Separable transformer type double-stator brushless double-fed motor

A doubly-fed machine, transformer-type technology, applied in electrical components, electromechanical devices, etc., to achieve the effects of low cost, high reliability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

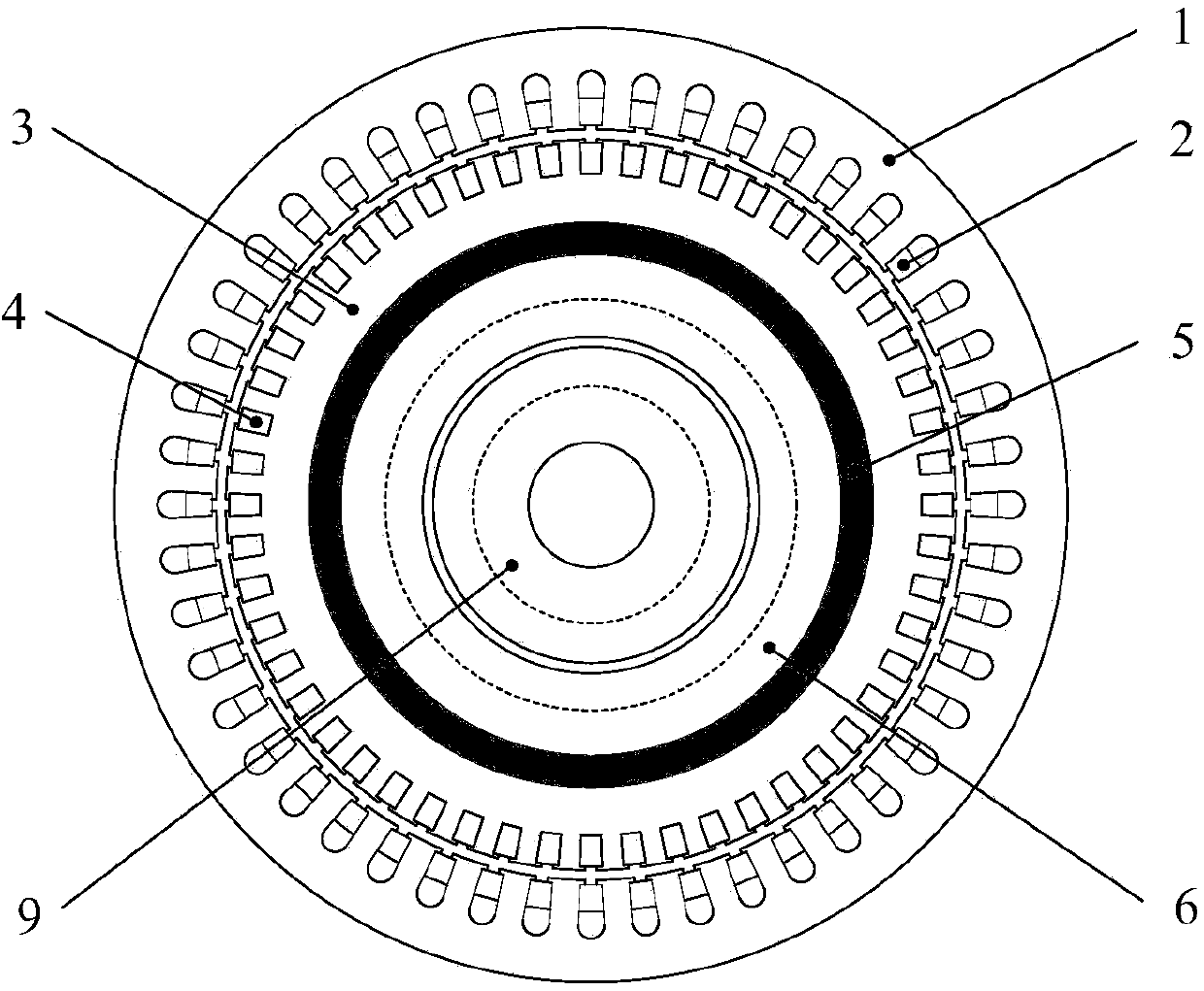

[0024] Such as figure 1 As shown, a separable transformer-type double-stator brushless double-fed motor includes an outer stator, a cup-shaped rotor, an inner stator, and a rotating shaft from the outside to the inside; the outer stator, the cup-shaped rotor, and the inner stator are coaxial and independent of each other. The rotor is fixed on the rotating shaft as the only mechanical port of the motor; an outer air gap is set between the outer stator and the cup-shaped rotor, and an inner air gap is set between the rotor and the inner stator;

[0025] The outer stator includes the outer stator core 1 and the outer stator winding 2 from the outside to the inside, and the outer stator core is made of laminated silicon steel sheets;

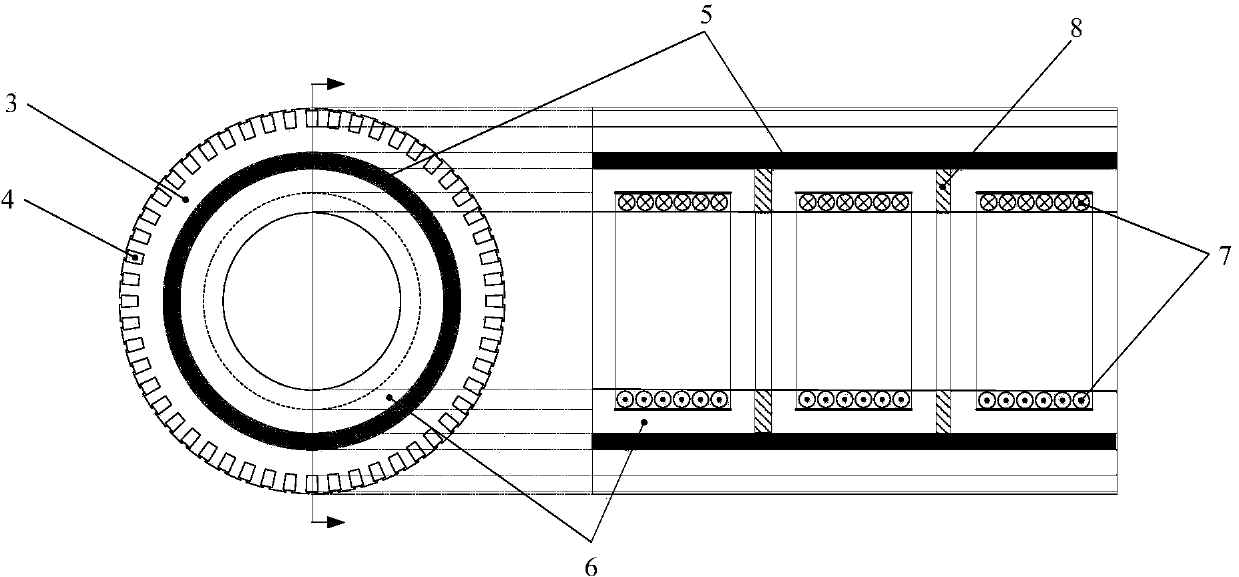

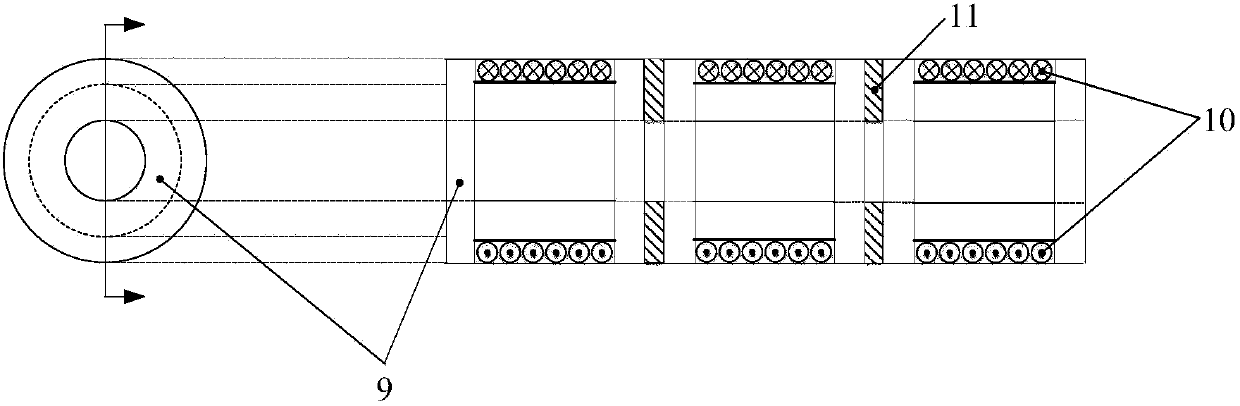

[0026] Such as figure 2 As shown, the cup-shaped rotor includes the rotor outer core 3, the rotor axial support 5 and the rotor inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com