Turbine blade fault test system and intelligent fault diagnosis method thereof

A technology for turbine blade and fault testing, applied in neural learning methods, biological neural network models, engine components, etc., can solve the problems of consuming a lot of manpower and material resources, not forming large-scale data sets, and lack of fault signal data sets, etc. Achieve the effect of rich database, high fault diagnosis accuracy and saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above subject of the present invention is limited to the following content. Without departing from the above idea of the present invention, various replacements or changes made according to common technical knowledge and customary means in this field shall be included in the scope of the present invention.

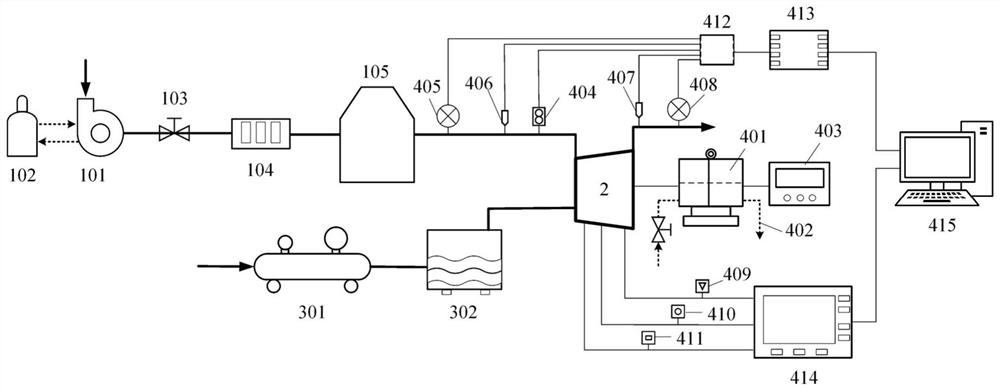

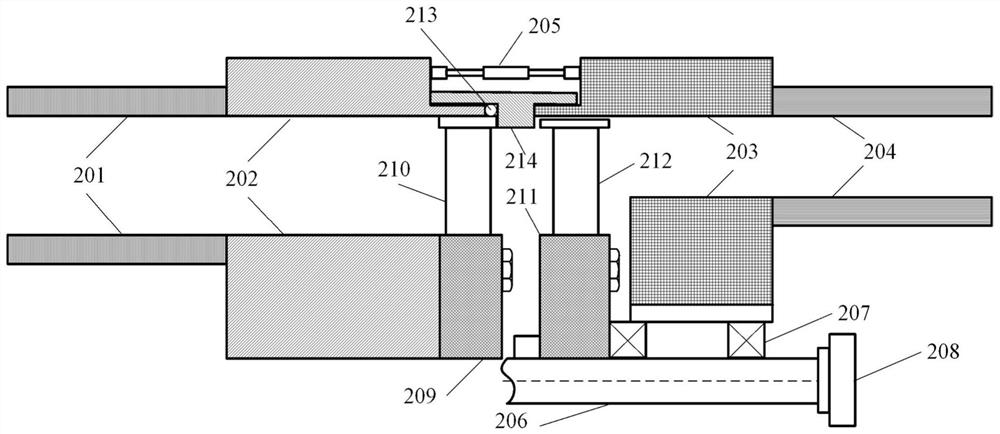

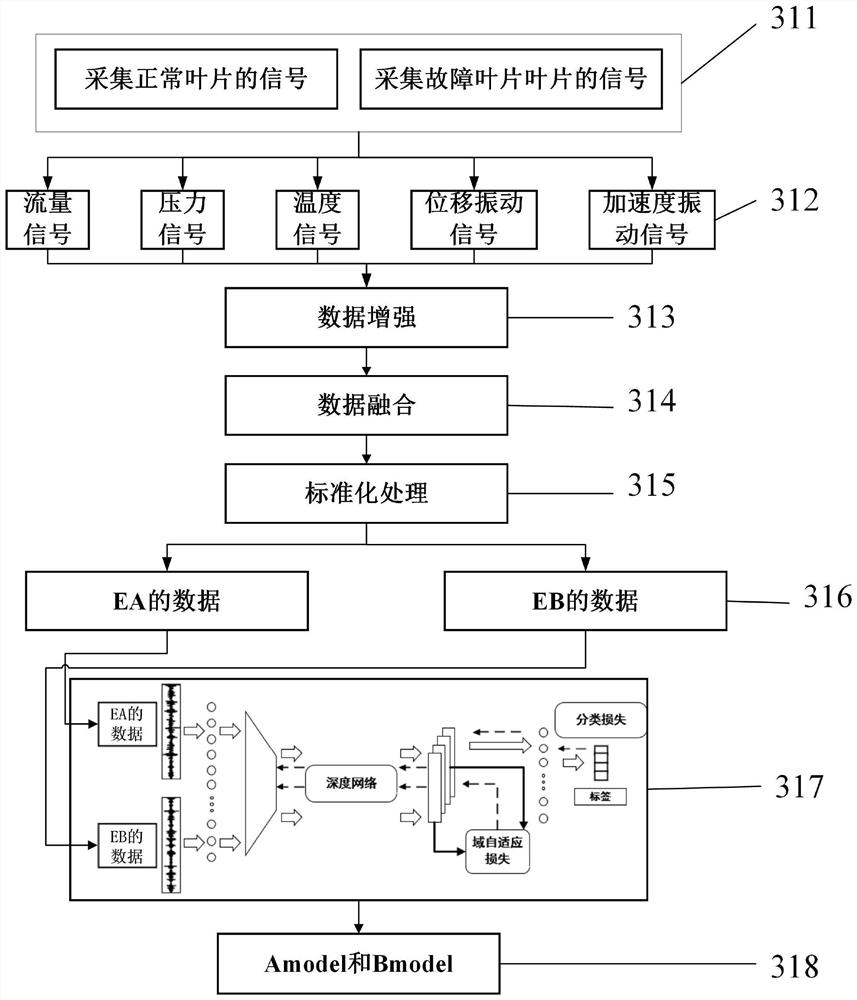

[0068] see Figure 1 to Figure 2 , a turbine blade fault testing system of the present invention includes an air supply system 1 , a turbine main system 2 , a lubrication system 3 and a measurement control system 4 . Among them, air supply system 1 includes blower 101, cooling water tank 102, control valve 103, heater 104, surge tank 105, etc.; turbine main system 2 includes intake section 201, intake cylinder 202, exhaust cylinder 203, exhaust section 204, tie rod 205, main shaft 206, bearing 207, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com