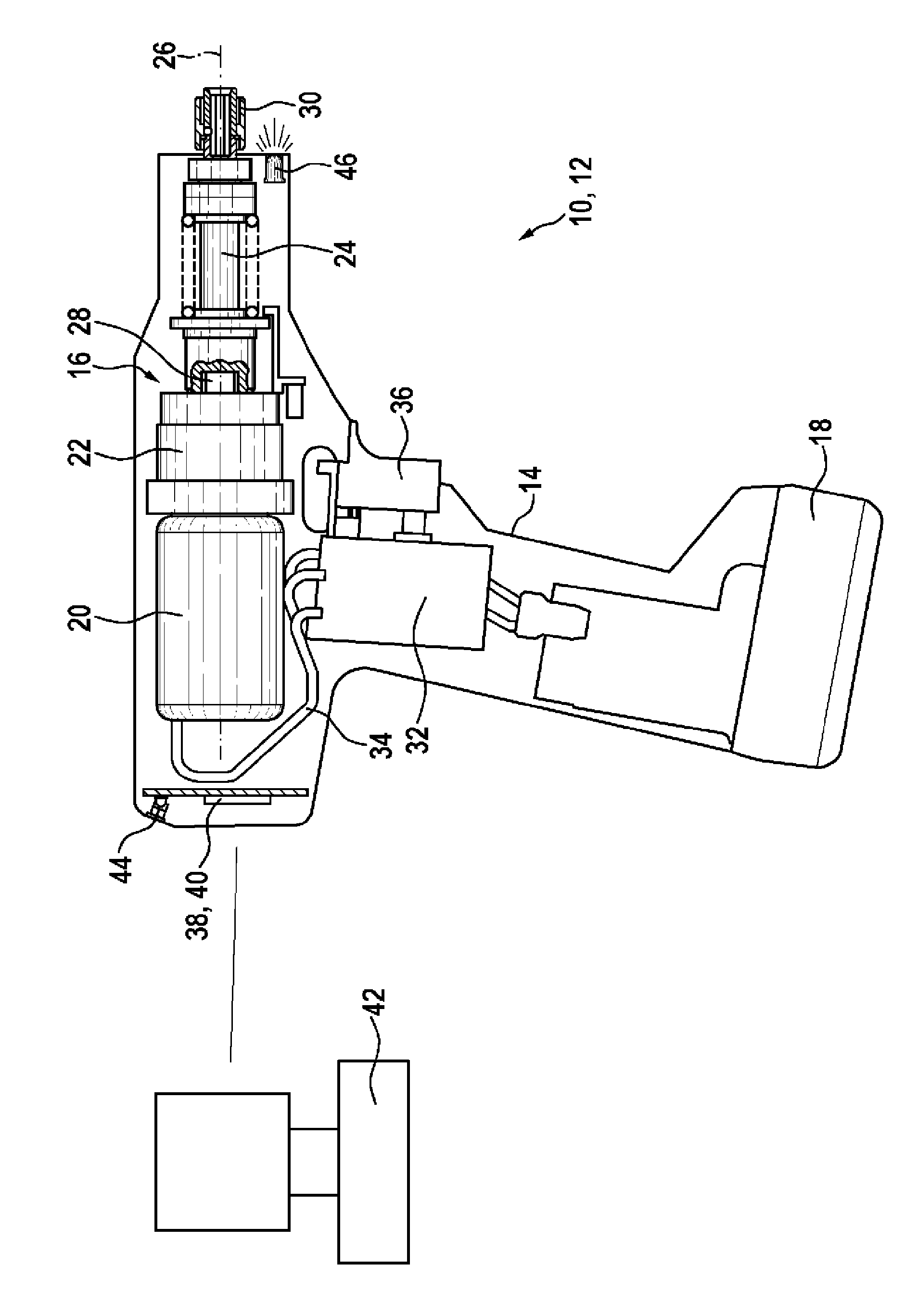

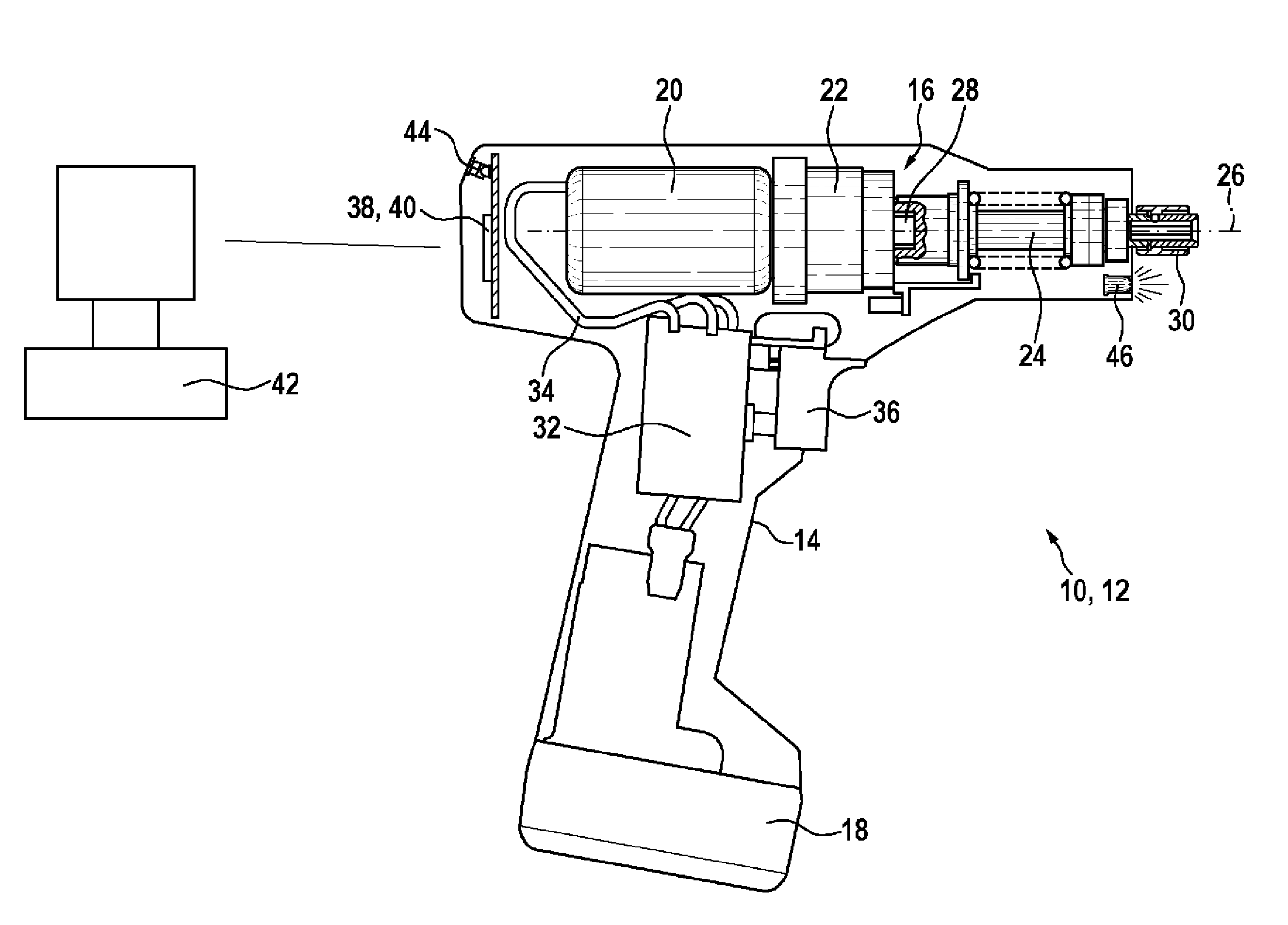

[0028] The drawing shows a hand-held power tool 12 designed as a screwing device 10 . The screwing device 10 is designed in the shape of a pistol and has a housing 14 which is divided into a body part for accommodating a drive 16 and a handle part at its lower end which accommodates a battery module 18 exchangeably. Hand-held power tool 12 is thus designed as a battery-operated electric hand-held power tool, more precisely as an electric drill. The drive 16 of the handheld power tool 12 has an electric motor 20 configured as an electric motor, a downstream transmission 22 and a coupling 24 configured as a disconnect coupling (slip coupling) from which In this respect, the transmission 22 is placed behind.

[0029] Instead of a pistol-shaped configuration of the screwing device 10 , it can also be designed as a stick-shaped screwing device or as an angled screwing device.

[0030] An electric motor 20 configured as an electric motor, a transmission 22 and a coupling 24 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com