Hand-push two-station mowing device

A lawn mowing device and two-station technology, applied in cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor intensity, low degree of automation, low work efficiency, etc., and achieve good adaptability, Simple mechanism and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

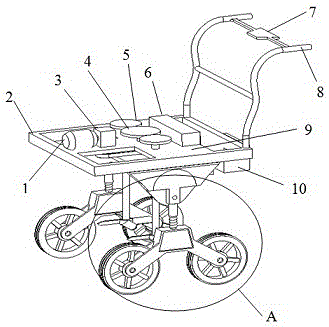

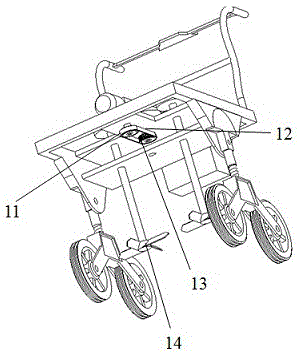

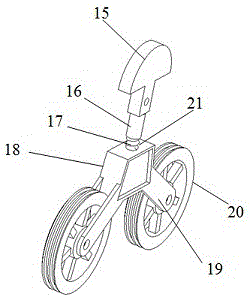

[0016] According to figure 1 As shown in -3, before the work, the operator pushes the device to a relatively flat grassland, and needs to use the tools in the tool box 10 to check whether the various parts of the device are fixed reliably, and then the main frequency conversion motor is started by the control panel 7 and passed Control the frequency to adjust the speed of the main frequency conversion motor 1. The determination of the main frequency conversion motor speed needs to consider the thickness and density of the grass layer and the flatness of the ground. The belt pulley 11 and the belt 12 drive the large pulley 13 to rotate, and the large pulley 13 drives the drive gear 4 to rotate through the shaft passing through the T-shaped plate 9. The drive gear 4 meshes with the mowing gear 5, and the mowing gear 5 drives the mowing Knife 14 rotates, thus completes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com