Large coal ash storage tank and coal ash storage system

A storage system and storage tank technology, applied in the field of fly ash storage system, can solve the problems of many dead spots in the coal ash storage tank, high energy consumption, and low fluidization pressure of Roots blower, so as to reduce the maintenance workload, Increase the effective volume of storage and eliminate the effect of stacking dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0038] The main technical terms of the present invention are explained below.

[0039] Large fly ash storage tank: generally refers to the storage effective volume of 3000m 3 ~50000m 3 Silos or tanks

[0040] Positive pressure fluidization: 0.1~1.0Mpa compressed air is used as the carrier to fluidize the solid particle material.

[0041] Underdrawing discharge: the material is discharged from the bottom of the storage tank.

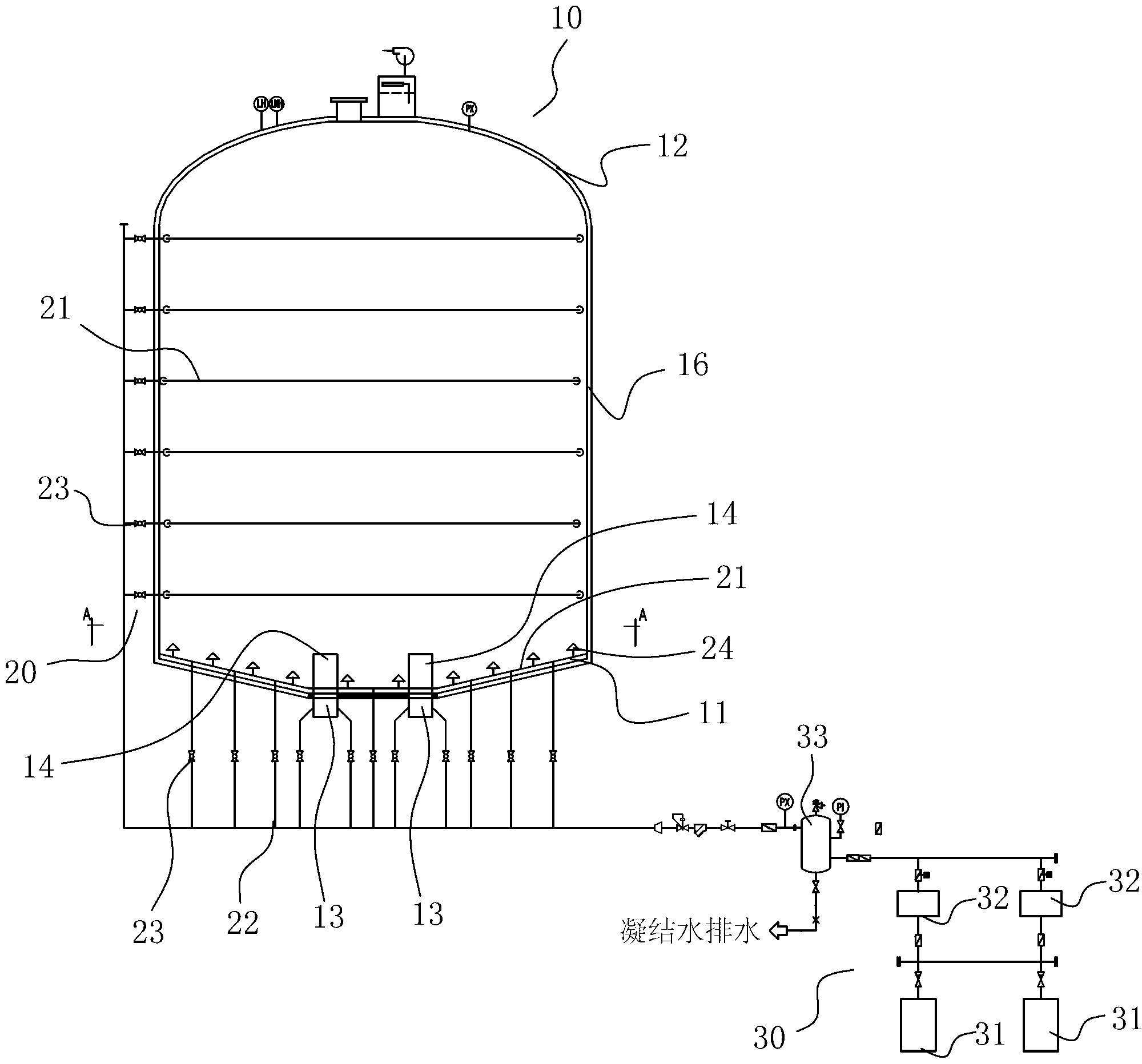

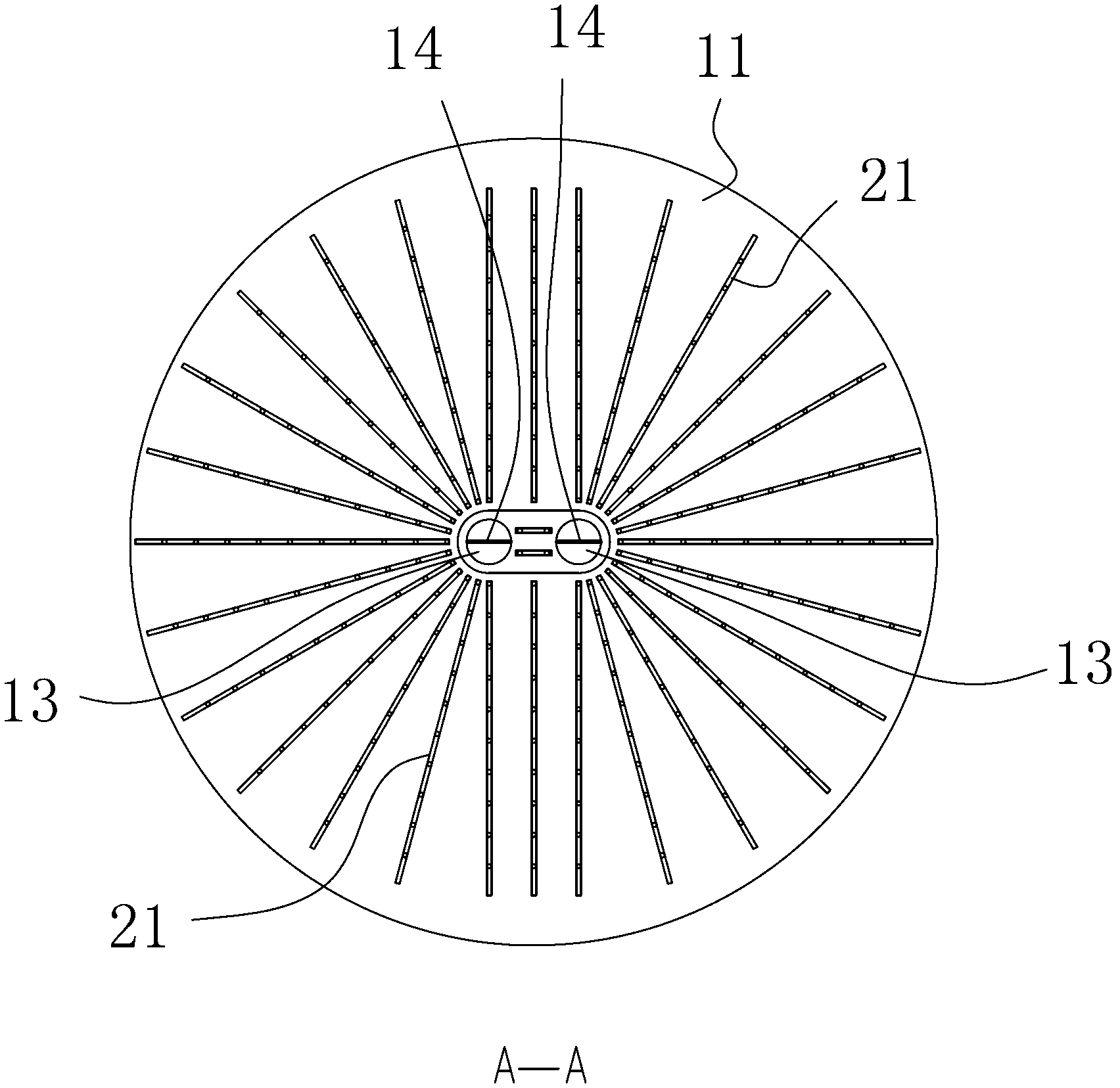

[0042] figure 1 A schematic structural view of the fly ash storage system of the present invention is shown. Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com