High energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder

A production equipment and nano powder technology, which is applied in the field of high-energy horizontal planetary ball milling Chinese medicine nano powder production equipment, can solve the problems of ball mill tank rotation, non-adjustable turnover speed, small ball mill tank volume, low work efficiency, etc., and achieve the elimination of material The effect of depositing image, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

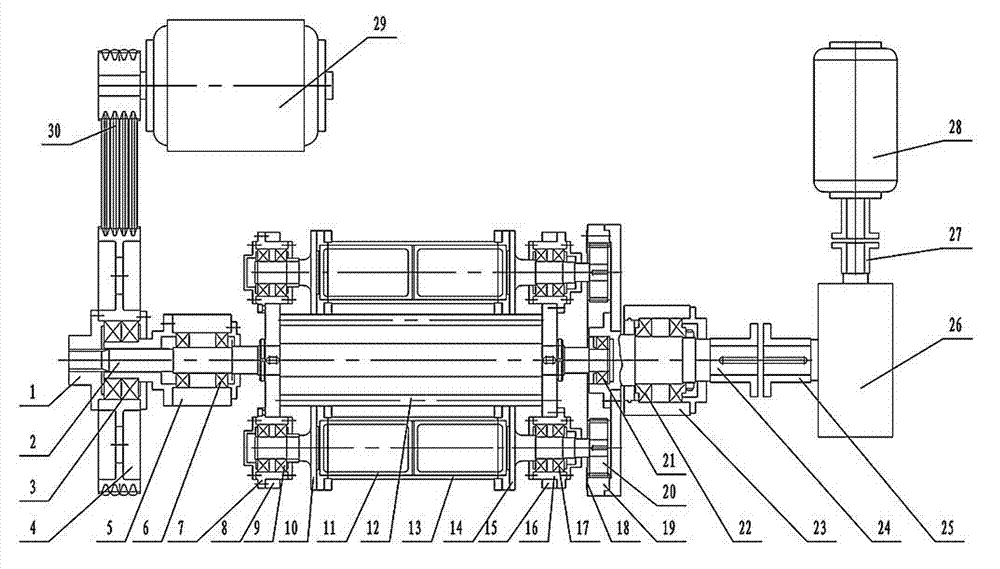

[0016] attached figure 1 Middle: spline sleeve 1, main shaft 2, first bearing 3, pulley 4, left support 5, second bearing 6, first bearing cup sleeve 7, left wheel disc 8, third bearing 9, left half shaft 10, Ball mill pot 11, pull rod 12, ball mill pot sleeve 13, right half shaft 14, right wheel disc 15, second bearing cup sleeve 16, fourth bearing 17, oil deflector ring 18, internal gear 19, planetary gear 20, fifth Bearing 21, the sixth bearing 22, right support 23, internal gear transmission shaft 24, first coupling 25, worm gear reducer 26, second coupling 27, secondary motor 28, main motor 29, transmission belt 30.

[0017] attached by figure 1 Shown: the equipment includes a main motor 29, a transmission belt 30, a pulley 4, a main shaft 2, a left wheel disc 8, a left half shaft 10, a right half shaft 14, a ball mill sleeve 13, a right wheel disc 15, a planetary gear 20, an inner Gear 19, internal gear transmission shaft 24, shaft coupling 25, worm gear reducer 26, au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com