Patents

Literature

181results about How to "Eliminate dead ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

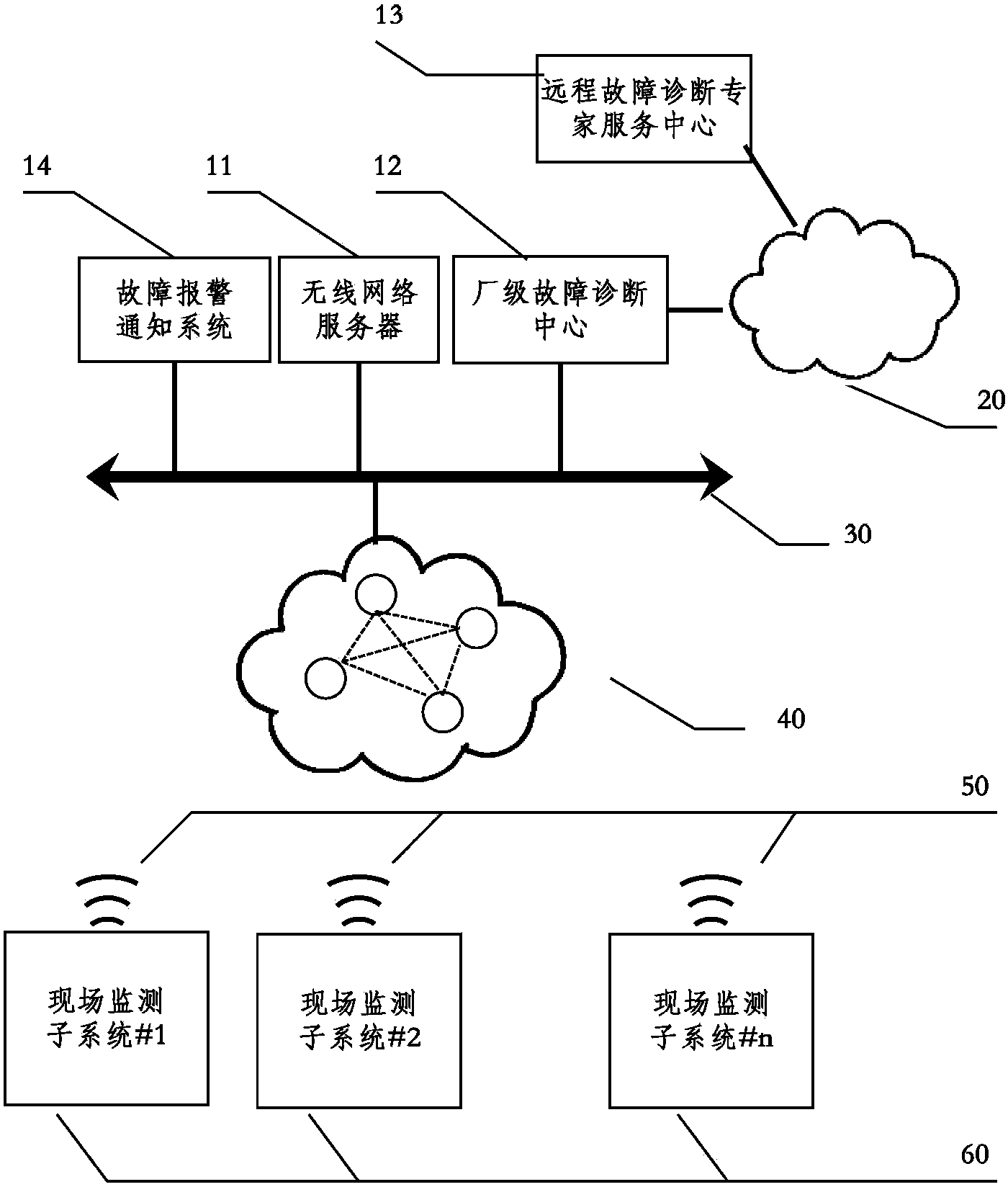

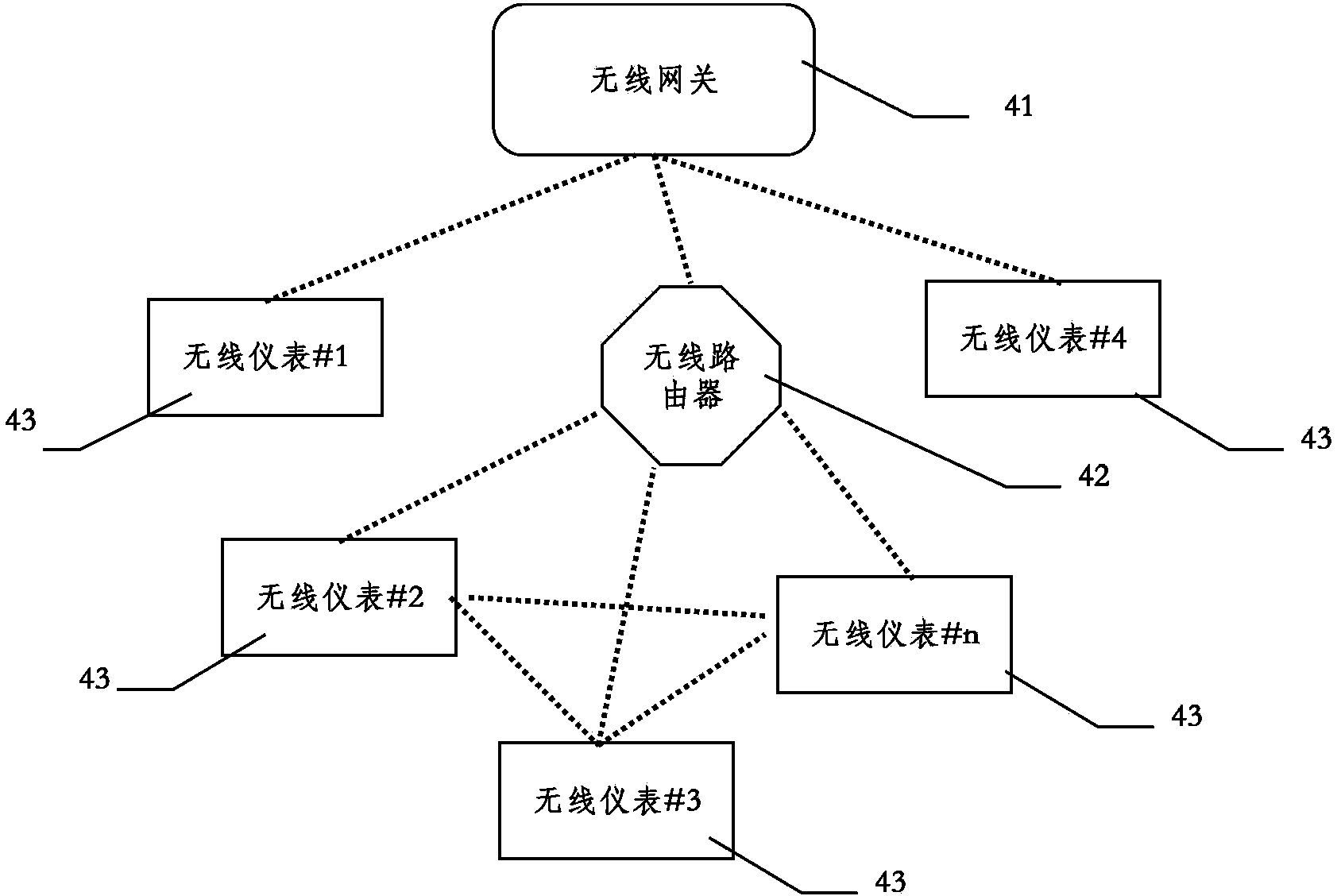

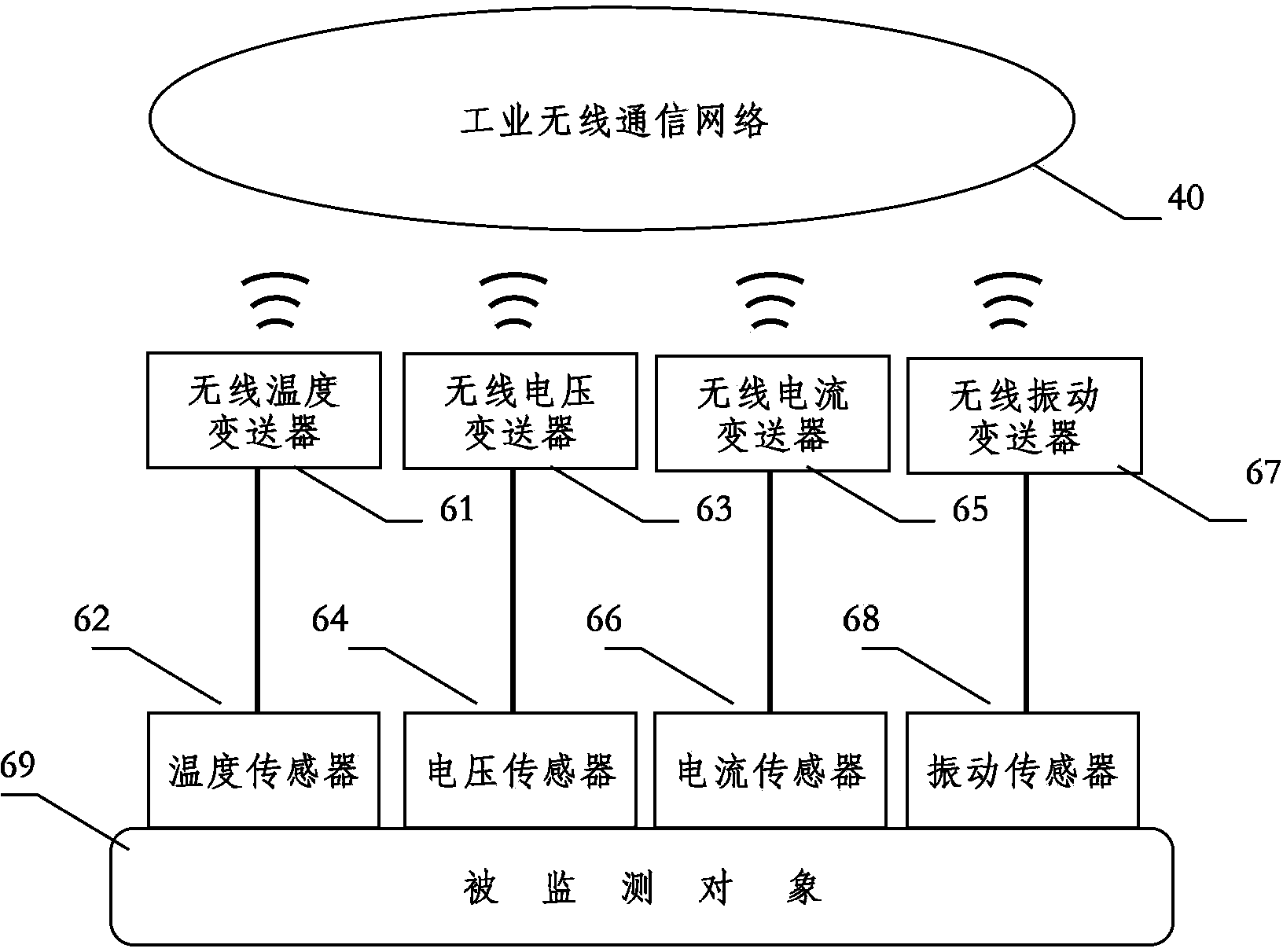

Device fault pre-maintenance method based on industrial wireless technology

InactiveCN103913193AEliminate dead endsIncrease flexibilityMeasurement devicesTransmission systemsIndustrial EthernetMonitor equipment

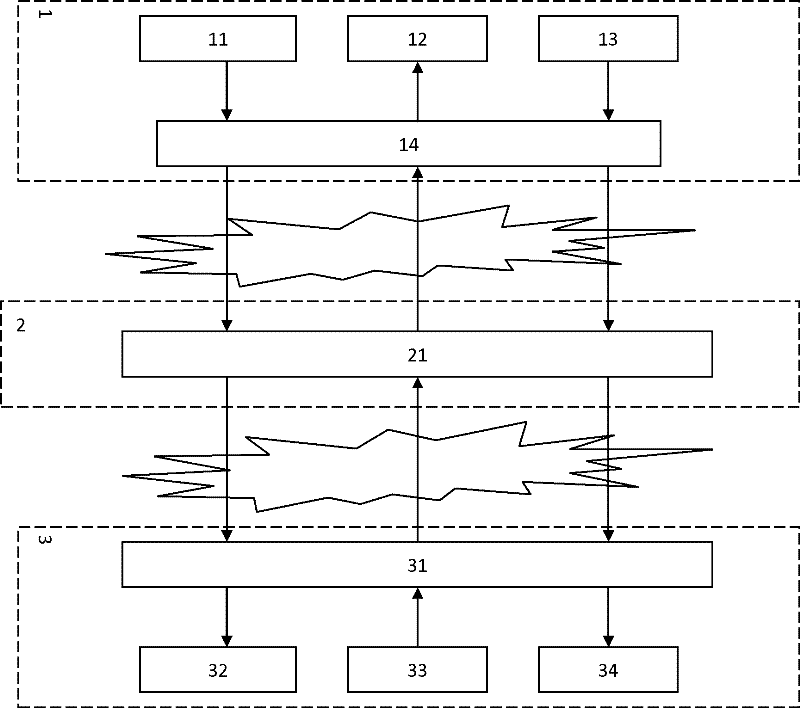

The invention relates to a device fault pre-maintenance method based on an industrial wireless technology. In the method, through data communication of an industrial wireless network and an industrial Ethernet, real-time monitoring and fault pre-maintenance are performed on an on-site device. The method includes the following steps: an upper computer performs parameter configuration on on-site instruments, which are used for monitoring the device, through the industrial Ethernet and the industrial wireless network; the instruments acquire sensor information of the on-site device according to the parameter configuration and upload result data, which is obtained after local processing of the sensor information, to the upper computer through the industrial wireless network and the industrial Ethernet; the upper computer performs fault diagnosis according to the result data and judges the operation state of the device; and if the fault diagnosis result is obtained, on-site maintenance personnel are notified through a fault alarm so as to maintain the device.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

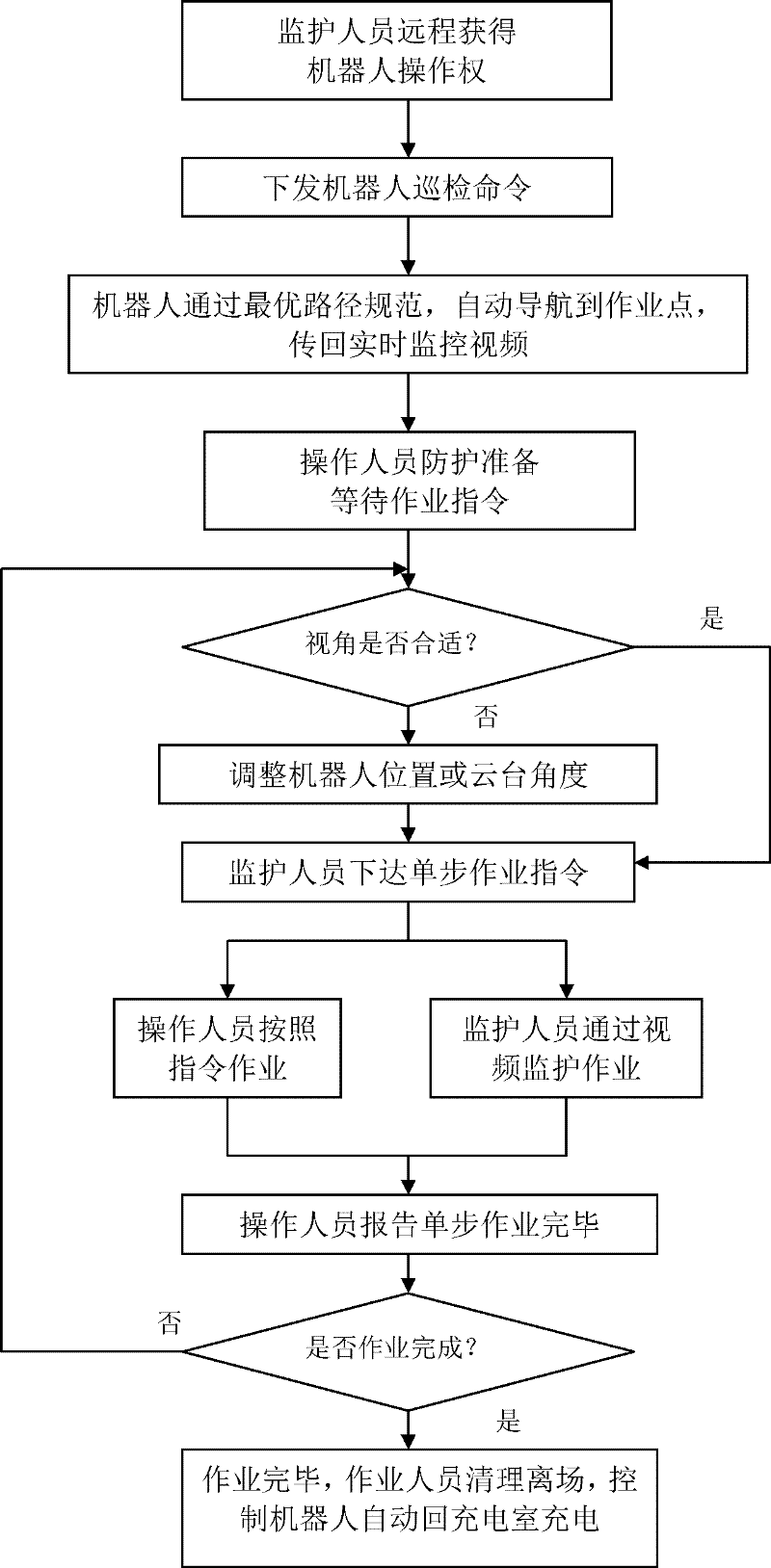

Routing inspection system based on intelligent robot of transformer station and method for monitoring operation of transformer station

InactiveCN102355052AReduce labor intensitySave operating timeCircuit arrangementsTransformerSimulation

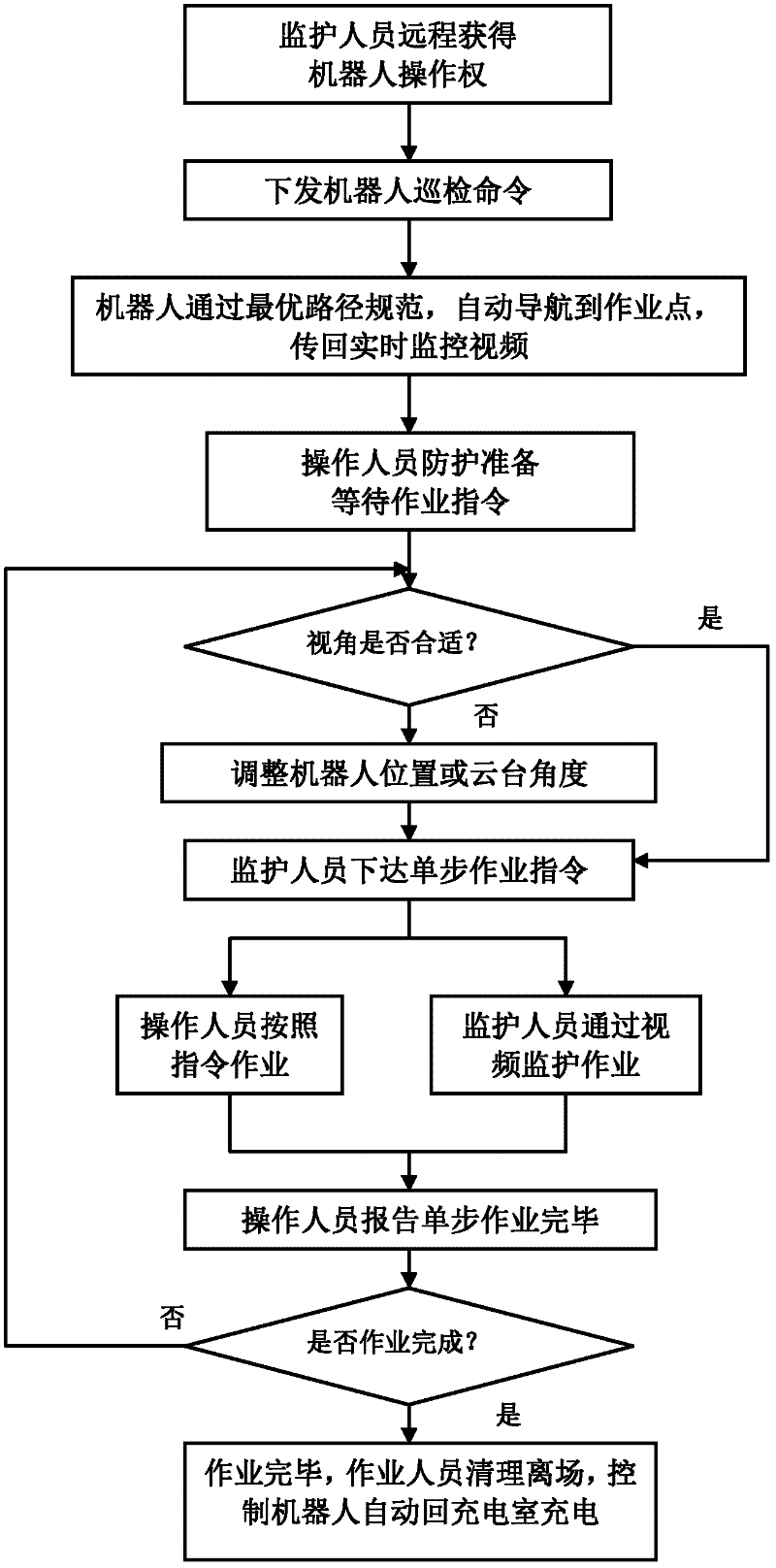

The invention relates to a routing inspection system based on an intelligent robot of a transformer station and a method for monitoring the operation of the transformer station and can meet all-weather working requirements. The method comprises the following steps of: 1) remotely taking over the right of control of an intelligent routing inspection robot; 2) issuing an equipment detection command to the intelligent routing inspection robot of the transformer station; 3) automatically navigating the intelligent routing inspection robot to an operation point by using an optimum path specification, and sending back a real-time monitoring video; 4) after an operator is in place on the scene, waiting for an operation command; 5) issuing a single-operation instruction to the operator; 6) monitoring the operation of a scene person by using the video of the intelligent routing inspection robot; 7) remotely controlling the intelligent routing inspection robot to move to an appropriate position or adjusting a holder of the intelligent routing inspection robot to be at an appropriate angle; 8) after the operation of the steps is finished, waiting for the next operation instruction; and 9) after all operation tasks are finished, controlling the intelligent routing inspection robot to automatically move back to a charging room for charging, and finishing the operation.

Owner:SHANDONG ELECTRIC POWER RES INST +1

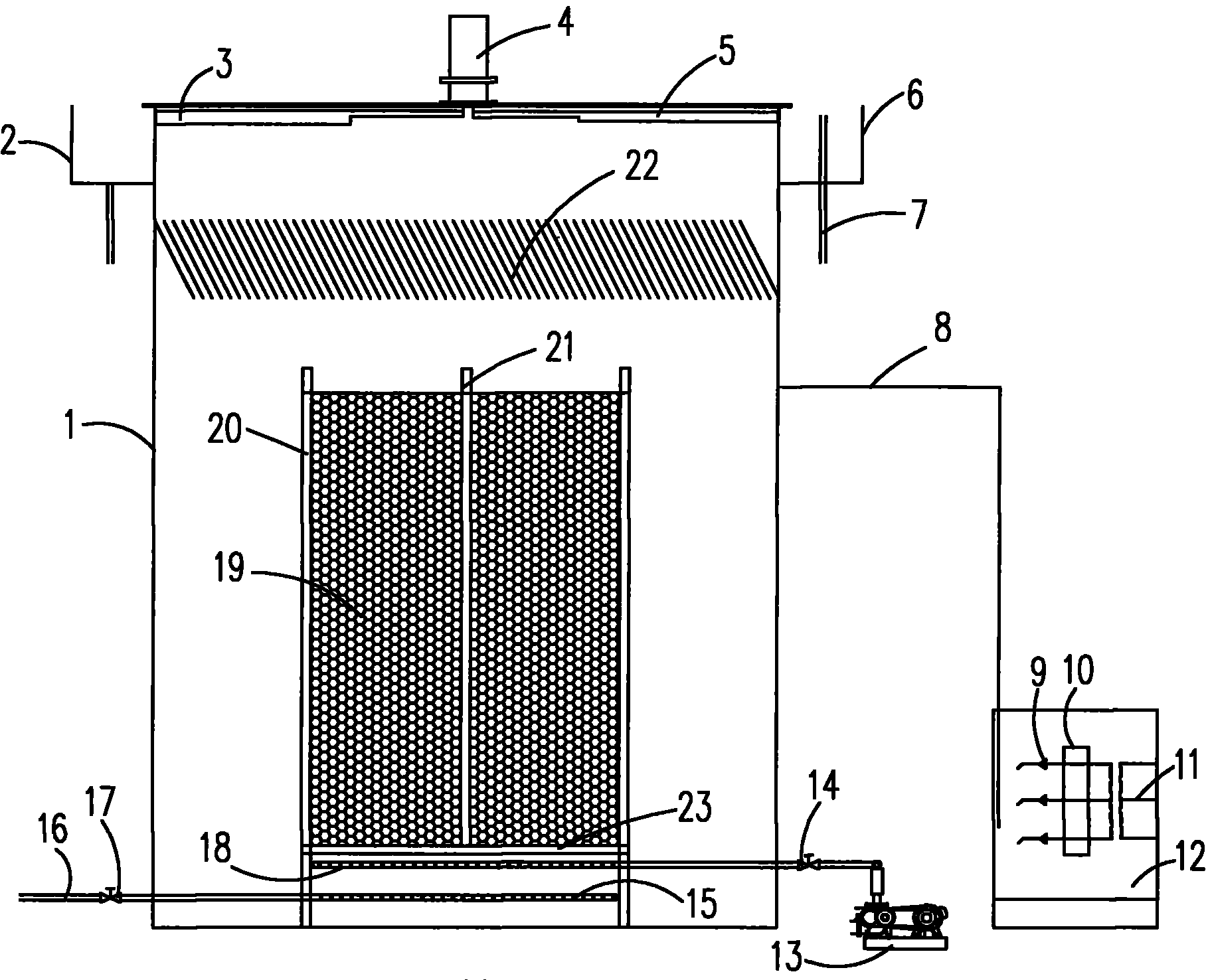

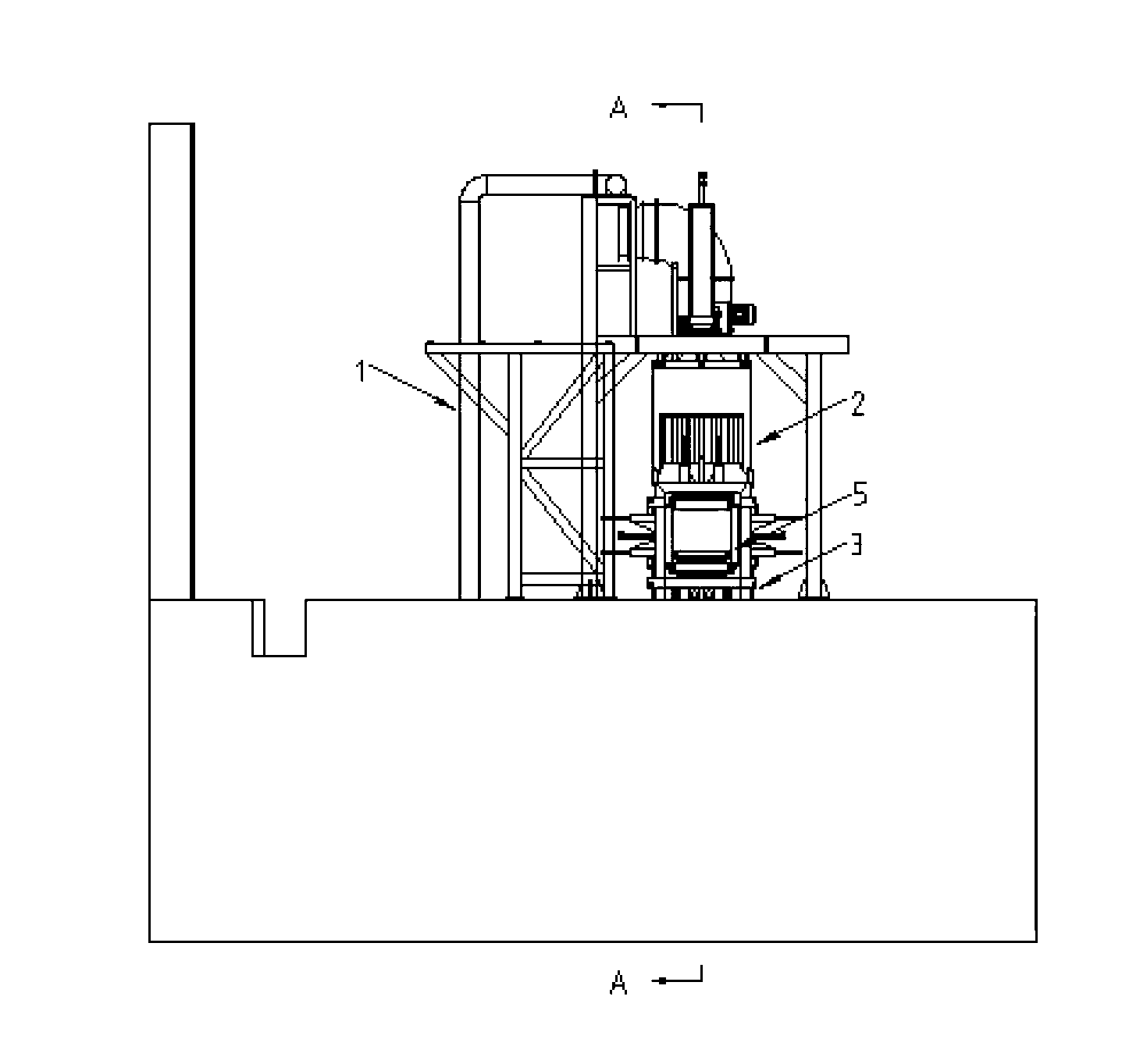

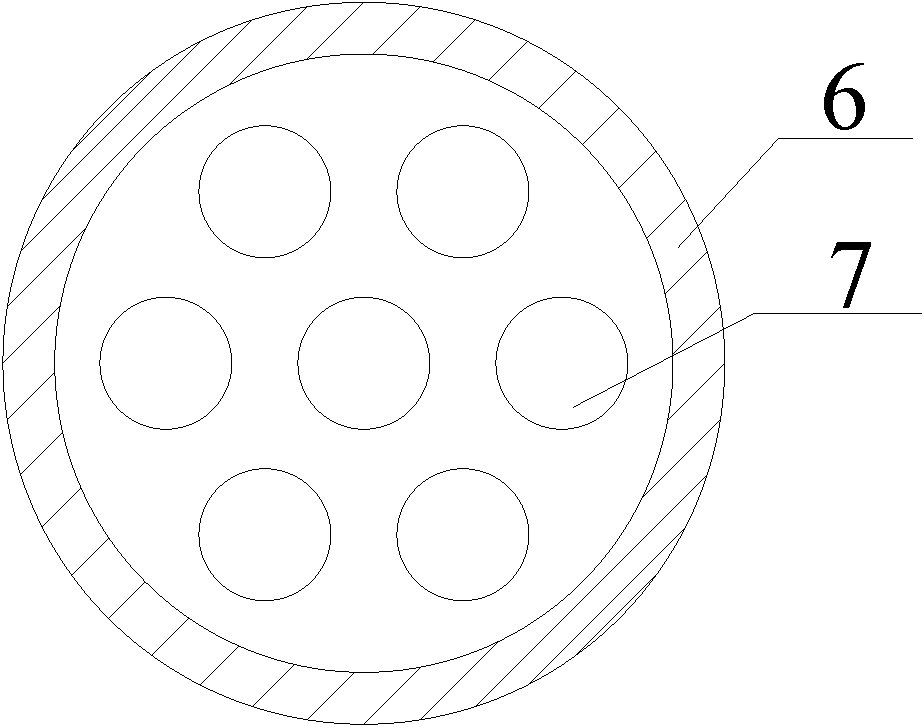

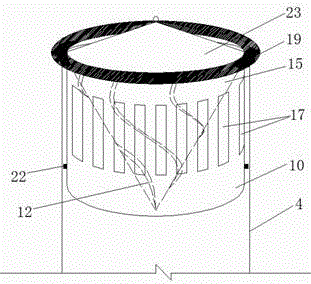

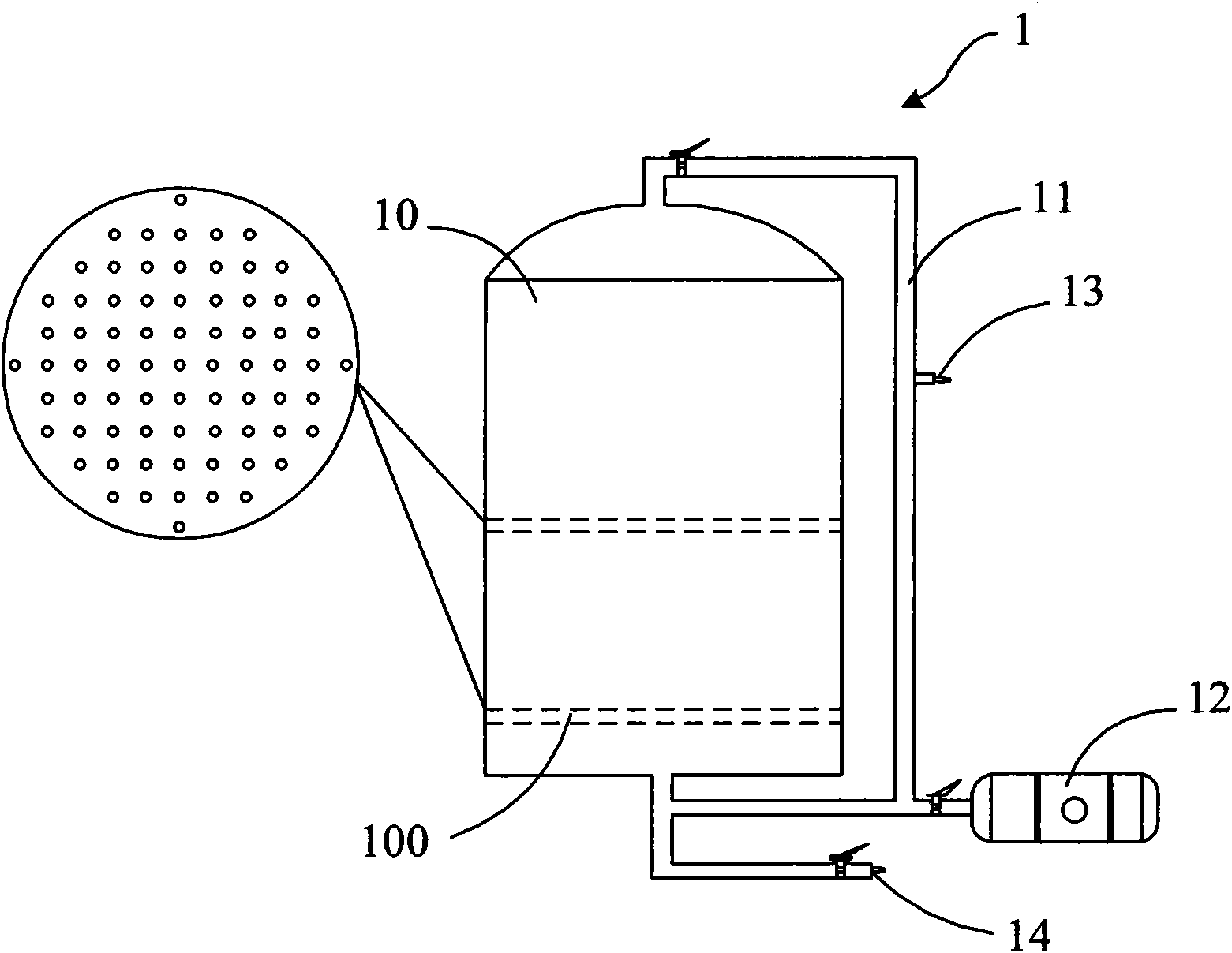

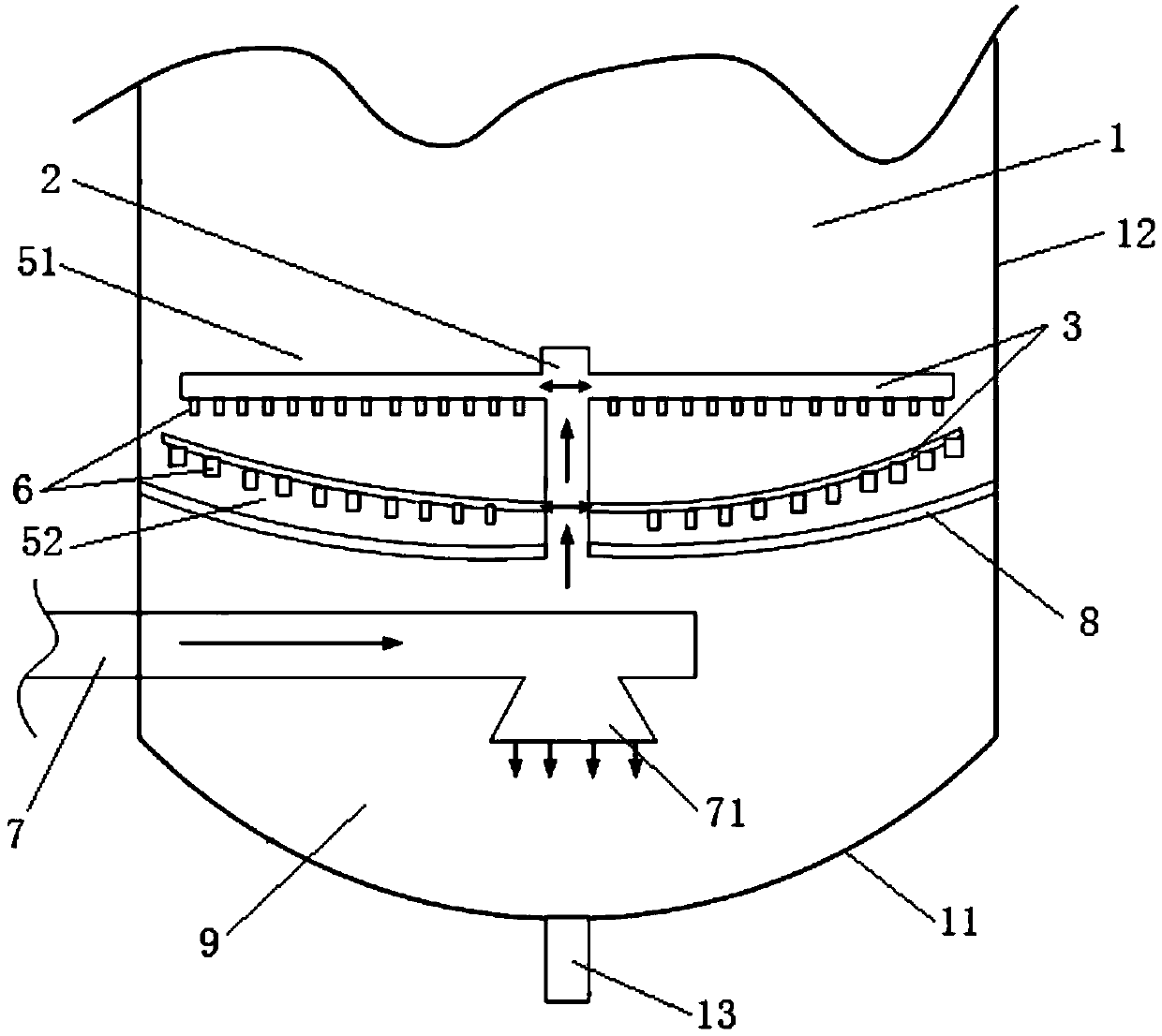

Internal recycle multi-dimensional electro-catalytic wastewater treating equipment

InactiveCN101863533AEasy to handleReduce energy consumptionWater/sewage treatment by electrochemical methodsWater/sewage treatment by sorptionElectricityCatalytic oxidation

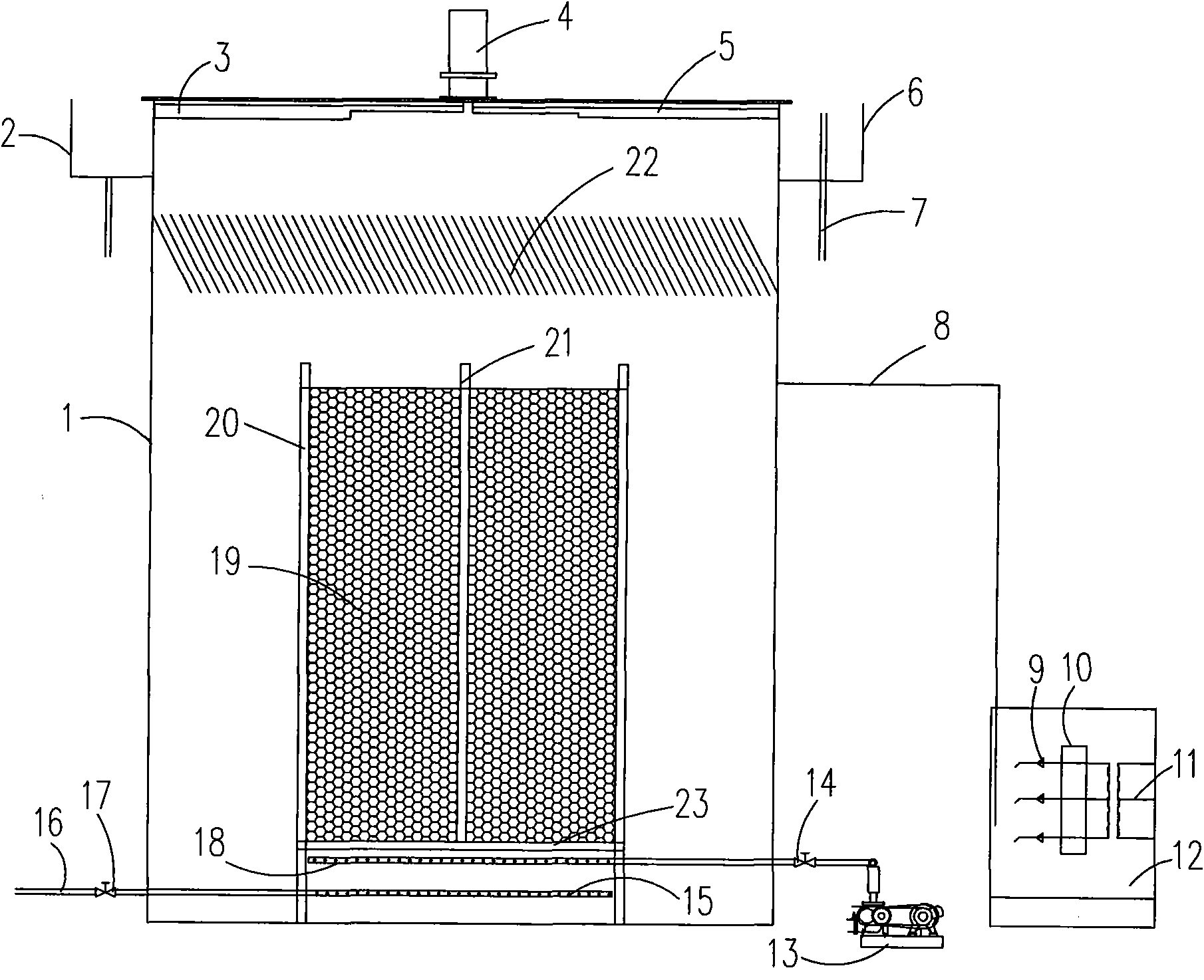

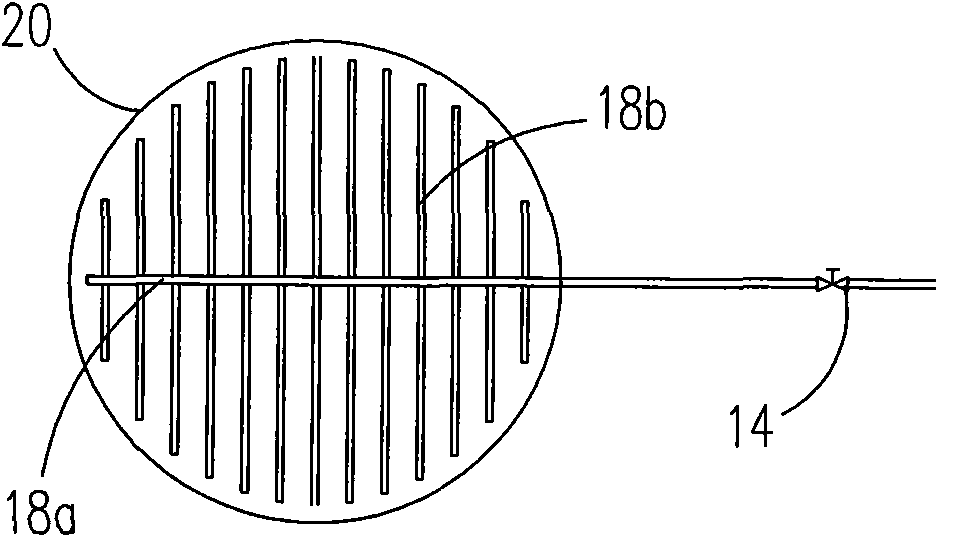

The invention discloses internal recycle multi-dimensional electro-catalytic wastewater treating equipment, which is characterized in that the wastewater treating equipment is provided with a cylindrical device which is internally provided with an inflow water distribution pipe, an aerator pipe, an electrode reaction region, a rectifying region, a water outlet region and a scum collecting region from bottom to top. The wastewater treating equipment of the invention integrates the electro-catalytic oxidation and air floating functions into a whole with good treating effect, low energy consumption and long electrode life.

Owner:HEFEI UNIV OF TECH

Preparation method of hydroxy methionine salt and compound

The invention provides a preparation method of hydroxy methionine salt and a compound, comprising the following steps: a. feeding metal hydroxide or basic metal oxide or amphoteric metal oxide and 2-hydroxy-4-methylthiobutyricacid into a closed and corrosion resistant reaction kettle to react for 0.5-12h according to a stoichiometric ratio, taking the low-boiling polar organic solvent or the mixed solvent thereof with water as the reaction medium, stirring, separating the target product, washing and drying to obtain the products; and b. recycling the reaction medium. The preparation method of the invention has short route, no consumption of acid or alkali reagent, low cost, easily-controllable product quality, environmental friendliness and the like, thus being applicable to large-scale industrial production.

Owner:李宁 +1

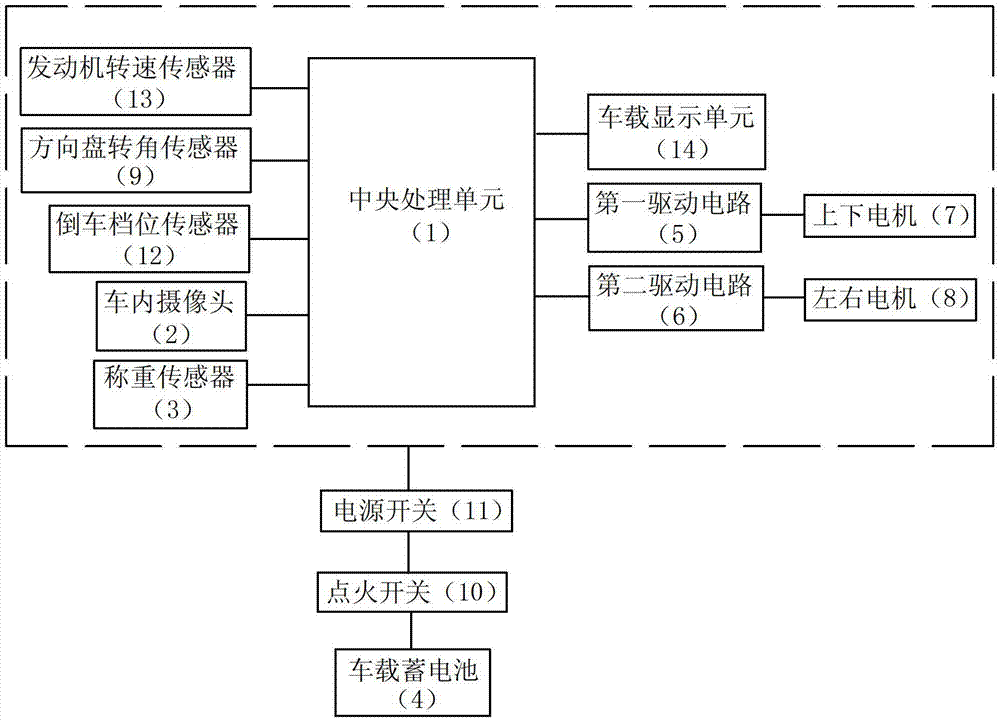

Vehicle side rear view mirror intelligent regulation control system and control method

The invention relates to a vehicle side rear view mirror intelligent regulation control system and a vehicle side rear view mirror intelligent regulation control method. The vehicle side rear view mirror intelligent regulation control system comprises a central processing unit as well as an in-vehicle camera, a vehicle weighing sensor, a steering wheel corner sensor, a reverse gear sensor and a first driving circuit and a second driving circuit, which are connected with the central processing unit; the first driving circuit is connected with an upper motor and a lower motor of the vehicle side rear view mirror; the second driving circuit is connected with a left motor and a right motor of the vehicle side rear view mirror; and the in-vehicle camera is mounted in front of a driver's seat or mounted obliquely in front of the driver's seat. The control method is as follows: the angle of the vehicle side rear view mirror is timely regulated according to the space position change of the driver and the change of vehicle traveling state, as a result, the vehicle side rear view mirror is regulated to the optimal angle, blind zones and dead angles are eliminated, the driver always keeps the optimal driving view, and comfort and safety of the vehicle driving are improved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

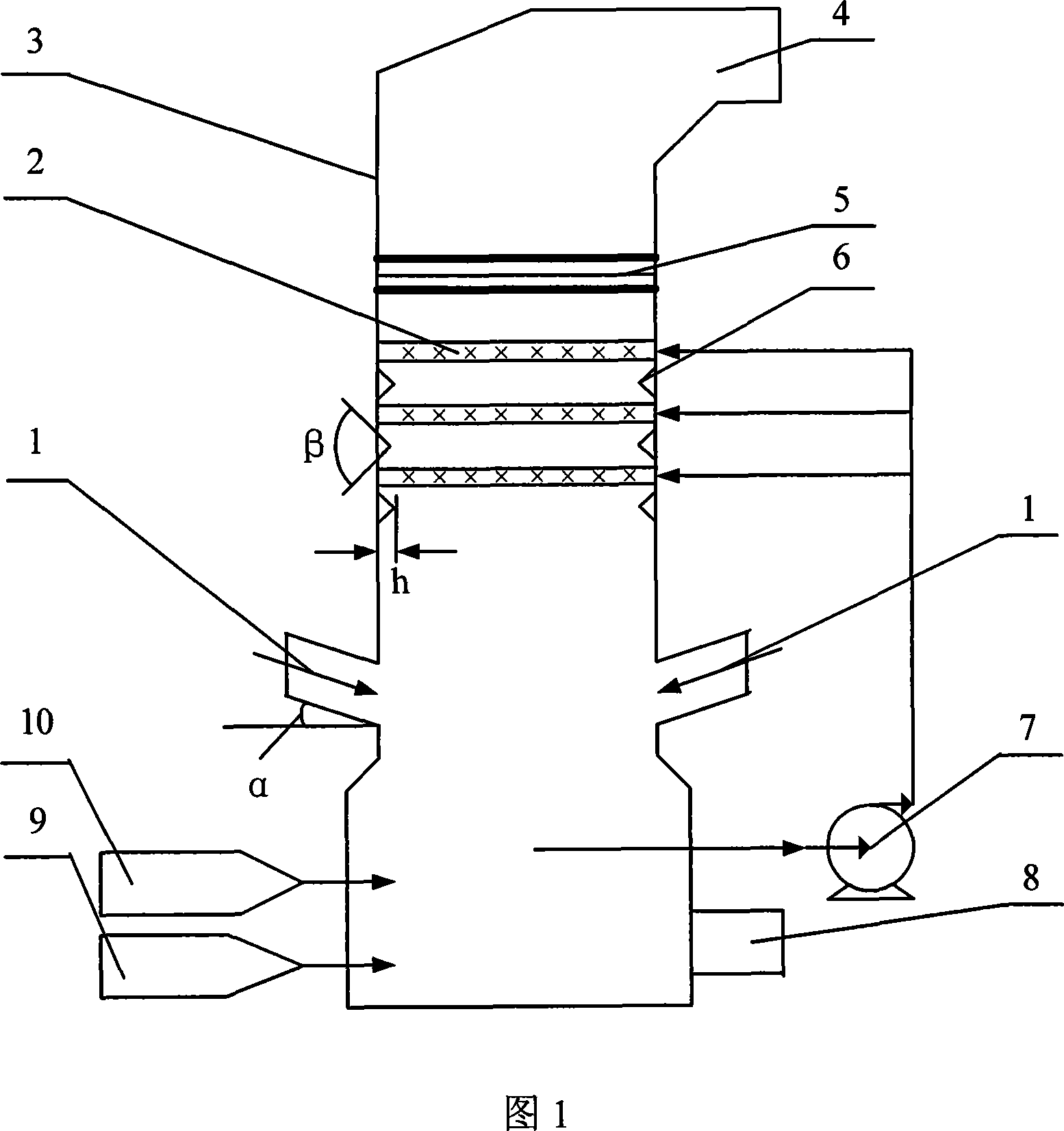

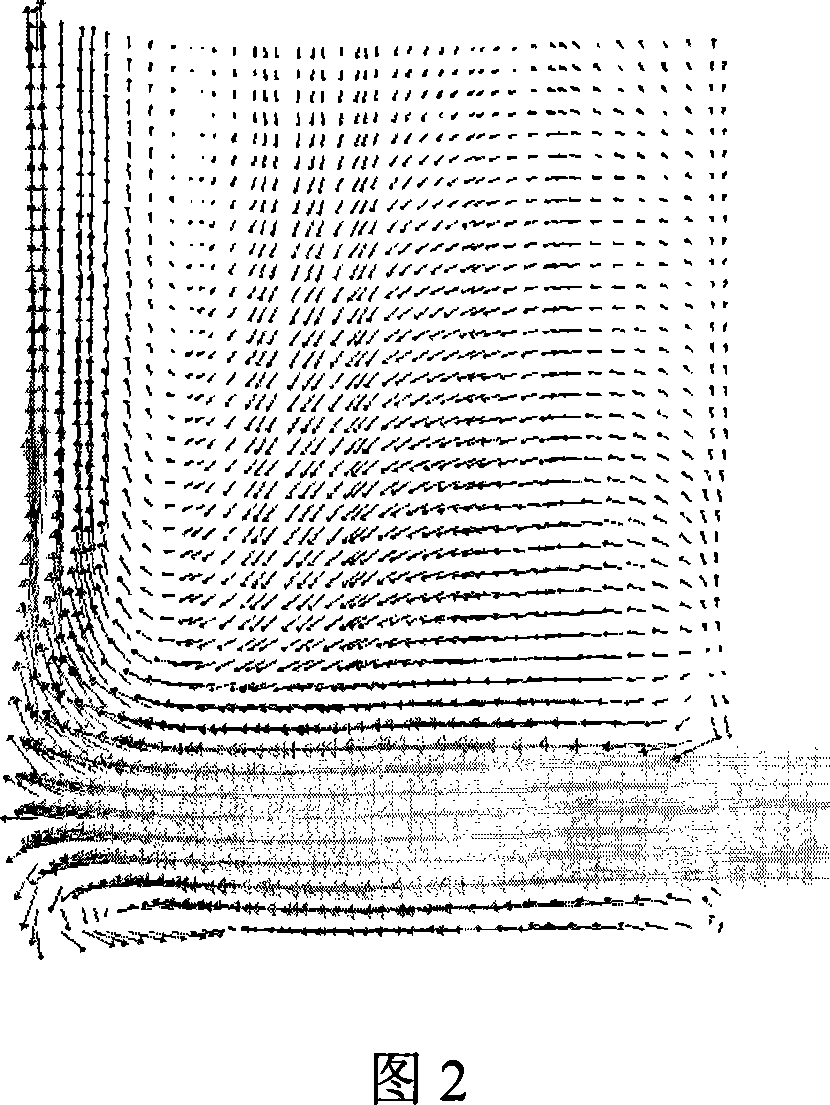

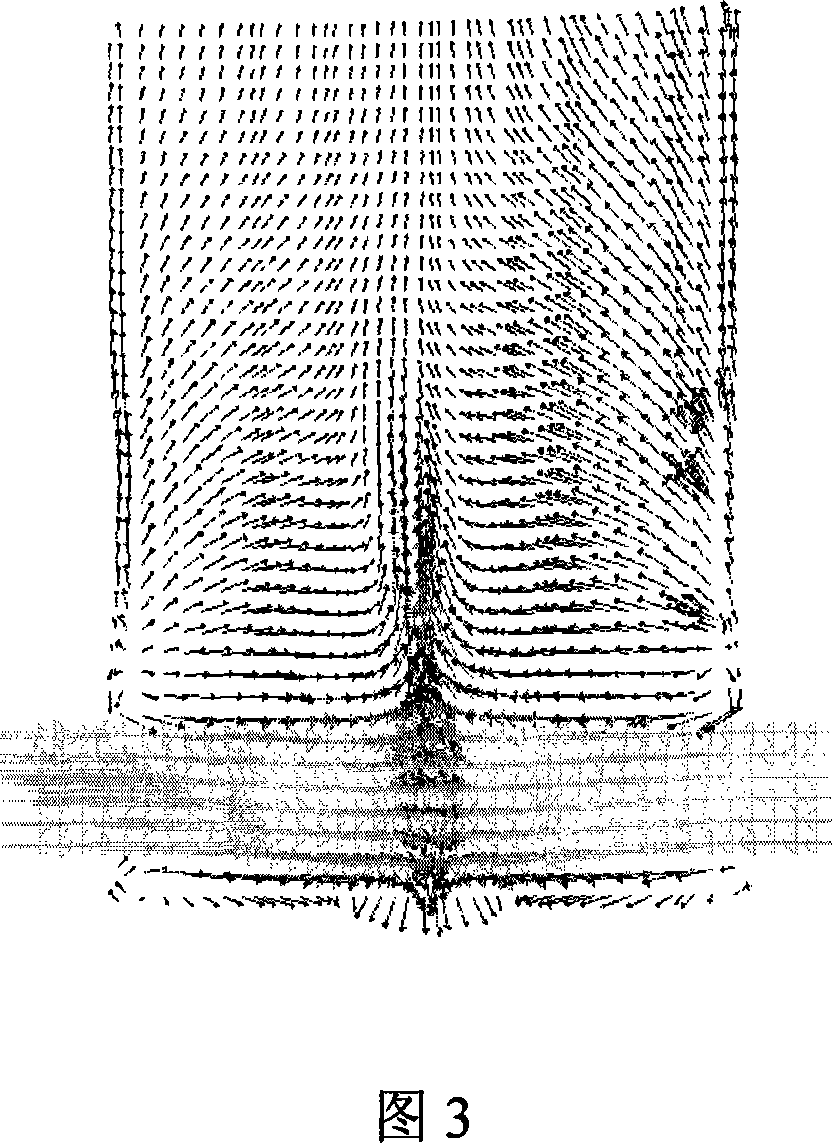

Bilateral opposite flushing inlet wet ammonia method for flue gas desulfurizing technology and device thereof

InactiveCN101053743AOptimizing the smoke flow fieldImprove desulfurization efficiencyDispersed particle separationChemistrySulfur dioxide

A wet ammonia method flue gas desulfurization process of two-side opposed inlet and device thereof, which makes the flue gas to form uniform upward opposed turbulence, then makes the flue gas to pass through flue gas antivortex baffle and ammonia desulfurizer cycle spraying layer which are staggered arranged to rapidly transmute the sulfur dioxide in the flue gas to be ammonium salt admixture, lastly, oxidates the ammonium sulfite in the ammonium salt admixture to be ammiaonia sulfate and outputs the clear flue gas after demisted. The device comprises an ammonia replenishment system and an air feeding device at the bottom of the thionizer, an opposed flue gas inlet at the lower of the thionizer, flue gas antivortex baffle and ammonia desulfurizer cycle spraying layer interleaving mounted at the middle of the thionizer, and a demister at upper of the thionizer, wherein the bottom of the thionizer is connected with the ammonia desulfurizer cycle spraying layer by cycle pump, the process and the device can improve the flue gas flow field effectively, enhance the gas-liquid mass transfer, and largely raise the desulfurization and the utilance of desulfurizer at the precondition without increasing the thionizer resistance and the consume of desulfurizer.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

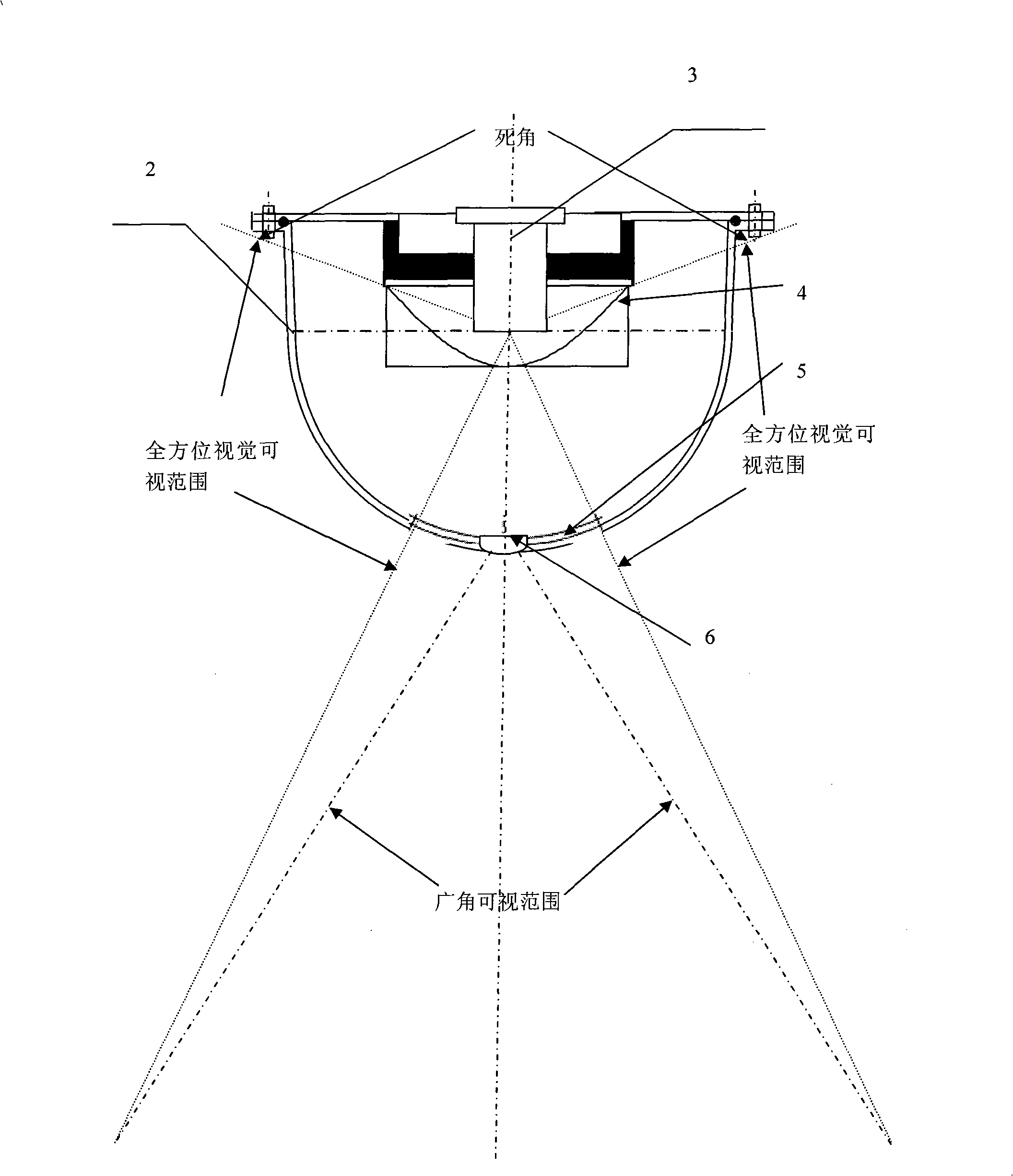

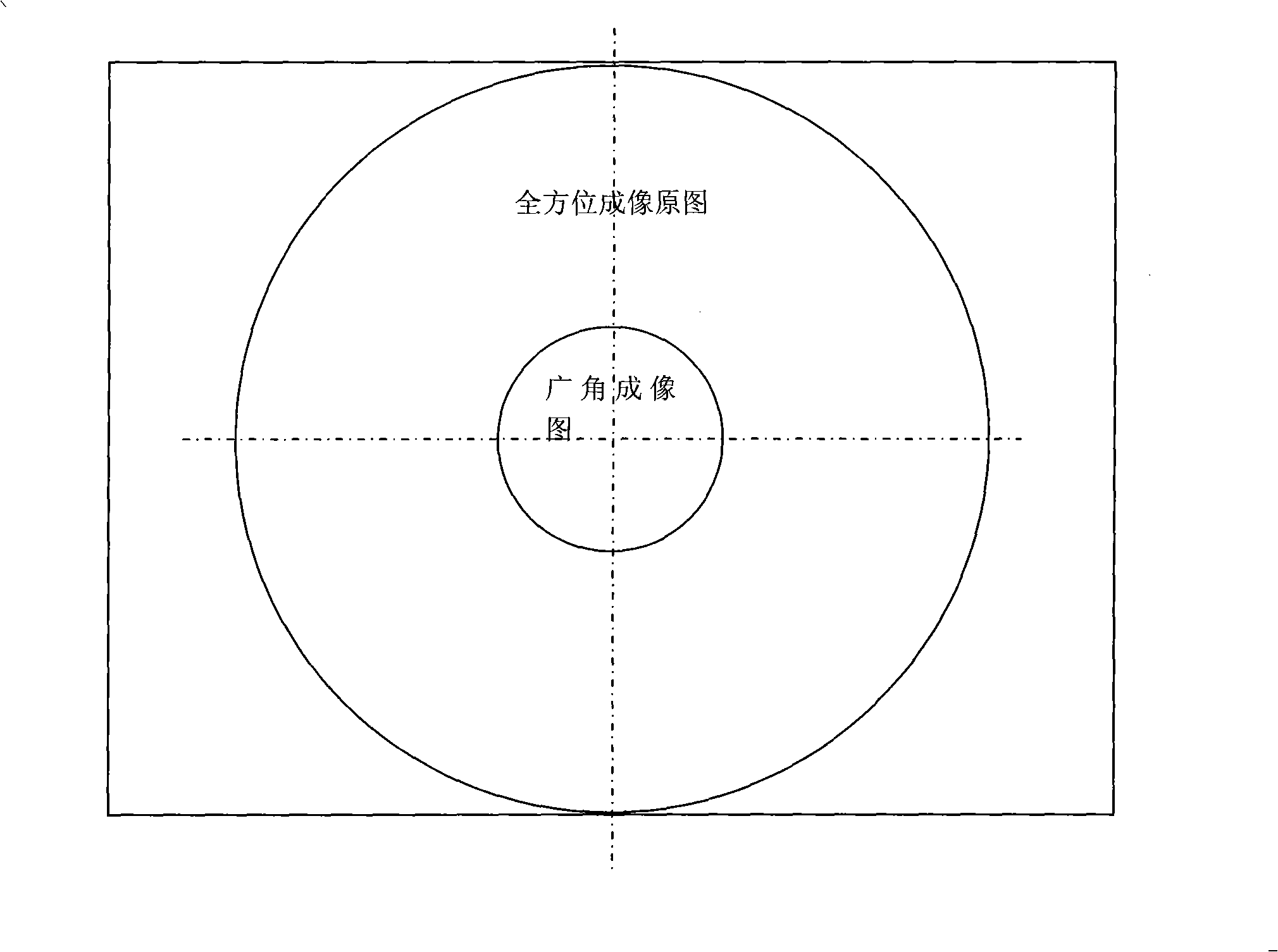

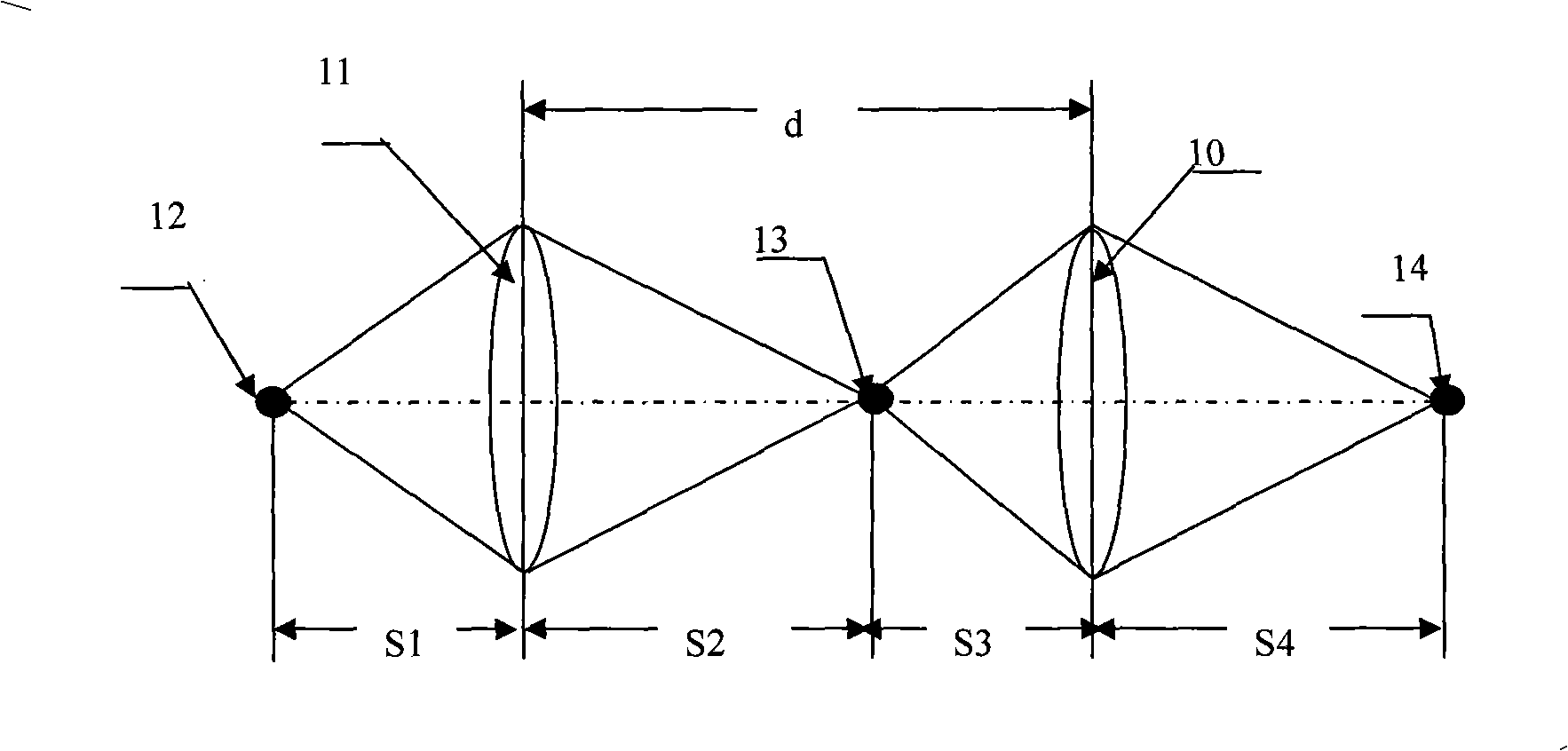

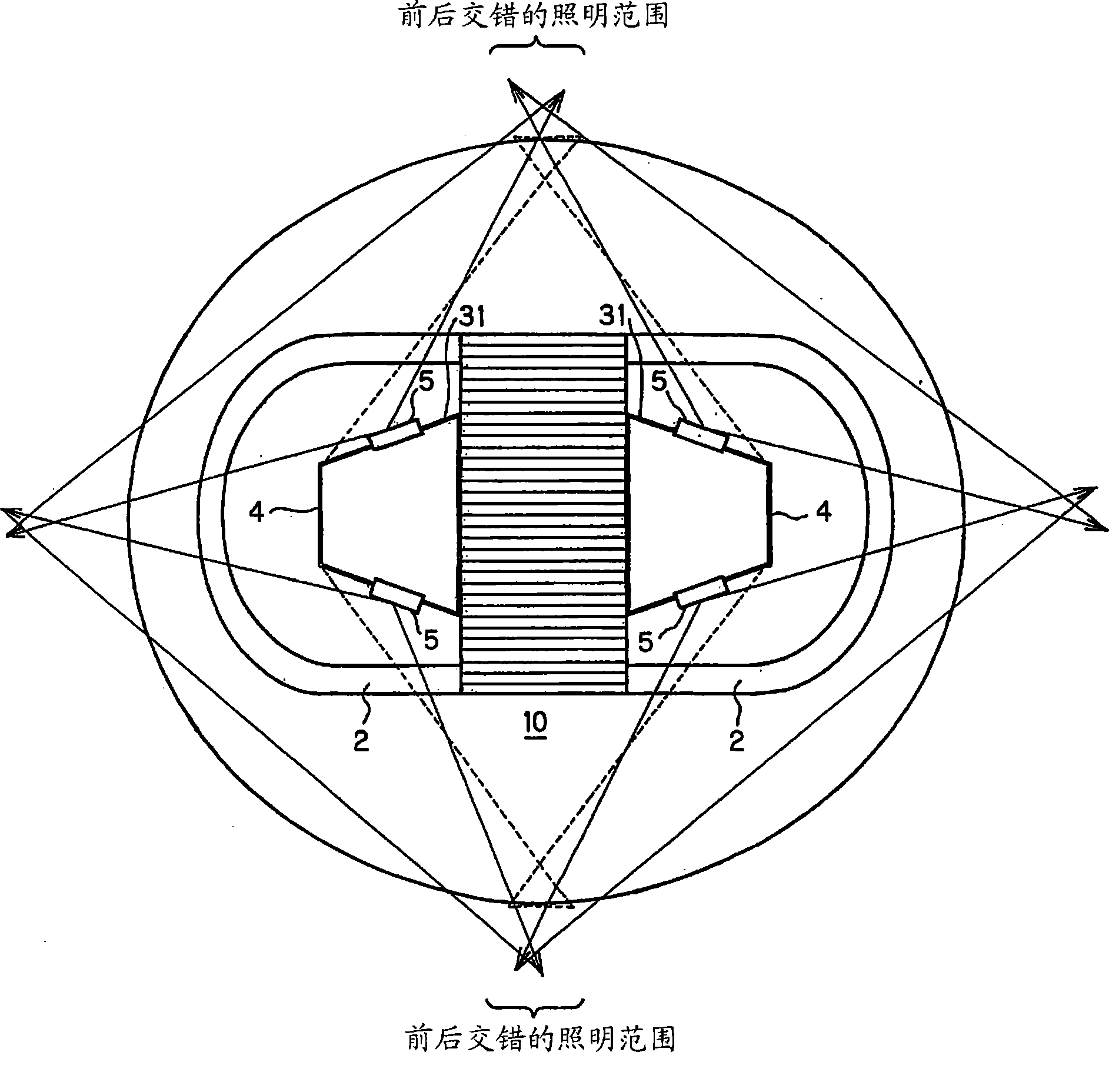

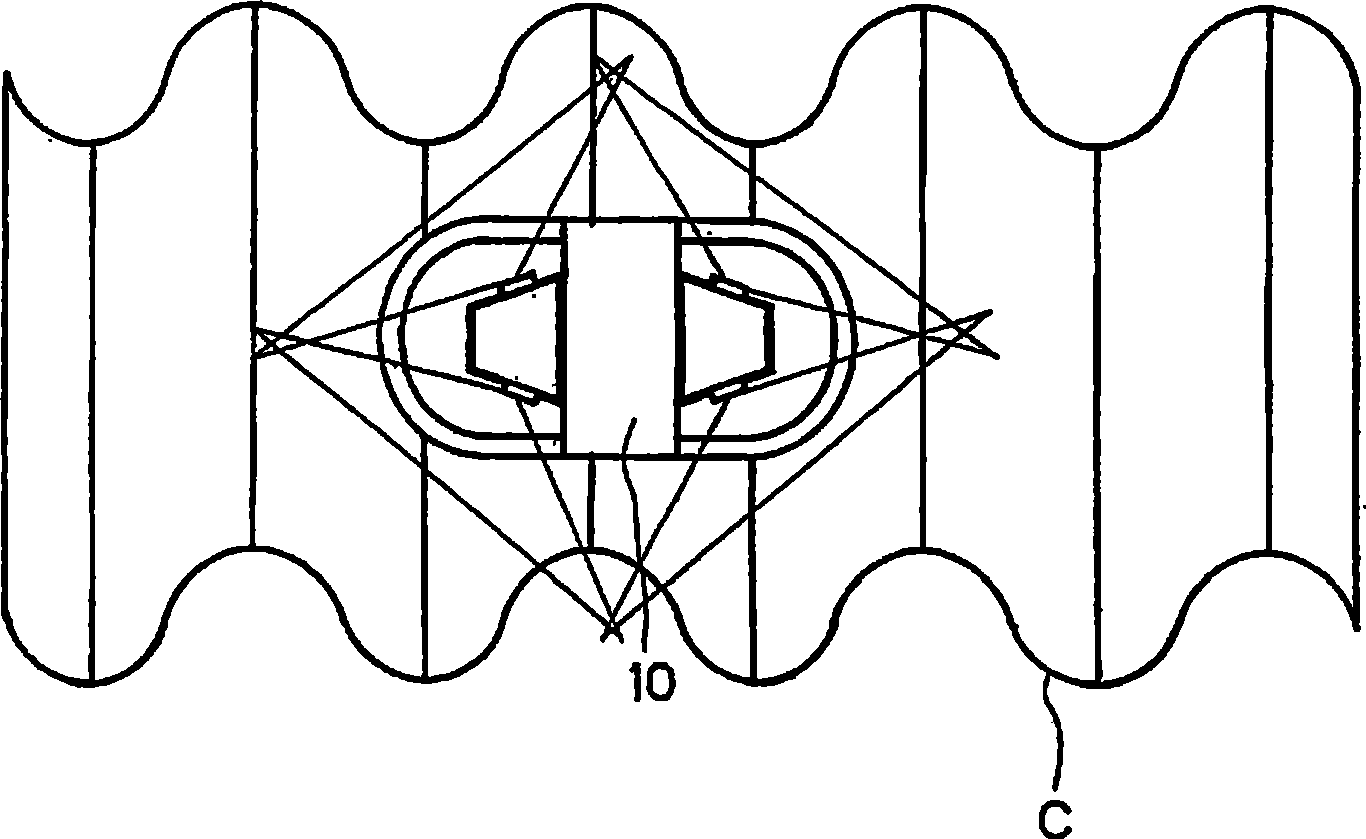

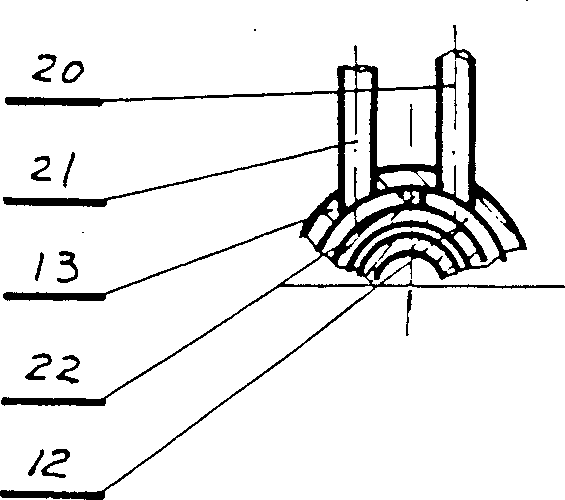

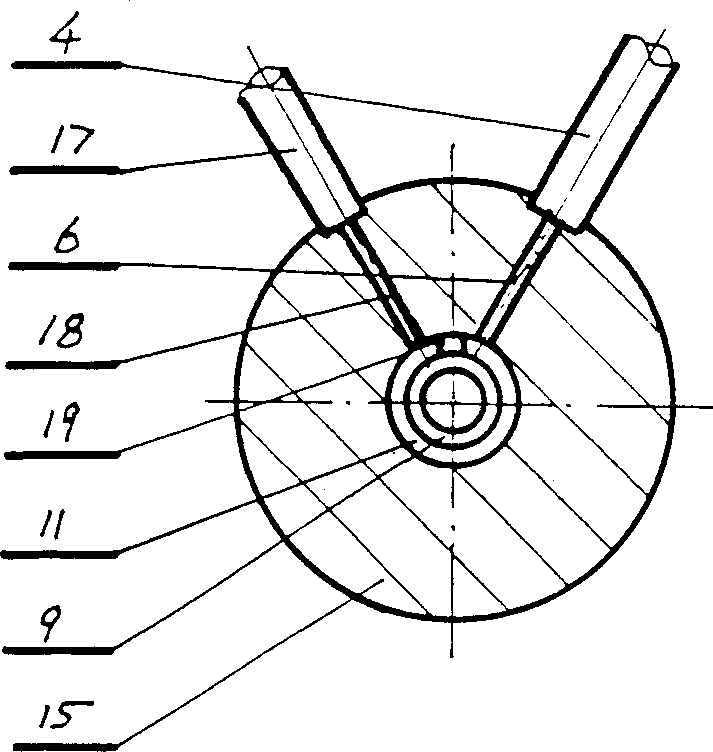

Non-dead angle binocular solid all-directional vision sensing equipment

InactiveCN101271187AEliminate dead endsImage enhancementOptical elementsCamera lensOmnidirectional vision

A double-eye solid omnidirectional vision sensing device without a dead angle comprises two omnidirectional vision sensors with the same average resolving power, a connecting unit and a microprocessor used for processing an image. The omnidirectional vision sensor comprises a once catadioptric mirror face, a twice catadioptric mirror face, a transparent cover and a videography component. The once catadioptric mirror face and the twice catadioptric mirror face are arranged at the transparent cover; the videography component is arranged at a vision point at the back of the once catadioptric mirror face. The twice catadioptric mirror face is arranged in front of the once catadioptric mirror face. The once catadioptric mirror face and the twice catadioptric mirror face are both provided with a pore. The twice catadioptric mirror face is embedded into a wide-angle lens. A videography component lens, the wide-angle lens and the central shafts of the once catadioptric mirror face and the twice catadioptric mirror face are collocated at the same axial line. The backs of the two omnidirectional vision sensors are connected with each other by the connecting unit. The double-eye solid omnidirectional vision sensing device without dead angle can eliminate the dead angle in the vertical direction and capture the omnidirectional images of the large range of real time 360 degrees multiplied by 360 degrees.

Owner:汤一平

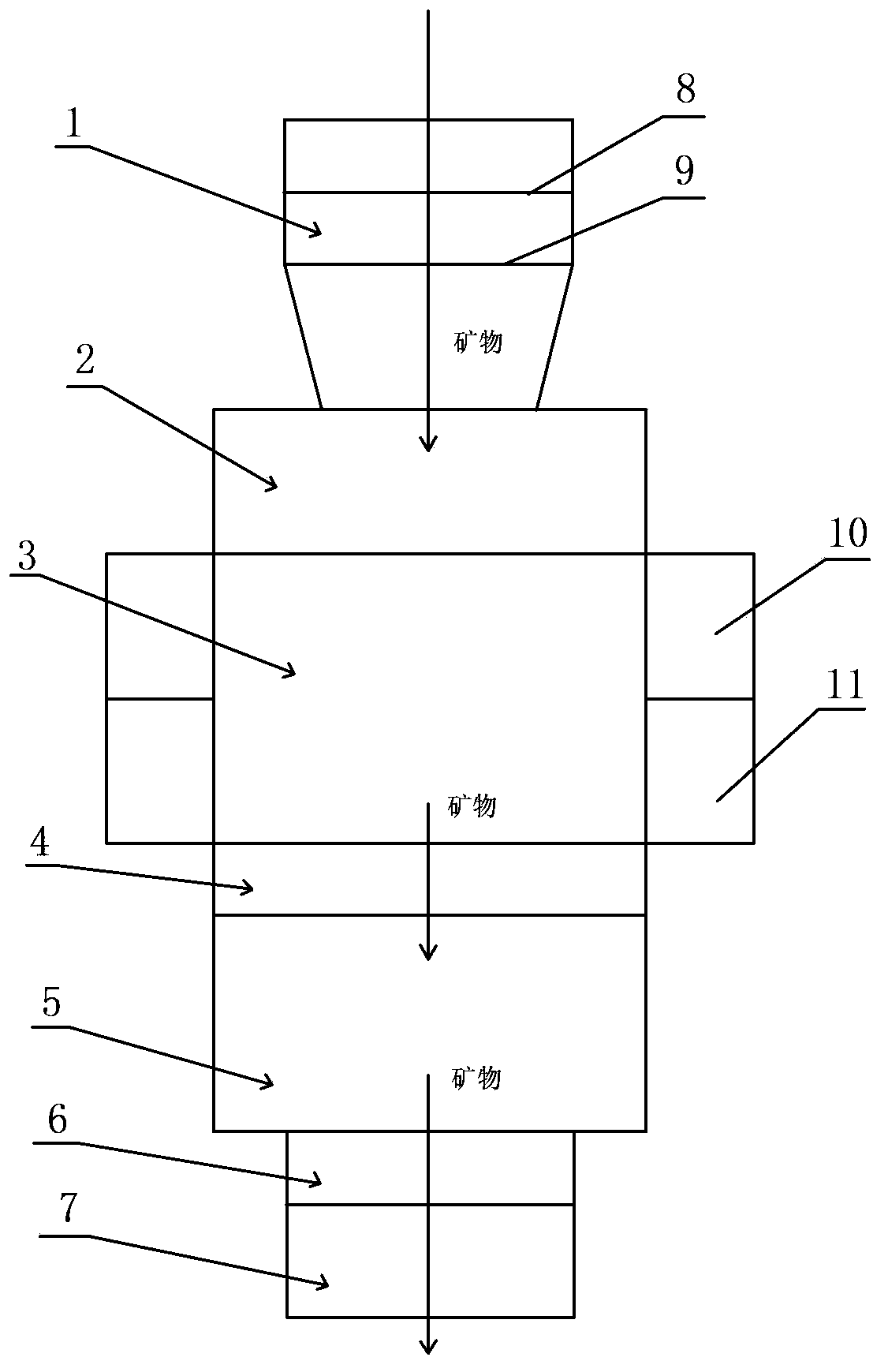

Mineral roasting reduction device and application method thereof

The invention discloses a mineral roasting reduction device. The device comprises a feeding zone, a drying preheating zone, a roasting oxidation reaction zone, a pressure-regulating zone, a reduction reaction zone, a discharging zone and a water-sealing cooling zone, which are arranged from the top down and communicated with one another, wherein the feeding zone is provided with an automatic sealing device; the drying preheating zone is provided with a directional pressurizing device for vacuum-pumping; the roasting oxidation reaction zone is provided with an incendiary agent adding device; the pressure-regulating zone is provided with a plurality of pressure-regulating air doors; the reduction reaction zone is provided with a reducing agent adding device. The mineral roasting reduction device is provided with the directional pressurizing device, so that negative pressure can be generated in the inner part of the device; molecular flows of both an incendiary agent and an reducing agent are in uplink, while mineral is in downlink, so that a convection current movement is formed to ensure conversion affinity of the solid phase and the gas phase; in the device, the mineral sequentially is subjected to drying, preheating, heating, resolving, reducing, water quenching, cooling and discharging from the top down, and all processes are performed in an air-free state thoroughly to complete roasting reaction.

Owner:QINGDAO ZHIBANG FURNACE DESIGN RES

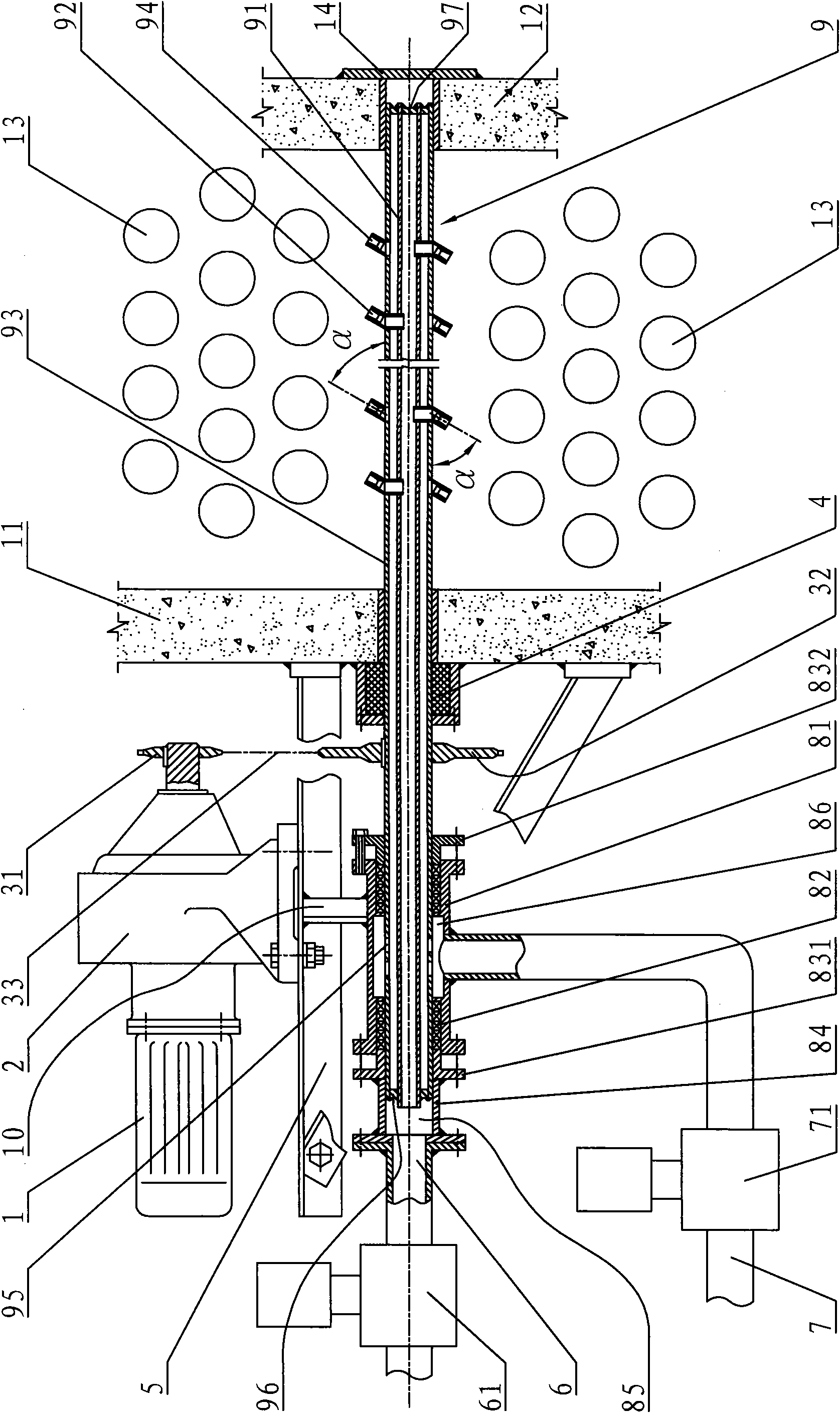

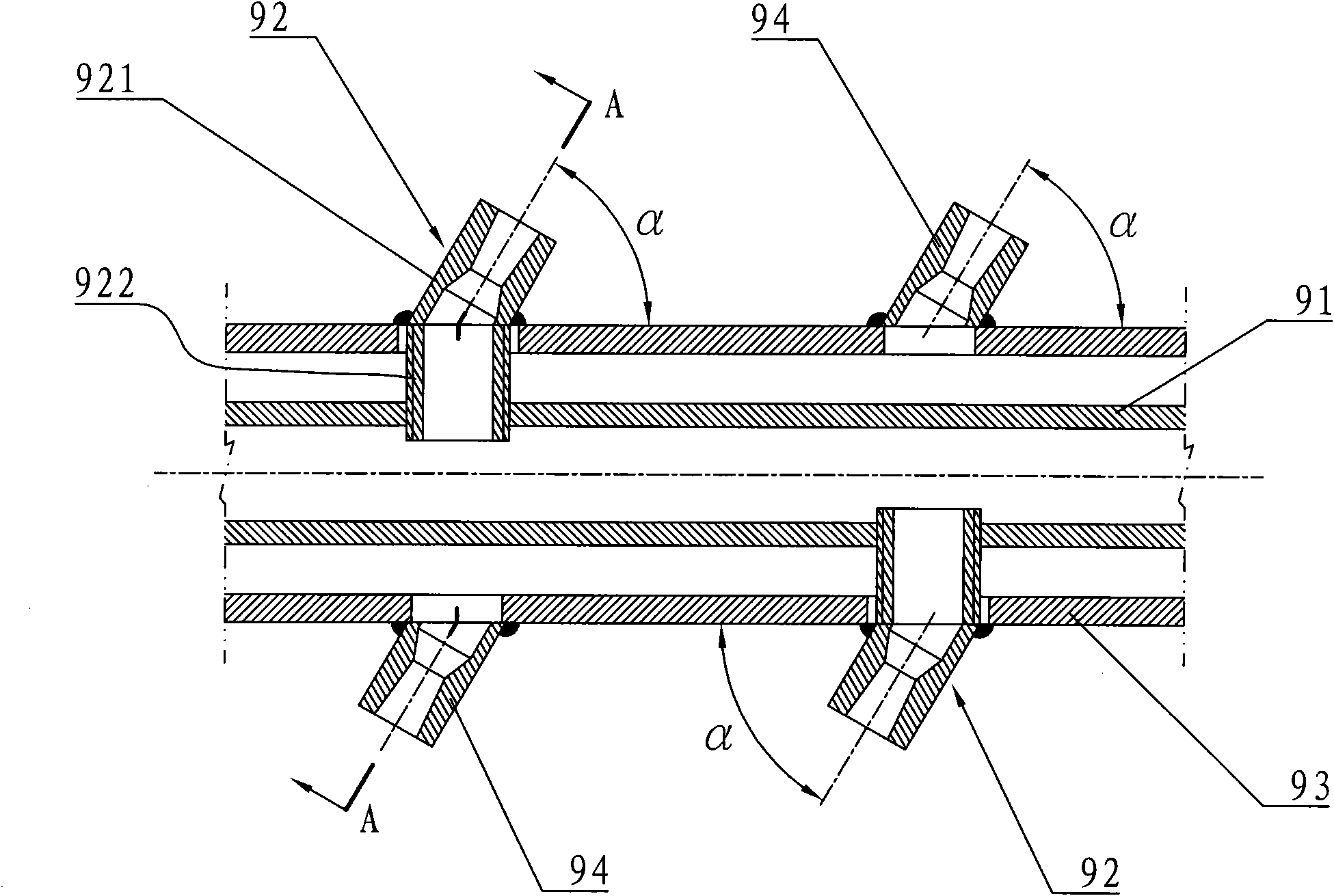

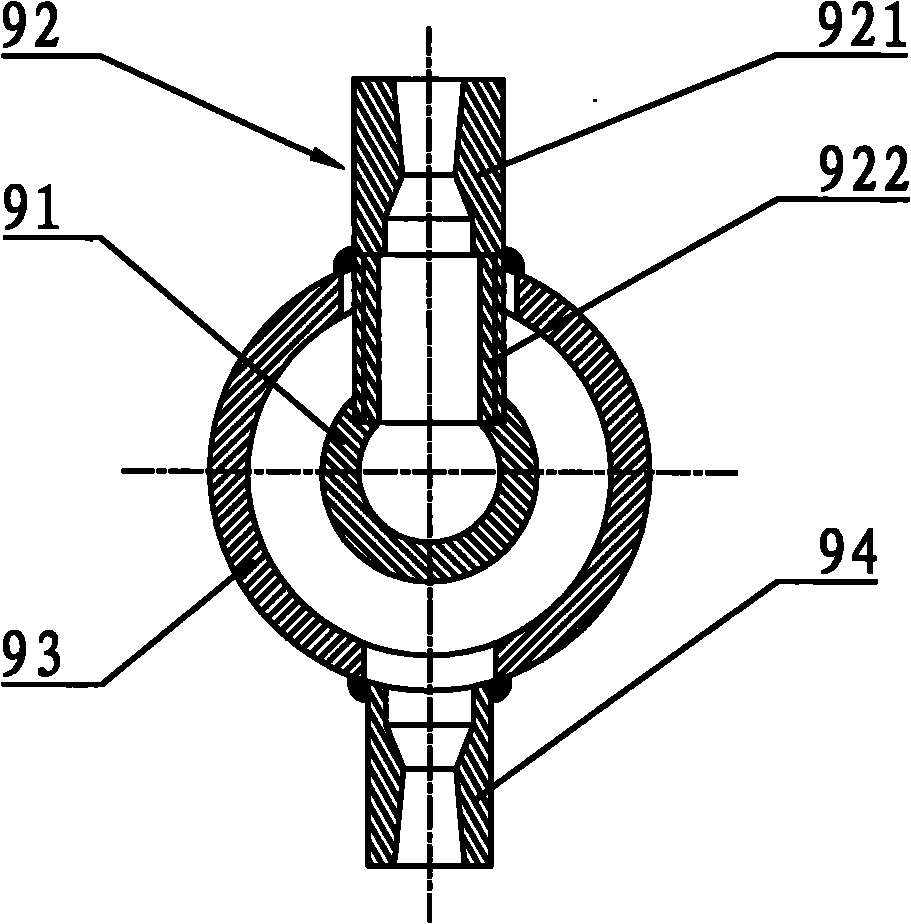

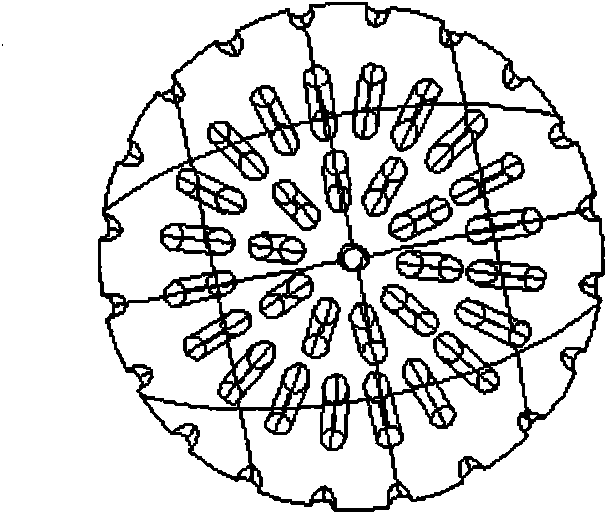

Soot blower

The invention discloses a soot blower in order to solve the problems that the existing soot blower has higher operating failure rate, unreachable blowing area and poor blowing effect. The transmission system of the soot blower of the invention comprises a motor, a reducer and a chain transmission device, wherein the reducer is particularly a cycloidal pin-wheel reducer. The soot blower is provided with an internal soot blower and an external soot blower, and an internal soot blower nozzle and an external soot blower nozzle are arranged on the internal soot blower and the external soot blower respectively; the inclined section of the internal soot blower nozzle is arranged in a way that the inclined section thereof is inclined relative to the axis of the soot blower; an air inlet is formed on the inlet section of the external soot blower; the air inlet system of the soot blower is provided with an air inlet tube, and a second air inlet chamber arranged in the middle of the air inlet tube is communicated with the air inlet and a second air inlet pipe; a first air inlet chamber is arranged at the end part of the inlet section of the internal soot blower and communicated with the end part of the inlet section of the internal soot blower and the first air inlet pipe; a first electromagnetic valve is arranged on the first air inlet pipe; and a second electromagnetic valve is arranged on the second air inlet pipe. The invention is mainly applicable to tubular heating furnaces in the field of petroleum refining and petroleum chemical engineering.

Owner:CHINA PETROCHEMICAL CORP +1

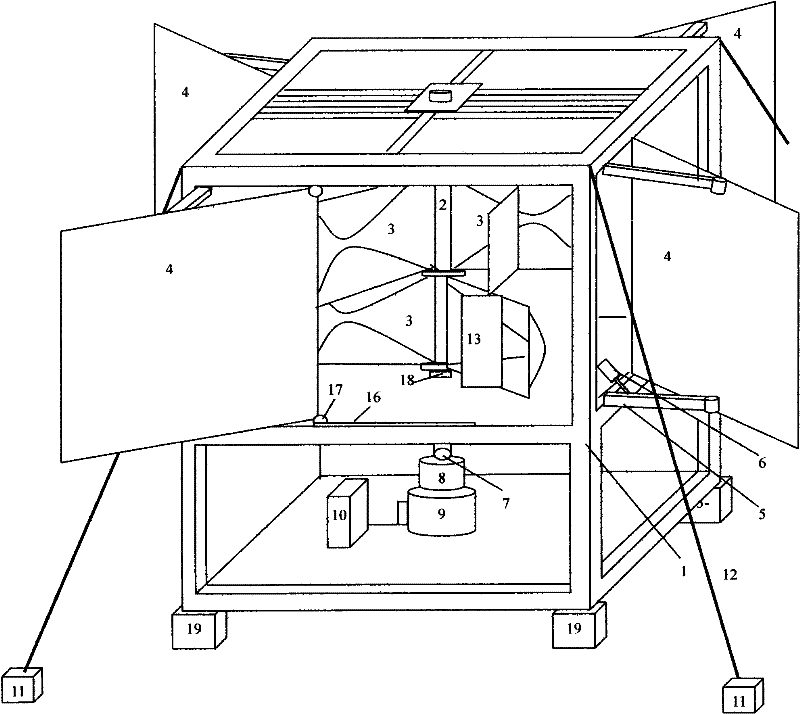

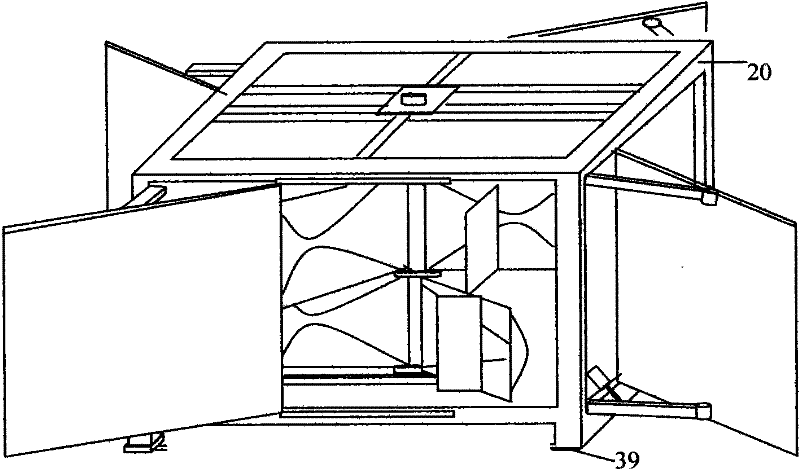

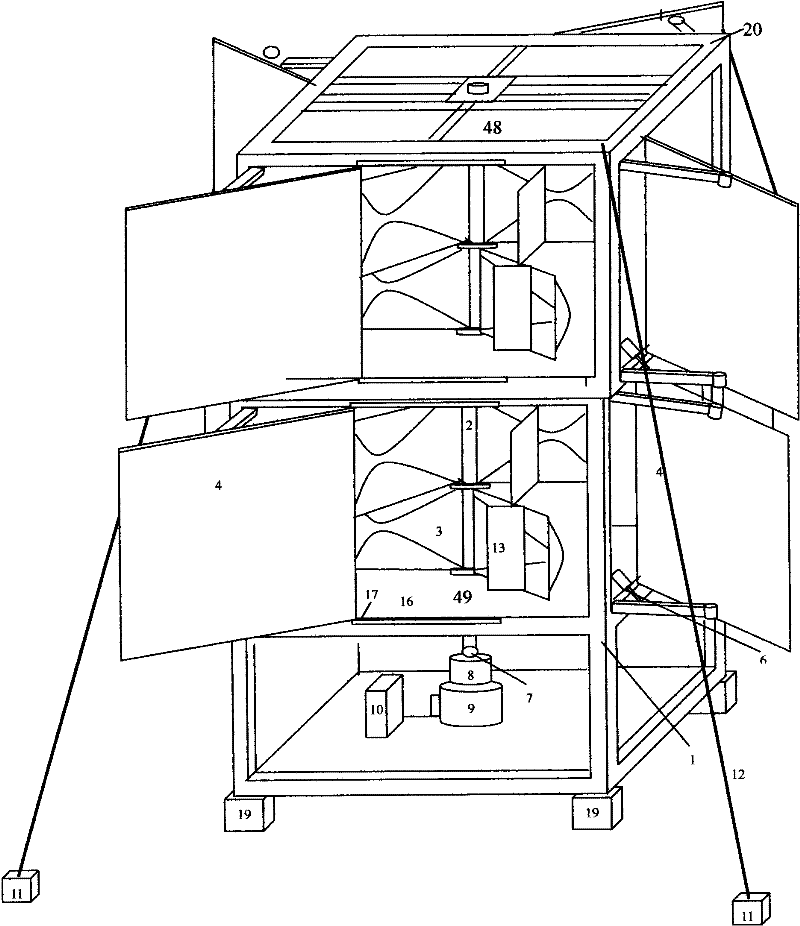

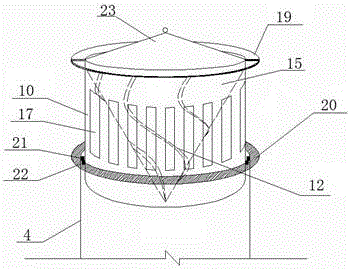

Multilayer stacking combined vertical type wind power generation system

InactiveCN102128138AReduce deformationReduce vibrationYielding couplingEngine fuctionsCouplingFan blade

The invention discloses a multilayer stacking combined vertical type wind power generation system, which comprises multi-section combined crankshafts, multilayer stacking combined vertical type wind power systems and a multilayer stacking combined type frame, wherein each layer of wind power system has a box frame structure and comprises a fan blade system, a wind collection and protection system, a double-speed increasing device and a multi-winding electrode variation generator system; each layer of wind power system individually forms an independent wind power system for operation or all layers of wind power systems are fixed together by vertical posts at all corners; a detachable combined coupling is used for connecting all layers of fan blade crankshafts into a whole, so that synchronous turning moment can be generated by each layer of fan blades; and the lower shaft end of a fan blade crankshaft on the lowermost layer of the multilayer wind power system is connected with the double-speed increasing device and the multi-winding electrode variation generator system together through the detachable combined coupling. In the invention, the wind power generation system is decomposed into a plurality of layers of combined structures, is convenient to manufacture, transport, mount, assemble and maintain, has a small volume and high performance and can form a high-capacity power generation system.

Owner:HARBIN POWER VERTICAL WIND POWER EQUIP ENG TECH RES CENT

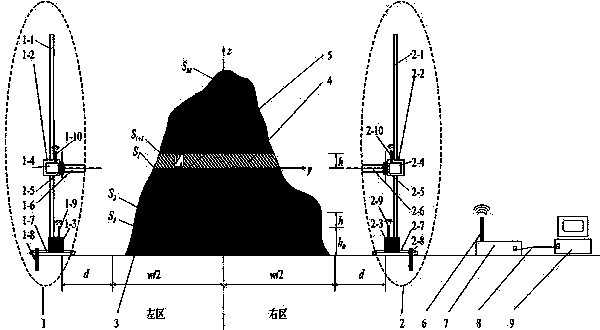

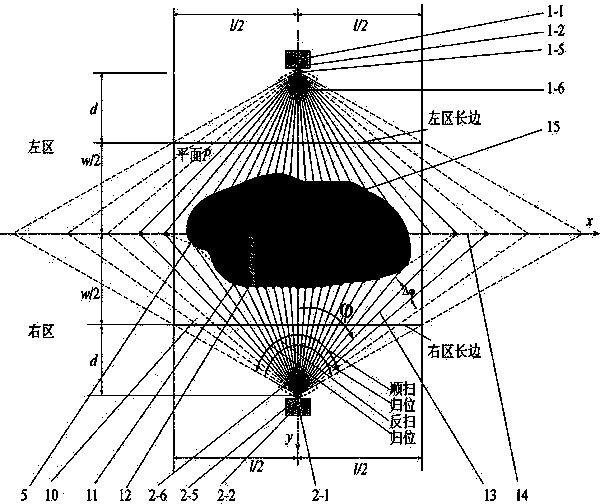

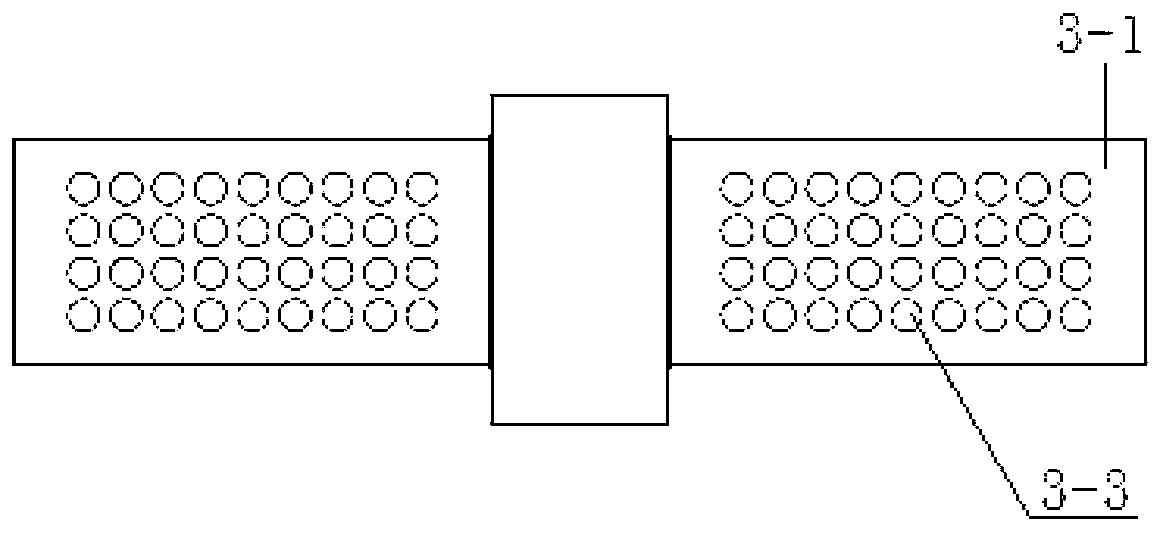

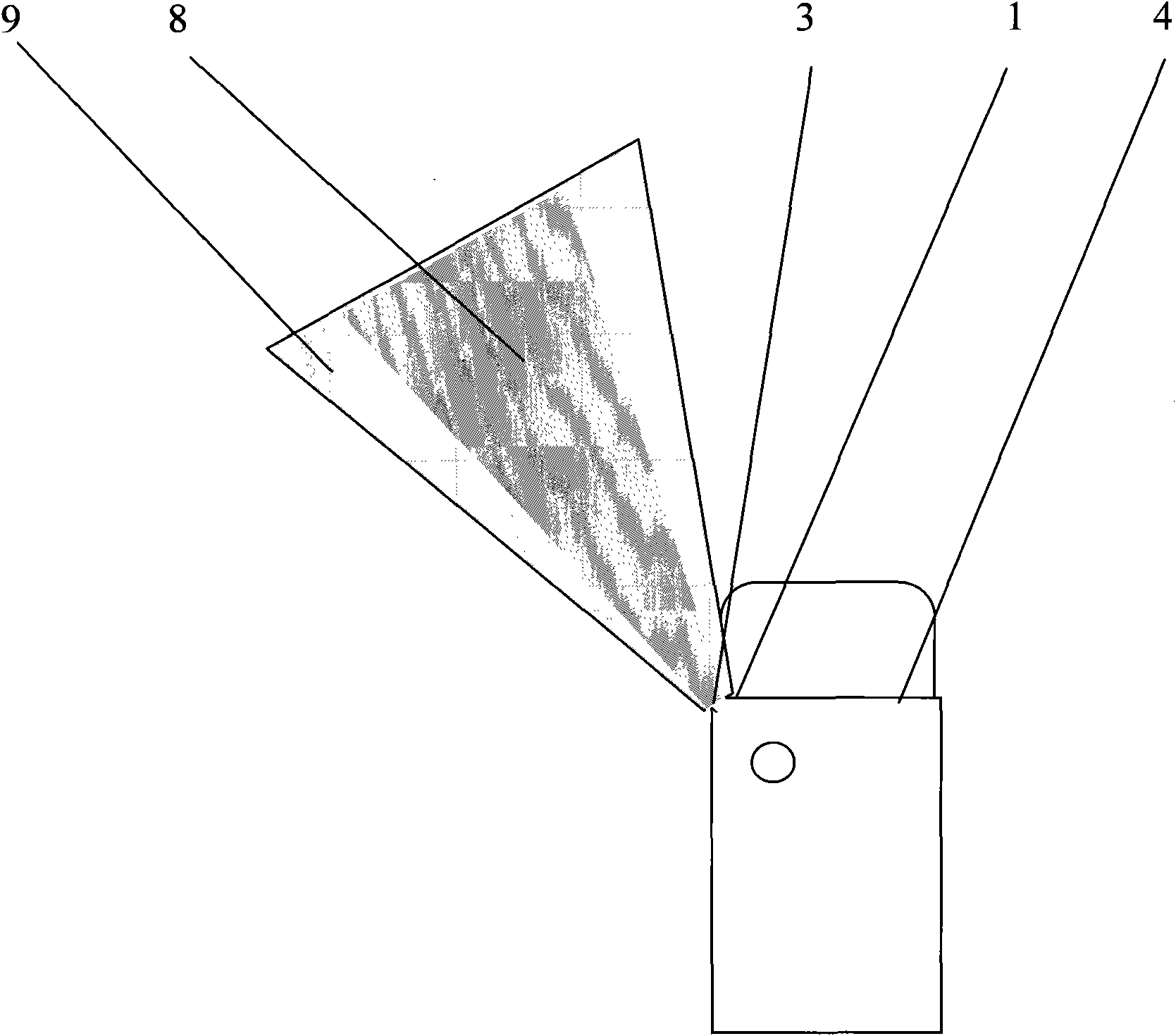

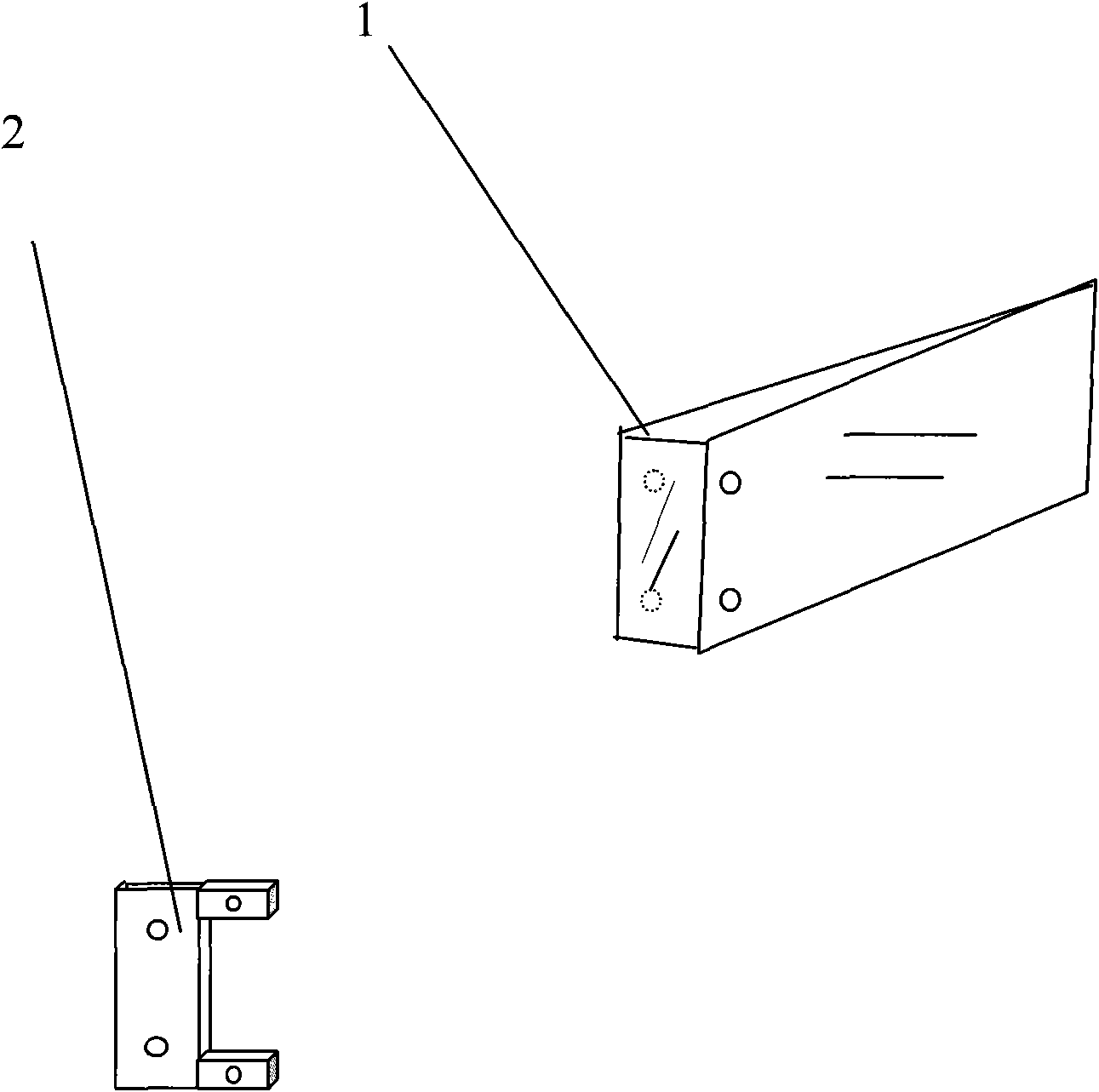

Wireless network symmetrical laser ranging-based automatic coal checking method for power plant

InactiveCN104251664AEliminate dead endsIncrease coal speedUsing optical meansNumerical controlLaser ranging

The invention discloses a wireless network symmetrical laser ranging-based automatic coal checking method for a power plant. The wireless network symmetrical laser ranging-based automatic coal checking method for the power plant adopts a system which is formed by a computer, a wireless switch, a measuring system and a wireless local area network; the measuring system comprises a left area measuring system and a right area measuring system which are formed by guide rails, sliding platforms, numerical control electromechanical boxes, scanning ranging electromechanical boxes, rotary shafts, laser ranging machines, bases, fixedly installed bolts, numerical control electromechanical box wireless access points and scanning ranging electromechanical box wireless access points. The sectional area is obtained by adding the sectional area of a left partition and the sectional area of a right partition; the volume of a coal heap is calculated by accumulating layered volume elements. According to the wireless network symmetrical laser ranging-based automatic coal checking method for the power plant, a right and left partition symmetrical synchronous laser ranging chromatographic volume calculation method is adopted, dead angles are easy to eliminate, and the coal checking speed is improved; the measuring system is fixedly installed, the left area and the right area are subjected to synchronous control and data analysis through the wireless network, full-automatic coal checking of the power plant is achieved, and the disadvantage that a conventional coal checking instrument requires professionals to operate and use is overcome.

Owner:STATE GRID CORP OF CHINA +1

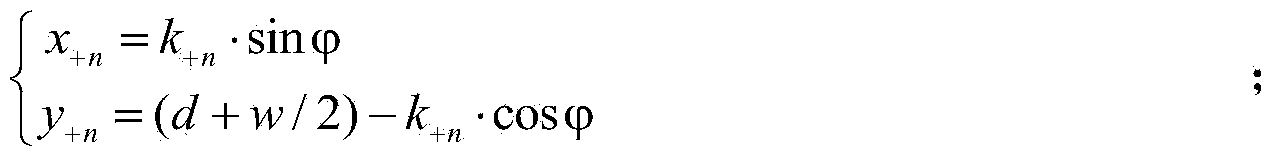

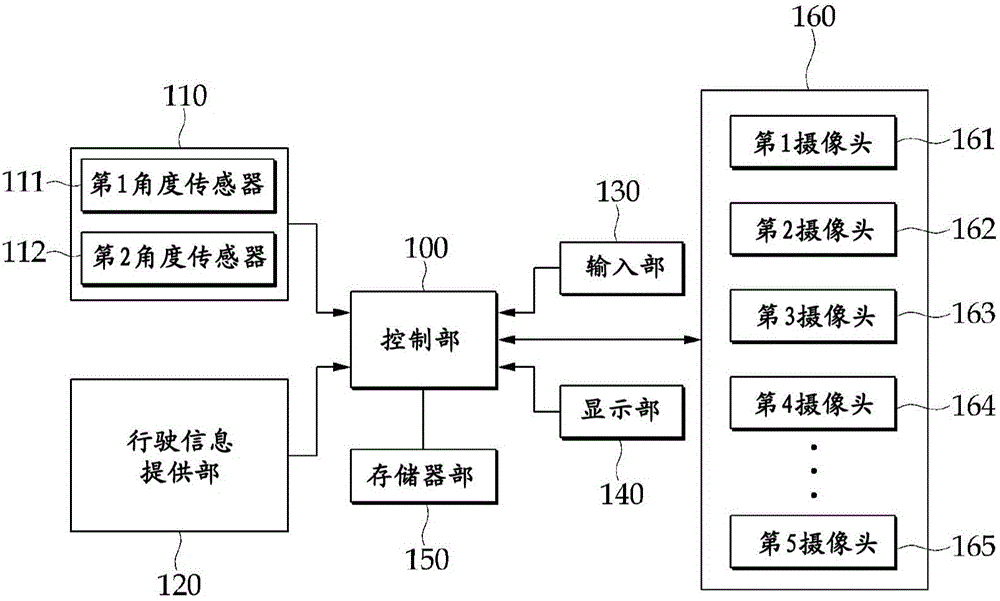

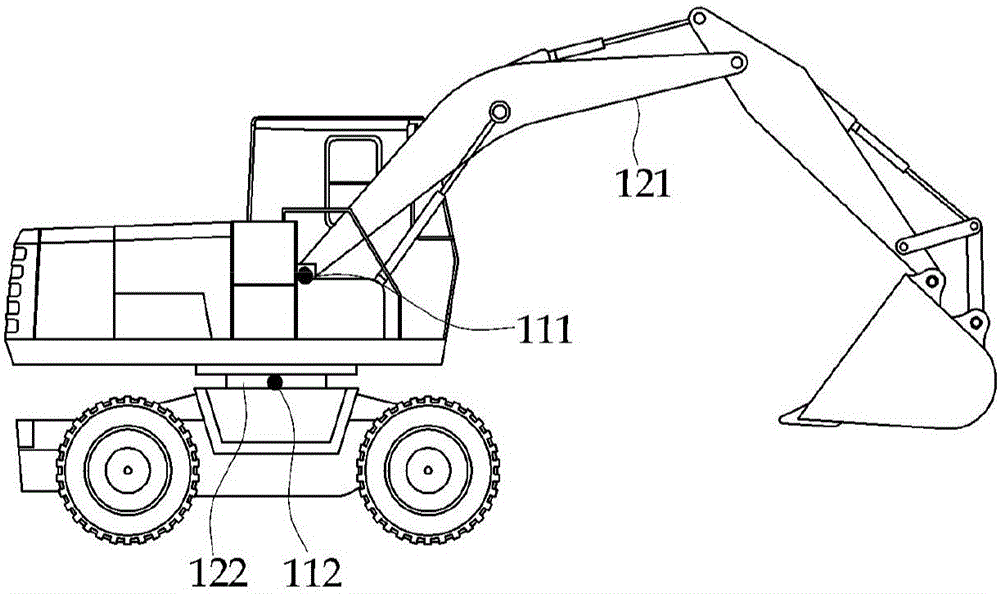

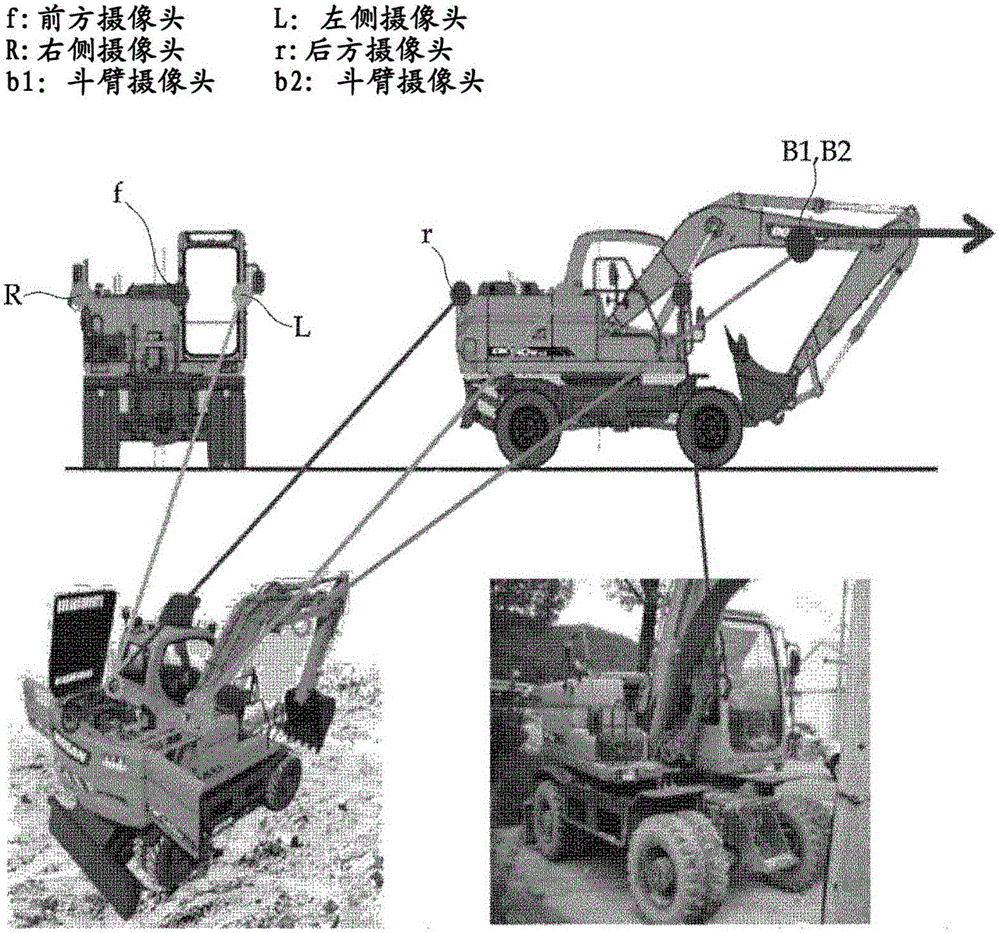

Apparatus and method for selecting screen mode

ActiveCN105793496AImprove securityEliminate dead endsMechanical machines/dredgersOptical viewingTurn angleOperation mode

An embodiment disclosed in the present specification relates to an apparatus and a method for selecting a screen mode for each operation mode in a construction equipment. The apparatus for selecting the screen mode for each operation mode in the construction equipment provides an optimal screen which can determine an operation mode using a boom angle and a turning angle and a driving speed of an upper body, remove a blind spot according to an operation mode, and improve stability.

Owner:HYUNDAI DOOSAN INVIGORATE CORP

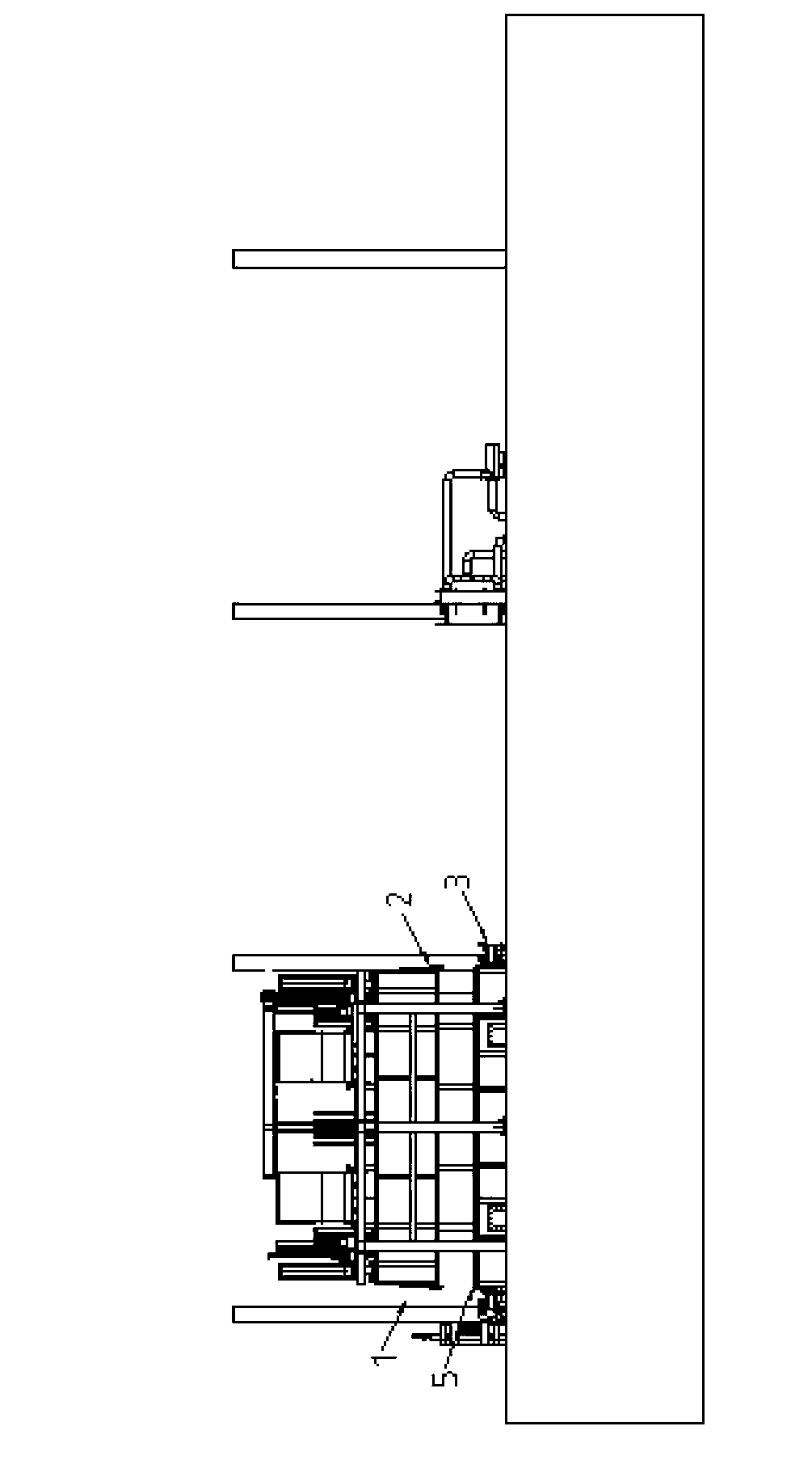

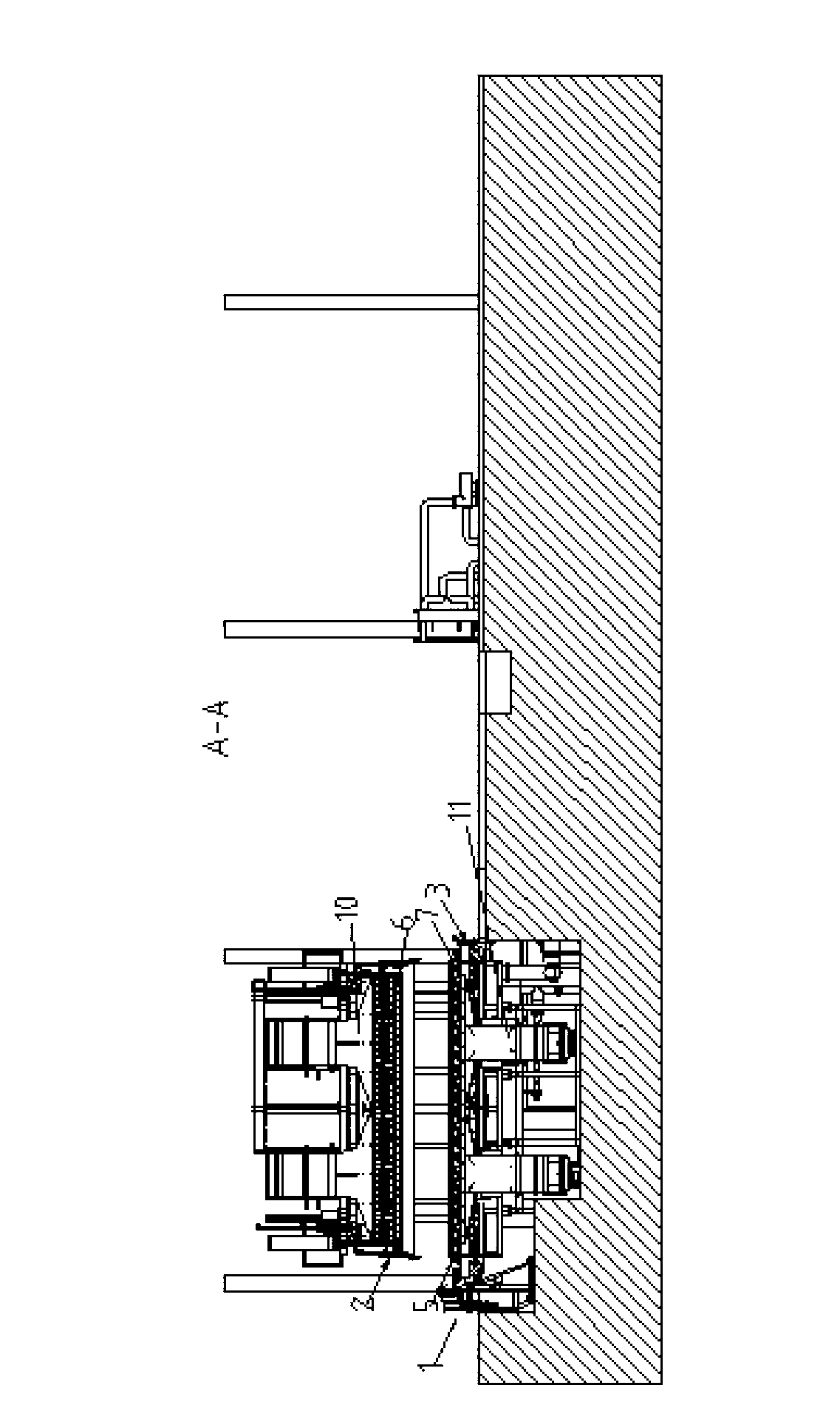

Aluminum section online combined quenching apparatus

The invention discloses an aluminum section online combined quenching apparatus. The apparatus comprises a frame, an upper cooling system, a lower cooling system and a side cooling system, the upper cooling system comprises a plurality of upper water cooling nozzles, the lower cooling system comprises a plurality of lower water cooling nozzles, the side cooling system comprises a plurality of side water cooling nozzles, each of the upper water cooling nozzles, the lower water cooling nozzles and the side water cooling nozzles is connected with a water supply device through a water tube, the water tube is provided with a waterway control system for controlling the water pressures of the corresponding upper, lower and side water cooling nozzles, and all the waterway control systems are controlled by a PLC programmable controller. The water pressures of all the water cooling nozzles are controlled by individual waterway control systems, and parameters are set through the controller, so the water pressure adjustment of all aluminum sections is realized individually, the apparatus is suitable for processing different aluminum section products, and uniform cooling and cold deformation prevention of the aluminum section are realized.

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

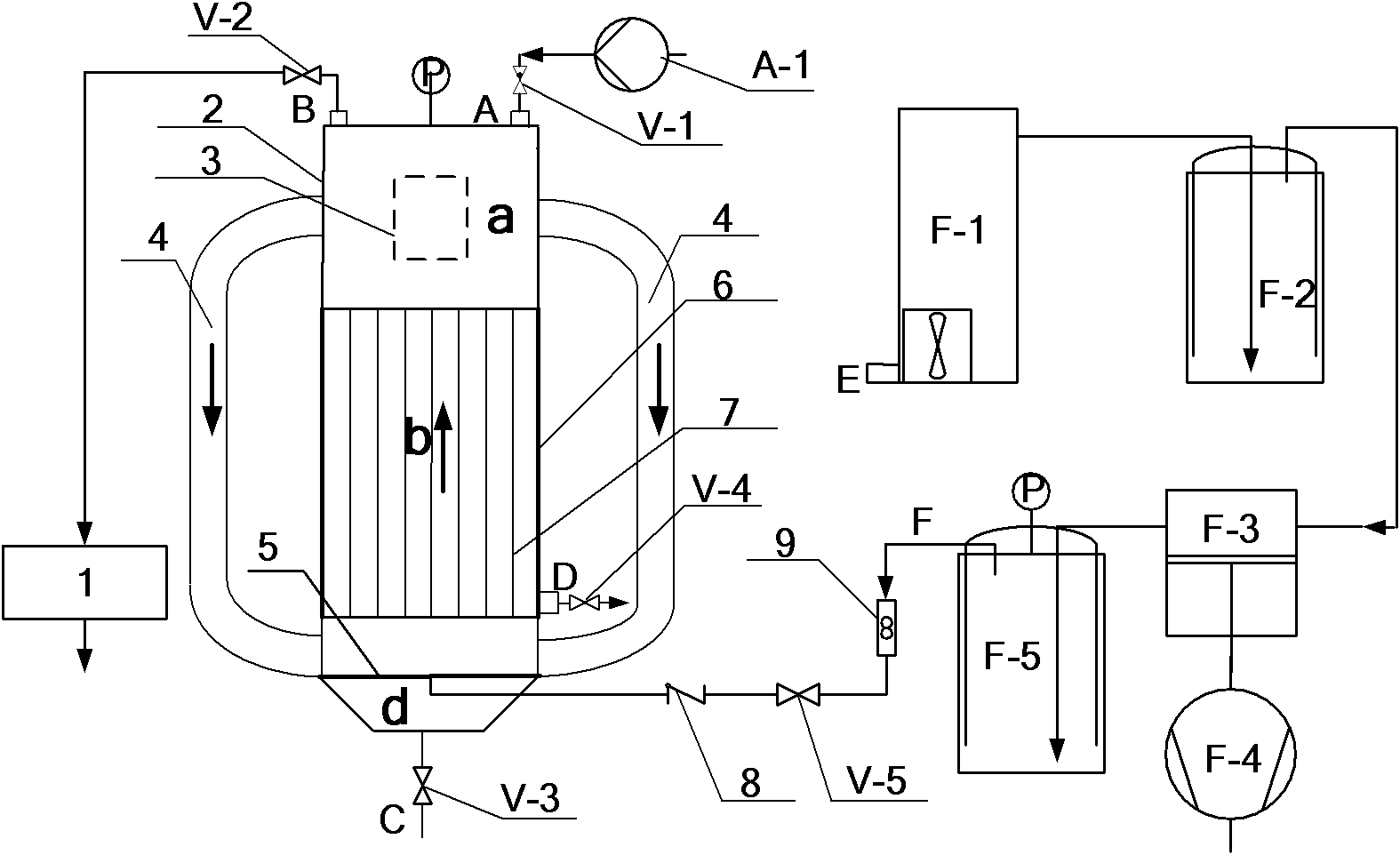

Oxidation nanofiltration membrane reactor

ActiveCN102219326AIncrease concentrationSmall footprintWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentAir compressorHigh pressure

The invention relates to an oxidation nanofiltration membrane reactor. The oxidation nanofiltration membrane reactor consists of a reaction-separation system (a raw material pump, an oxidation reaction kettle, a circulating pipe and a gas distribution plate), a pressurizing system (an ozone generator, a buffer tank, a pneumatic booster pump, an air compressor and a pressure-stabilizing tank) and a tail gas treatment system (an ozone absorption device), wherein a membrane component is encapsulated in a membrane component and placed into the reaction kettle; the circulating pipe is arranged at the position of a side arm of the kettle body; and the gas distribution plate is positioned on the top of a settling region. In the reactor, the kettle body serves as a liquid ascending region, the circulating pipe serves as a liquid descending region, gas is redistributed through a membrane channel, and gas liquid phases form slug flow in the membrane channel, so that gas liquid mass transfer is enhanced, the reaction process is enhanced and the utilization ratio of the gas is increased; and high-pressure ozonized air generated by the pressurizing system serves as a reaction source and a circulating power source of the reactor, so that the degradation of organic matters in the reactor is accelerated and a necessary impelling force is provided for separation of the nanofiltration membrane.The reactor has the advantages of simpleness and convenience in operation, high mass transfer efficiency, low energy consumption, easiness in amplification and the like.

Owner:南京工大釜鼎能源技术有限公司

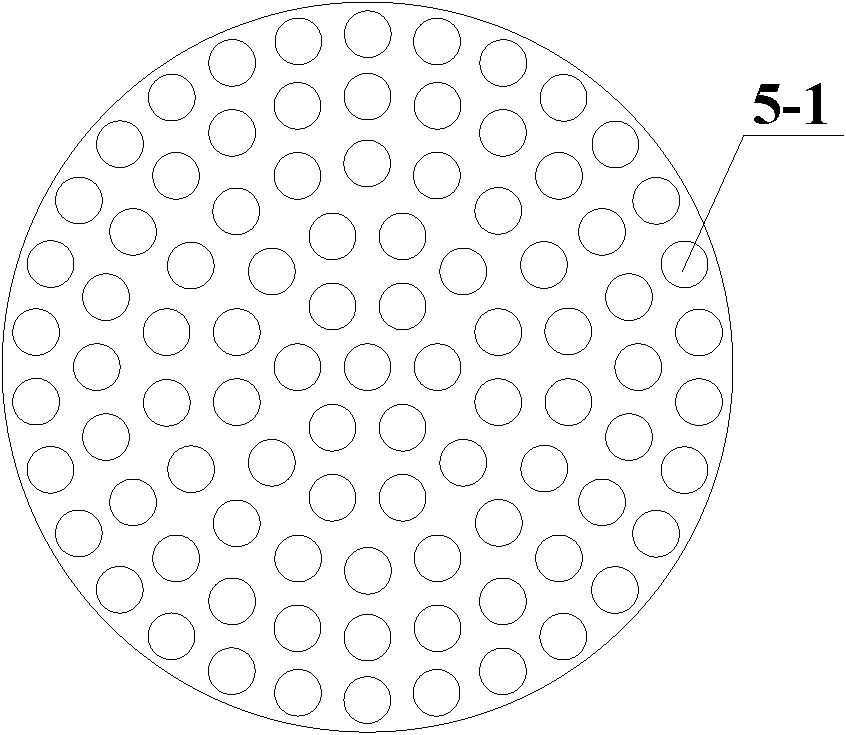

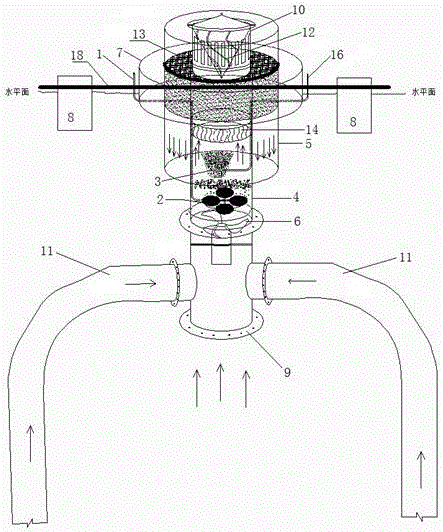

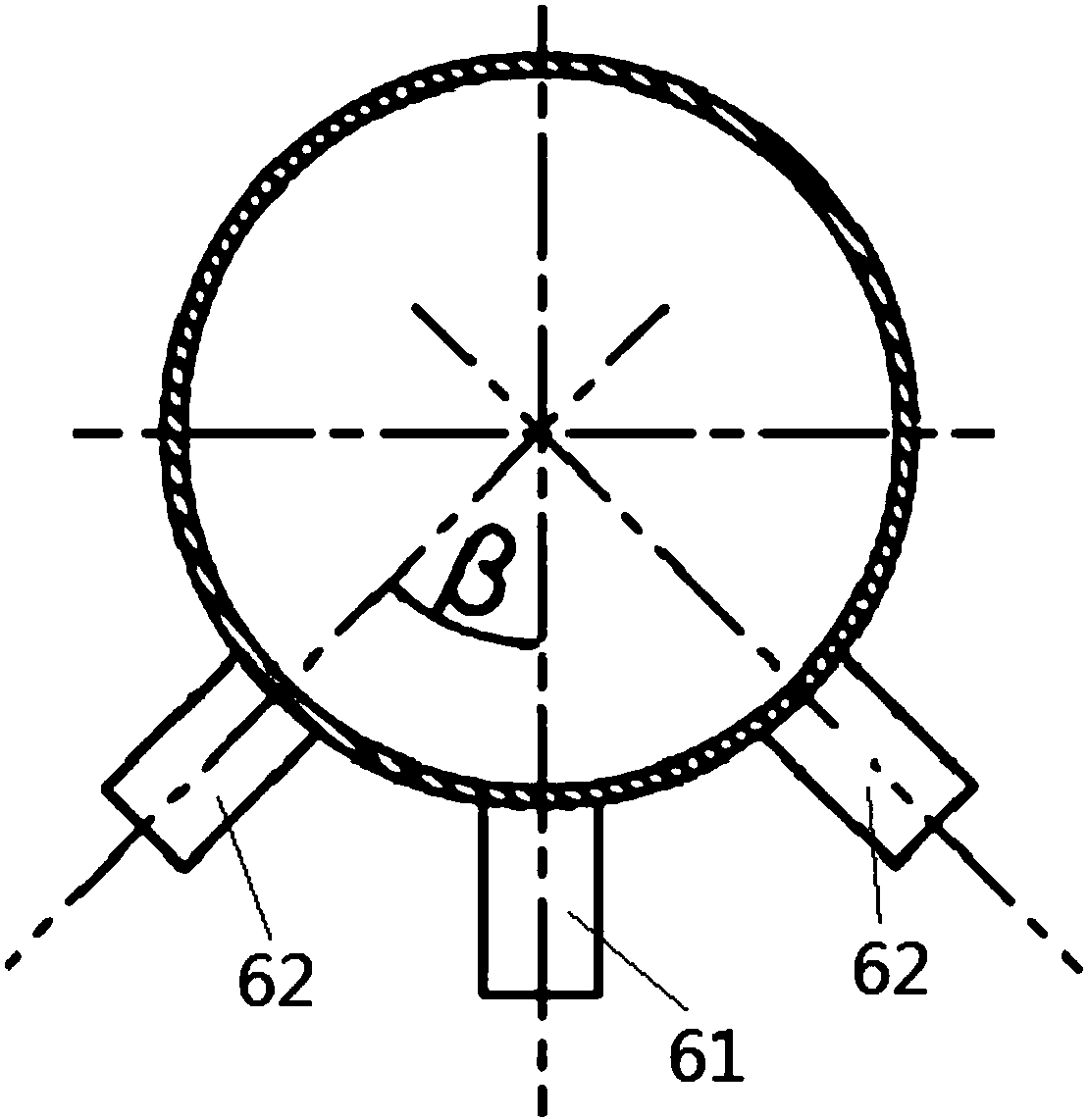

In-situ multi-medium purification system with self-rotation partial-pressure water distributor

ActiveCN106477712AAvoid pollutionEasy to form scale effectWater aerationSustainable biological treatmentMicro nanoCounter flow

The invention discloses an in-situ multi-medium purification system with a self-rotation partial-pressure water distributor. The in-situ multi-medium purification system comprises a counter-flow outer drum, a drainage inner drum, a vortex unit and an aeration plate. A micro-nano bubble releaser is arranged above the aeration plate, and a biological reaction membrane filler area is arranged above the micro-nano bubble releaser. The self-rotation water distributor is arranged in a top opening end of the drainage inner drum, the middle upper portion of the drainage inner drum and the self-rotation water distributor are arranged in the counter-flow outer drum with the upper end closed and the lower end open, a filler area is arranged between the upper portion of the drainage inner drum and the counter-flow outer drum, a plurality of far-end drainage pipes are arranged on the lower portion of the drainage inner drum, and an in-situ water inlet is formed in an opening position of the lower end of the drainage inner drum. The in-situ multi-medium purification system integrates the functions of oxygen enrichment, vertical convection, horizontal displacement drainage, energy conservation and consumption reduction of water bodies, and is an ecological restoration system for in-situ water bodies of large lakes, reservoirs and ponds. Compared with the prior art, the in-situ multi-medium purification system has the advantages that the in-situ multi-medium purification system is capable of achieving large-range aeration and clearing dead angles of the water bodies and wide in flow pushing and perturbance range.

Owner:刘牧

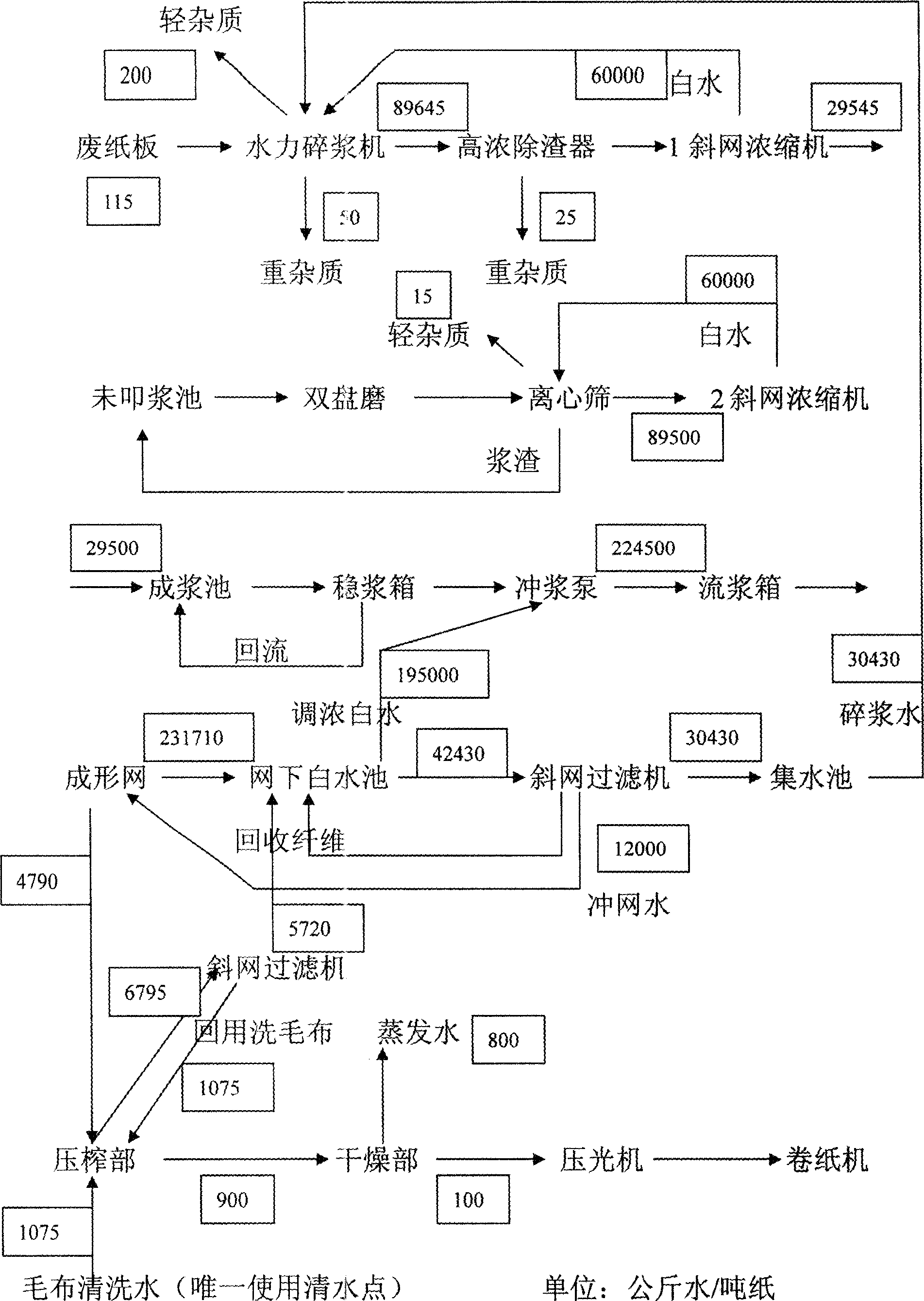

Non-process sealing circulation technology for wastewater from pulp and paper making by non-delignify reaction

InactiveCN101153471AIncrease concentrationReduce water consumption per ton of paperPulp liquor regenerationImpurityUntreated wastewater

The invention provides a closed circulation technology of untreated wastewater of non-delignification reaction pulp and paper and mainly adjusts and reforms a pulp and paper system of the non-delignification reaction to adapt a segment short process closed circulation reuse which is processed to discharge wastewater without chemical, biochemical treatment in a production process of pulp and paper, and to control added quantity of clear water which is the same as the demanded water consumption of the pulp and paper process (namely a sum of evaporated water of a dryer section of paper machine and carried water in impurities which is separated when the paper machine pulps); therefore, wastewater can not be discharged outward, and water consumption per ton production during the production process of pulp and paper is greatly reduced.

Owner:吴解生

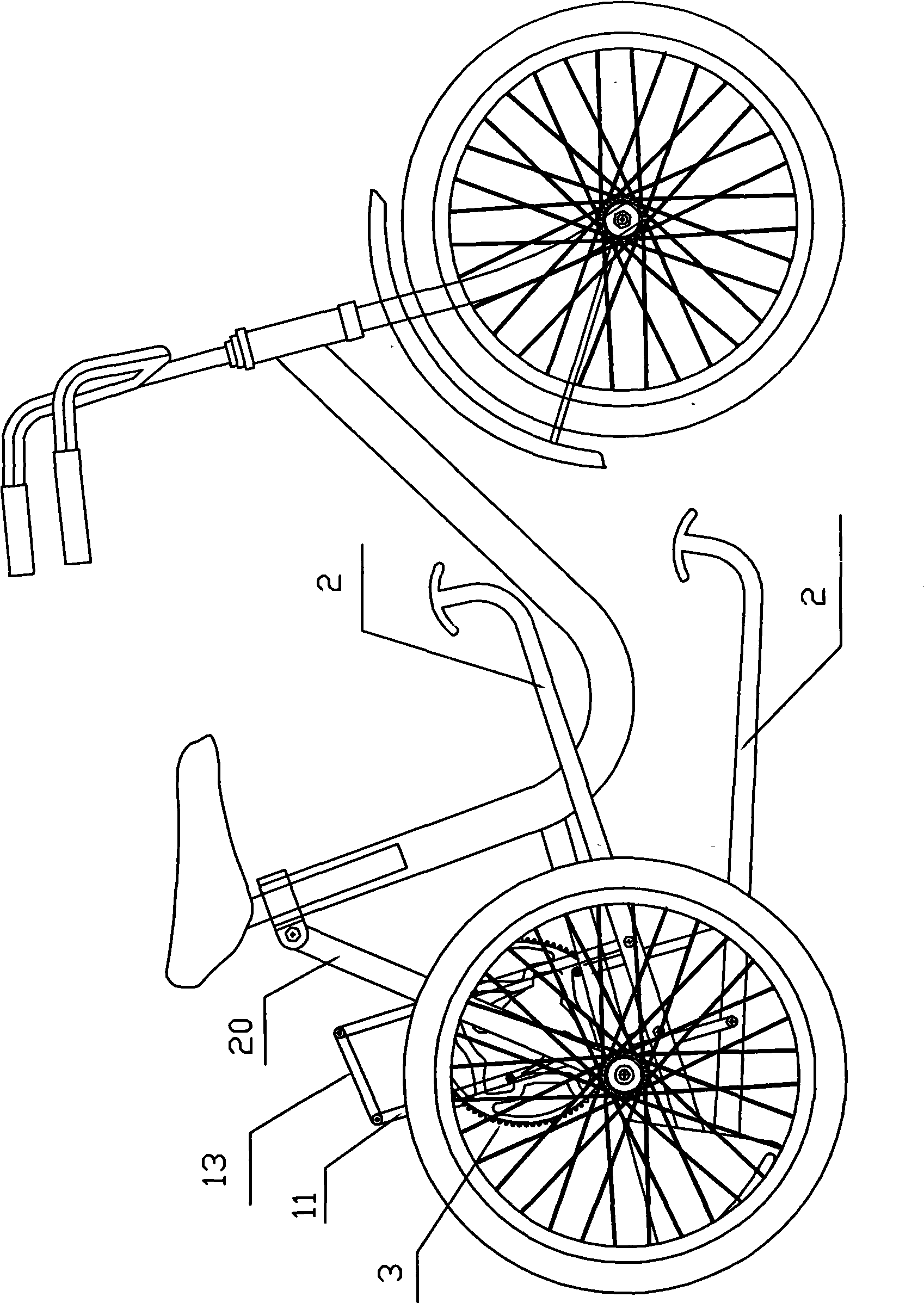

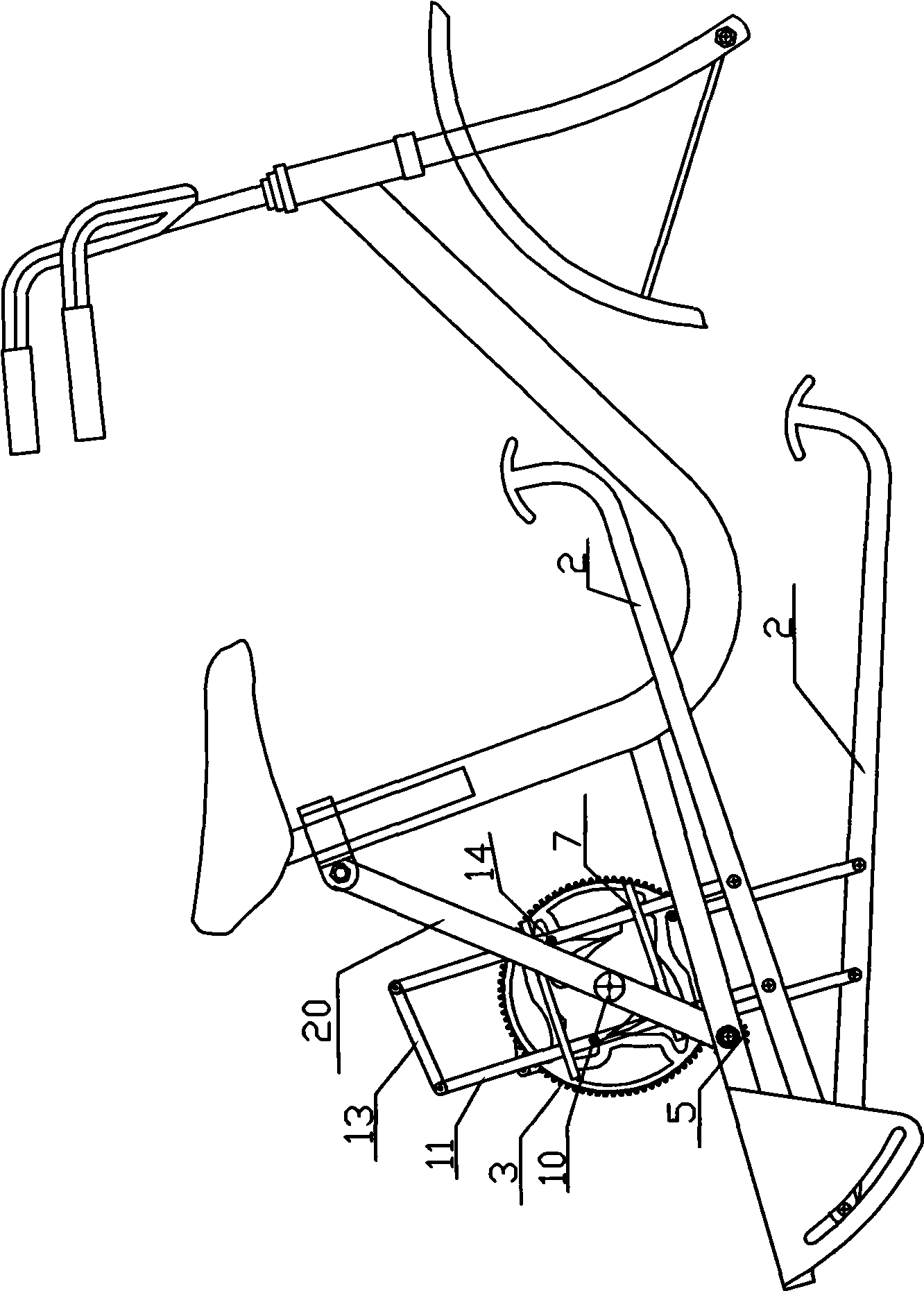

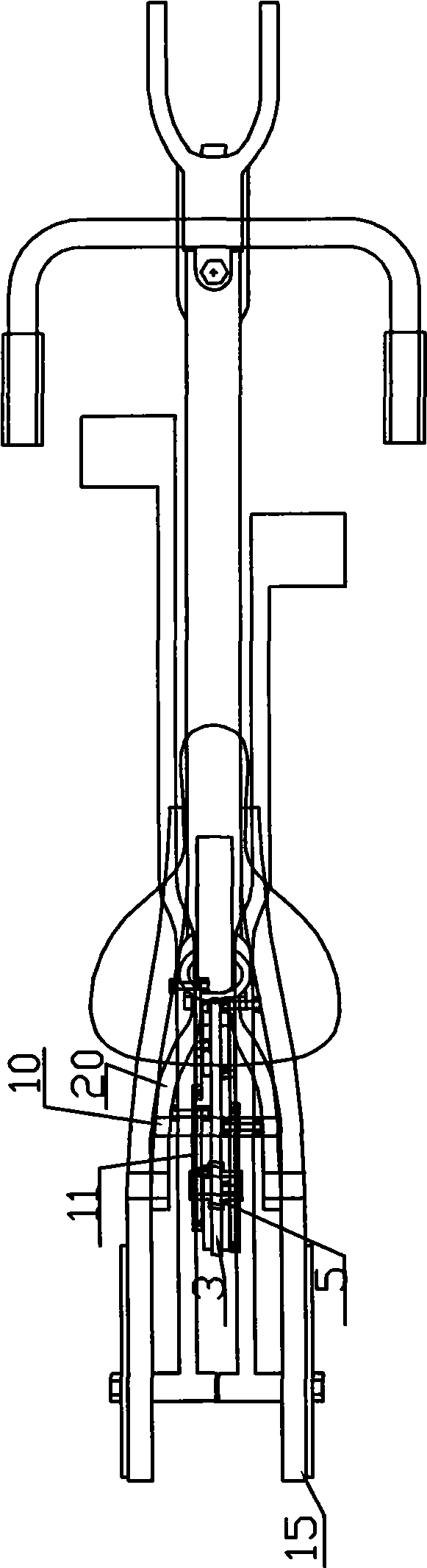

Bicycle with linking lever and cam

InactiveCN101519092AGood labor saving effectImprove efficiencyWheel based transmissionBicyclesVehicle frameDrive wheel

The invention discloses a bicycle with linking lever and cam, comprising a vehicle frame, a front vehicle wheel, a back vehicle wheel and a vehicle wheel drive device. The vehicle wheel drive device comprises a lever, swinging rods, a drive wheel and a speed-change mechanism, wherein one end of the lever is a linear drive force-application end, and the other end is movably connected on the vehicle frame; the lower end of each swinging rod is articulated with the lever, a roller is arranged at the upper end of each swinging rod, and the middle lower end of a front swinging rod is movably connected with the middle lower end of a back swinging rod through a hinged bar; the speed-change mechanism comprises a drive gear ring, an intermediate wheel, a driven gear ring, a triangular swinging plate and a pull rod. A contour curved surface which is movably connected with the roller is arranged in the drive wheel, and is provided a farthest lower pull surface, a farthest upper pull surface, a transition surface and a transition surface of delay angle, wherein the farthest lower pull surface and the farthest upper pull surface are symmetrically arranged taking the wheel shaft as the center; and the transition surface is used for communicating the farthest lower pull surface and the farthest upper pull surface. The invention cancels a double foot lost motion part of a crank mechanism to save more labor, thereby the utilization rate of force achieves a favorable state.

Owner:NANTONG BAOTIAN PACKING MACHINERY

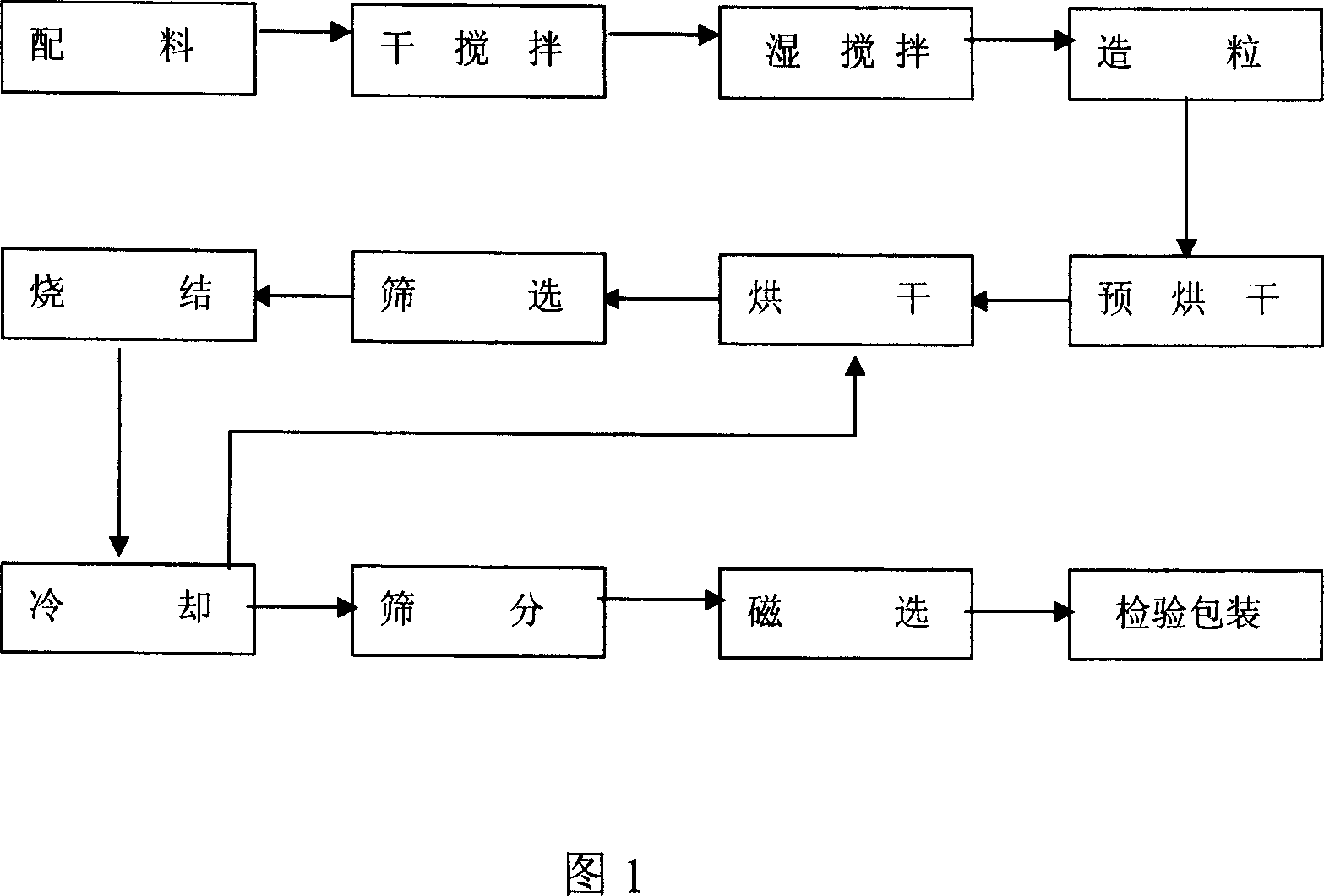

Sintered flux production process

ActiveCN1962156AEliminate dead endsGuaranteed uniformityWelding/cutting media/materialsSoldering mediaAnti adhesiveWork in process

The invention relates to a method for producing sinter solder, which comprises preparing material, mixing, making particles, pre-drying, drying, selecting, sintering, cooling, selecting, magnetic selecting, checking, and packing, wherein the invention uses dry-wet mixing separating technique, to eliminate the dead corner and confirm the uniform product, with stable product quality. And it uses vibration fluidize drying technique to reduce block ratio in drying process under 5%. And it coats anti-adhesive coat on the contact with material. The invention uses left heat recycle technique, to recycle the heat when cooling solder into former processes to dry the semi product. And the energy consumed by roller drier is from the left heat.

Owner:BAOJI PETROLEUM STEEL PIPE

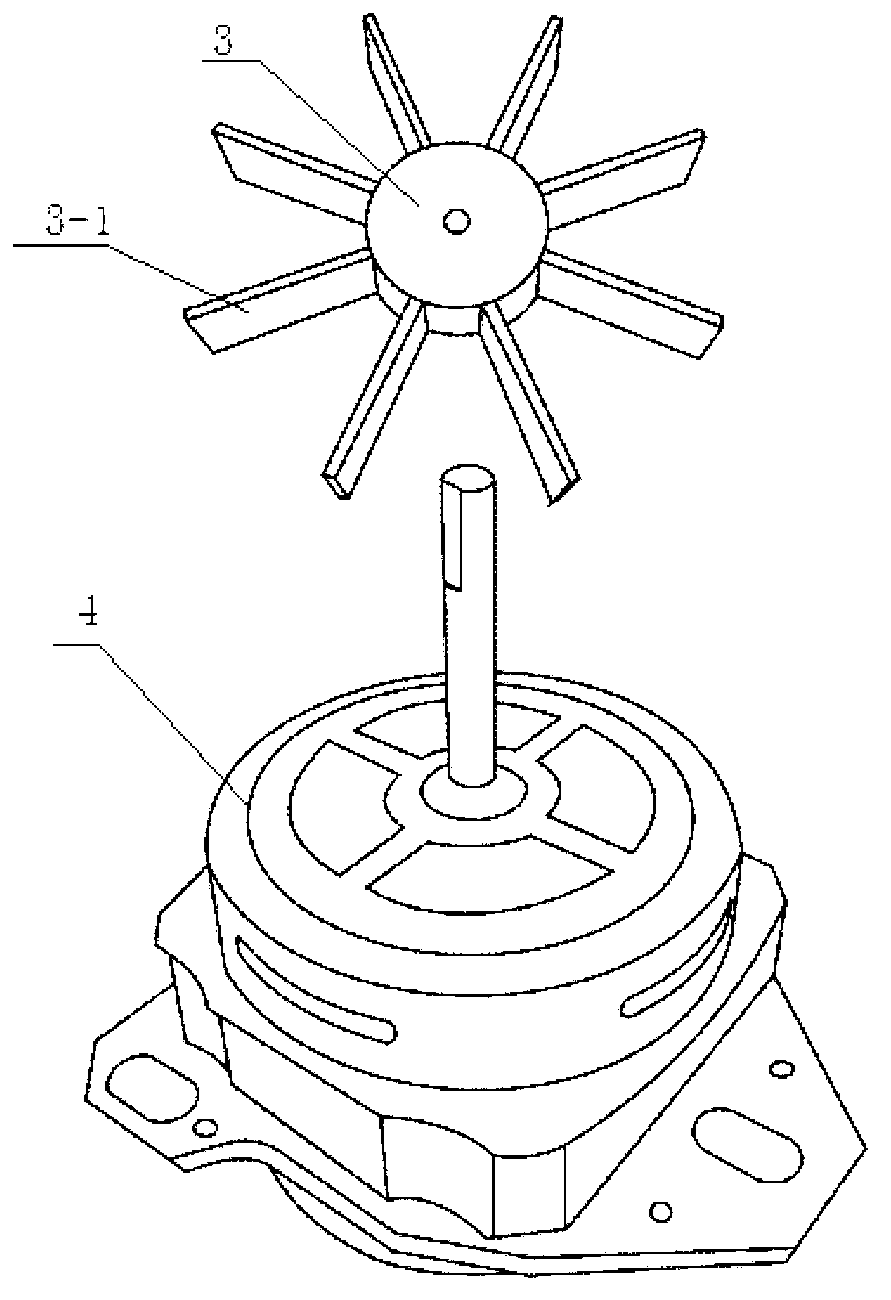

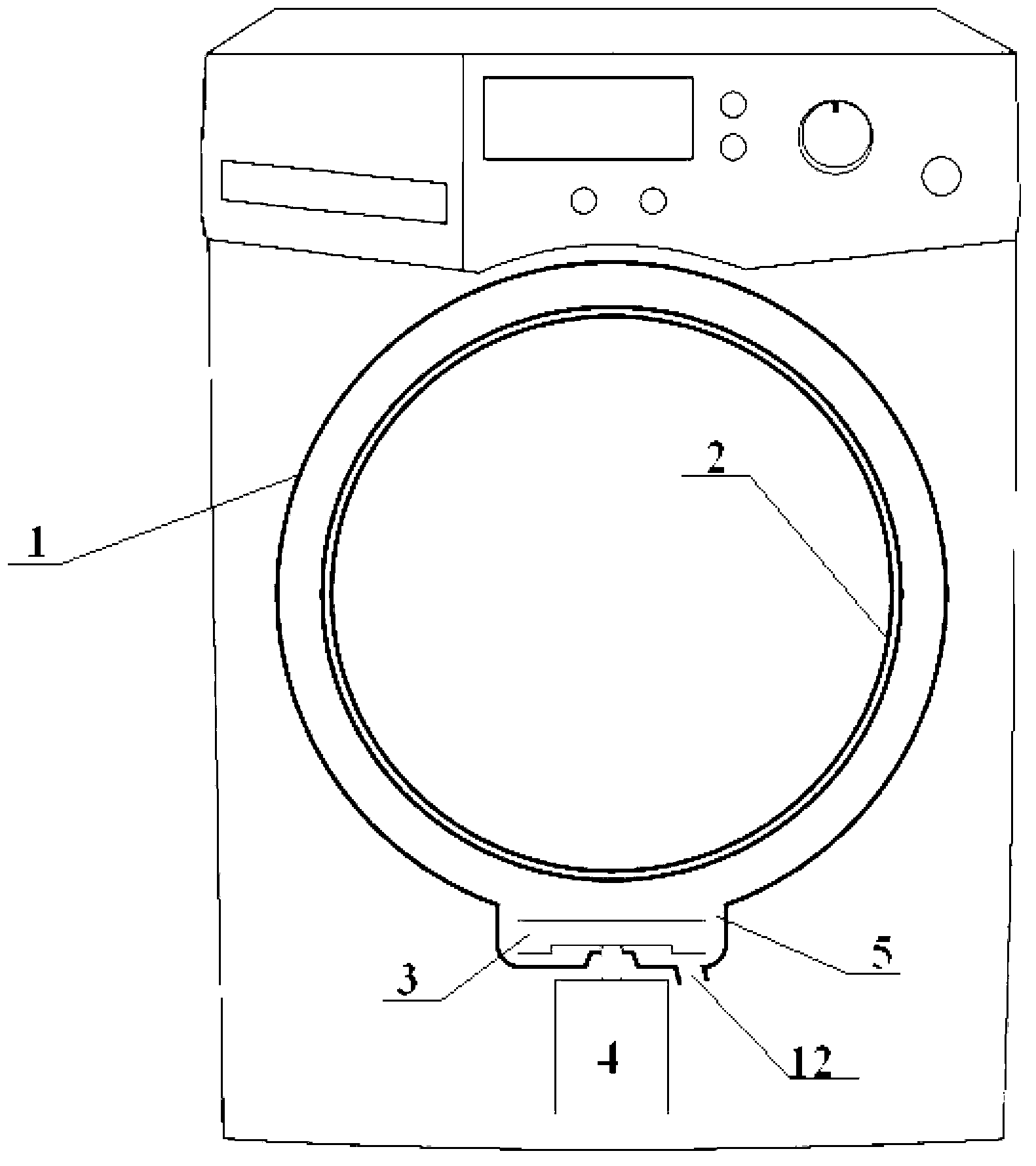

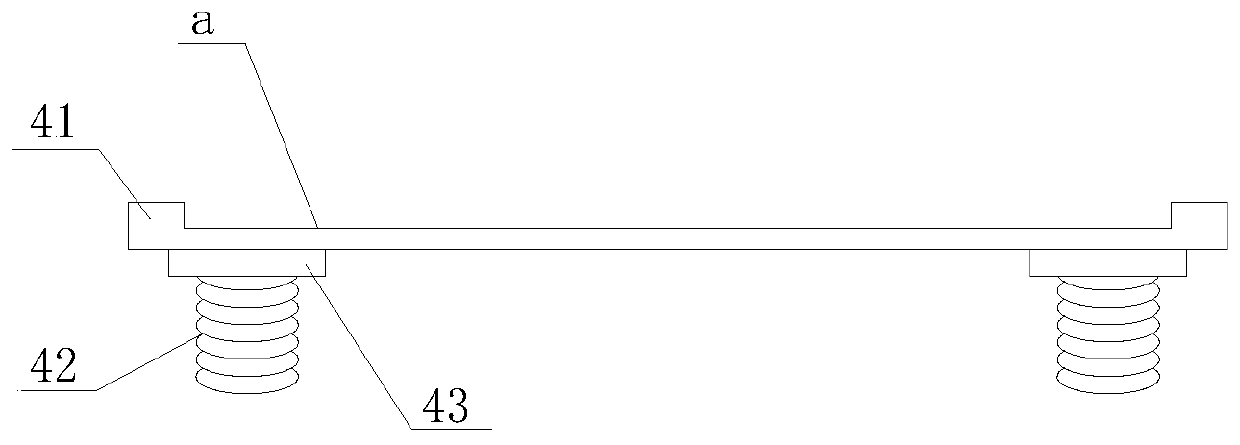

Water circulating device for low temperature fast dissolving of detergent and efficient washing of roller washing machine and working method thereof

ActiveCN103276561AImprove cleaning ratioLower turn-to-stop ratioOther washing machinesControl devices for washing apparatusWater flowWater cycling

The invention relates to a water circulating device for low temperature fast dissolving of detergent and efficient washing of a roller washing machine. The water circulating device comprises a water rotating wheel arranged at the bottom of the roller washing machine and between an outer barrel and an inner barrel, wherein the water rotating wheel comprises a middle shaft and paddle blades fixedly arranged on the middle shaft, and a motor which drives the water rotating wheel to rotate is arranged at the bottom of the outer barrel. The water circulating device achieves strong rotation and spewing for water currents at the bottom of the roller washing machine, then accelerates fast high dissolving of the detergent, and avoids the problem that the detergent is difficult to dissolve due to the facts that the detergent precipitates and stacks at dead angles below the inner barrel formerly. The water circulating device for the low temperature fast dissolving of the detergent and the efficient washing of the roller washing machine achieves double power washing for clothes simultaneously through rotation of a roller and rotating water currents, and achieves a good effect of reducing wear rate of the clothes by reducing the rotation stop rate and the rotation speed of the roller on the basis of improving the cleanly washing rate of the clothes. The water circulating device for the low temperature fast dissolving of the detergent and the efficient washing of the roller washing machine can use a low power motor to drive the water rotating wheel, achieves a good cleanly washing effect of low temperature fast dissolving detergent, and achieves energy conservation and emission reduction really.

Owner:李守林

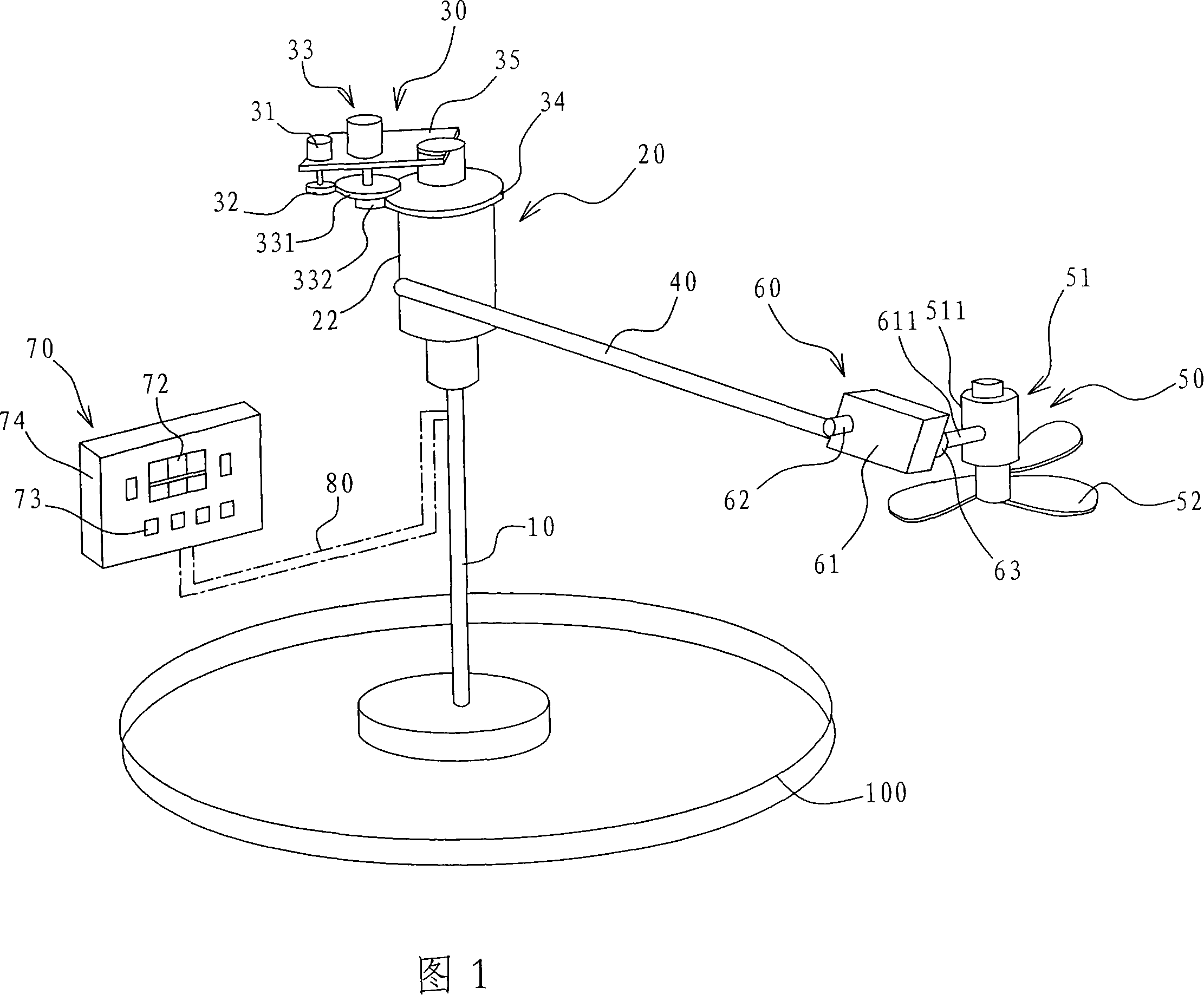

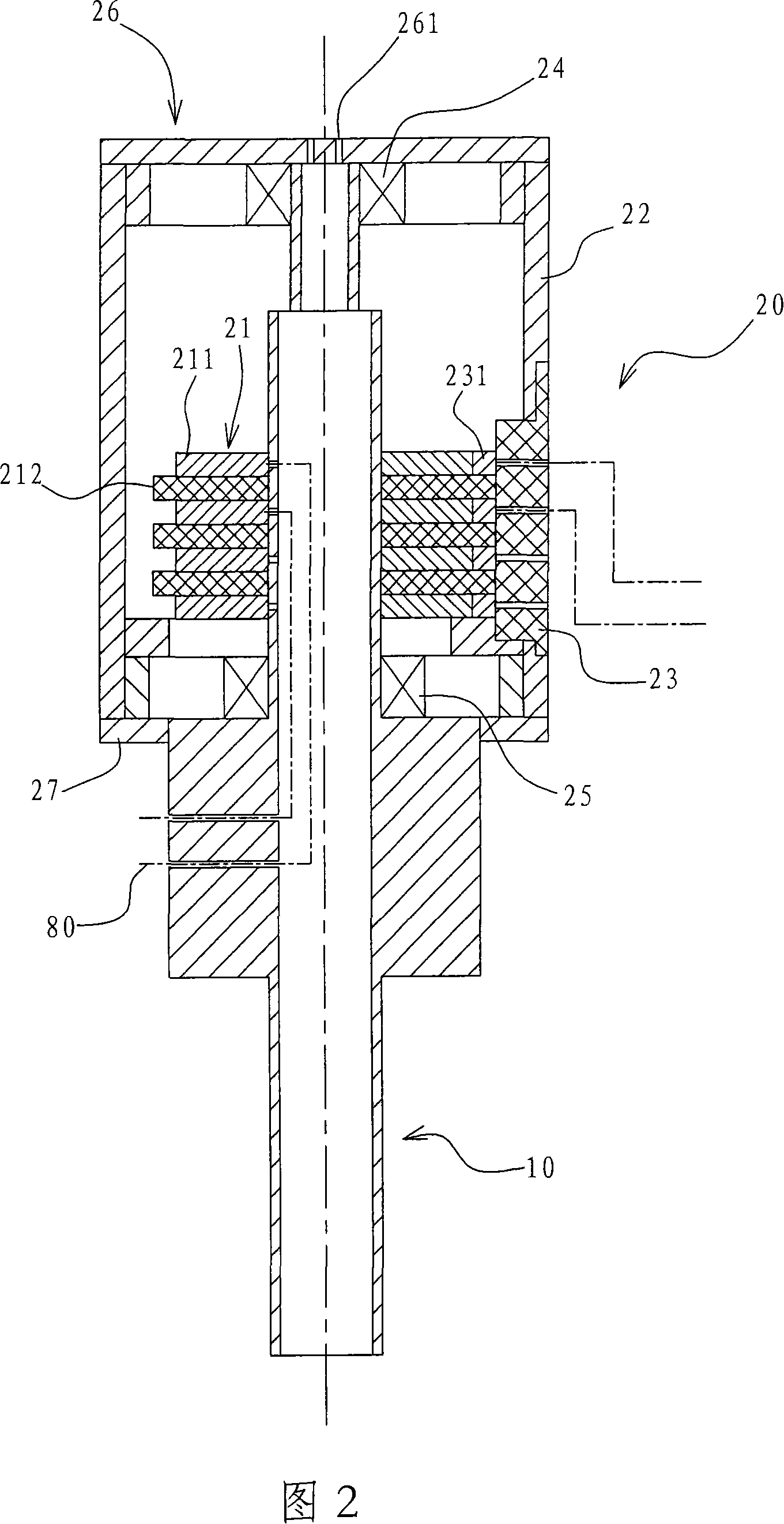

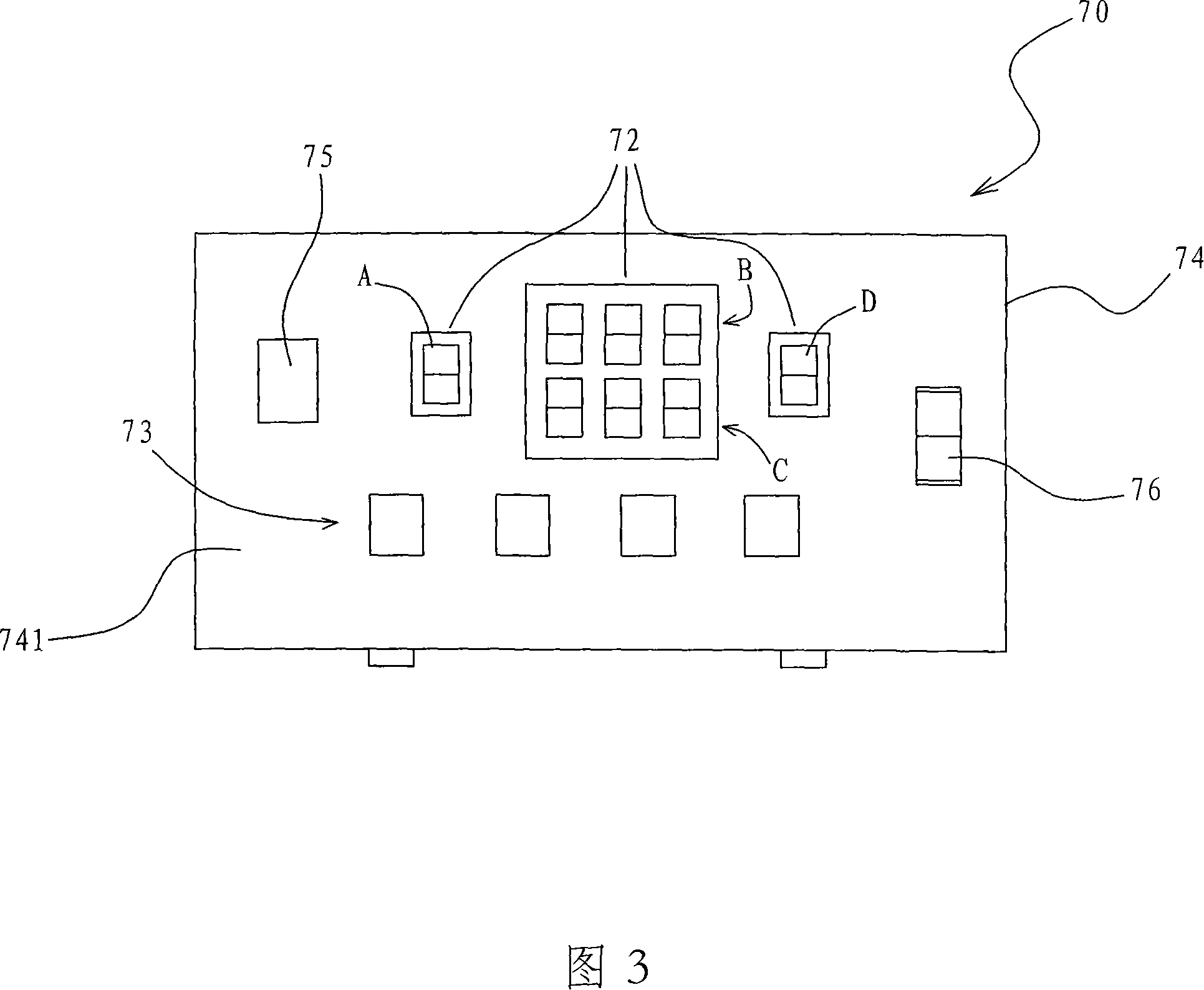

Tree-dimensional rotary knitting loom dust cleaning apparatus

ActiveCN101113549AAchieve compound movementReduce running noiseKnittingVertical planeTransverse plane

The invention relates to a three-dimension rotating knitter cleaner, comprising a vertical main rod, a rotating electrical connector, a driving mechanism, a fan connecting rod, a fan, a deceleration mechanism and a main controller, wherein, the vertical main rod is arranged on a machine table, the rotating electrical connector is arranged at the upper end of the main rod, the driving mechanism can drive the rotating electrical connector to rotate, and the fan connecting rod can rotate synchronously with the rotating electrical connector; the deceleration mechanism is used for the deceleration and inversion, the fan is arranged at the end part of the fan connecting rod, and is capable of rotating around the main rod in a horizontal plane to do circumference movement and rotating with any angle in the vertical plane around an output shaft of the deceleration mechanism, and the main controller can control the running of the cleaner. The cleaning fan of the invention can not only rotate in a large circle above the machine table and in a plane being parallel to the machine table, but also rotate around the rotating shaft thereof in the vertical plane, thus realizing a complex movement of the cleaning fan in a three-dimension space, and effectively saving space and energy, enhancing the cleaning efficiency and decreasing noises.

Owner:YANCHENG WANDALI KNITTING MACHINERY

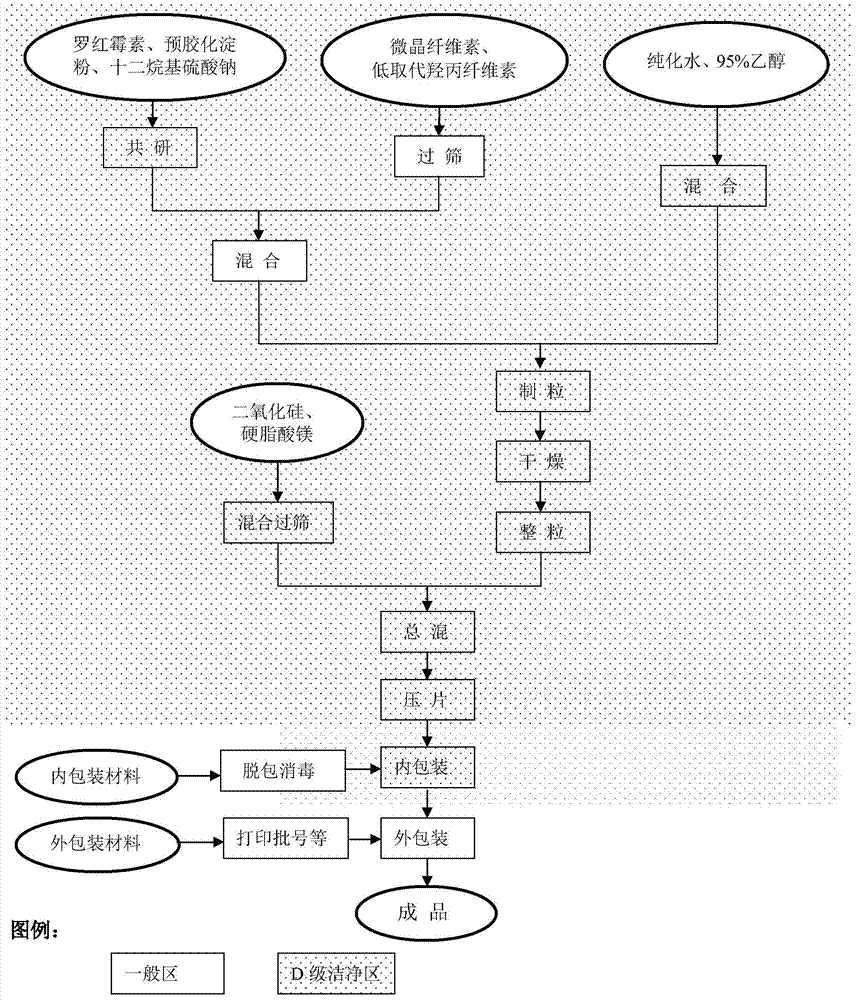

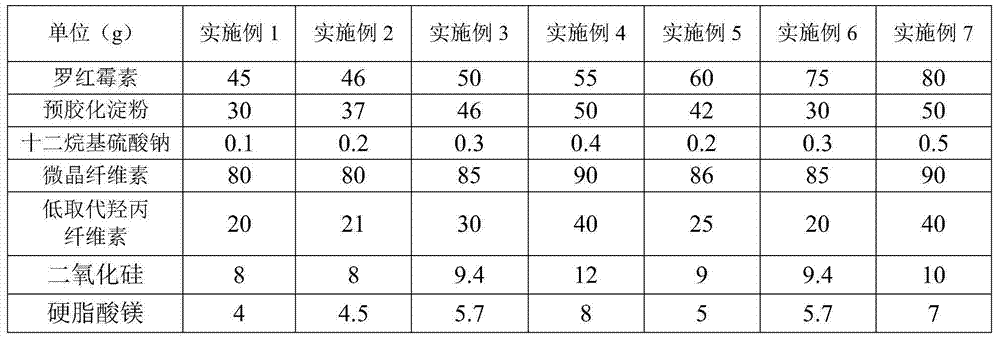

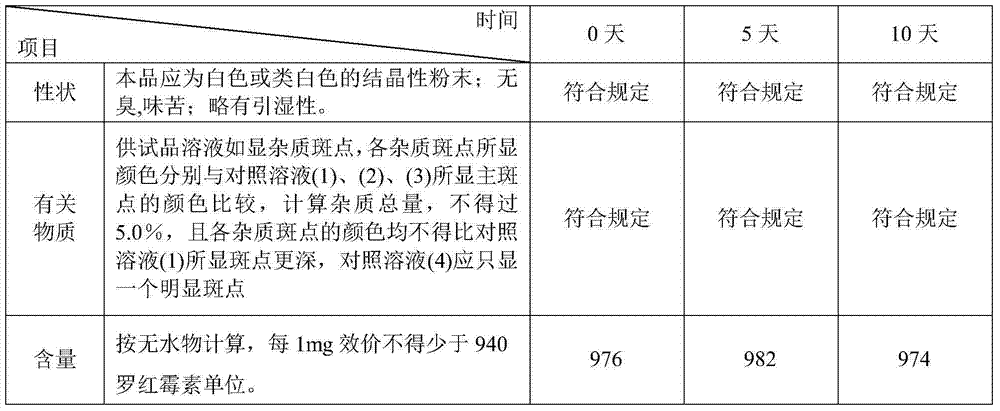

Method for preparing roxithromycin dispersible tablet

ActiveCN104739792AEffective absorptionMeet the needs of takingAntibacterial agentsOrganic active ingredientsRoxithromycinPrill

The invention discloses a method for preparing a roxithromycin dispersible tablet. The method comprises the following steps: (1) pre-grinding roxithromycin, pregelatinized starch and lauryl sodium sulfate to obtain a roxithromycin pre-ground material for later use; (2) mixing the roxithromycin pre-ground material, microcrystalline cellulose and low substituted hydroxypropy cellulose, adding an ethanol aqueous solution, granulating by a wet method, drying, screening through a 20-60-mesh screen to obtain a pre-mixed granular material for later use; (3) mixing the pre-mixed granular material, silicon dioxide and magnesium stearate, and tabletting to prepare the roxithromycin dispersible tablet. According to the method, roxithromycin and partial auxiliaries are together ground, so that the hydrophilicity of a medicine is improved, the contact angle is reduced, and the bioavailability of the medicine is improved; furthermore, high-efficiency wet-process granulation and boiling drying are adopted at the same time, so that the labor intensity is reduced, the production efficiency is improved, and the prepared dispersible tablet can be quickly uniformly dispersed in water to facilitate effective absorption of a human body after the dispersible tablet is taken.

Owner:SICHUAN KELUN PHARMA CO LTD

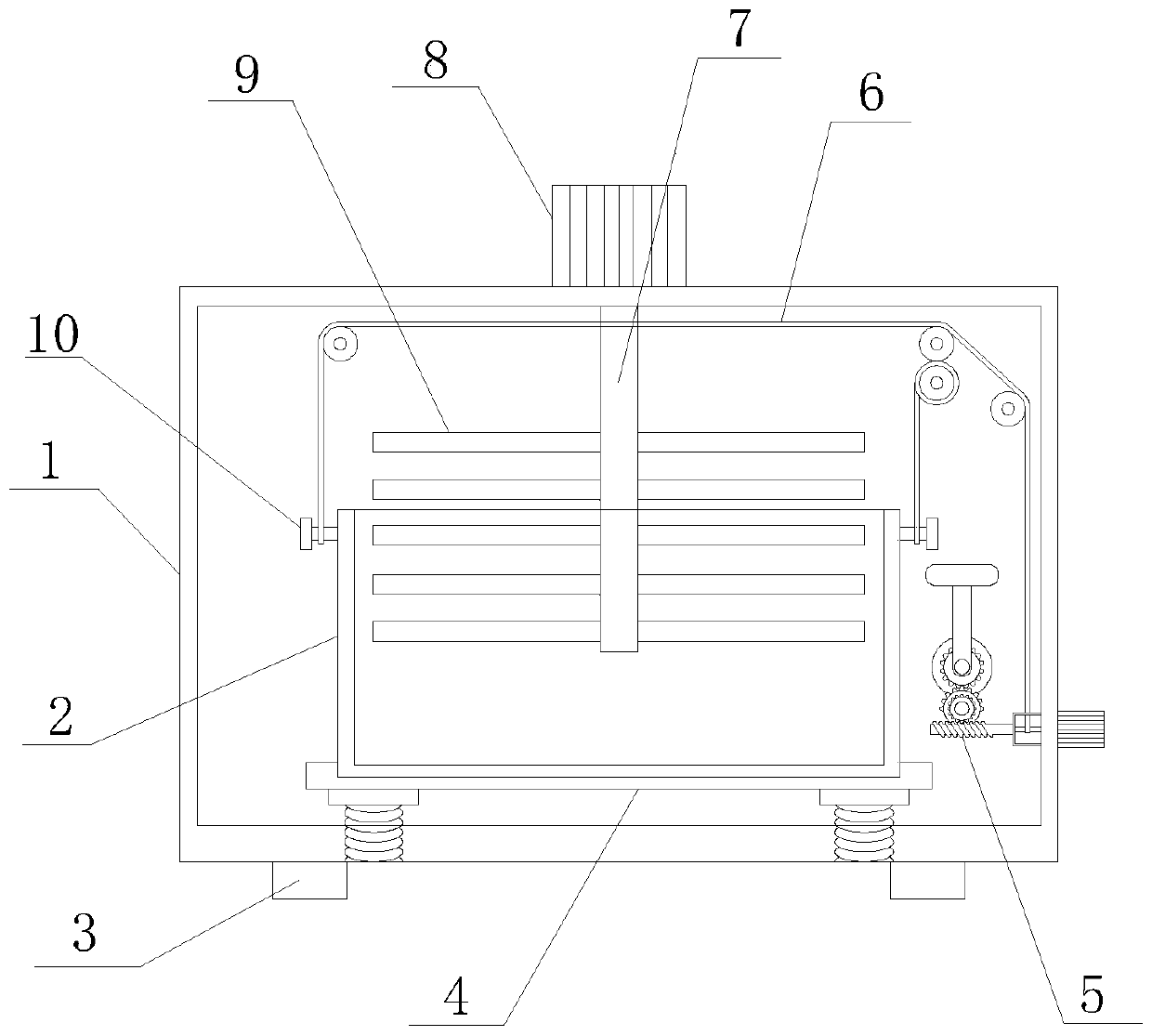

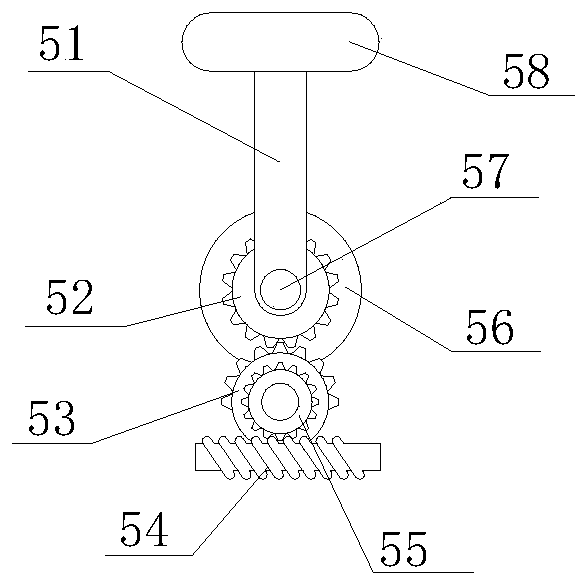

Manufacturing device for processing aluminum curtain wall material

InactiveCN109894033AAvoid pollutionSave raw materialsShaking/oscillating/vibrating mixersMixer accessoriesGear wheelEngineering

The invention relates to a manufacturing device for processing an aluminum curtain wall material. The manufacturing device comprises a box, a processing barrel, a rotation shaft, a driving machine, astirring shaft, pin shafts, a long rope, an electric shaker, a short rope, a hammer handle, a transmission gear, an incomplete gear, a worm, a turbine, a torsion spring, an installation shaft, and a vibration hammer. The vibration hammer is connected to the output end of the driving machine in a transmission mode. The stirring shaft is arranged on the rotation shaft. One end of the long rope is wound in the electric shaker, and the other end sequentially goes through an angle changing device, a pulley (B), and a pulley (A) and is wound around one pin shaft. One end of the short rope is wound around a pulley (C). The worm is connected to the output end of the electric shaker in a transmission mode. The incomplete gear is coaxially fixed with the turbine and rotates along with the turbine. The transmission gear is rotatingly arranged in the box through the installation shaft. The vibration hammer is arranged on the top end of the hammer handle. The structure of the manufacturing device is excellent, the design is reasonable, the operation is convenient, the dead angle is eliminated, the cost is reduced, the stirring effect and the processing efficiency are improved, the application prospect is wide, and the creativity is strong.

Owner:安徽唯楚新材料有限公司

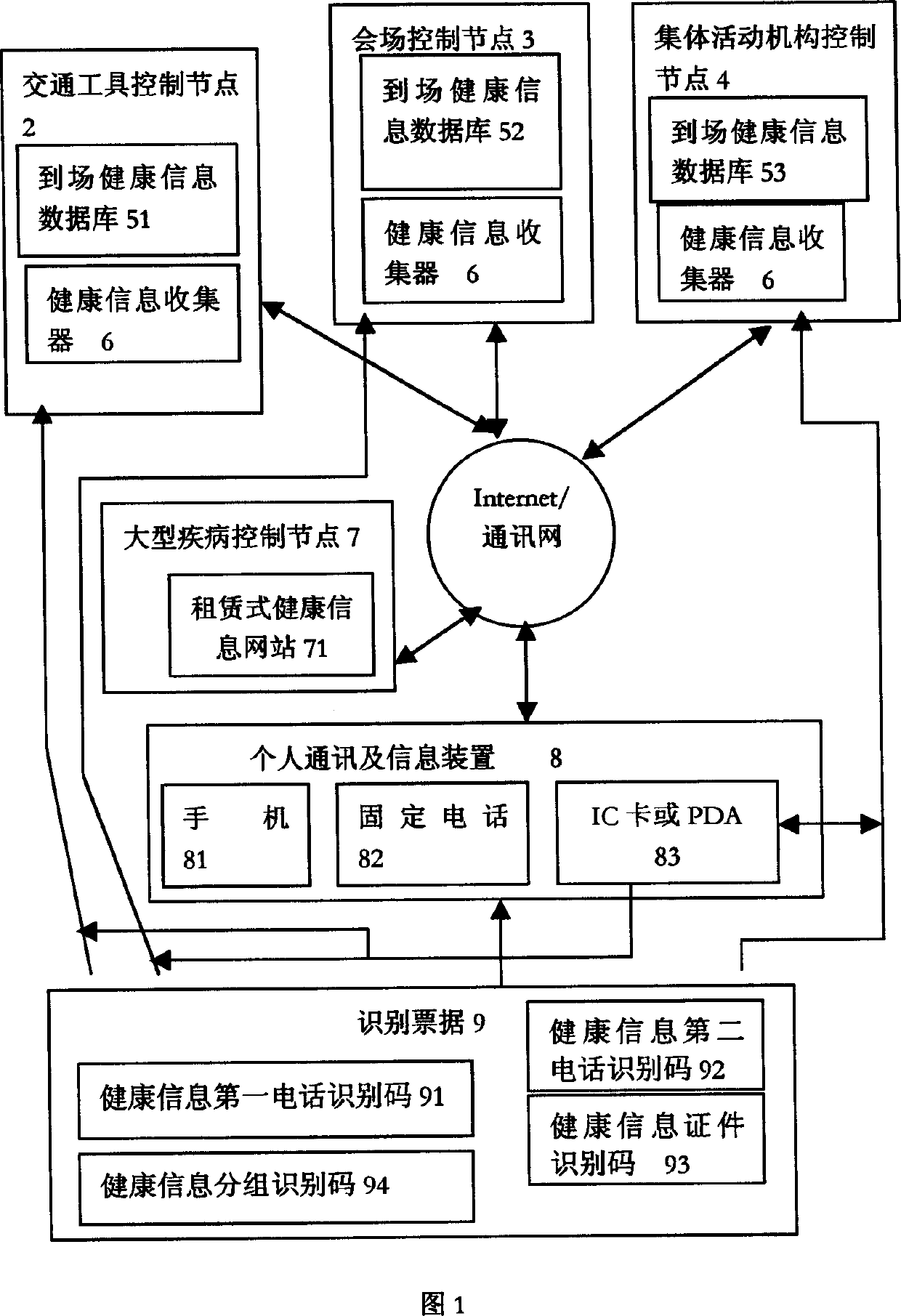

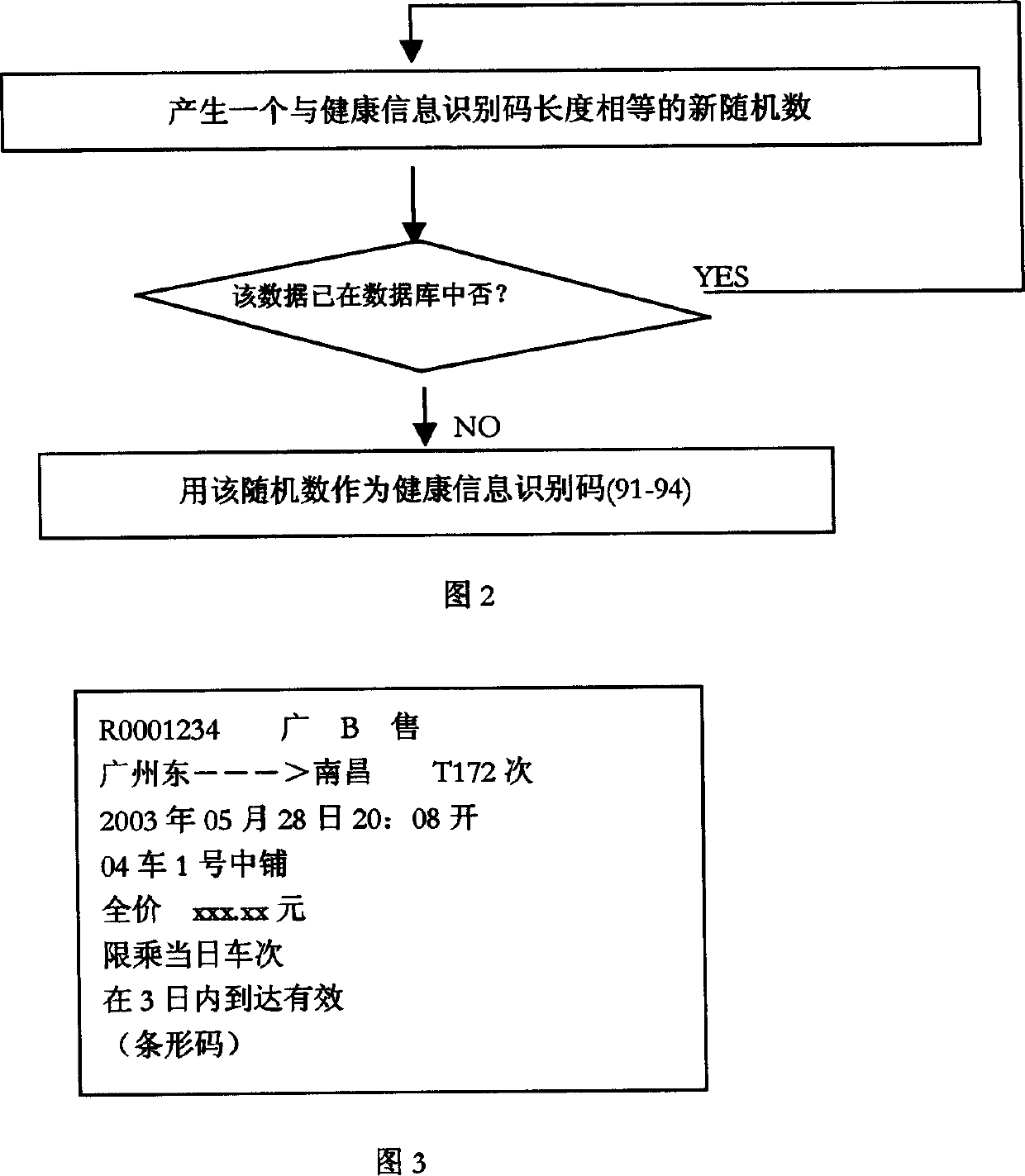

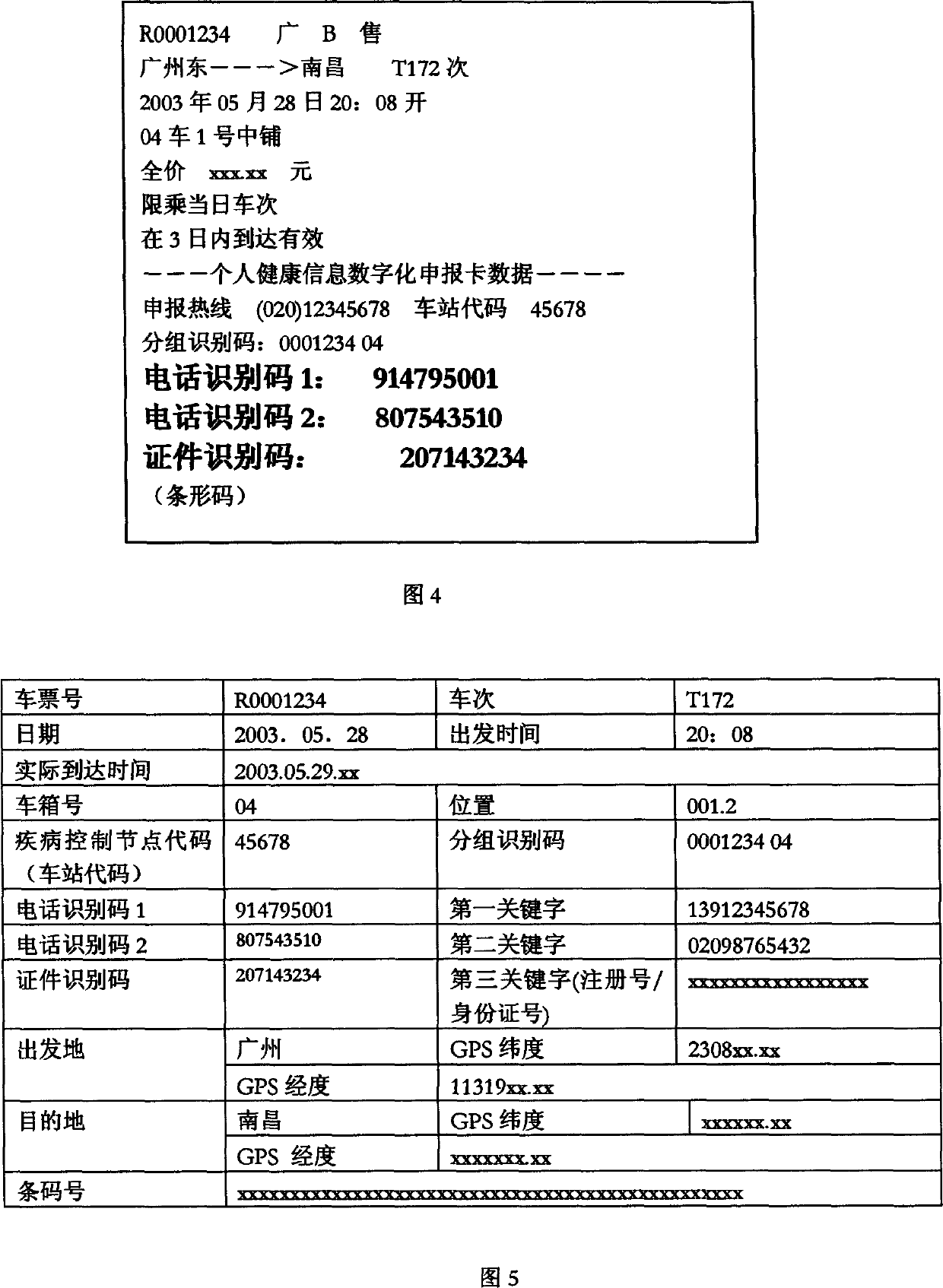

System and method of infection source health information reporting and tracing

InactiveCN1479220AStandardization of the reporting processEliminate dead endsSpecial data processing applicationsMeeting placeInformation device

The system includes node for controlling vehicle, node for controlling meeting place, collective activity organization control node, disease control node, personal communication and information devices and identification note. These parts including four-part, and information devices are connected each other through Intenet and communication network. Each control node includes at least one health information collector. The information of identification note is input by the health information collector. The invented method accomplishes report by using telephone or mobile phone number and number of ID, which are used all over world generally. Thus, people coming from different regions with different culture background, even from foreign countries can make correct report about own health information. The procedure for reporting health information is a normalized and electronic process with low operating cost.

Owner:李之彦 +1

Method and device for dissolving gas in oil

InactiveCN101664650AGuaranteed overall sealing performanceEliminate oil circulation dead angleMixing methodsProduct gasCirculating pump

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST

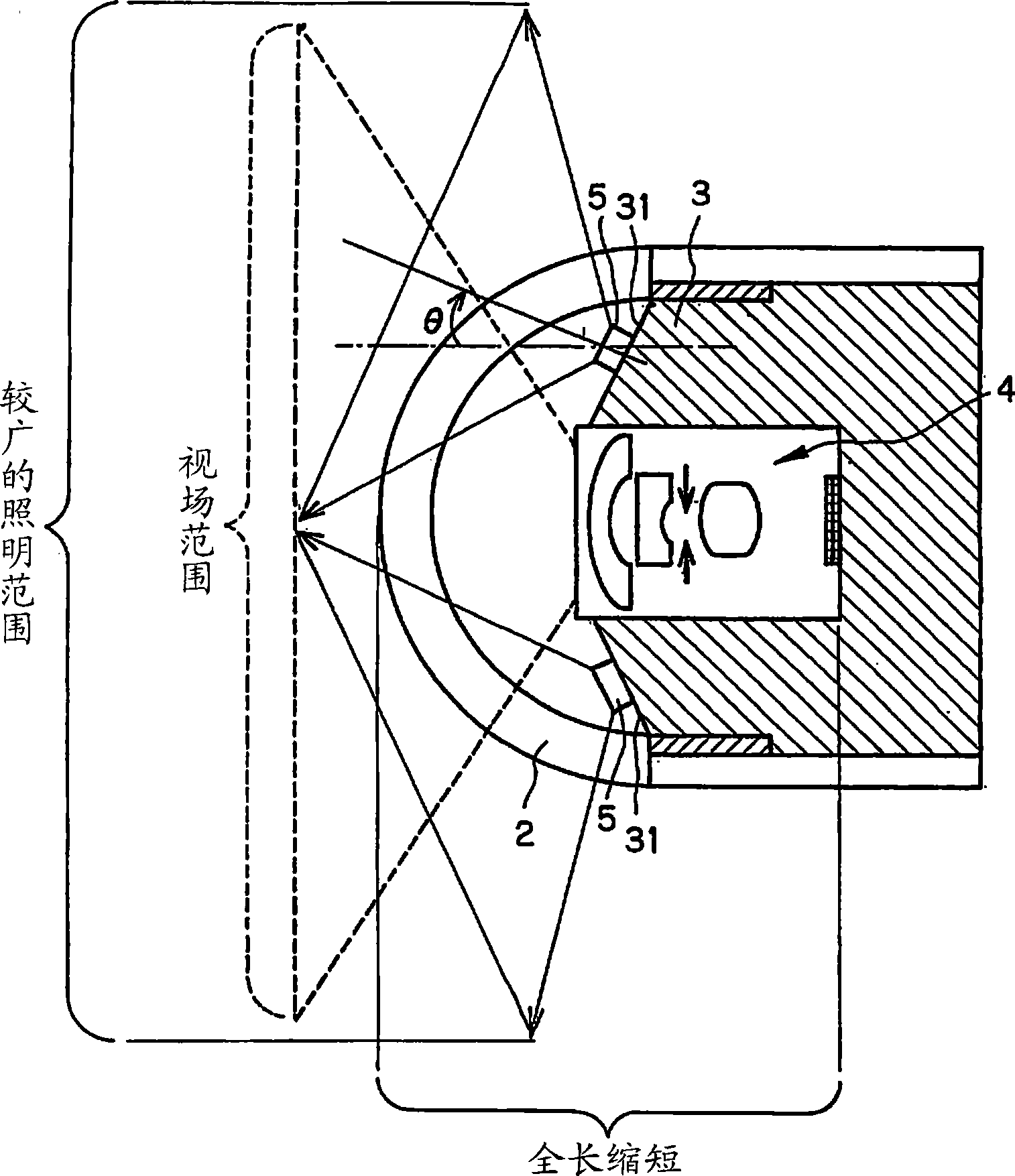

Capsule endoscope

The invention relates to a capsule endoscope layout capable of achieving a small-format, wide-angle, wide light-distribution arrangement with limited variations. A capsule endoscope 1 comprises an objective lens 4, a transparent dome 2 to cover the object side of the objective lens, and light emitter devices located around the outer periphery of the objective lens. The endoscope 1 further comprises an integral-piece holder member 30 adapted to hold the objective lens 4 in place and hold the light emitter devices 5 at a position set back from an end of, and around, the objective lens 4 while the light emitter devices 5 are inclined outward at an angle with a center axis of said objective lens 4.

Owner:OLYMPUS CORP

Automobile left A column visual dead angle observation mirror

InactiveCN101665096AEliminate the original dead angleEnsure driving safetyOptical viewingDriving safetyDriver/operator

The invention relates to an automobile left A column visual dead angle observation mirror, comprising a refraction glass sheet and a connecting bracket. The refraction glass sheet is fixed on the connecting bracket; and the connecting bracket is installed outside the automobile left A column, so that the refraction glass sheet is tightly adhered to the center of the left side of a front windscreenof the automobile. The refraction glass sheet is a glass, the upper section and the lower section of which have the shapes of bevel edge; and a certain angle is formed between the refraction glass sheet and the connecting bracket, and the angle is adjustable. By using the observation mirror, drivers can see the visual dead angle at the left front position which is originally baffled by the left Acolumn through the refraction glass sheet when driving. The angle between the refraction glass sheet and the connecting bracket is adjusted so as to obtain a better visual effect according to the practical situation of the drivers. Therefore, when the automobile drives straight or turns at corners, the original dead angle of the left A column is removed, the left front situation of the automobileis better grasped, and the driving safety is ensured.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

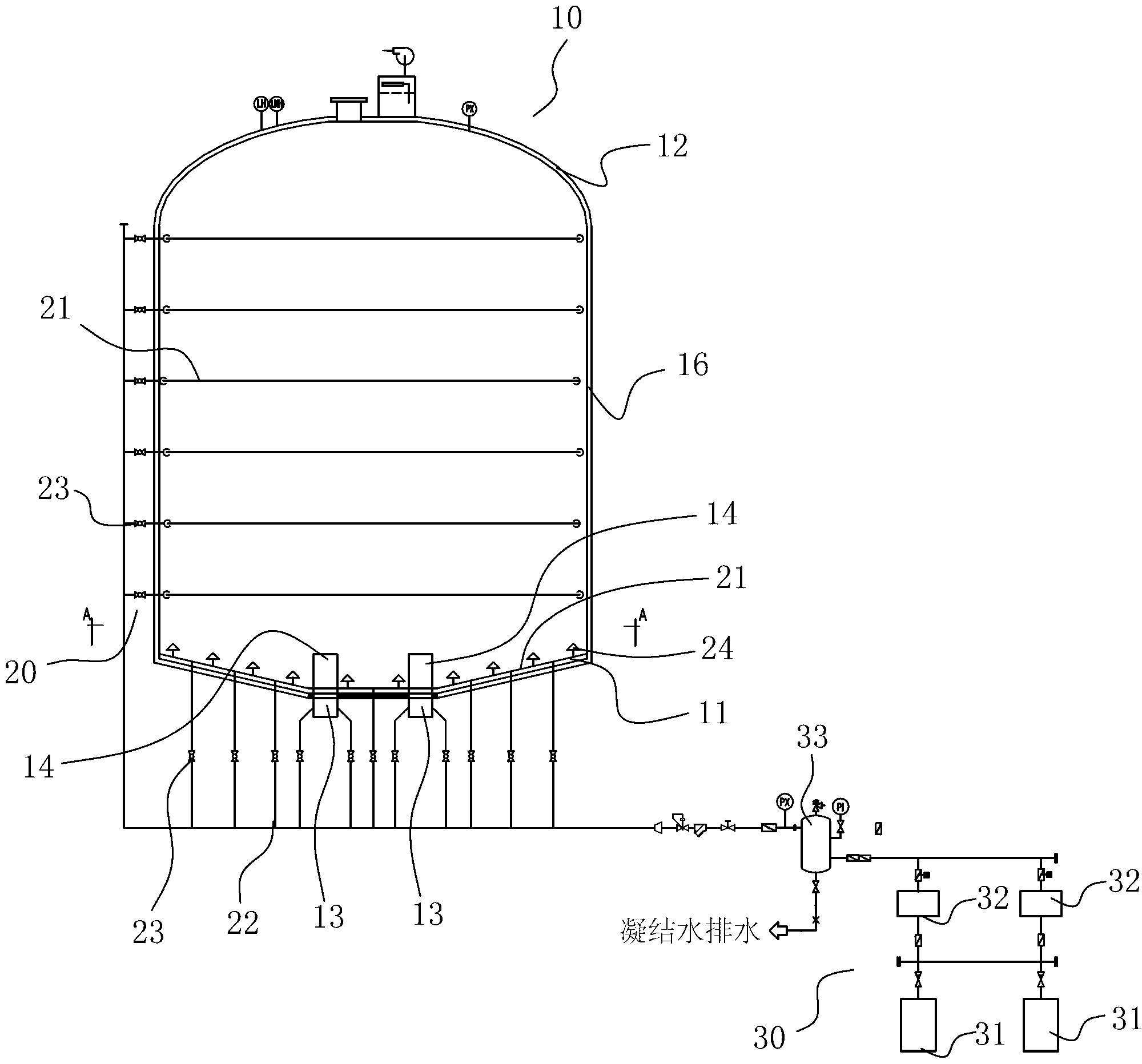

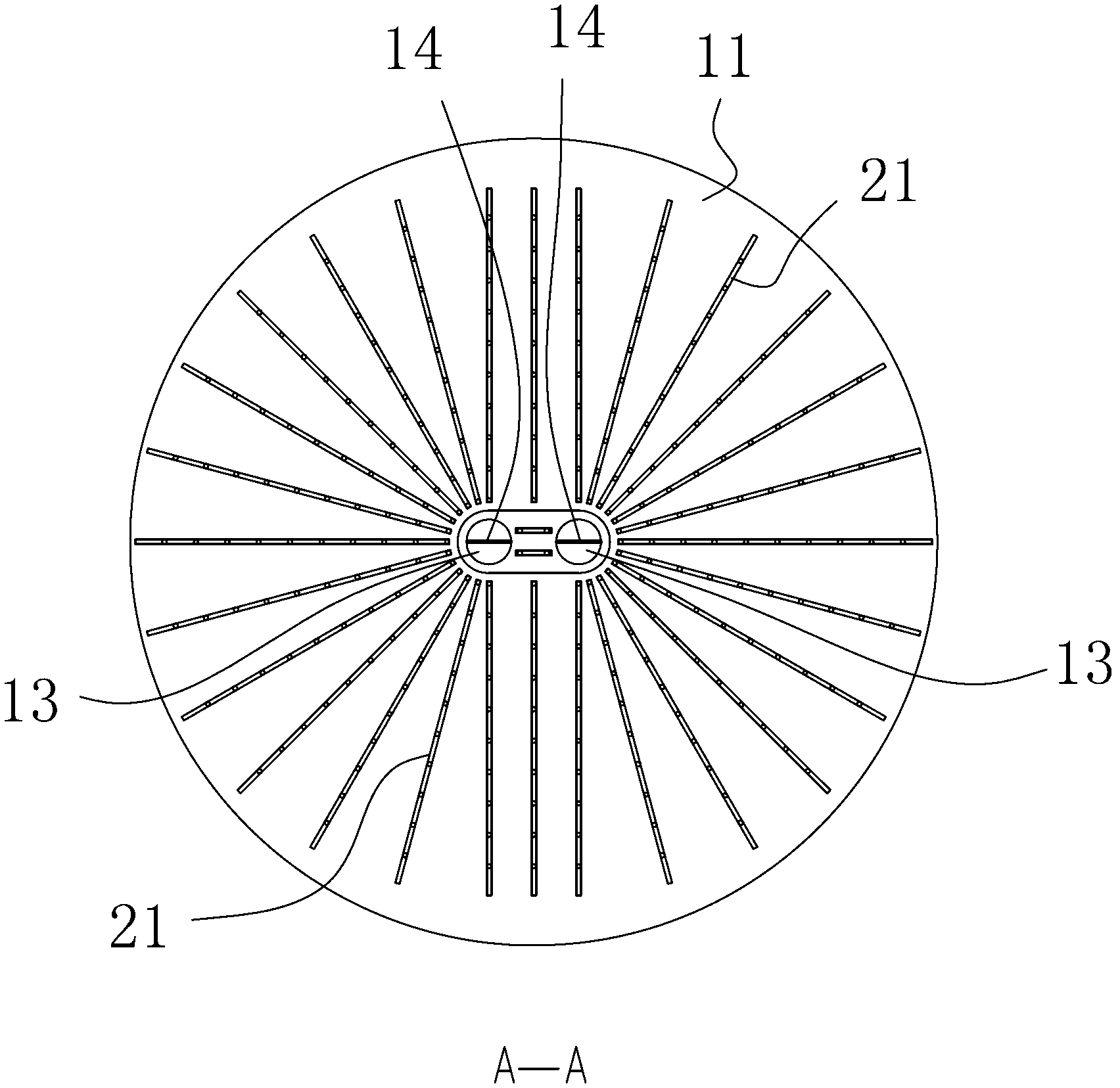

Large coal ash storage tank and coal ash storage system

The invention relates to a large coal ash storage tank and a coal ash storage system. The coal ash storage system comprises a large coal ash storage tank, a divided fluidization pipeline system and a compressed air source system. The large coal ash storage tank is provided with a hollow tubular structure and comprises a storage tank base part, a storage tank lateral wall and a storage tank top part, wherein a plurality of material discharging ports are arranged on the storage tank base part, and decompression conical partition boards are arranged on the material discharging ports. The divided fluidization pipeline system comprises a multilayer fluidization pipeline arranged on the storage tank lateral wall along the height direction of the storage tank, and a plurality of fluidization nozzles are arranged on the fluidization pipeline. The compression air source system blows air with certain pressure into the storage tank through the divided fluidization pipeline system, so that the coal ash in the storage tank can be fluidized in positive pressure mode. The large coal ash storage tank and the coal ash storage system are simple in structure, less in maintenance working load and high in reliability, fully fluidize the coal ash, greatly reduce and avoid storage accumulation dead angles, prolong the coal ash storage time and enlarge the effective using volume of a storage cabin.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

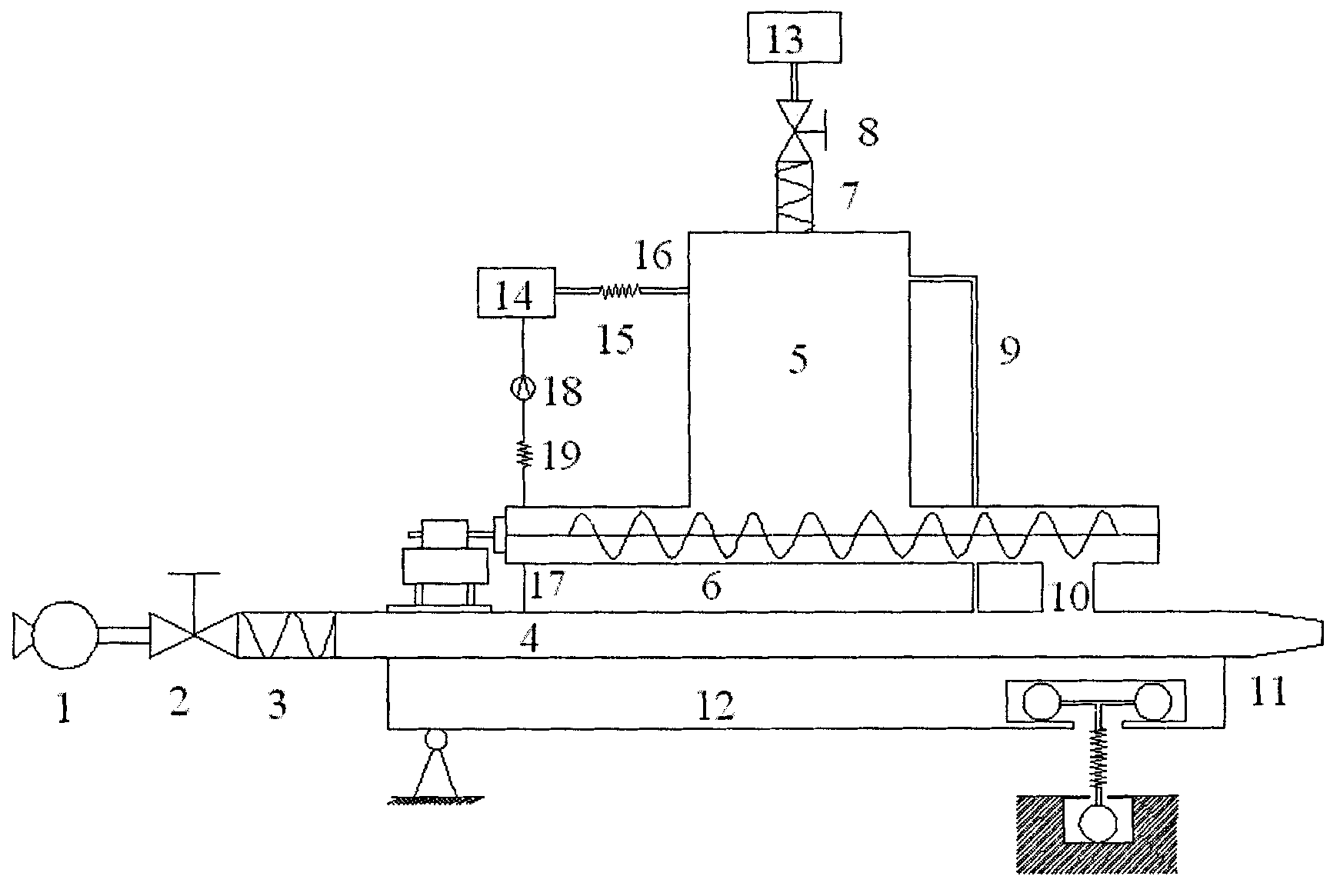

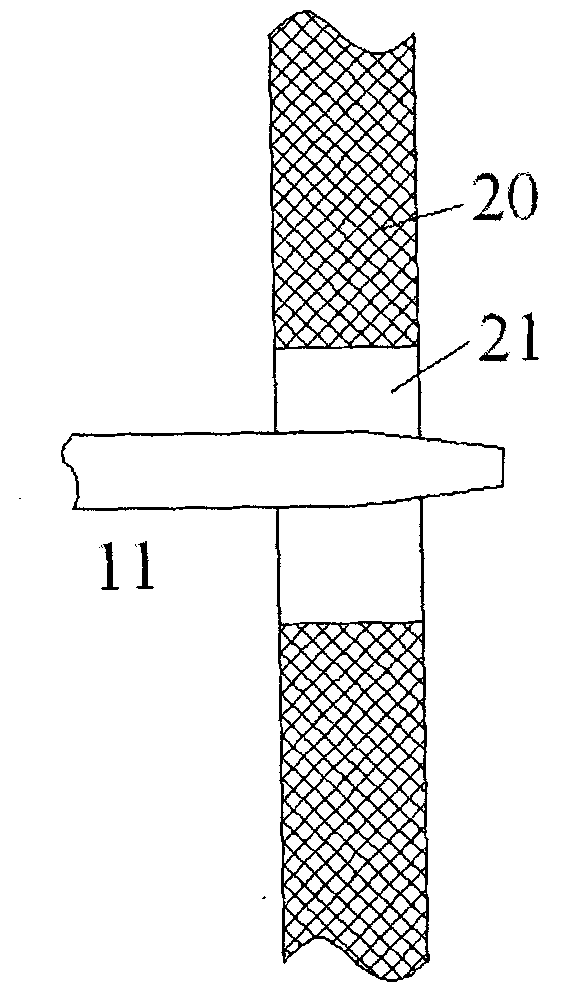

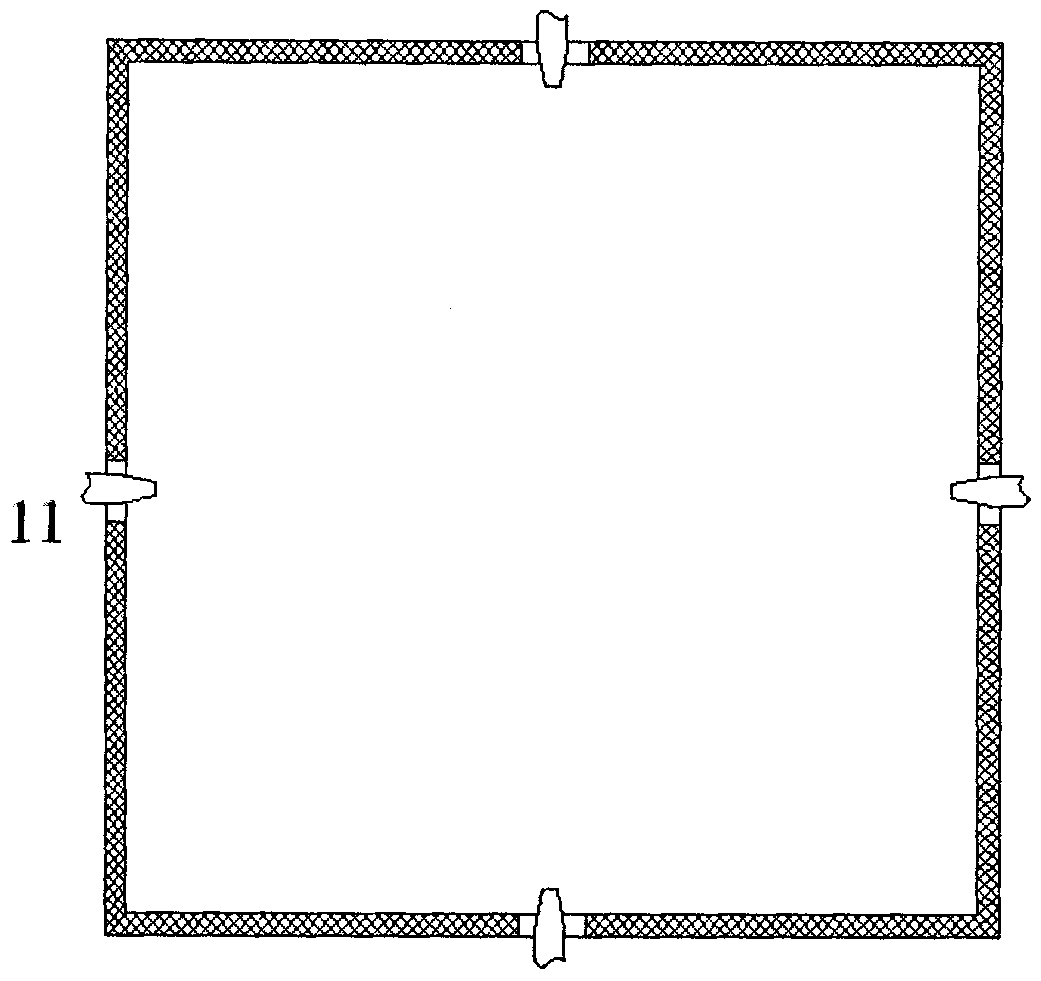

Hearth soot blower

InactiveCN101922720AReduce the temperatureThere will be no melting and bonding phenomenonLighting and heating apparatusCold airHearth

The invention discloses a hearth soot blower which is composed of a Roots blower, a volume regulating valve, a transmitting tube front hose, a transmitting duct, an ice bunker, a spiral conveyer, a scanning platform, an ice pellet machine, an air cooler, a cold air hose, a cold air inlet pipe, a cold air outlet pipe, a recirculating blower, a cold air return hose and the like, wherein the Roots blower pressurizes air into the transmitting duct; the prefabricated ice pellets are filled into the ice bunker; the ice pellets are continuously and quantitatively added into the transmitting duct through the spiral conveyer and a blanking port so as to form the air-particle two-phase mixture; the mixture accelerates at the jet port to form a high-speed jetted ice pellet particle group; and the high-speed jetted ice pellet particle group is transmitted into the hearth and impacts the opposite hearth soot deposit wall surface to realize the soot blowing operation after short-time flying. The invention uses high speed ice pellets to realize soot blowing, has the advantages of low mass of soot blowing medium and favorable soot blowing effect, can greatly relieve the problems of thermal shock, load, efficiency and the like, basically eliminates dead spaces of soot blowing, is convenient to install and operate, and is applicable to hearth soot blowing (deslagging) of a station boiler.

Owner:NANJING UNIV OF SCI & TECH

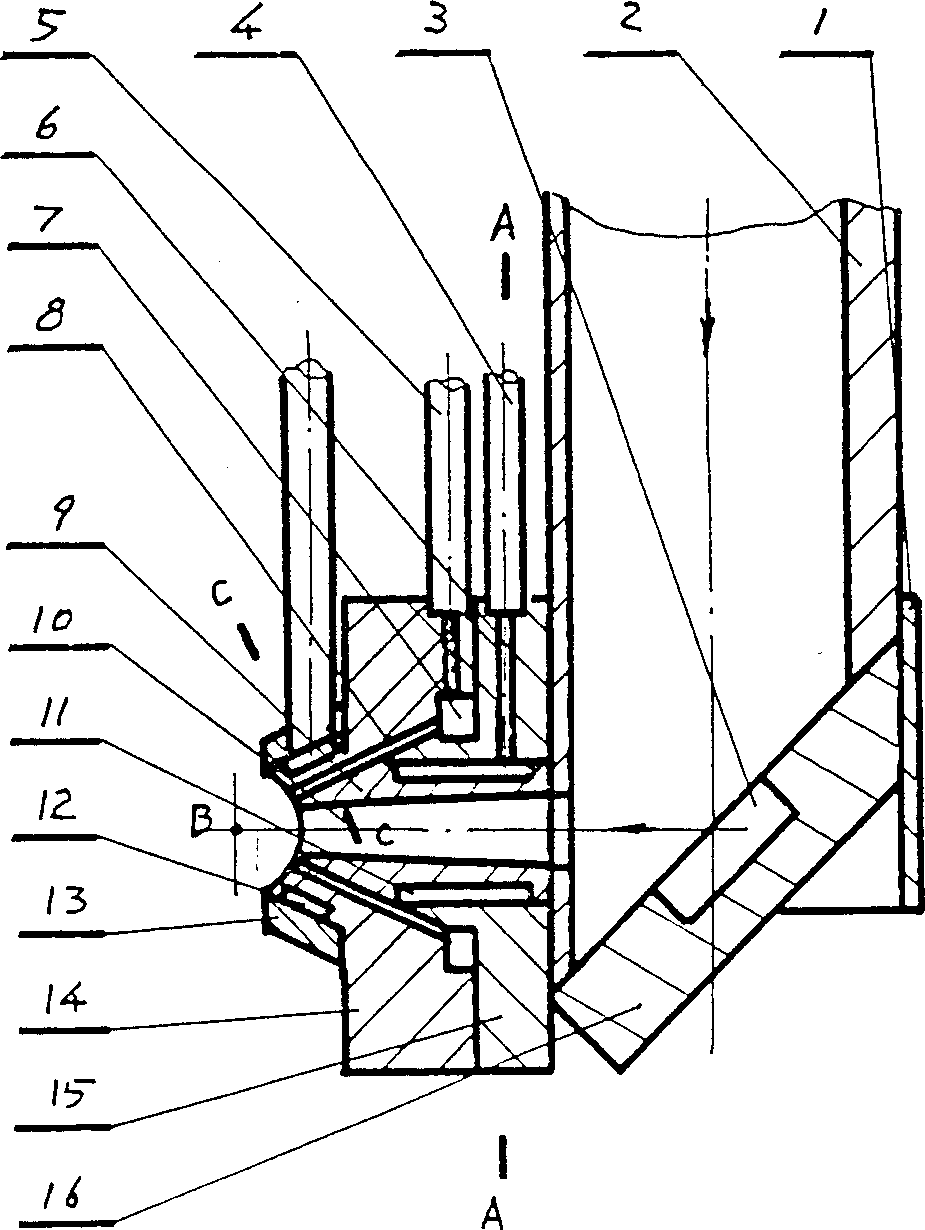

Coaxial powder-feeding mouth for inner wall laser metling covering and alloying treatment of hold pieces

InactiveCN1371779AEliminate dead endsOvercoming the disadvantages of uneven coolingMolten spray coatingLiquid spraying apparatusWater dischargeTelecommunications

The coaxial power-feeding nozzle, belonging to the field of laser processing equipment technology, is formed from laser channel, U-shaped fastener, outer ring, cone ring, cone cover, internal coolingwater channel, external cuoling water channel and powder feeding channel, in which the laser channel is formed from light guide tube, cooling cover, reflector and internal cone body, and its internalcooling water channel is formed from water intake pipe, water intake channel, water discharge pipe, water discharge channel, internal ring water channel and its partion, board, its powder-feeding channel is composed of power-feeding pipe, ring mixing cavity and conical ring groove, it has 2-8 powder-feeding pipes which are distributed along the radial direction, and its external cooling water channel is formed from water-intake pipe, water outlet pipe, external ring water channel and its partion board.

Owner:青岛启源泉能源设备有限责任公司

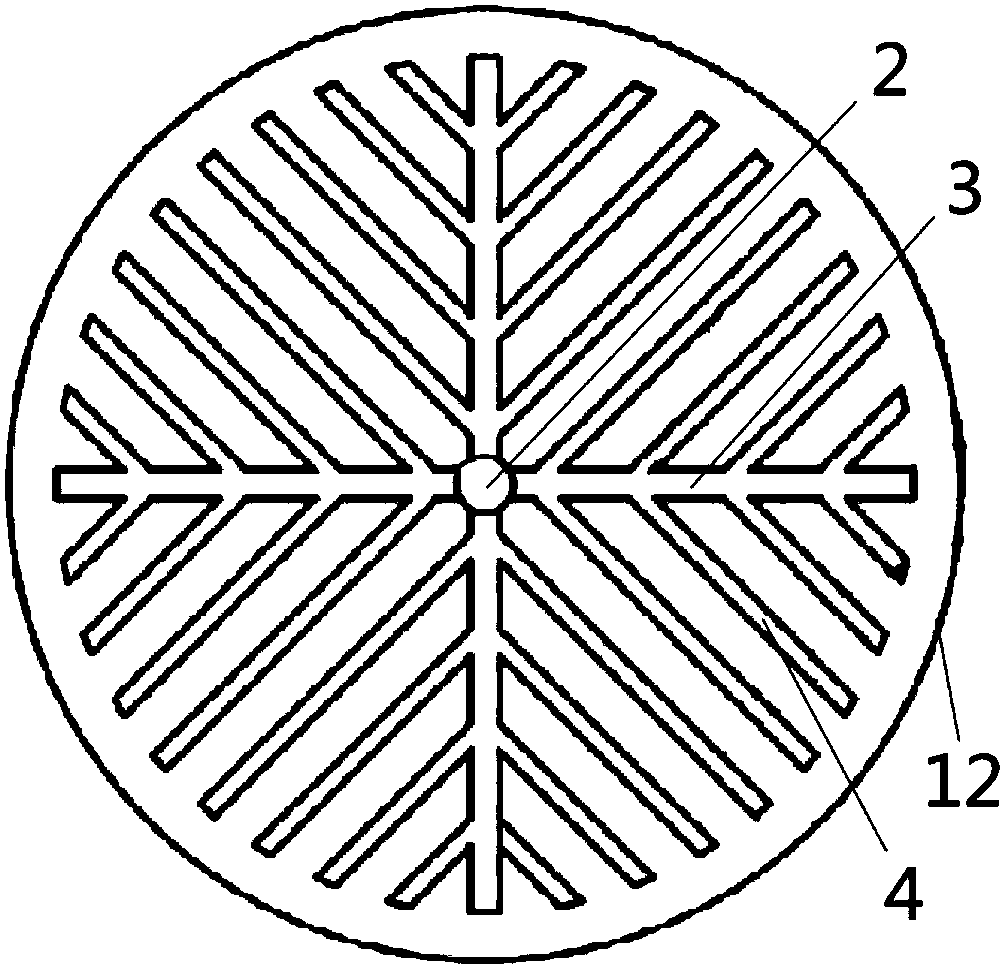

Gas distributor and reactor

ActiveCN110201610AEvenly distributedReduced flow distributionChemical/physical processesSpray nozzleEngineering

The present invention discloses a gas distributor and a reactor. The gas distributor includes a main gas inlet tube, a dummy plate, at least one gas riser tube and a plurality of layers of top-and-bottom spaced pipeline assemblies from the bottom to the top, one end of the gas riser tube go through the dummy plate, and the other end goes through each layer of the pipeline assembly; and each layerof the pipeline assembly includes a plurality of feed distribution tubes that are connected to the gas riser tube at one ends and closed at the other ends, and a plurality of nozzles communicated withthe feed distribution tubes, and a gas introduced through the main gas inlet tube goes through the gas riser tube, is distributed in the feed distribution tubes, and is sprayed out through the nozzles, wherein the internal diameters of the feed distribution tubes in every layer of the pipeline assembly gradually decrease along a direction away from the dummy plate to the vicinity of the dummy plate, and the internal diameters of the nozzles in every layer of the pipeline assembly gradually increase along the direction away from the dummy plate to the vicinity of the dummy plate. The gas distributor can make gas streams respectively be uniform when used in the reactor in order to prevent catalyst deposition and wearing and avoid a slurry from blocking the main gas inlet tube.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com