Multi-track vertical-shaft planetary mixer

A planetary mixer and vertical shaft technology, applied in the field of concrete mixing, can solve the problems of inability to adjust the rotational speed, insufficient mixing, short mixing time, etc., and achieve the effects of shortening mixing time, improving mixing efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments.

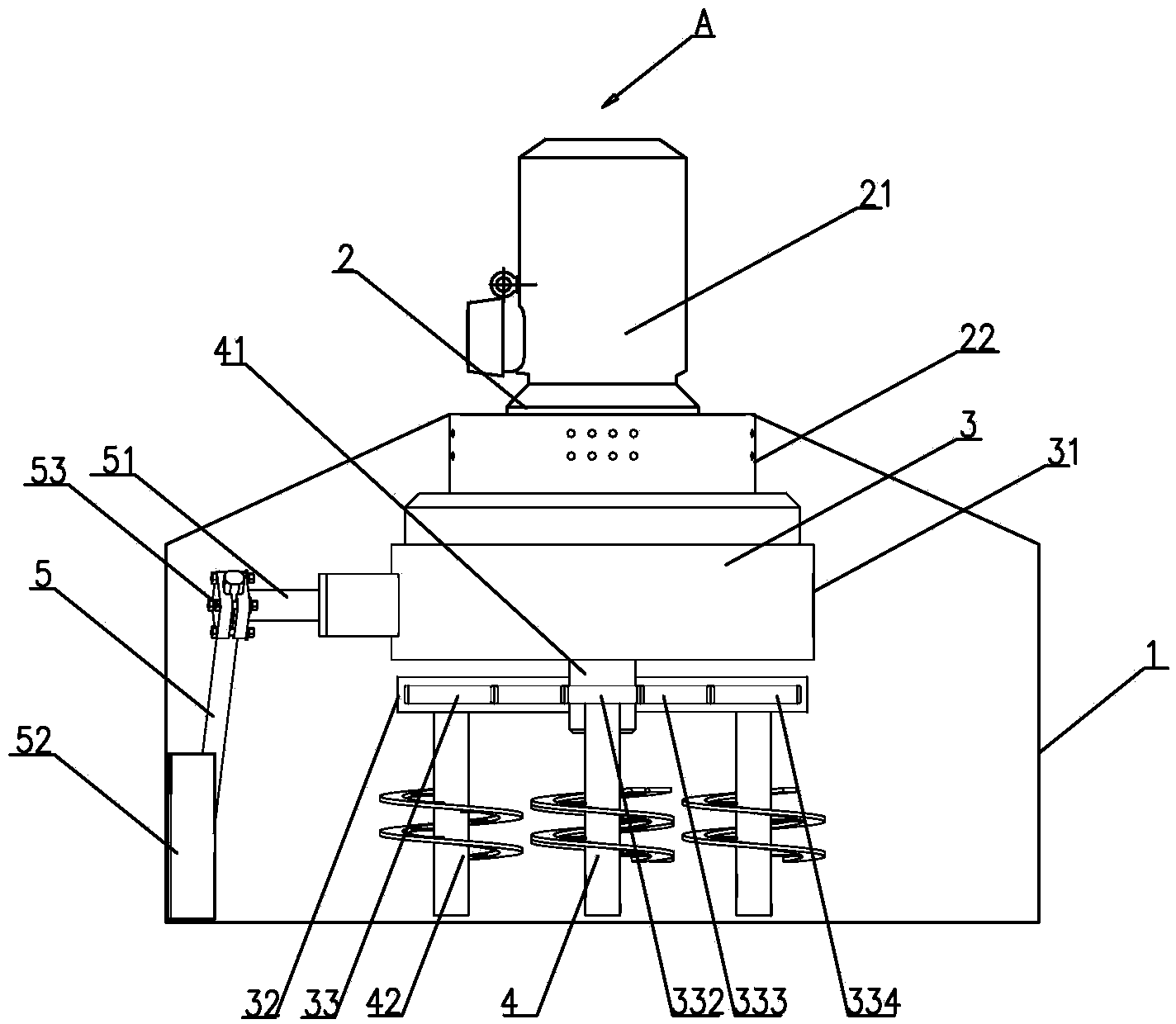

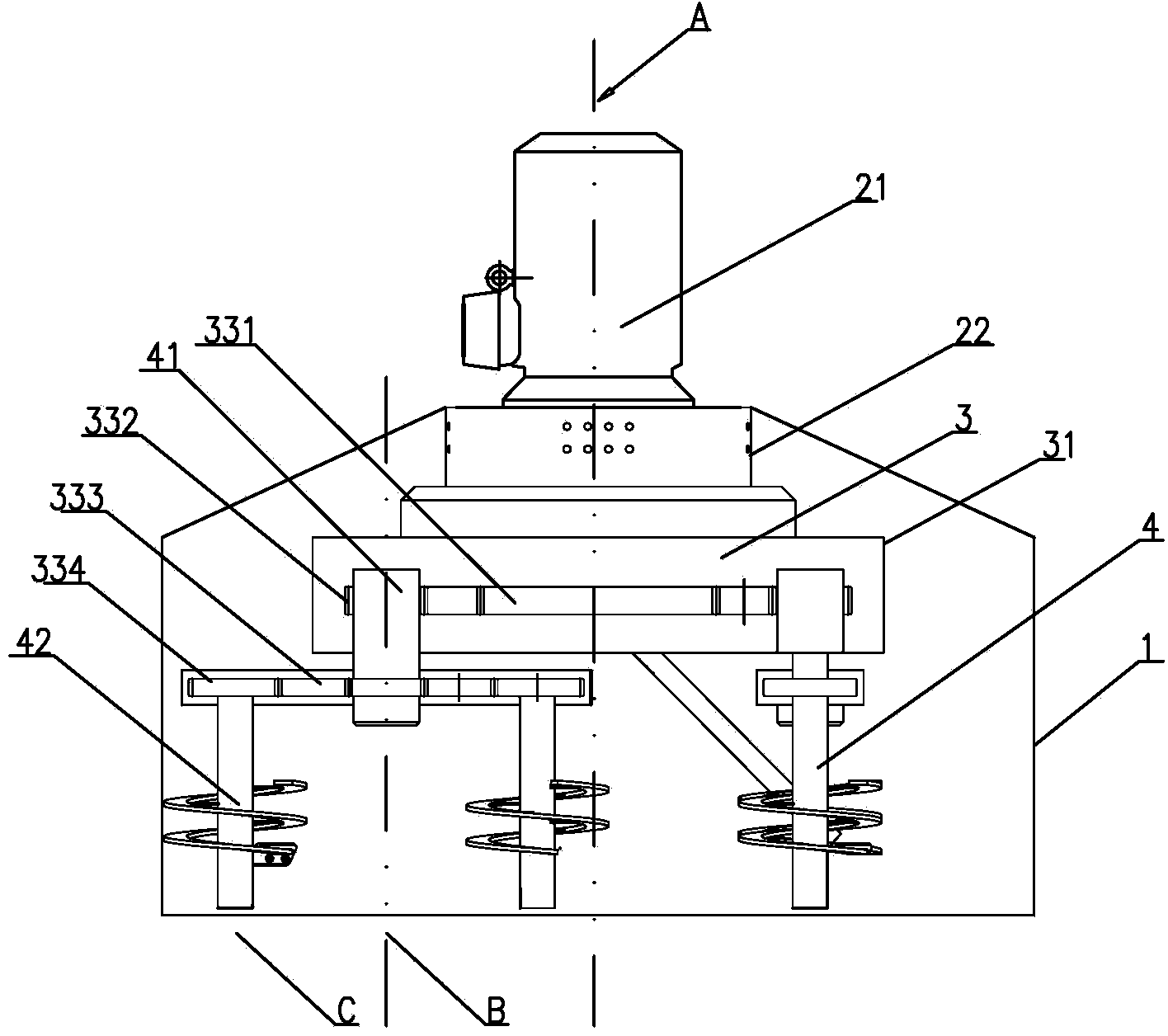

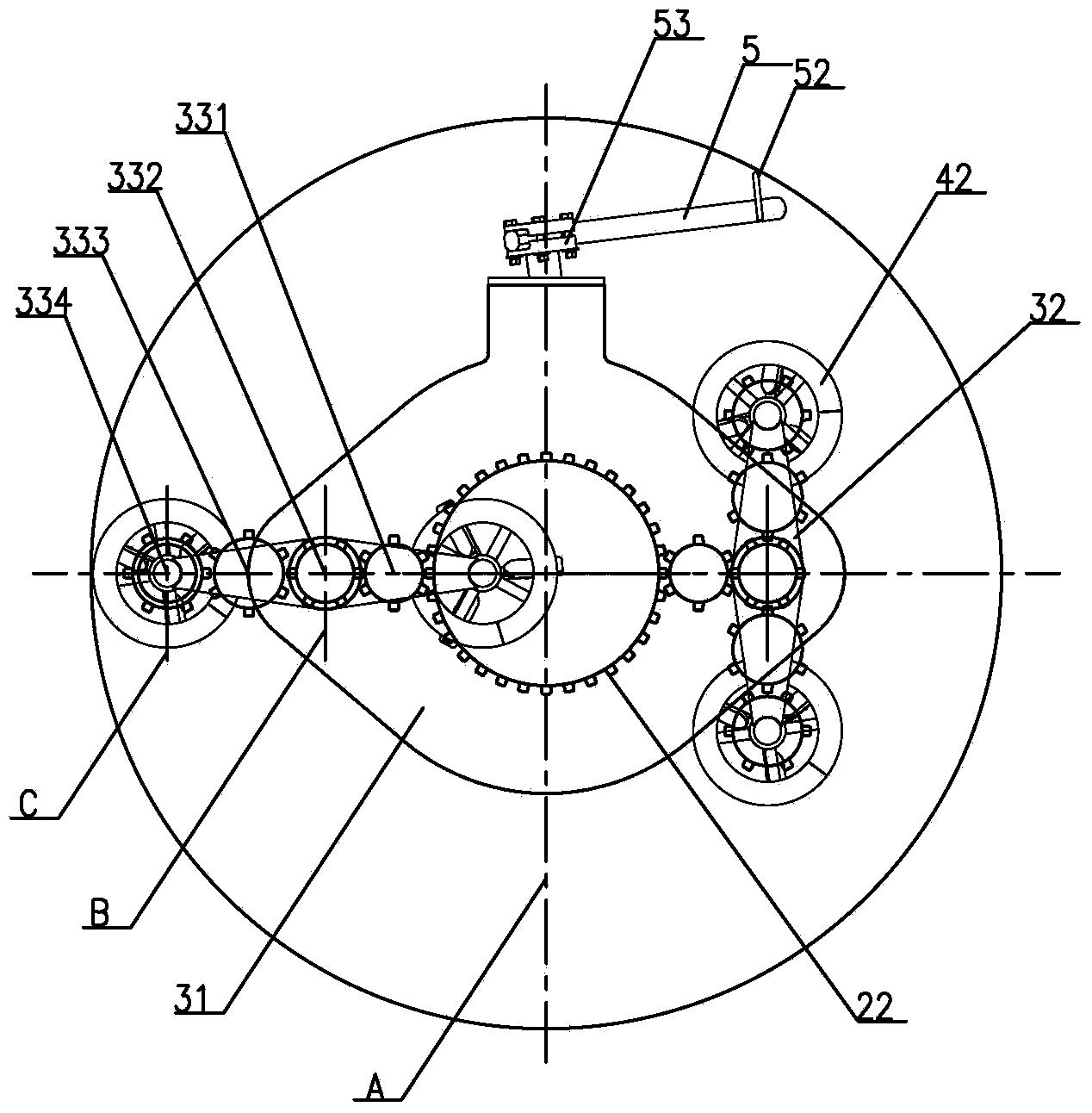

[0022] refer to Figure 1 to Figure 5 As shown, a multi-track vertical shaft planetary mixer includes a cylinder body 1, a driving mechanism 2, a transmission mechanism 3, a stirring mechanism 4 and a scraping mechanism 5, wherein the driving mechanism 2 includes a driving motor 21 and a reducer 22, and the transmission mechanism 3 Including a first-stage revolving turntable 31, a second-stage revolving turntable 32 and a gear set 33, the stirring mechanism 4 includes a stirring arm 41 and a stirring shaft 42, wherein the first-stage revolving turntable 31 and the second-stage revolving turntable 32 can be provided with two or more;

[0023] The driving mechanism 2 arranged on the cylinder body 1, the transmission mechanism 3 and the stirring mechanism 4 arranged in the cylinder body 1, the driving mechanism 2 drives the stirring mechanism 4 to rotate through the transmission mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com