Hearth soot blower

A technology of soot blowing device and furnace, which is applied in the direction of lighting and heating equipment, etc. It can solve the problems of poor combustion stability, dead angle of soot blowing in the furnace, and decrease of boiler output, so as to achieve less medium loss, eliminate dead angle of soot blowing, and relieve heat. Alluvial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

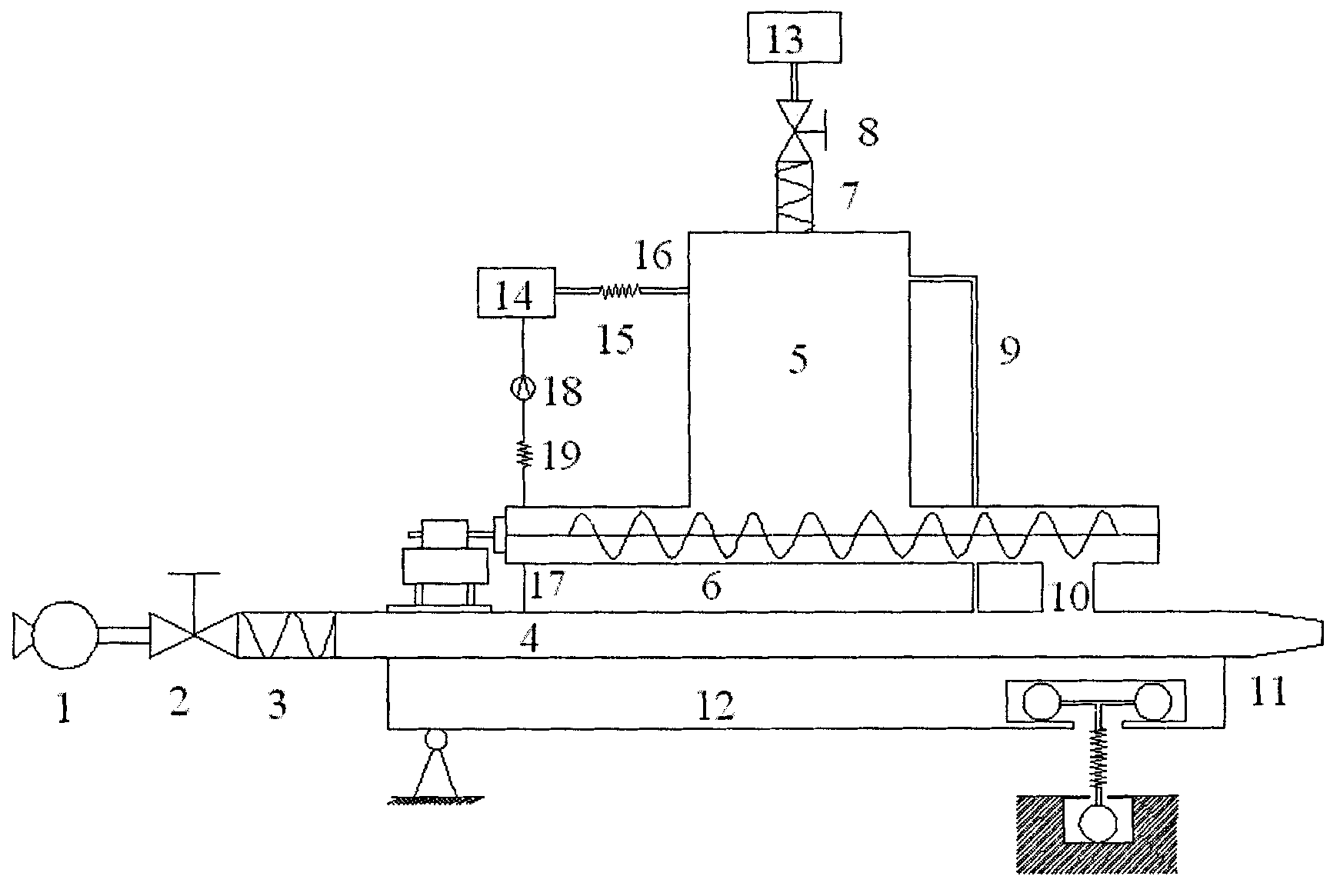

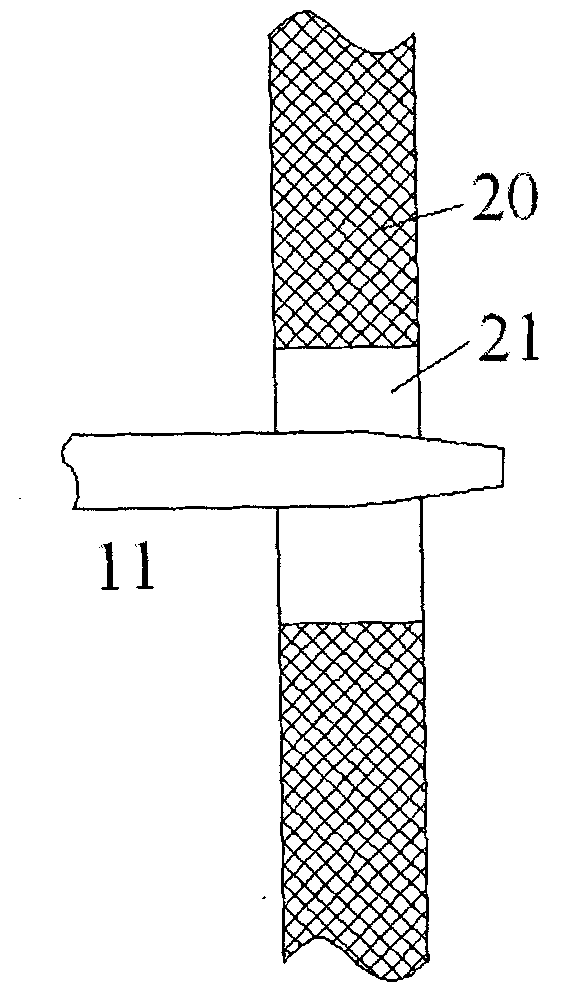

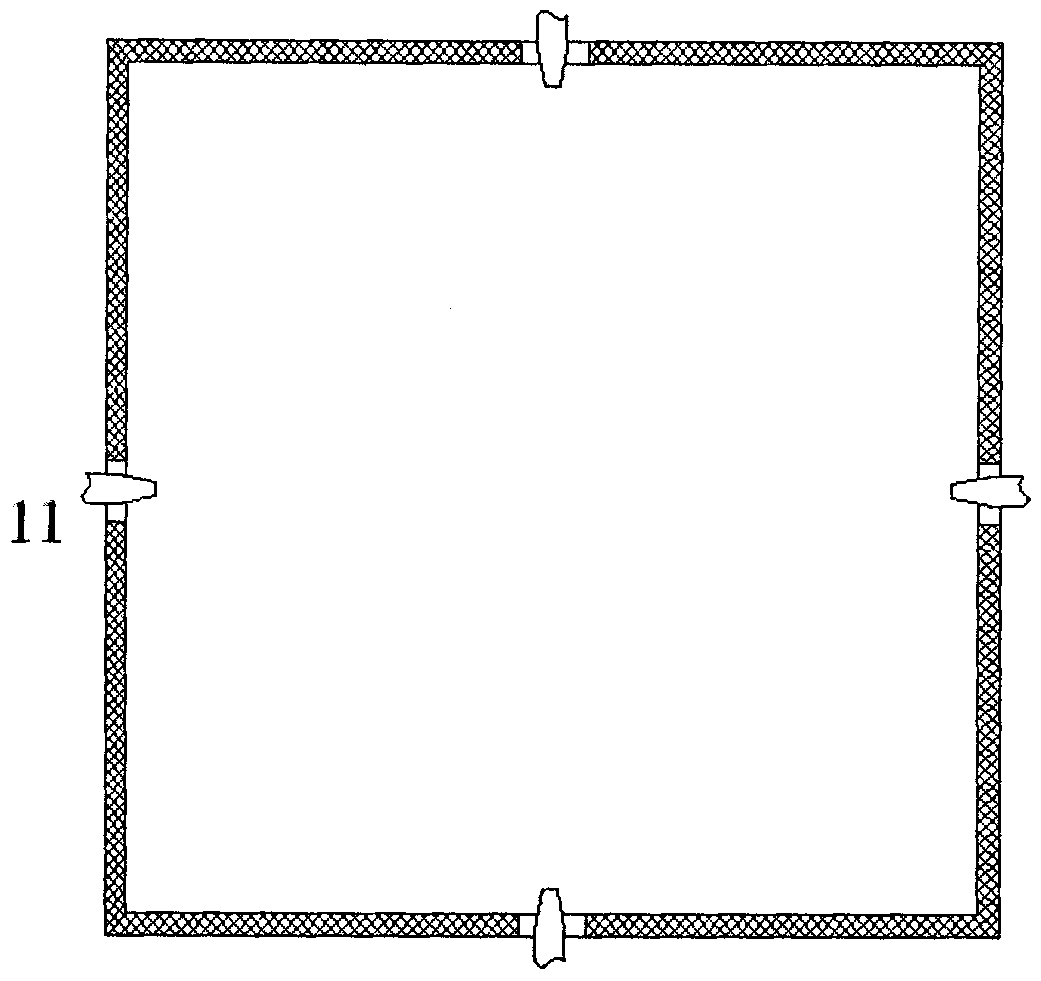

[0015] figure 1 It is a structural schematic diagram of the furnace soot blowing device of the present invention. The furnace soot blowing device of the present invention mainly includes a Roots blower 1, an air volume regulating valve 2, a hose 3 in front of the launching tube, a launching air duct 4, an ice bin 5, and a screw conveyor 6 , ice bin inlet hose 7, ice bin inlet valve 8, pressure balance pipe 9, discharge port 10, nozzle 11, scanning platform 12, ice pill machine 13, air cooler 14, cold air supply hose 15, cold air inlet pipe 16. Cold air outlet pipe 17, circulating fan 18, cold air return hose 19; launch air duct 4, ice bin 5, screw conveyor 6, pressure balance pipe 9, and discharge port 10 adopt double-layer wall structure, the outer wall and inner wall There is a cold air channel between them, see figure 2 , Roots blower 1, air volume cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com