Absorption type rotating wheel gas purifying device

A gas purification device and adsorption technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large volume and weight, and achieve the effects of small volume, flexible use, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

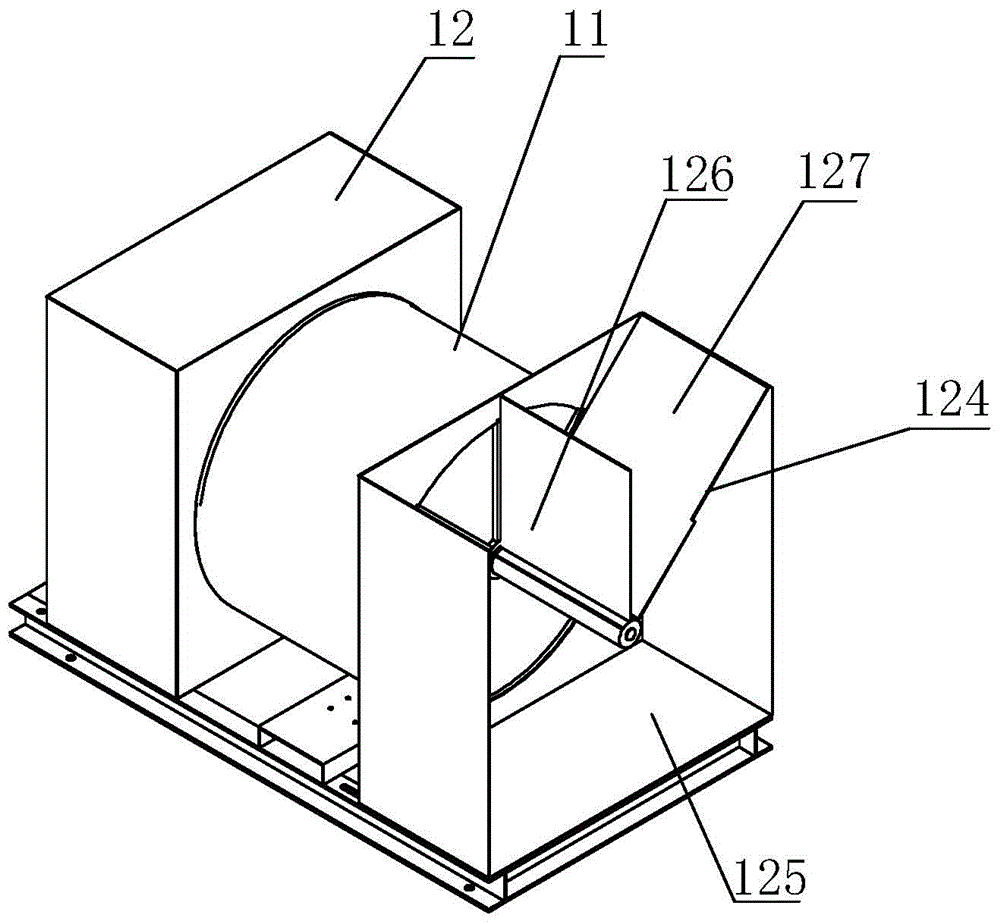

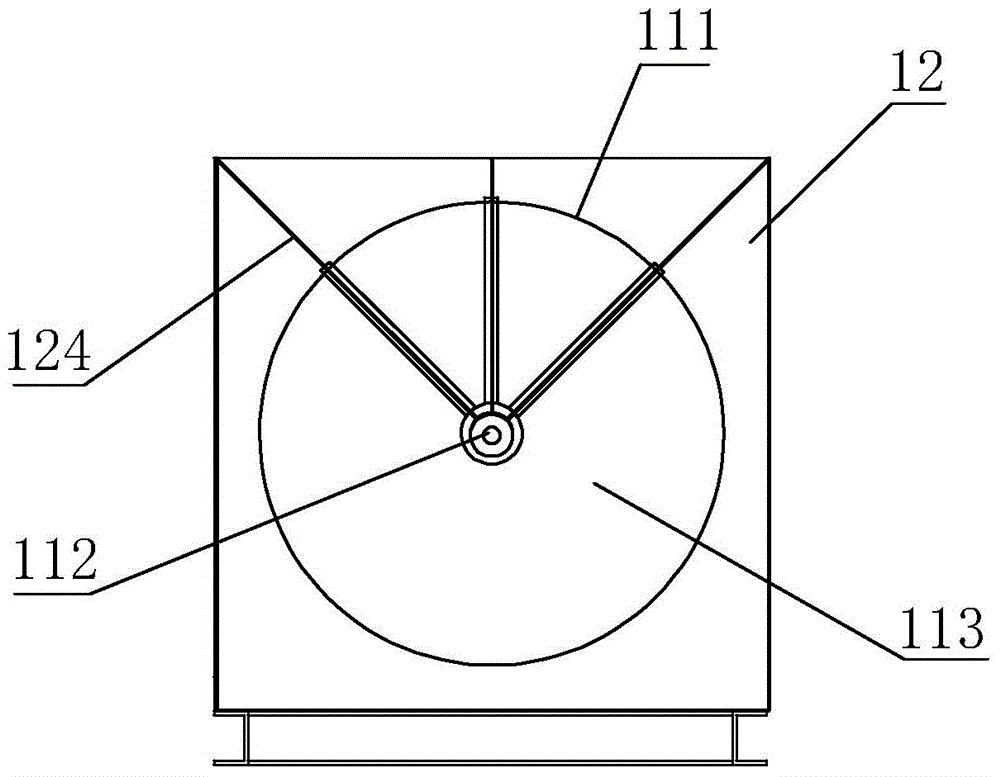

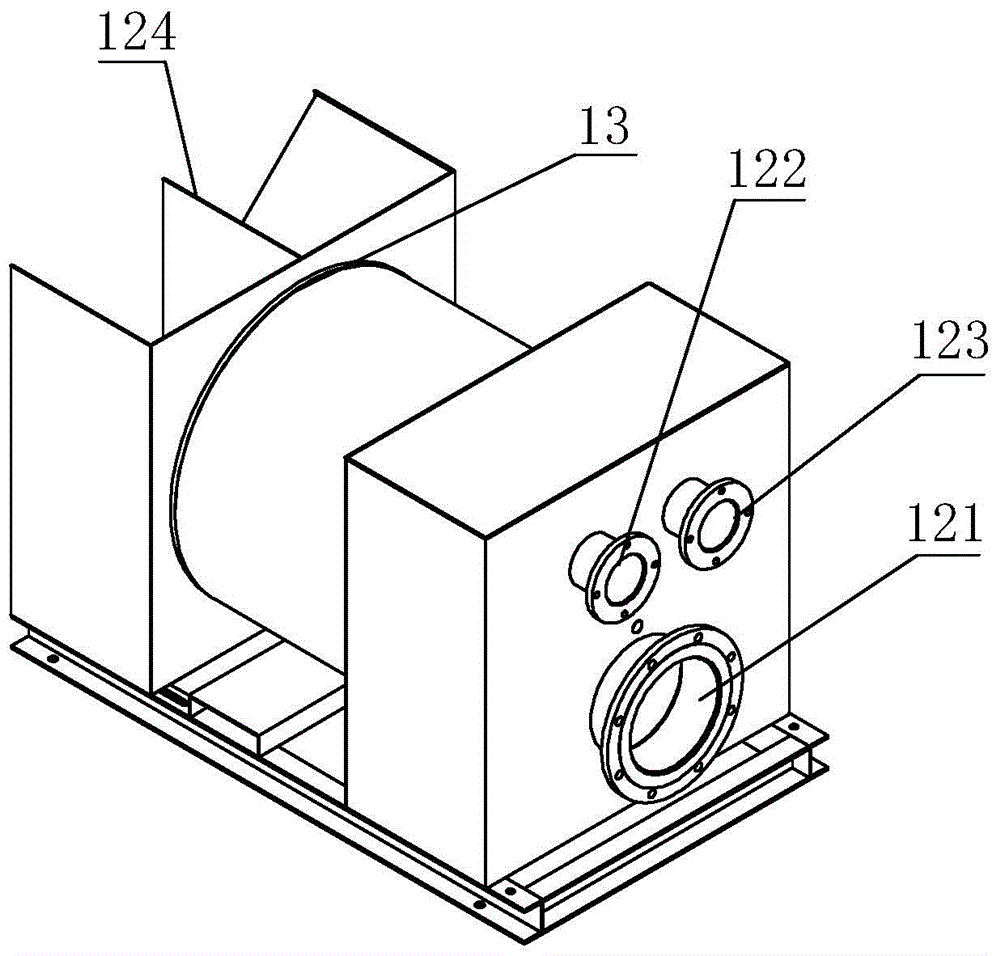

[0032] Such as Figure 1-3 As shown, an adsorption runner gas purification device includes a runner 11 and two gas separation boxes 12 . The runner 11 includes a housing 111, a mandrel 112 and an adsorption material 113. The housing 111 rotates around the mandrel through a mechanical drive. A shaft tube is set outside the mandrel 111. The adsorption material is filled in the housing. The adsorption material 113 is a whole honeycomb body. The gas passages in the honeycomb are arranged along the length of the shell. Two gas separation boxes 12 are respectively arranged on both sides of the runner 11. The gas separation box 12 includes a box body, and an inlet and outlet gas pipeline is connected to one side of the box body. figure 1 Shown in the figure is an adsorption gas inlet 121, a desorption gas inlet 122 and a cooling gas inlet 123, and a circular opening with the same diameter as the runner shell is opened on the other side of the box, and the box is divided into two par...

Embodiment 2

[0035] Such as Figure 4-8 As shown, an adsorption runner gas purification device includes an intermediate runner 21 and two gas separation boxes 22, and the two gas separation boxes 22 are respectively located on both sides of the intermediate runner 21. The runner 21 includes a cylindrical housing 211 , a mandrel 212 , a spacer 213 and an adsorption material 214 . The casing 211 is connected to the timing belt 3 and driven by a motor to rotate around the mandrel 212. A shaft tube is sheathed on the outside of the mandrel 212. The casing 211, the shaft tube and the spacer 213 are steel structural parts. There are multiple partitions 213, which are respectively arranged between the casing and the shaft tube along the axial direction of the casing 211, and divide the inner cavity of the casing 211 into 12 areas on average. Adsorption material 214 is embedded in each region, and adsorption material 214 is made up of multi-layer small pieces of activated carbon honeycomb body 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com