Wireless network symmetrical laser ranging-based automatic coal checking method for power plant

A technology of laser distance measurement and wireless network, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that are difficult to achieve complete automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

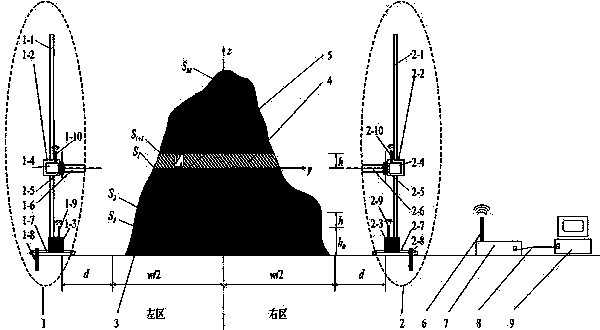

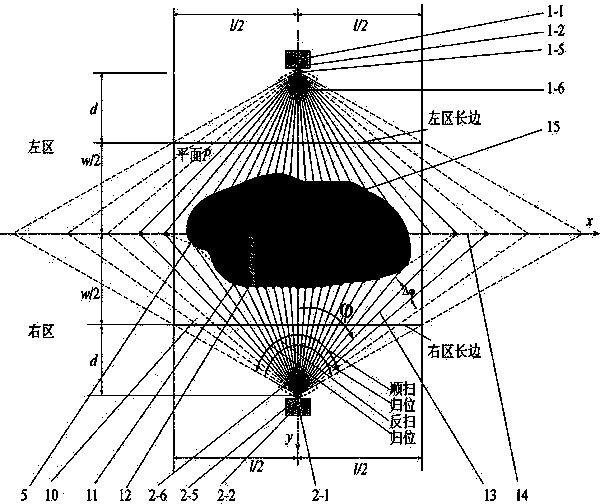

[0056] The specific embodiment of the present invention is as figure 1 , figure 2 shown.

[0057] The coal piles 3 to be coaled in the power plant are stacked on the coal yard 10, and the rectangular area of the coal yard 10 has a length of l and a width of w. The vertical bisector of the width of the coal yard is the partition line 14, along which the rectangular area is divided into two areas of equal width w / 2, the left area and the right area.

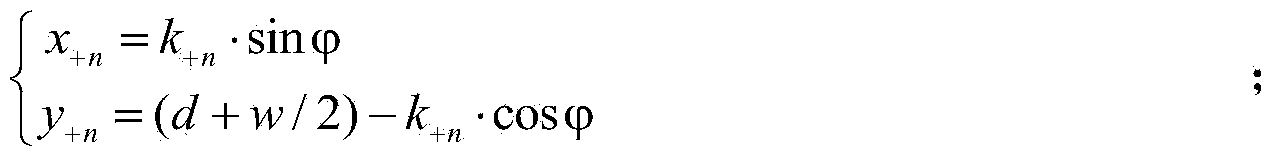

[0058] The automatic coal pan system is composed of a computer 9, a wireless switch 7, a wireless local area network networking of the left area measurement system 1 and the right area measurement system 2. The measurement system 1 in the left area is exactly the same as the measurement system 2 in the right area. They consist of the first guide rail 1-1 and the second guide rail 2-1, the first sliding platform 1-2 and the second sliding platform 2-2, the first numerical control electromechanical box 1-3 and the second numeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com