Patents

Literature

75results about How to "Fully fluidized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

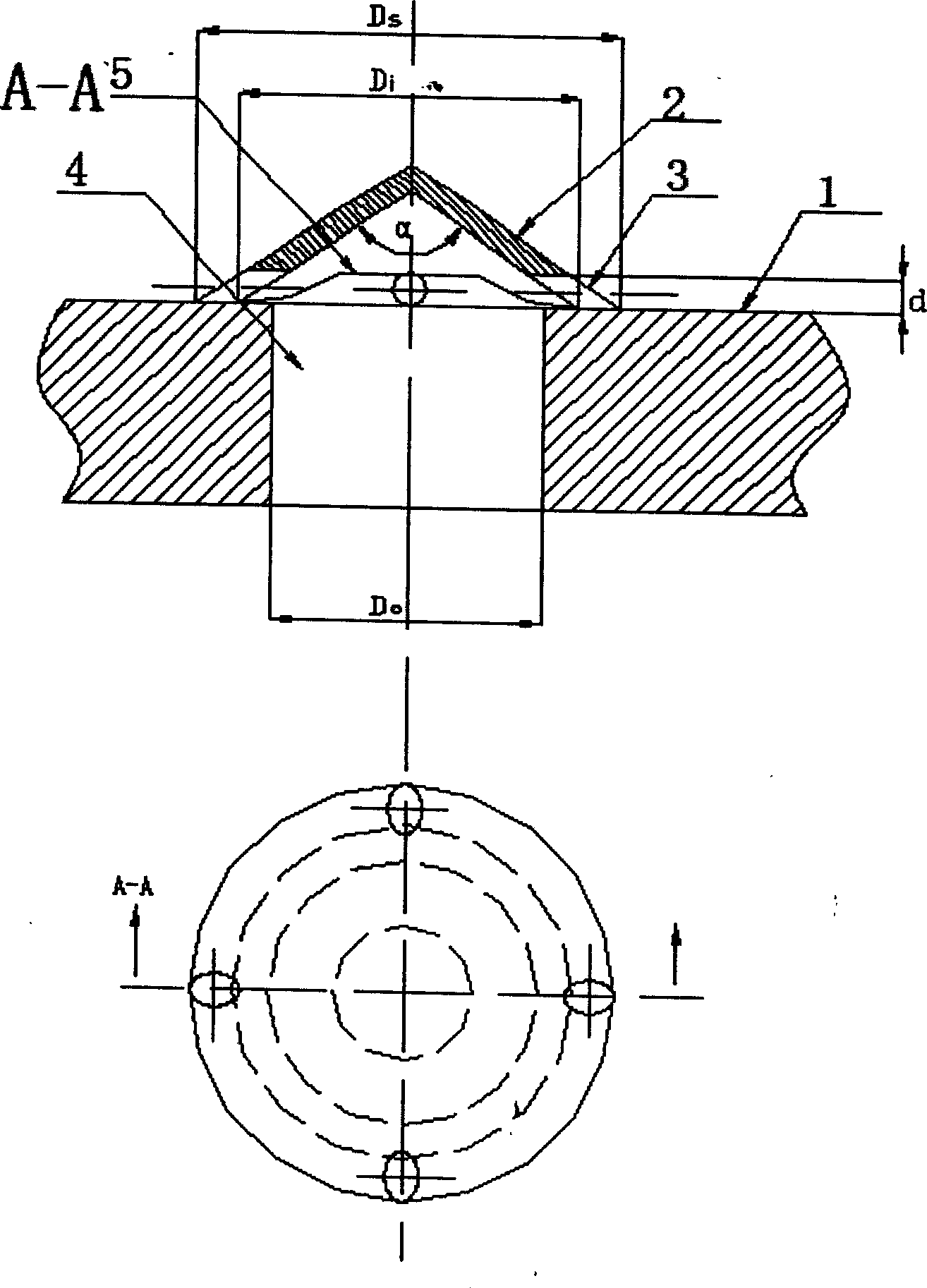

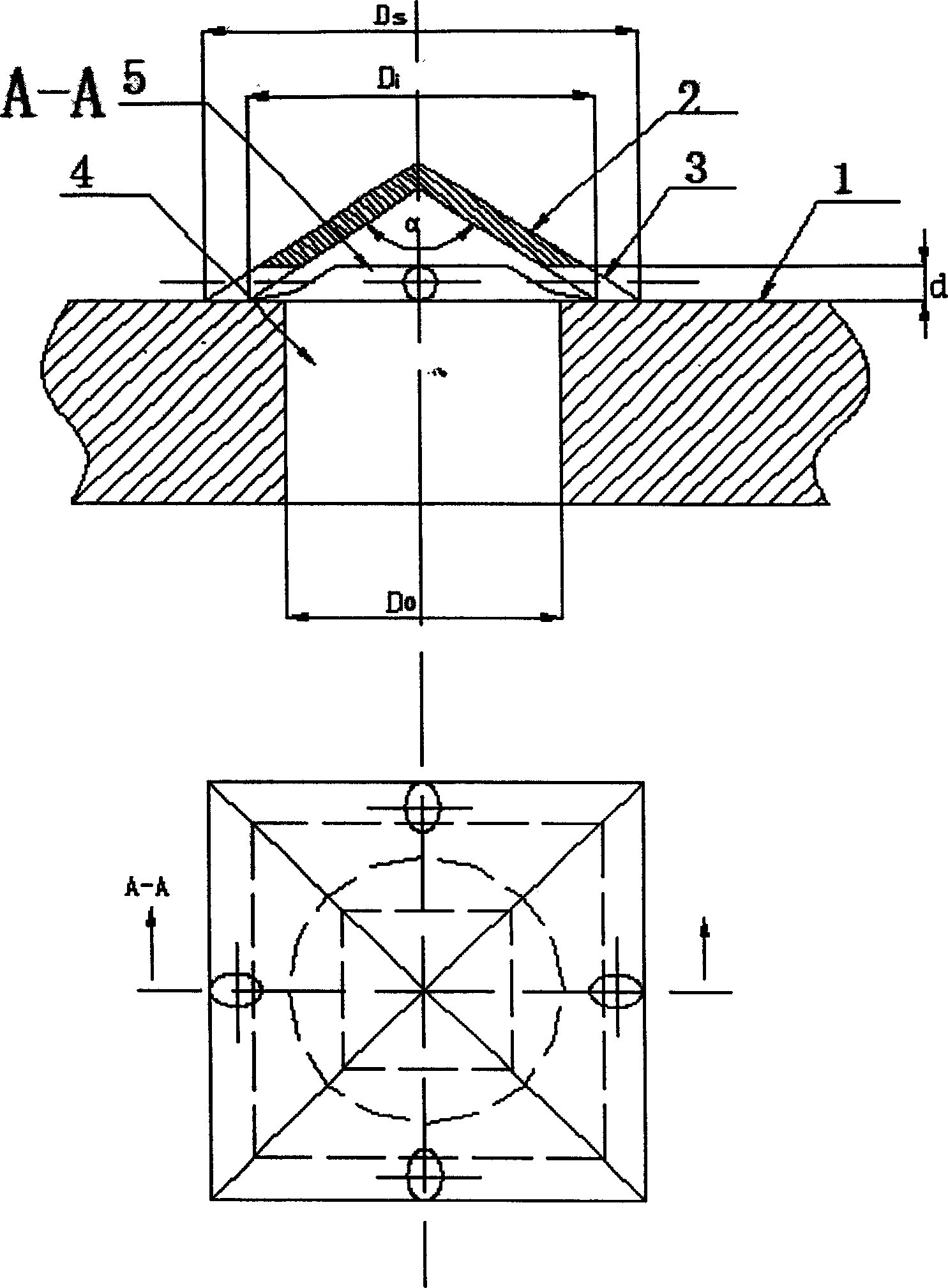

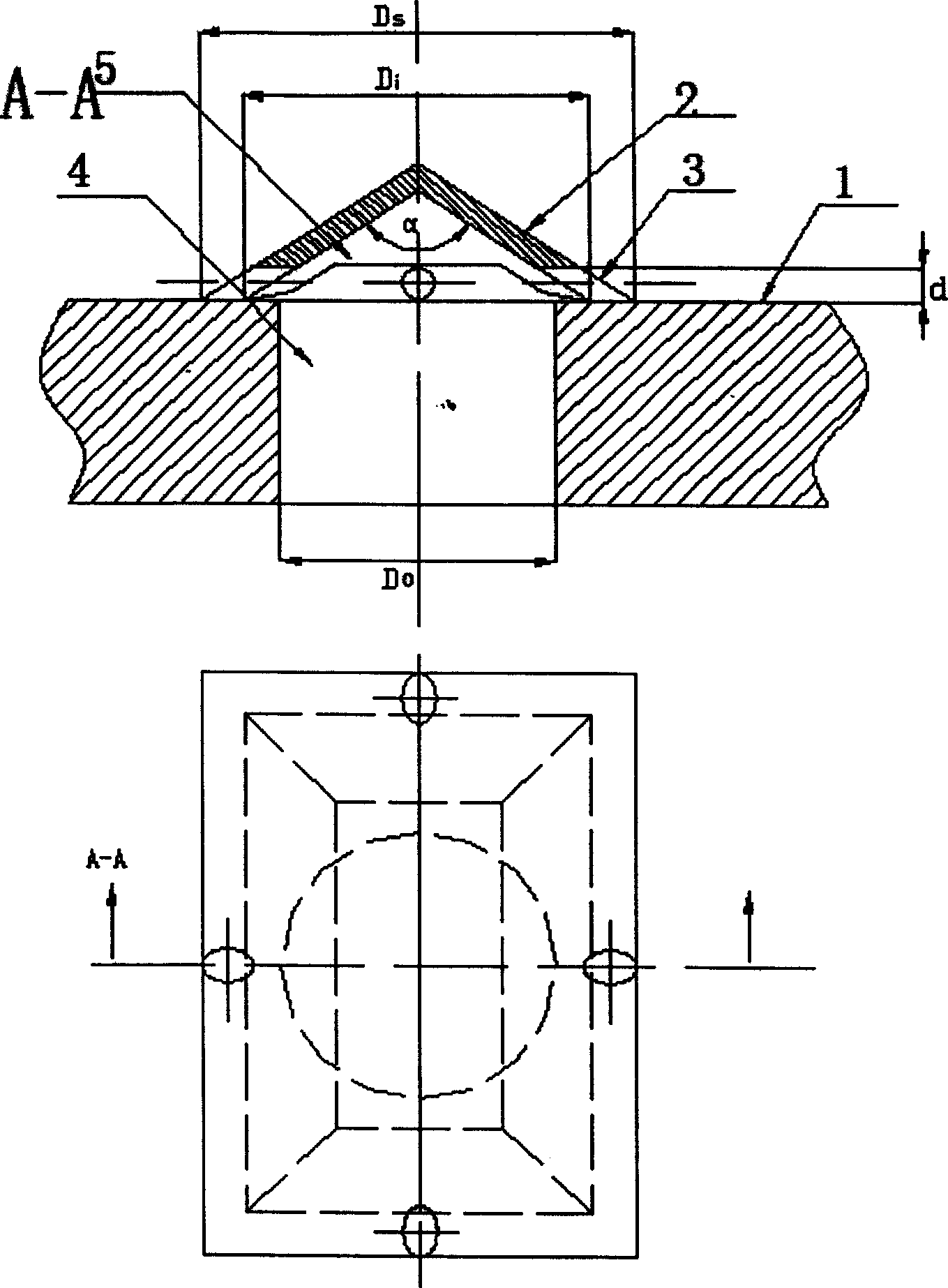

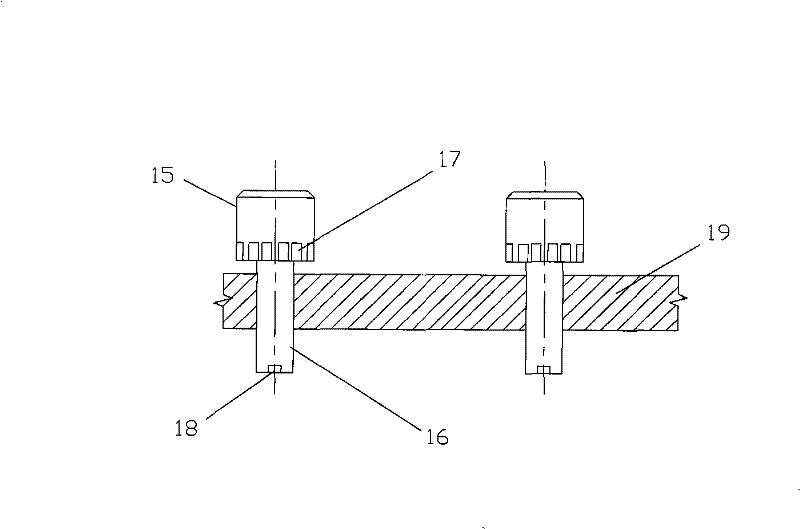

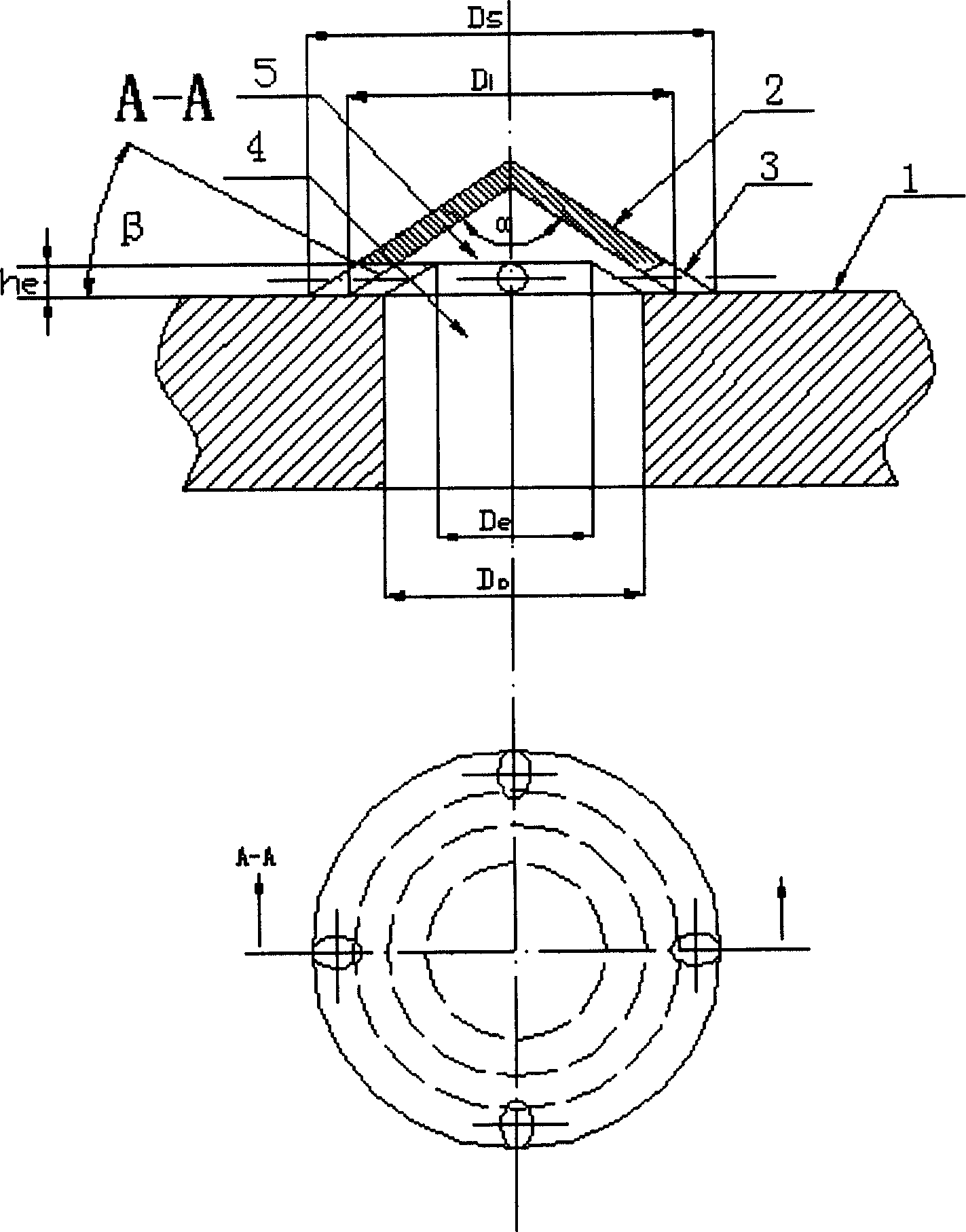

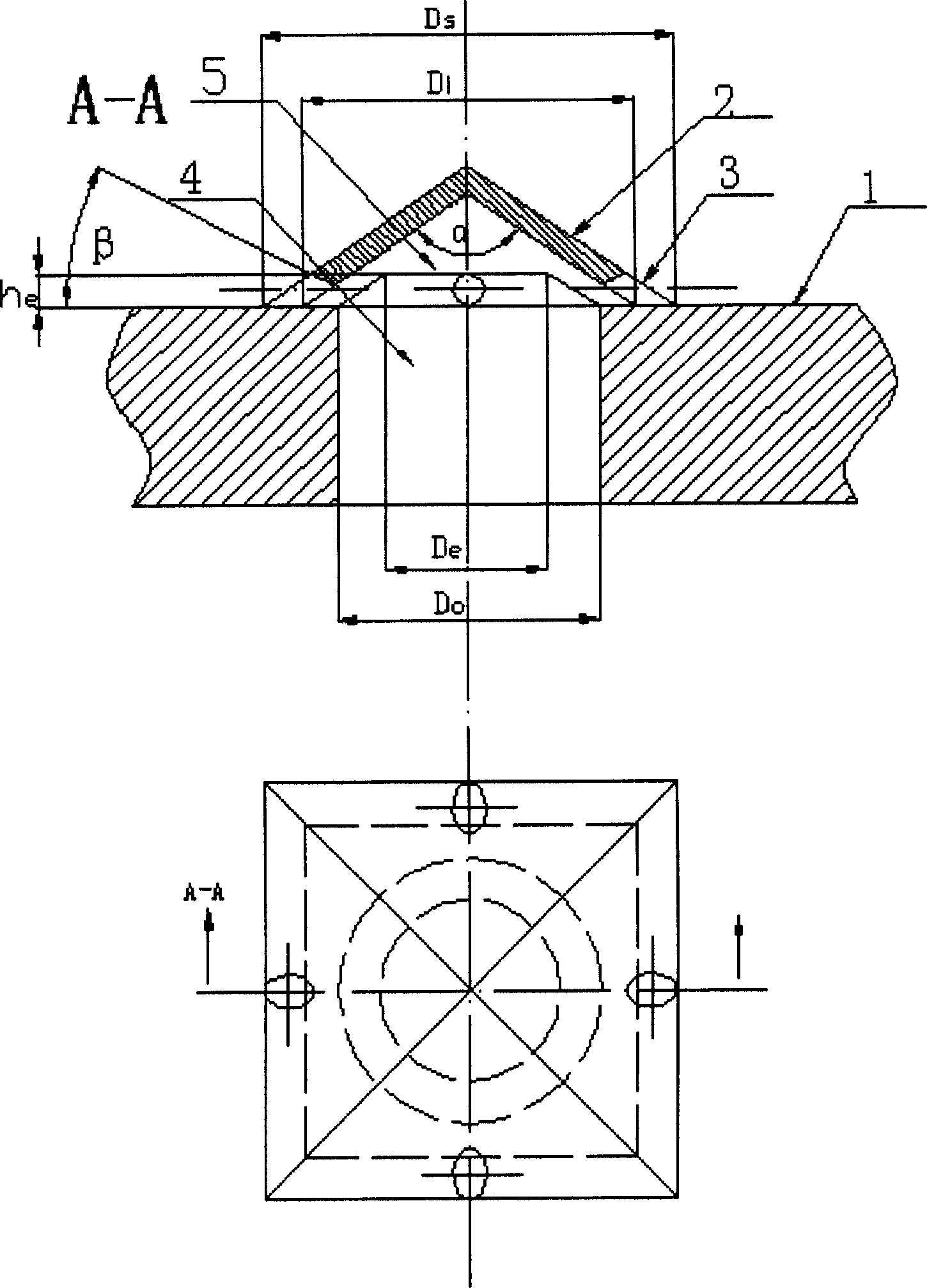

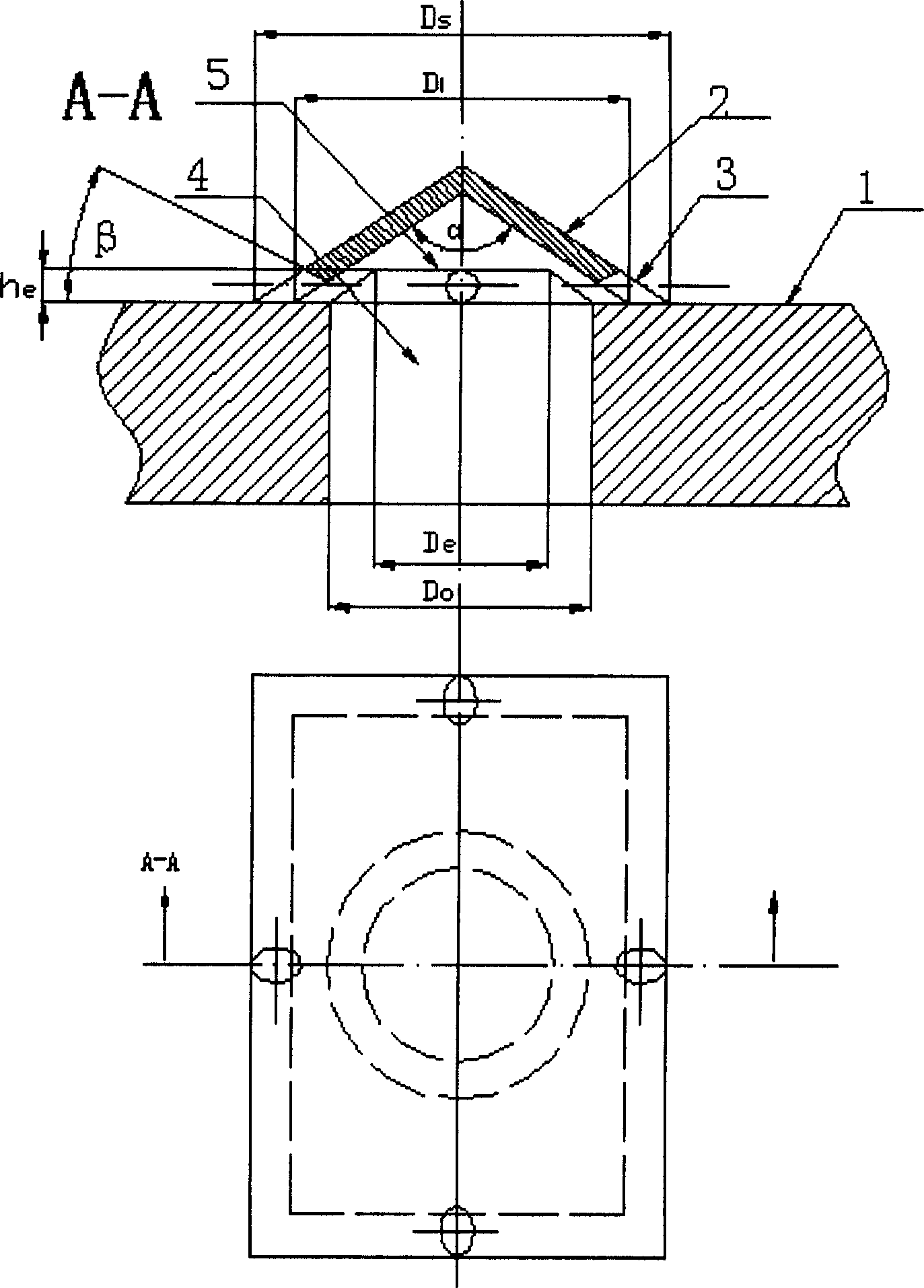

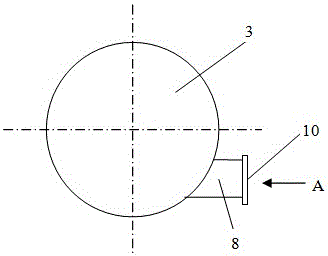

Fluidized bed reactor gases distributing plate

InactiveCN1481930AIncreased jet velocityEnhanced anti-deposition abilityChemical/physical processesFluidized bedProduct gas

The gas distributing board for fluidized bed reactor has air intake openings and each air intake opening has one air distribution button welded. The air distribution button has two or more circular or rectangular jet holes or jet slots with equivalent diameter of 0.2-0.6 time that of air intake opening and jetting direction in an angle of 0-75 deg to the horizontal line. Inside the air distribution button and over the air intake opening, there is one circular, squared or conic leakproof weir. The gas distributing board of the present invention has the advantages of no deposit of large grains; one gas film layer formed on the surface to raise material for full fluidizing; raised fluidized bed stability and convenient and flexible air distribution button cleaning and replacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

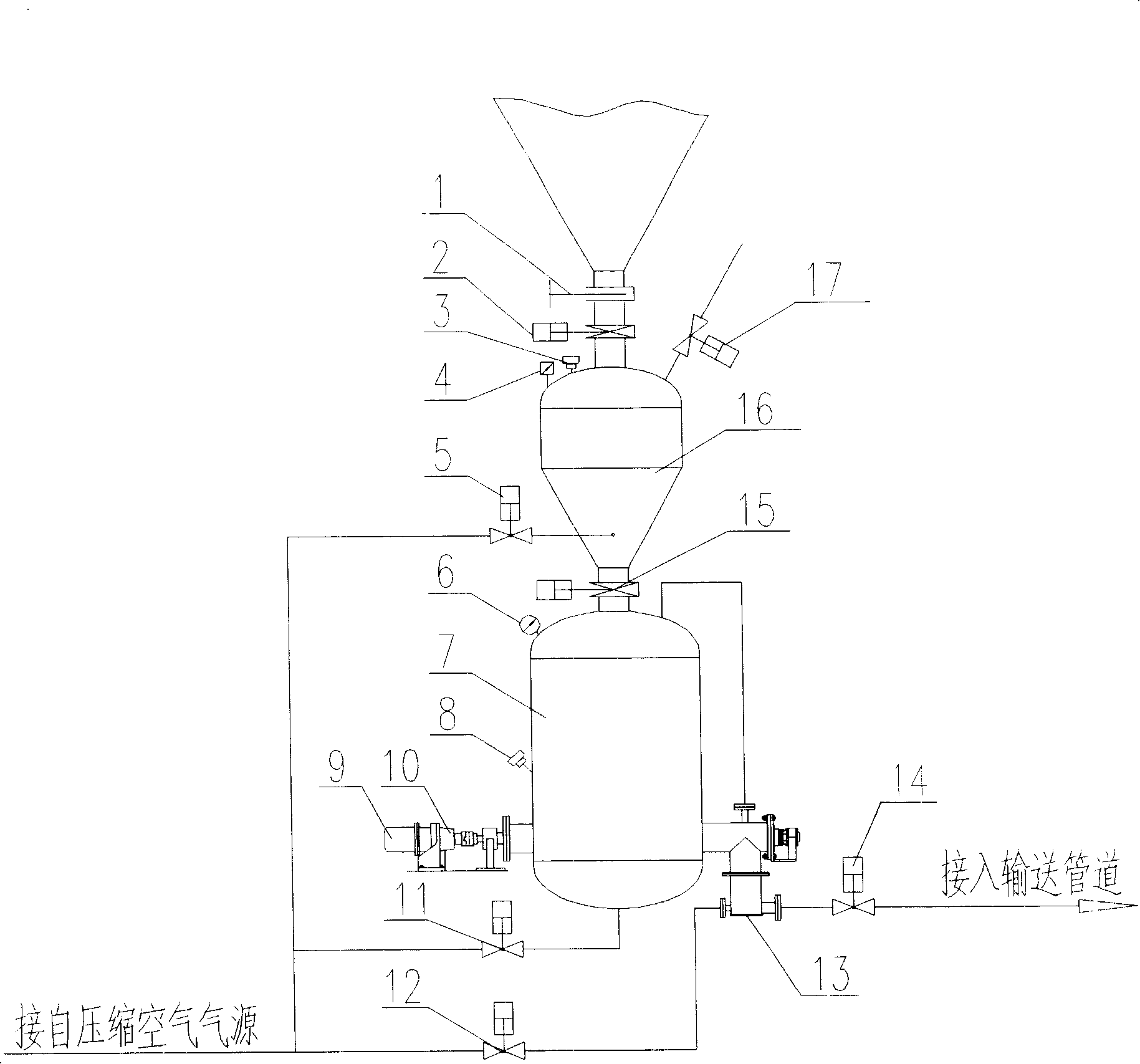

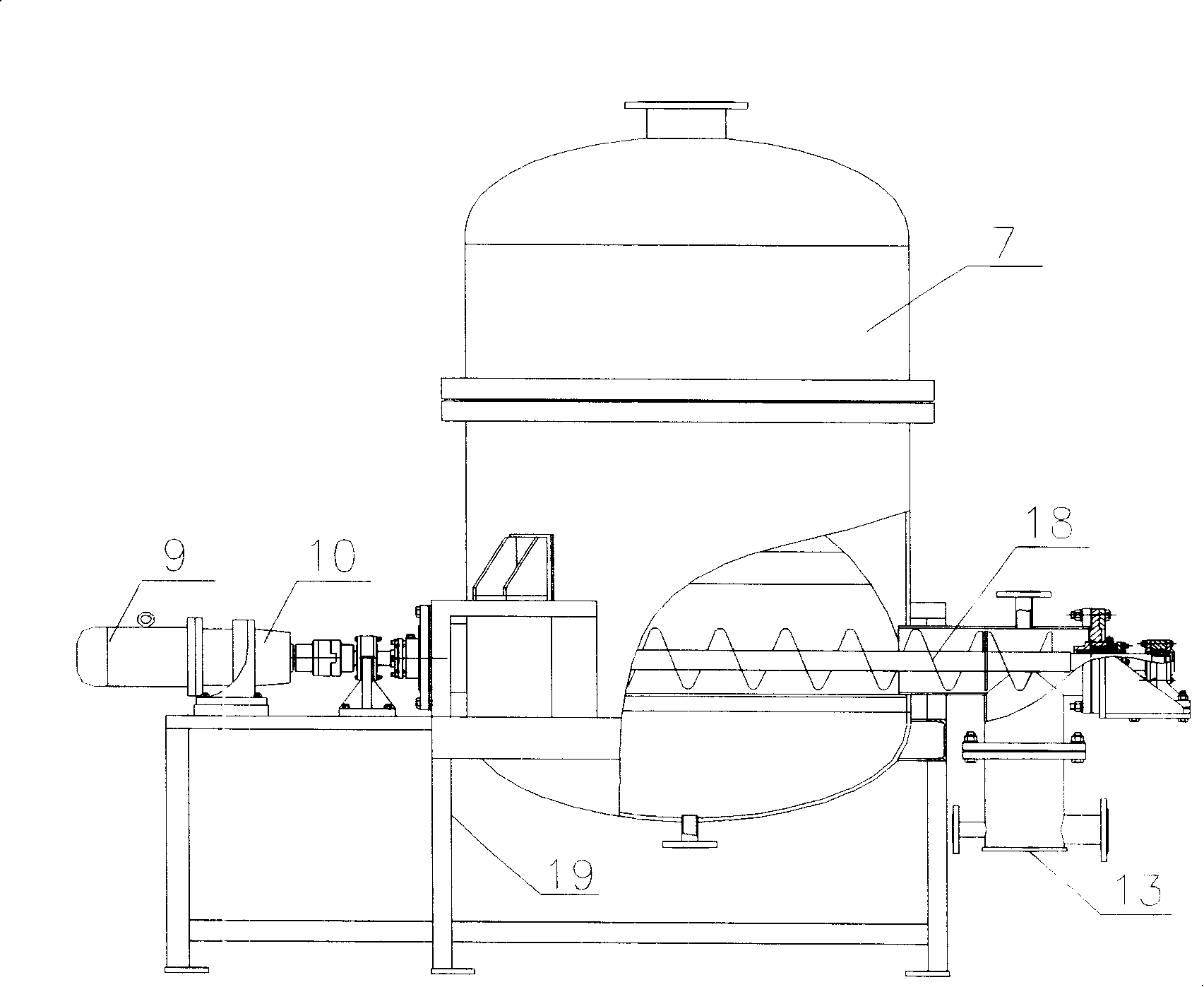

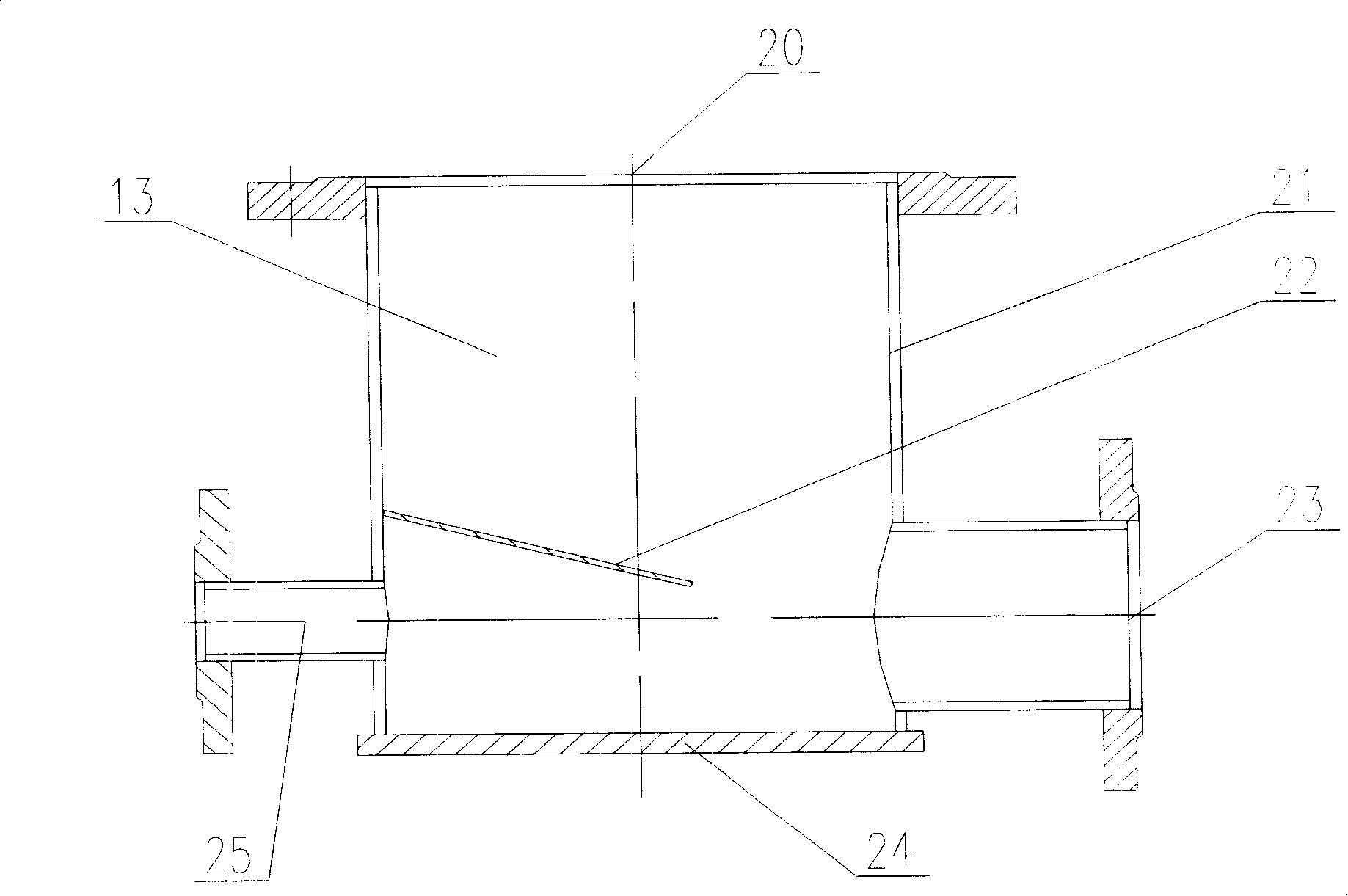

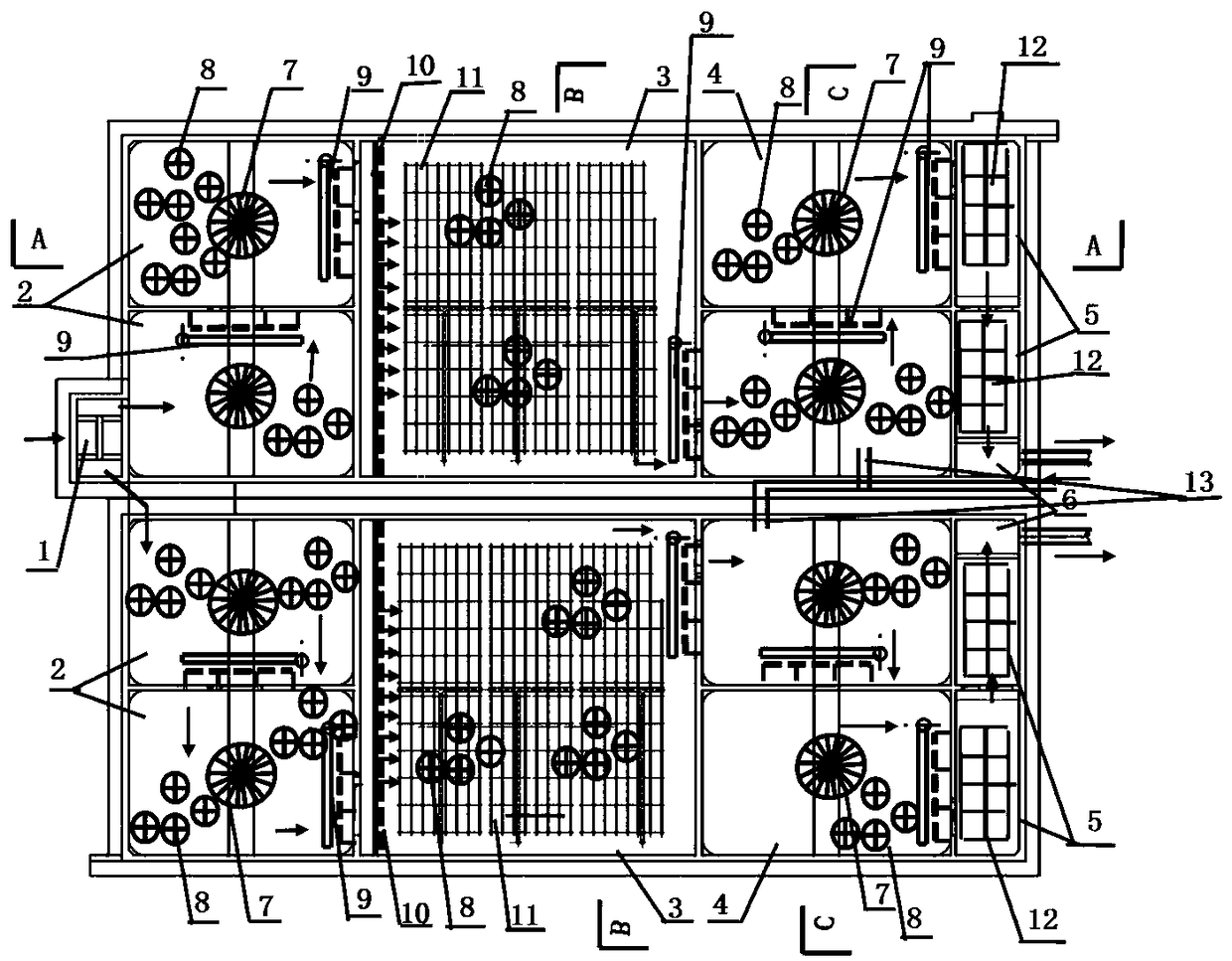

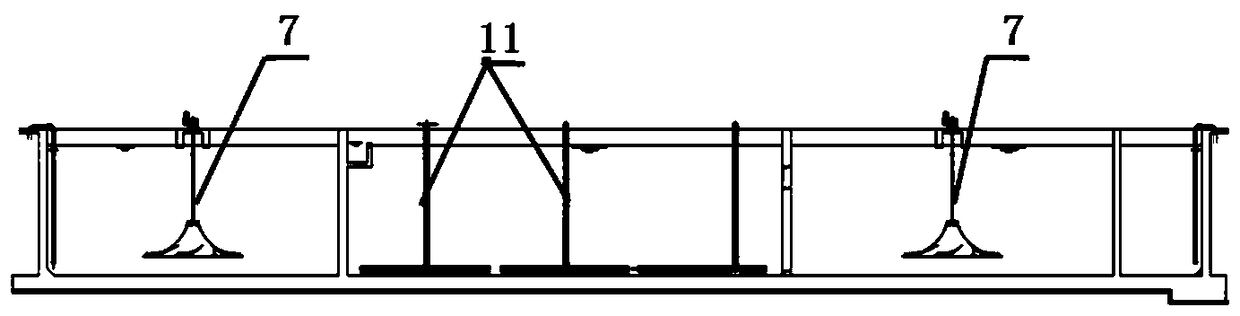

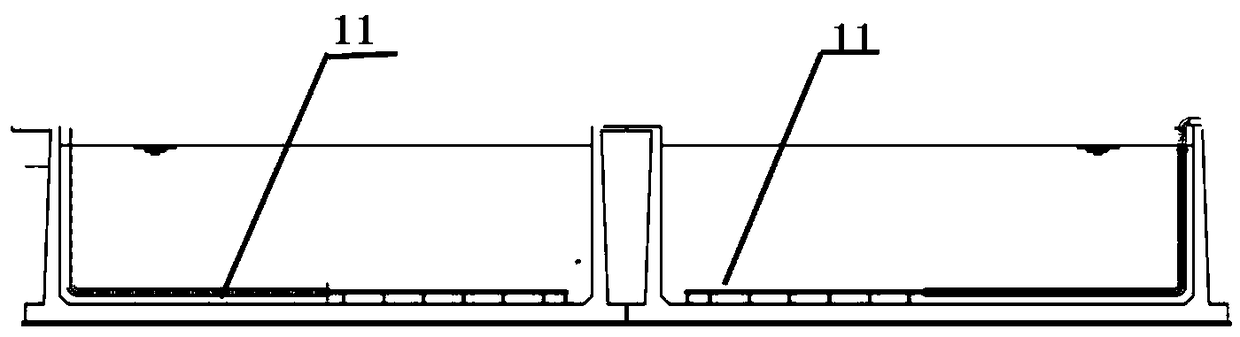

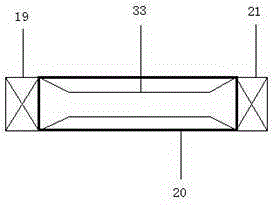

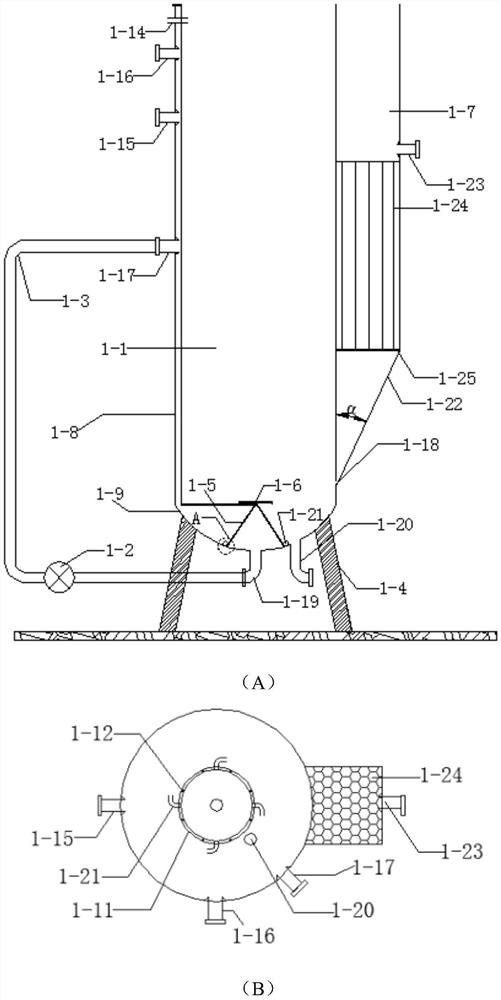

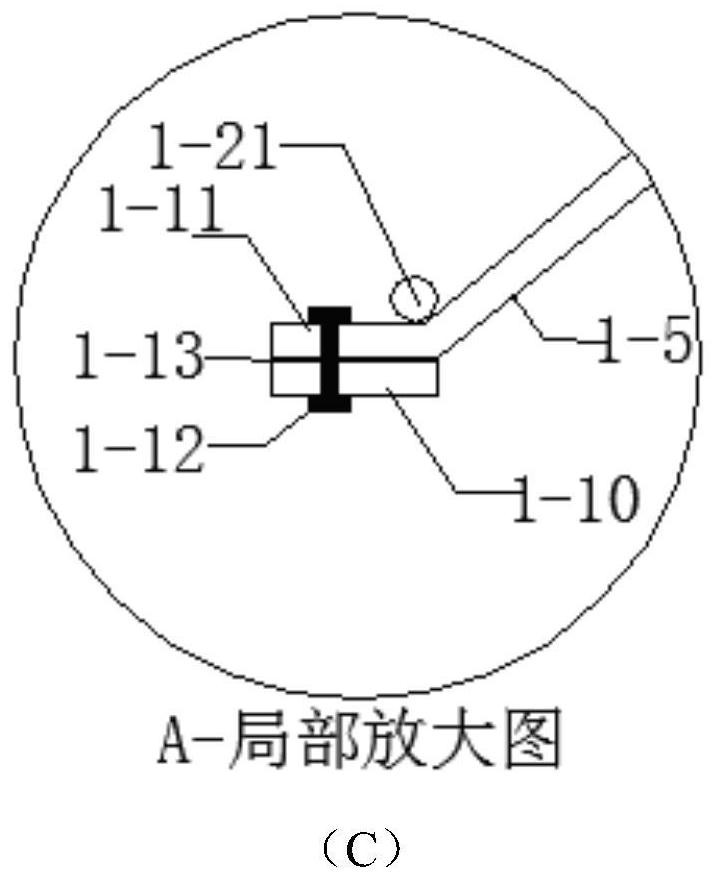

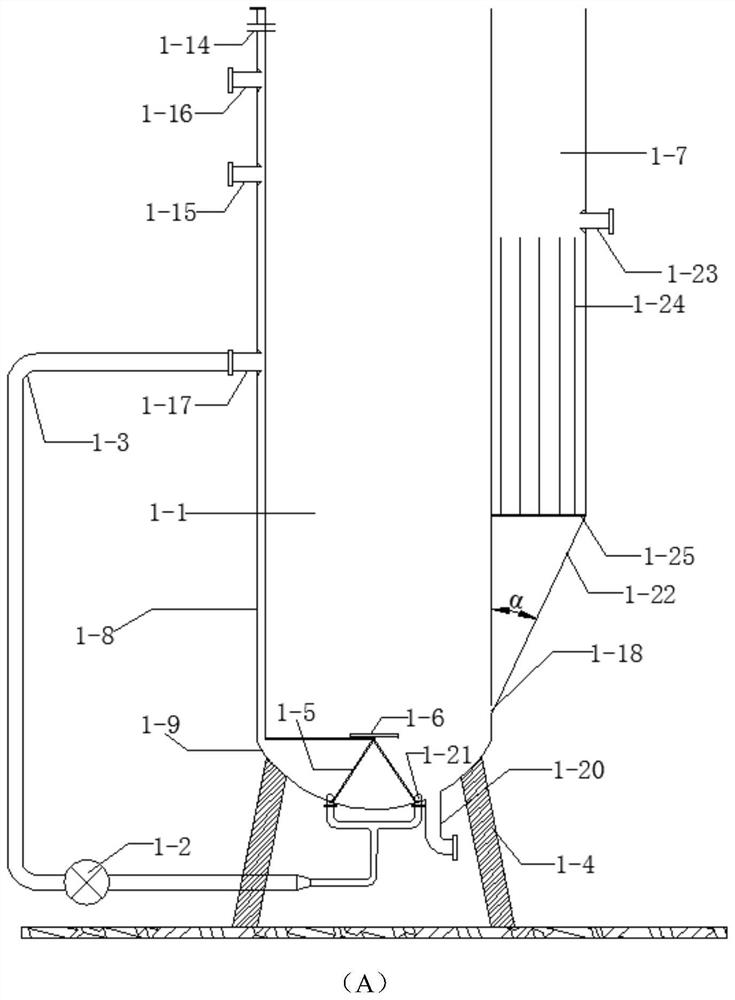

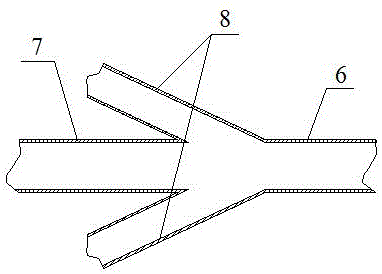

Cabin type helix transporting device

ActiveCN101205020ASolve easy blockageFully fluidizedLarge containersBulk conveyorsHigh energyScrew conveyor

The invention discloses a spiral delivery device of storehouse type to solve the problems of easy pipe blocking and high energy consumption in the prior device. The invention adopts a spiral conveyor (18) installed in a lower hopper (7). A discharge hole of the spiral conveyor (18) is connected with an inlet orifice (20) of a material and gas mixing cavity (13). An air inlet (25) and a discharge orifice (23) are respectively arranged at the lower part of the material and gas mixing cavity (13). The air inlet (25) of the material and gas mixing cavity (13) is connected with compressed air. The discharge orifice (23) of the material and gas mixing cavity (13) is connected with a delivery pipe. Therefore, the invention has the advantages of few occurrences of blockage and can reduce energy consumption.

Owner:FUJIAN LONGKING

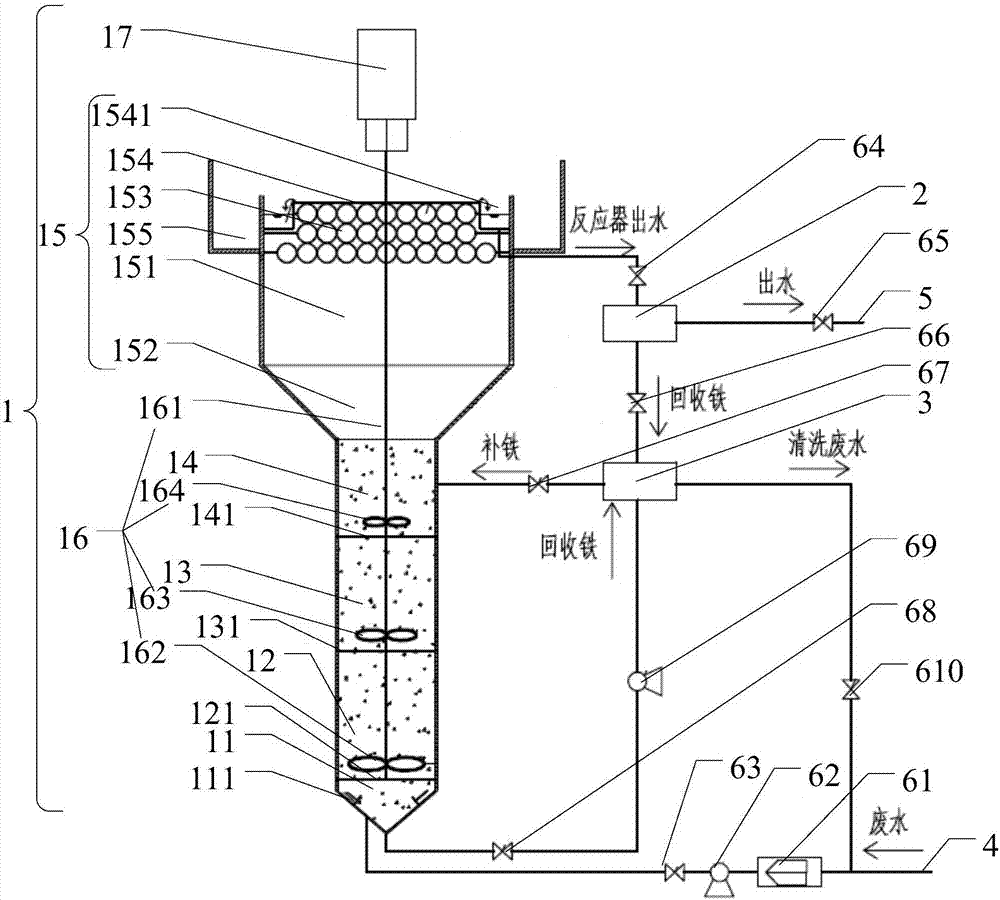

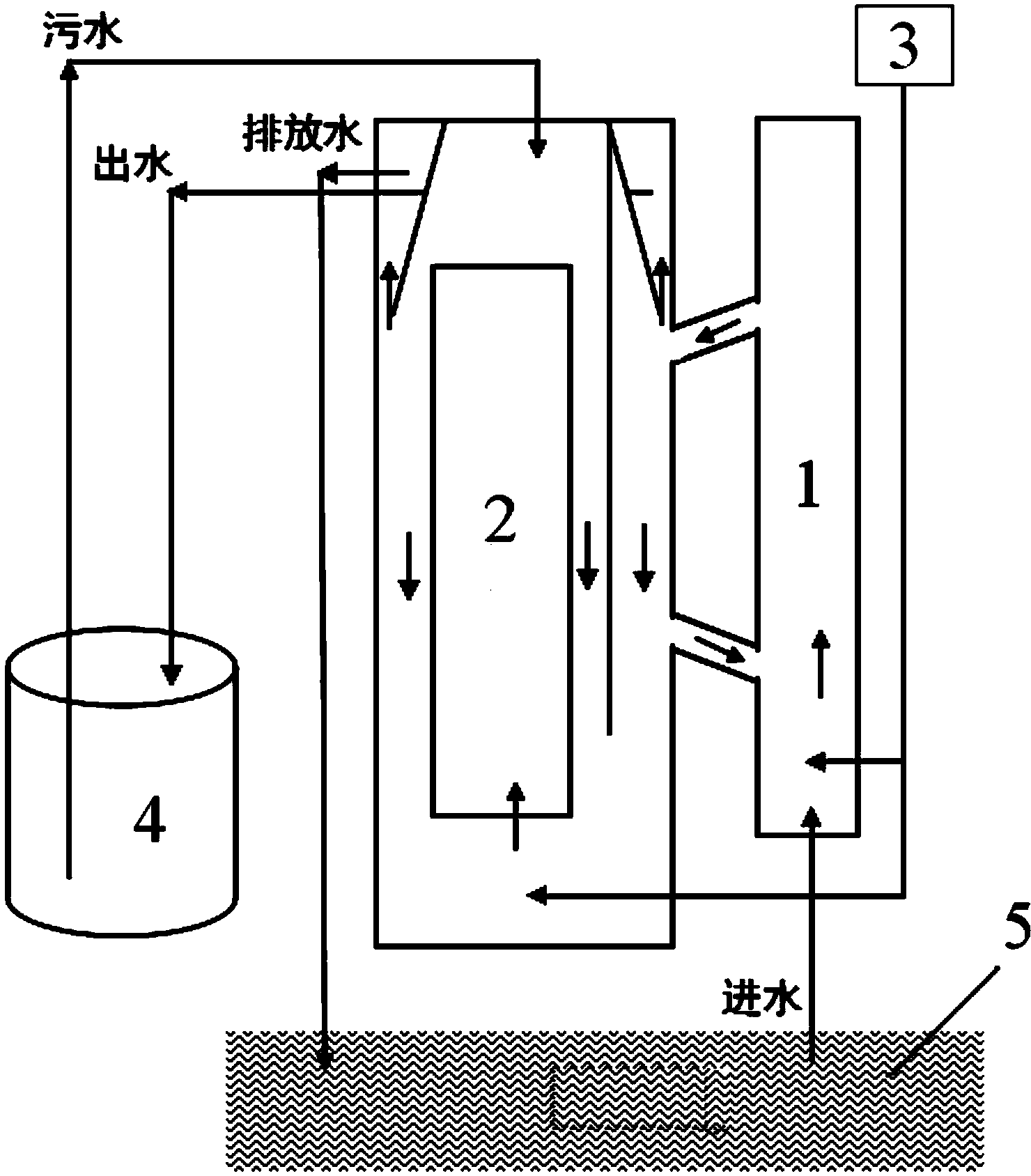

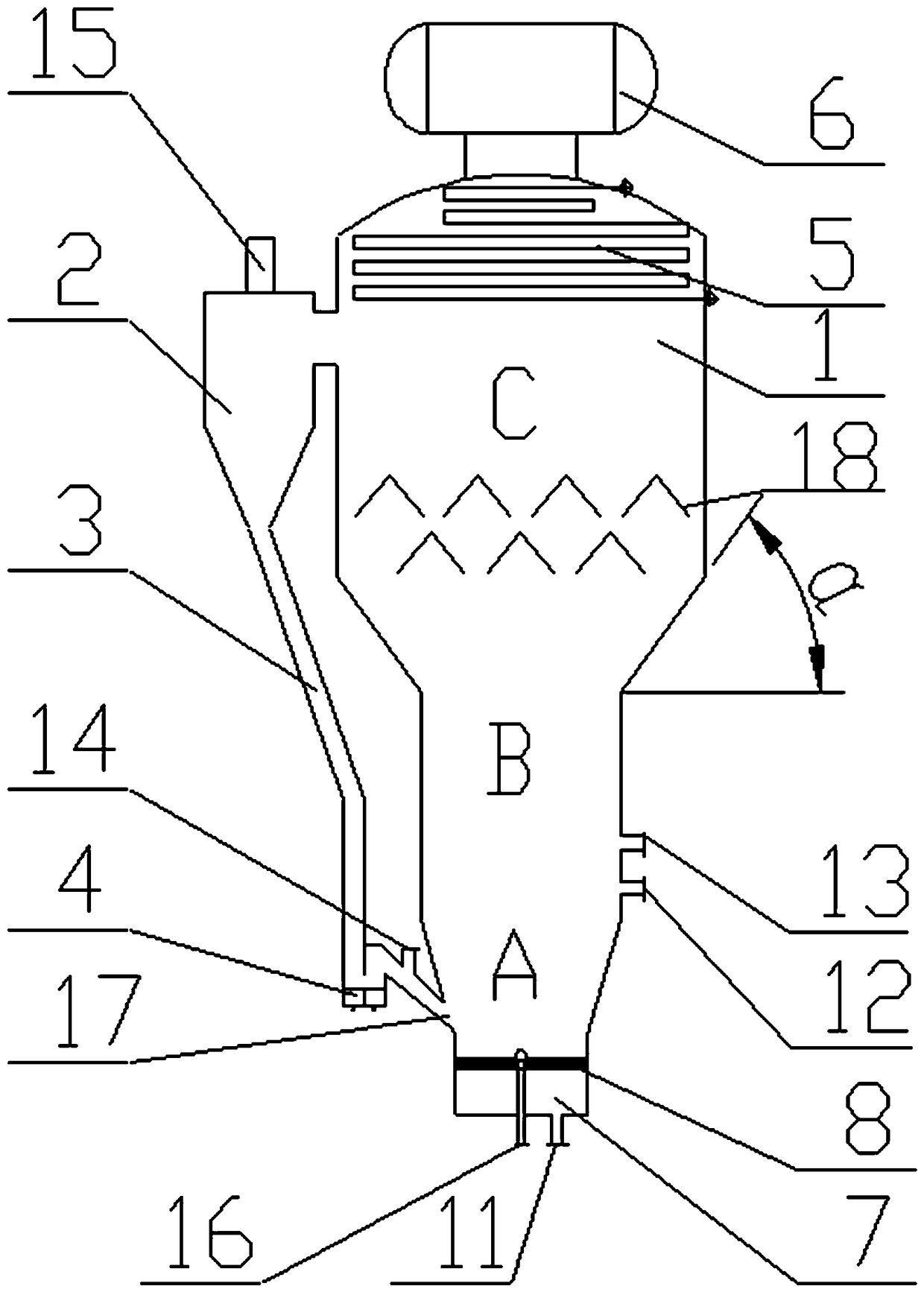

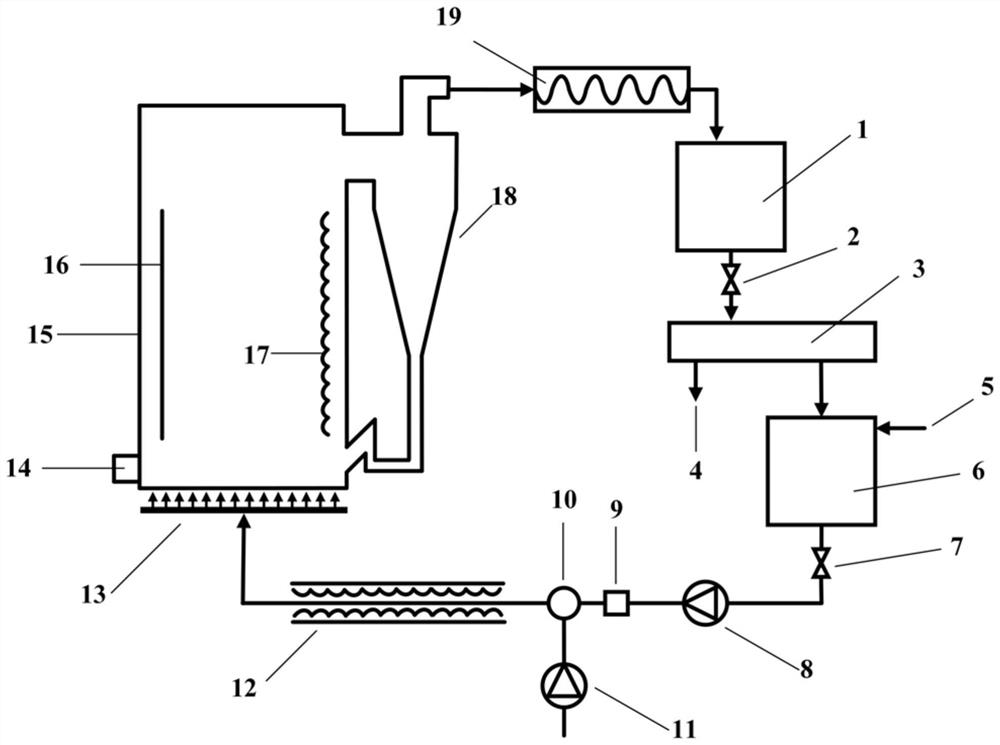

System for waste water treatment by utilizing fluidized state partition iron powder

ActiveCN107032473AFully fluidizedImprove surface mass transfer efficiencyTreatment involving filtrationMultistage water/sewage treatmentIron powderWastewater

The invention provides a system for waste water treatment by utilizing fluidized state partition iron powder. The system comprises a reactor, a separating device and an iron powder cleaning device. A mud scraping area, a preliminary reaction area, a primary enhanced reaction area, a secondary enhanced reaction area and a solid-liquid separation area which are communicated in sequence are arranged in the reactor from bottom to top. A water inlet of the mud scraping area is communicated with a waste water inlet pipe, the solid-liquid separation area is communicated with the separating device, the separating device is further communicated with a waste water outlet and an iron powder cleaning device through pipes respectively, and the iron powder cleaning device is further communicated with the secondary enhanced reaction area, a water outlet of the mud scraping area and the waste water inlet pipe through pipes respectively. According to the system, uniform mixing, precipitation and recycling integrated reaction separation of the iron powder and the waste water are implemented, shortcomings that an iron material fixed bed is easily subjected to passivation hardening and iron granules in a conventional micron iron treatment method are unevenly distributed and lost easily are overcome, and shortcomings that the cost of adopting nano-iron is too high and it is difficult to recycle the nano-iron are overcome.

Owner:TONGJI UNIV +1

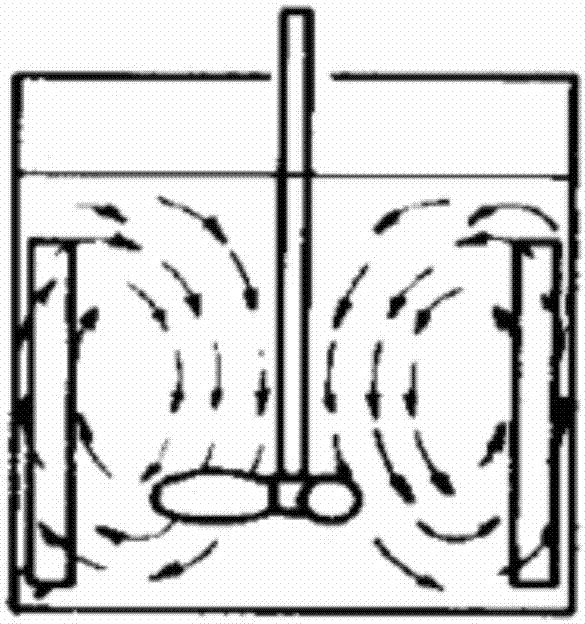

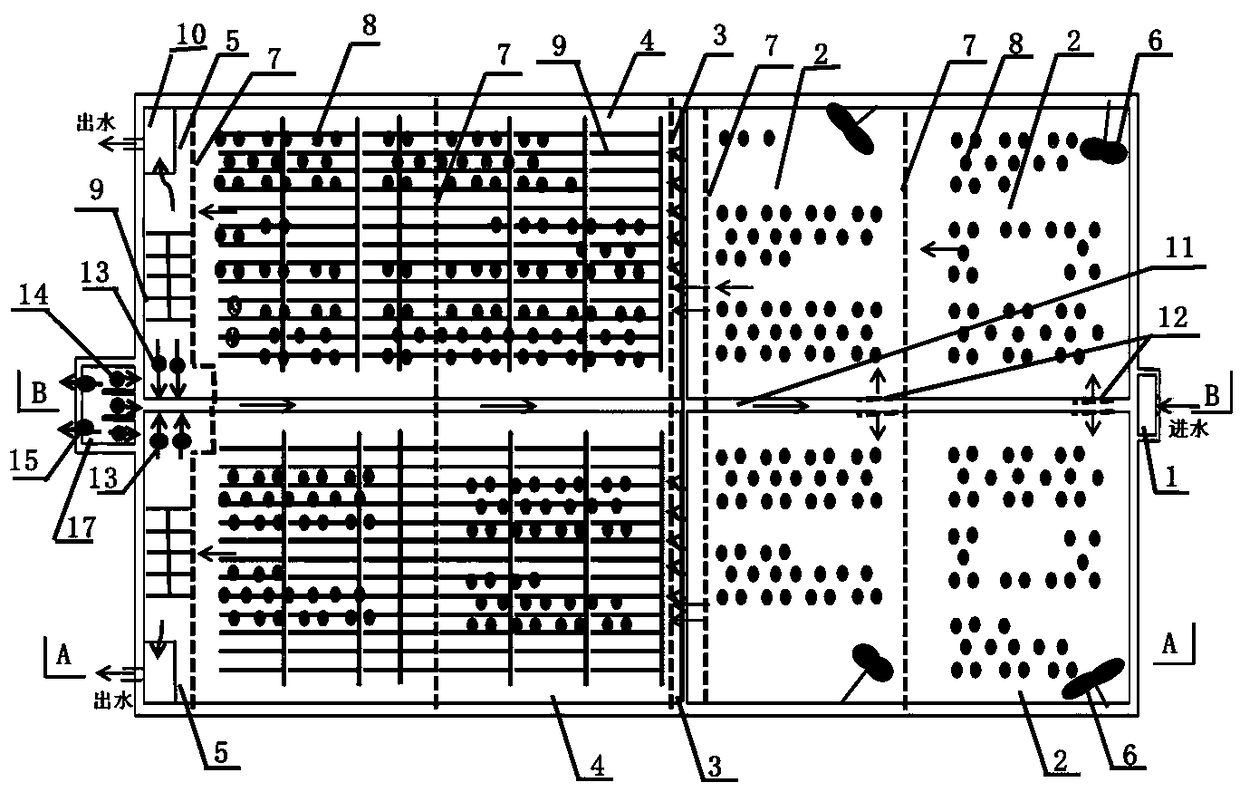

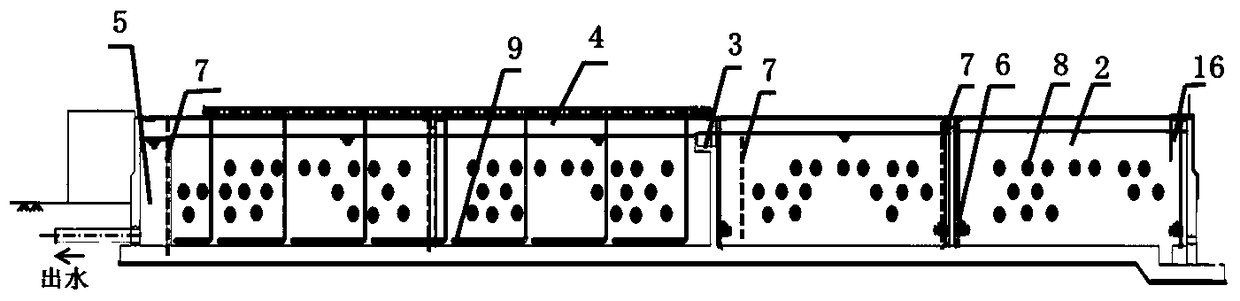

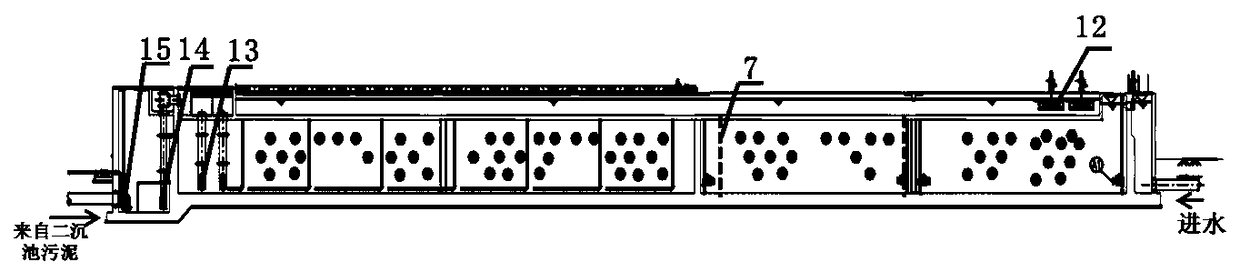

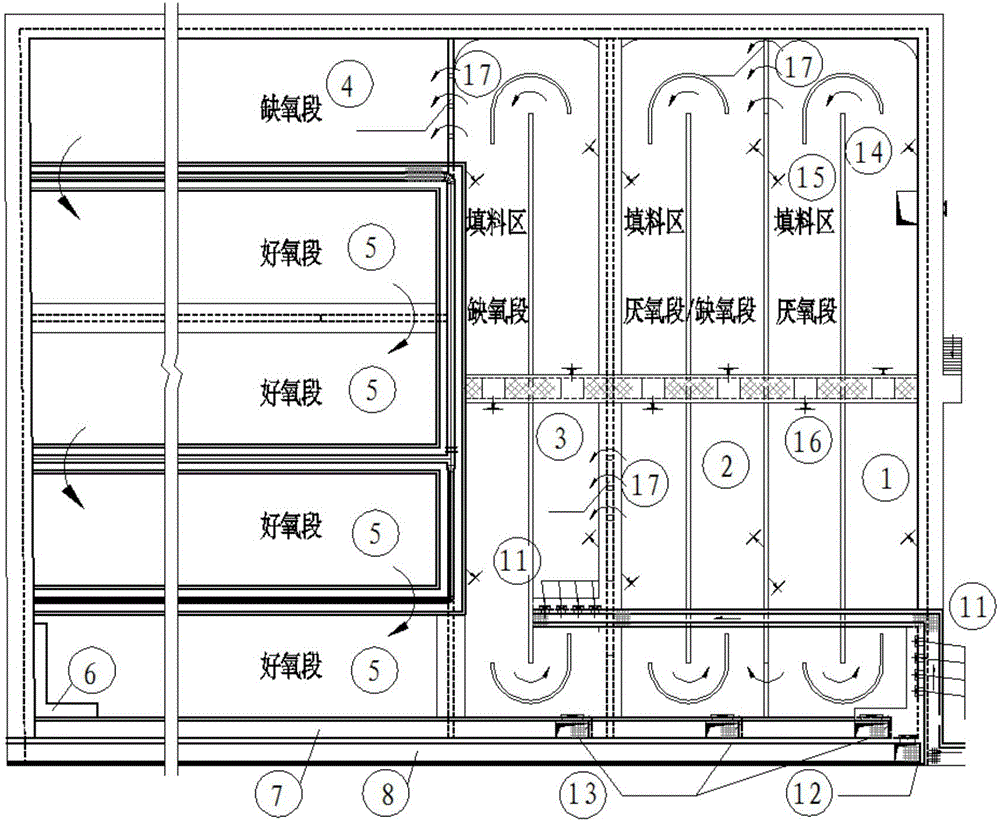

AA-MBBR sewage treatment system and sewage treatment method

ActiveCN107055784ARelieve swellingEasy to handleTreatment with aerobic and anaerobic processesSustainable biological treatmentWater treatment systemSludge

The invention discloses an AA-MBBR sewage treatment system. The AA-MBBR sewage treatment system comprises a water inlet pond, a water inlet pump, an anoxic MBBR pond, a main reaction pond, a sludge refluxing pump and a secondary sedimentation tank. The water inlet pond is connected to the anoxic MBBR pond via a water inlet tube through the water inlet pump; the main reaction pond is divided into an aerobic MBBR pond positioned in the outer ring and an anaerobic pond positioned in the inner ring; a water outlet tube of the anoxic MBBR pond is connected into the anaerobic pond in the inner ring of the main reaction pond through a pipeline; an aerator tube is arranged at the bottom in the aerobic MBBR pond and is provided with an aerator; a refluxing hole is formed in the bottom of the anaerobic pond; a water inlet hole which communicates to the inside of the aerobic MBBR pond is formed in a position, which is close to the bottom, of the anaerobic pond; a water outlet is formed in the upper part of the outer side of the main reaction pond and is connected into the secondary sedimentation tank via a pipeline; the bottom of the secondary sedimentation tank is connected with a refluxing tube; and the secondary sedimentation tank is connected to the refluxing hole of the anaerobic pond via the refluxing tube through the sludge refluxing pump. The AA-MBBR sewage treatment system is high in nitrogen and phosphorus removal ability and good in effect.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

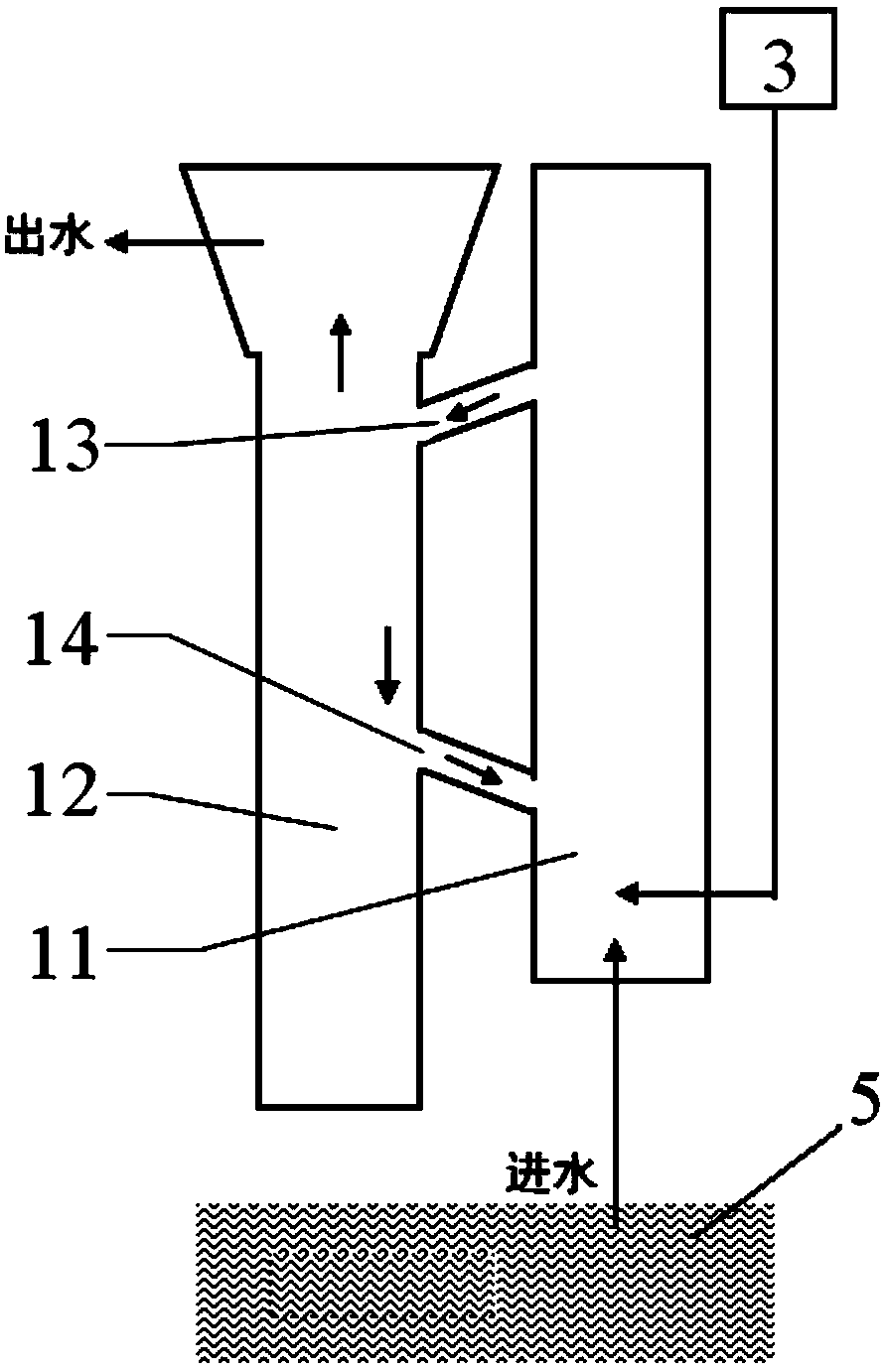

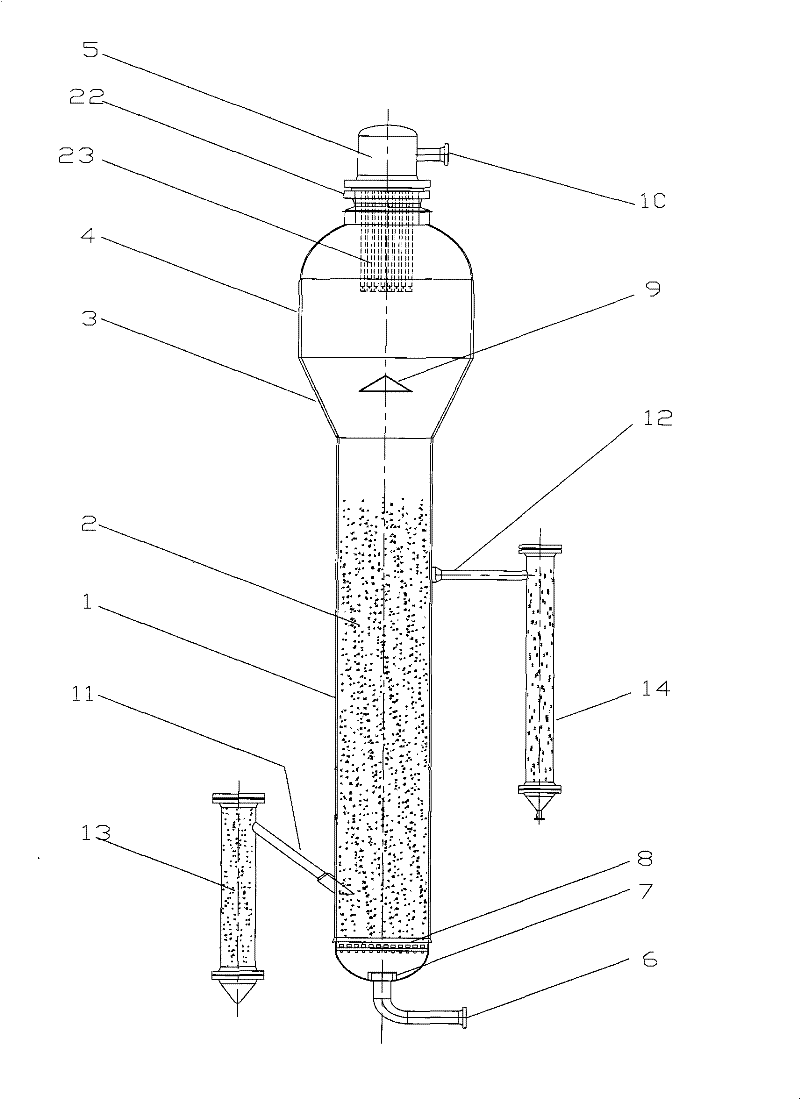

Integrative composite structure of marine internal and external circulation three-phase biological fluidized beds

InactiveCN103910471APromote growthGuaranteed superficial gas velocityEnergy based wastewater treatmentMultistage water/sewage treatmentFluidized bedEngineering

The present invention relates to an integrative composite structure of marine internal and external circulation three-phase biological fluidized beds. The integrative composite structure is composed of an external circulation three-phase biological fluidized bed (TBFB), an inner circulation three-phase biological fluidized bed (also called airlift inner circulation suspended filler fluidized bed, ACFB), suspended fillers and an air pump, wherein the external circulation three-phase biological fluidized bed is composed of a main bed and an auxiliary bed connected with the main bed by virtue of an upper communicating pipe and a lower communicating pipe, and a sewage inlet is arranged on the bottom of the main bed; the inner circulation three-phase biological fluidized bed comprises a main bed and an auxiliary bed which are embedded together, the main bed is embedded in the auxiliary bed, a settling bed is arranged above the auxiliary bed or a settling bar is arranged in the auxiliary bed to serve as a water outlet, a solid-liquid separating hopper is arranged below the auxiliary bed, the main beds of the outer circulation three-phase biological fluidized bed and the inner circulation three-phase biological fluidized bed are connected with the air pump to be supplied with power by the air pump, the auxiliary beds are combined into a whole, and the suspended fillers containing biological species are filled in the structure. The integrative composite structure provided by the invention has the advantages of being compact in structure, high in efficiency, low in energy consumption and capable of being industrialized, having nitrification and denitrification functions and the like.

Owner:上海华业水处理工程有限公司

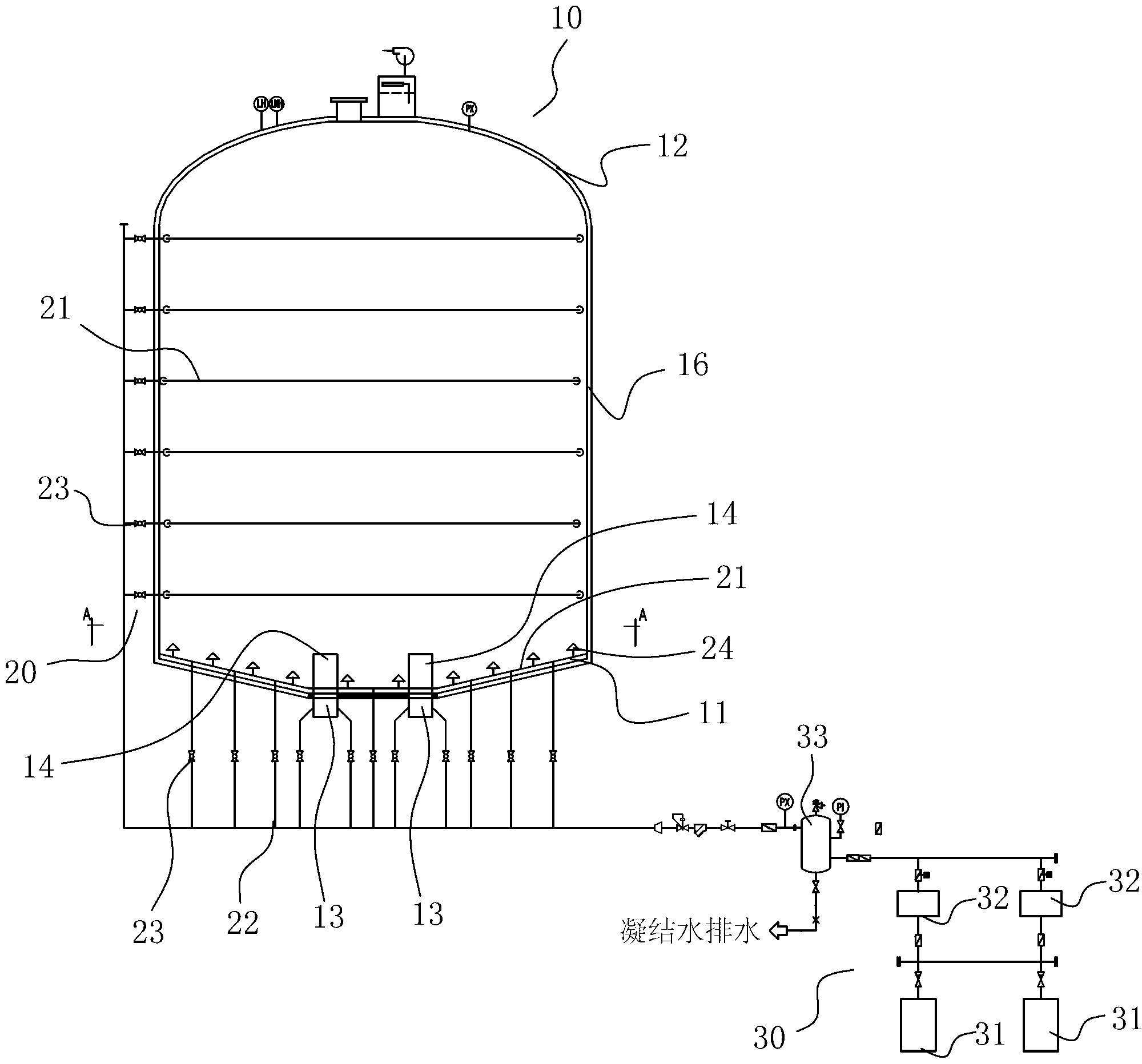

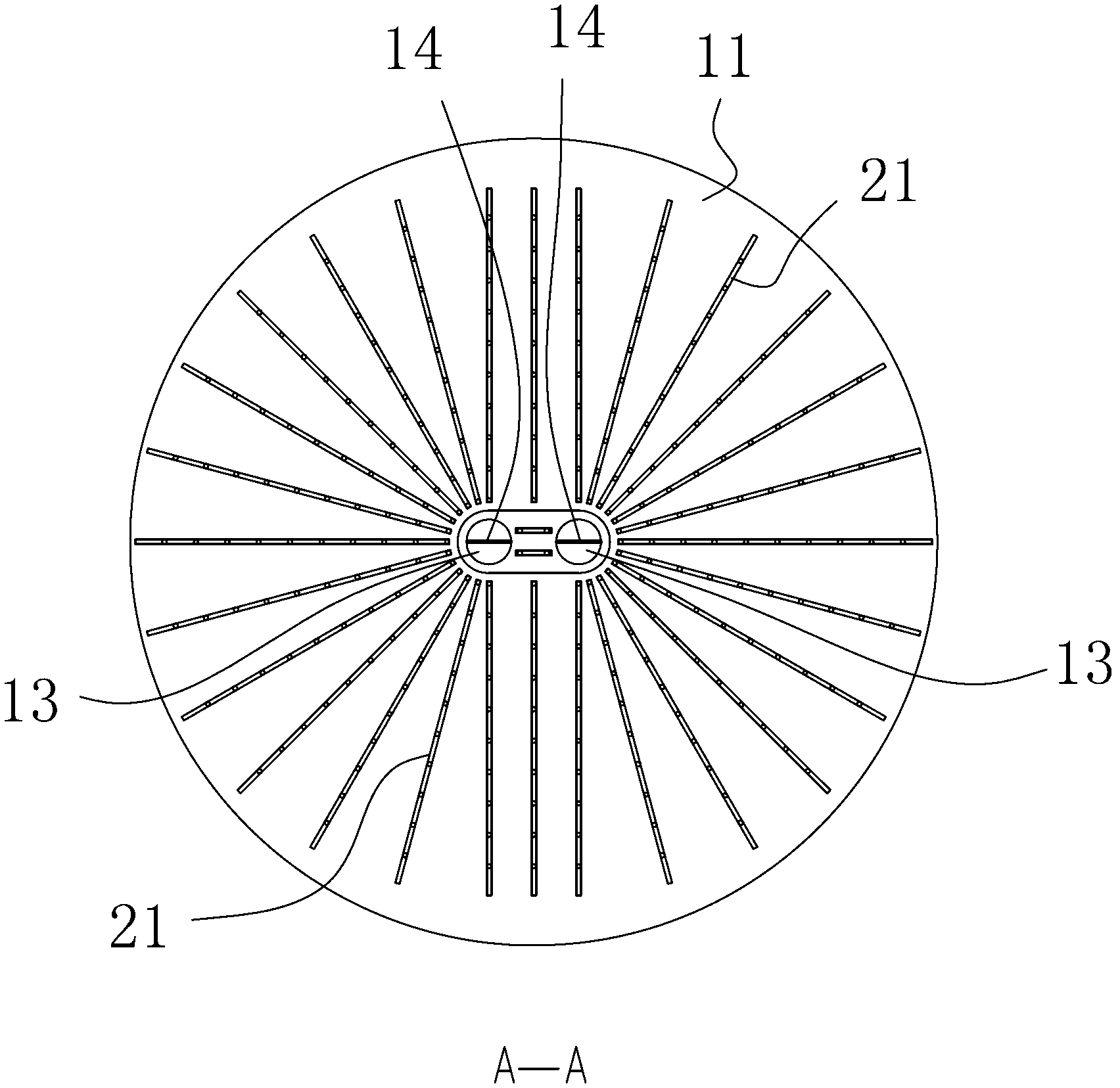

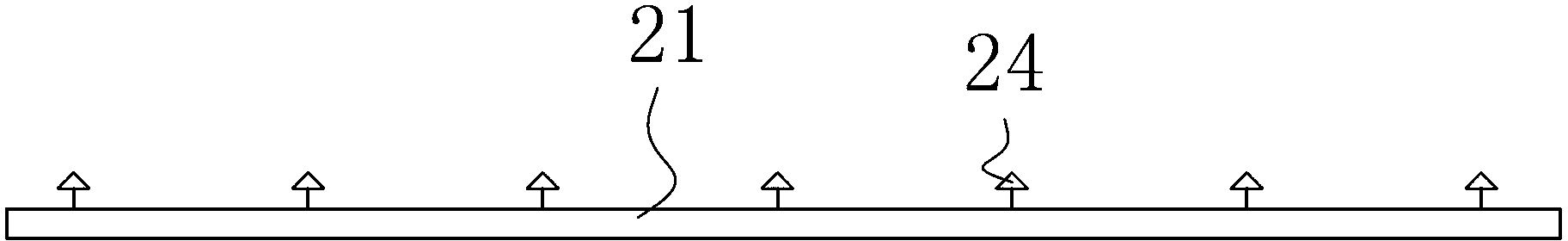

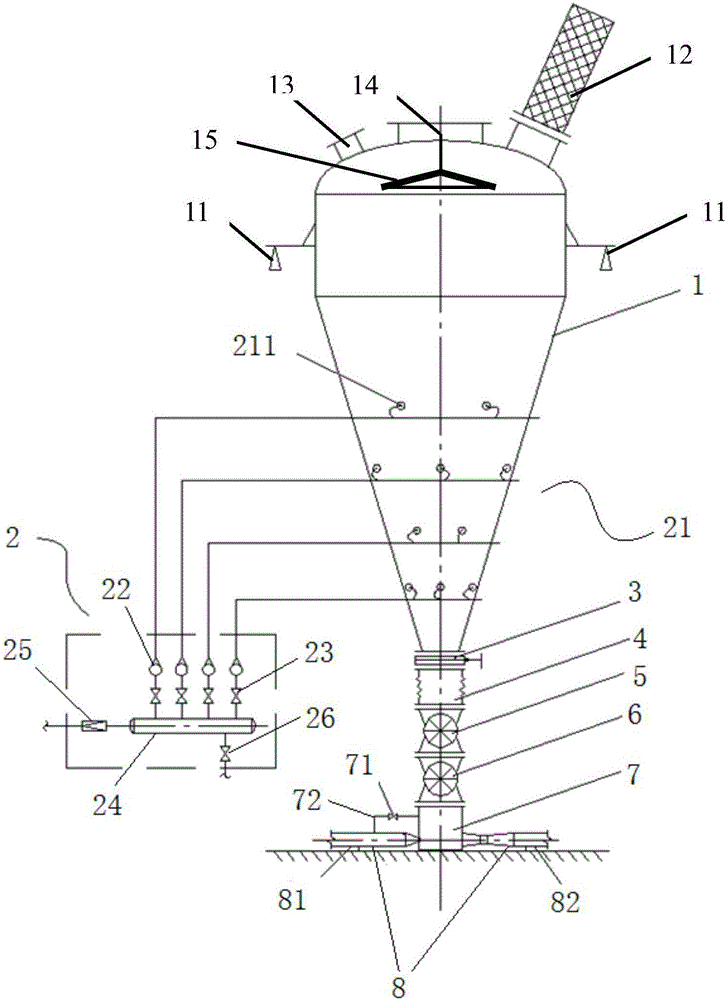

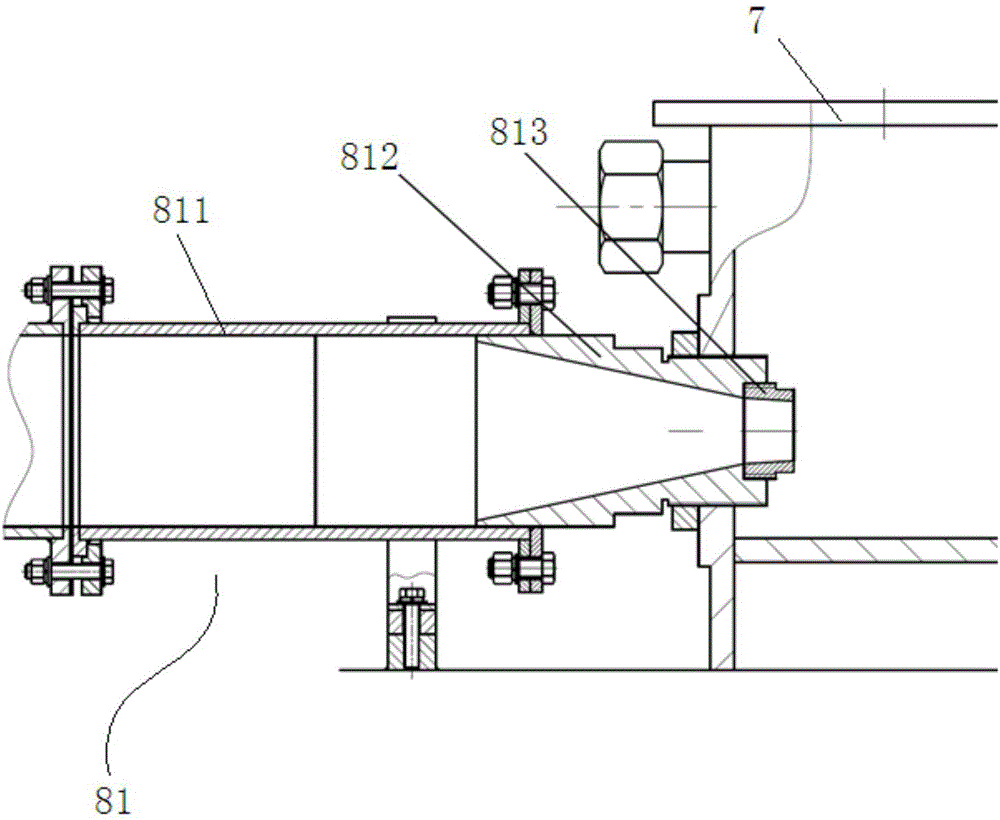

Large coal ash storage tank and coal ash storage system

The invention relates to a large coal ash storage tank and a coal ash storage system. The coal ash storage system comprises a large coal ash storage tank, a divided fluidization pipeline system and a compressed air source system. The large coal ash storage tank is provided with a hollow tubular structure and comprises a storage tank base part, a storage tank lateral wall and a storage tank top part, wherein a plurality of material discharging ports are arranged on the storage tank base part, and decompression conical partition boards are arranged on the material discharging ports. The divided fluidization pipeline system comprises a multilayer fluidization pipeline arranged on the storage tank lateral wall along the height direction of the storage tank, and a plurality of fluidization nozzles are arranged on the fluidization pipeline. The compression air source system blows air with certain pressure into the storage tank through the divided fluidization pipeline system, so that the coal ash in the storage tank can be fluidized in positive pressure mode. The large coal ash storage tank and the coal ash storage system are simple in structure, less in maintenance working load and high in reliability, fully fluidize the coal ash, greatly reduce and avoid storage accumulation dead angles, prolong the coal ash storage time and enlarge the effective using volume of a storage cabin.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

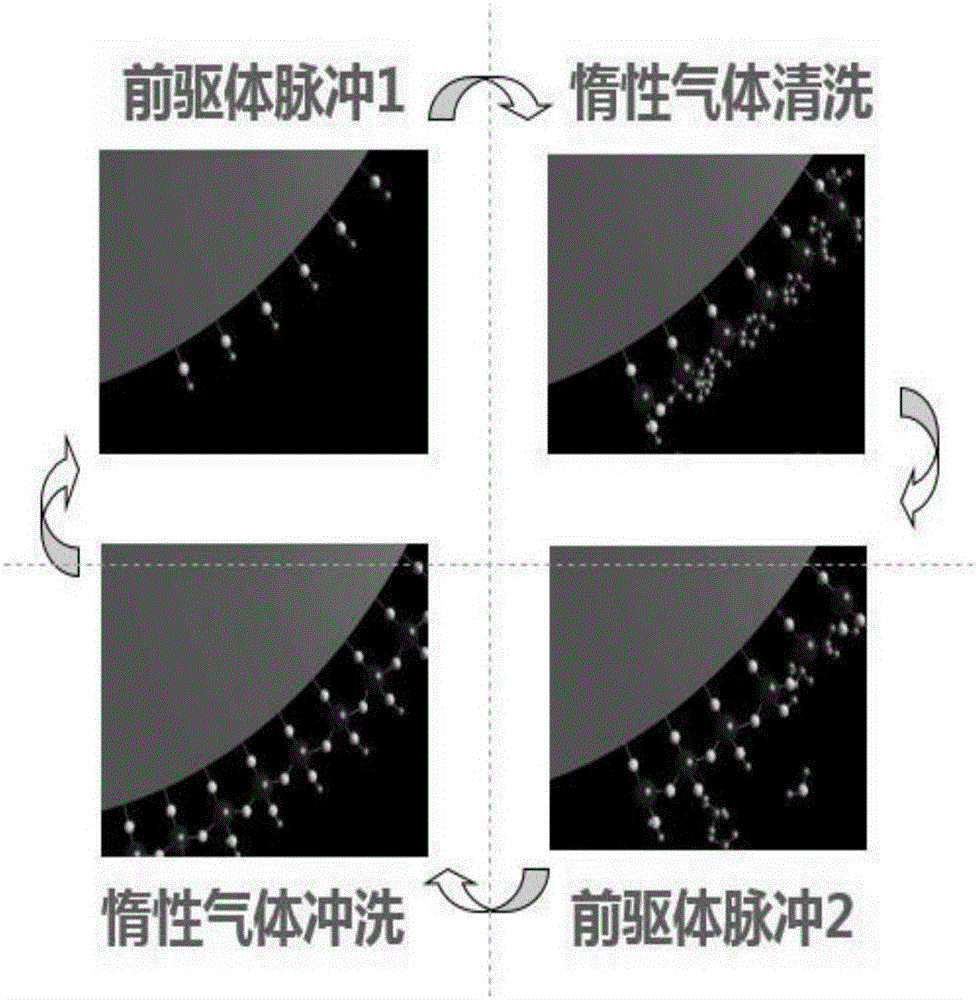

Method for achieving aluminum powder passivation by wrapping aluminum powder with zirconium oxide

ActiveCN106498365AAddress reactivitySolve the problem of changing its own chemical propertiesChemical vapor deposition coatingVacuum pumpingAluminium powder

The invention discloses a method for achieving aluminum powder passivation by wrapping aluminum powder with zirconium oxide. The method comprises the following steps that firstly, the aluminum powder needing to be wrapped is placed in a powder clamping device with the bottom provided with a filter net, and then the powder clamping device is placed in a cavity of an atom layer deposition reactor to be subjected to vacuum pumping; secondly, the cavity is heated, the cavity is constantly inflated with fluidization gas in the heating process, and the aluminum powder is pre-scattered; thirdly, when the cavity temperature reaches the preset temperature, the atom layer deposition reaction is started, and a layer of zirconium oxide film is deposited on the surface of the aluminum powder; and fourthly, the third step is repeatedly conducted, multiple layers of zirconium oxide films are deposited on the surface of the aluminum powder, and aluminum powder passivation is achieved. According to the method, the atom deposition technology is used for wrapping the surfaces of aluminum powder particles with a layer of zirconium oxide film with the nanometer thickness, aluminum powder passivation is achieved, and the beneficial effects that operation is convenient, and the technology is simple are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

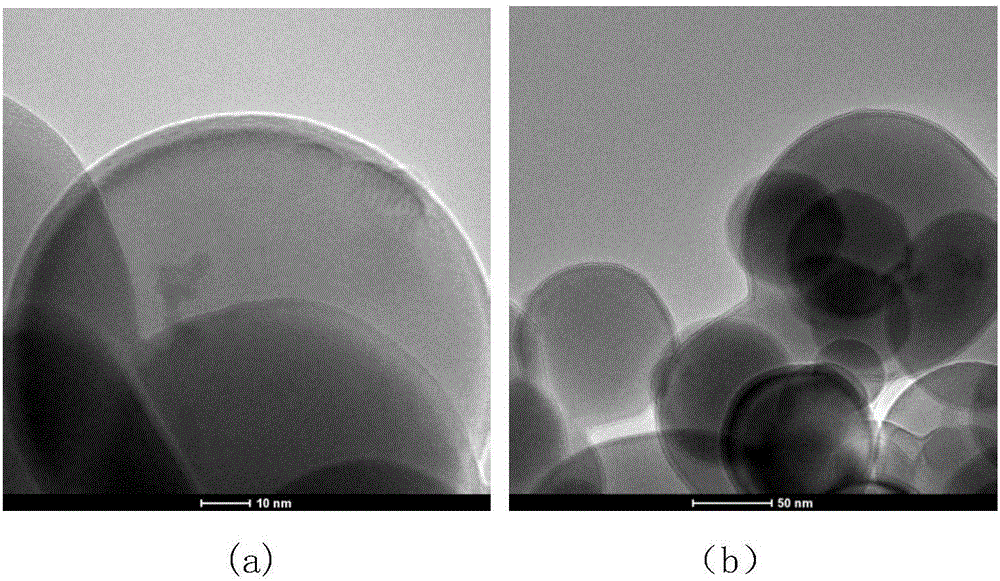

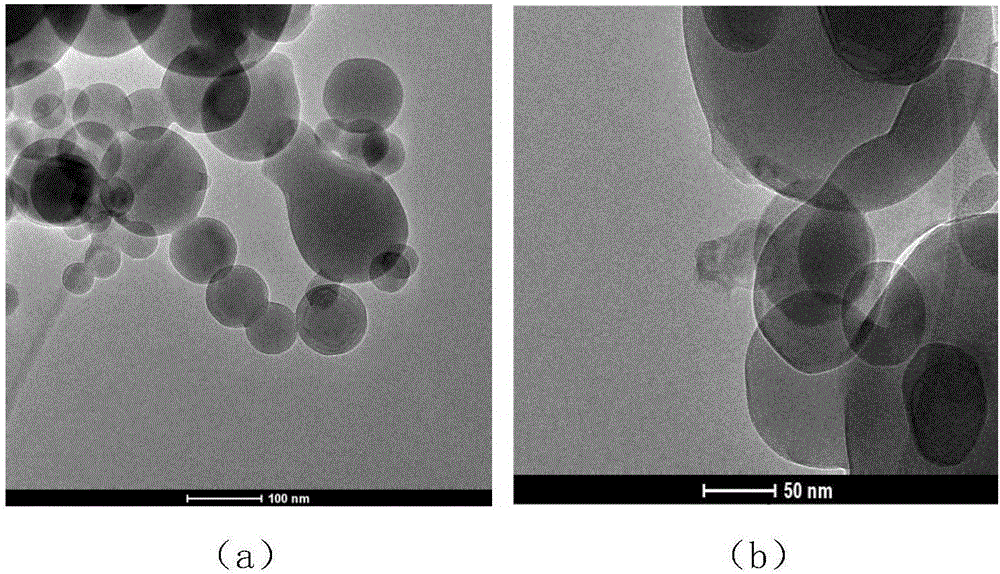

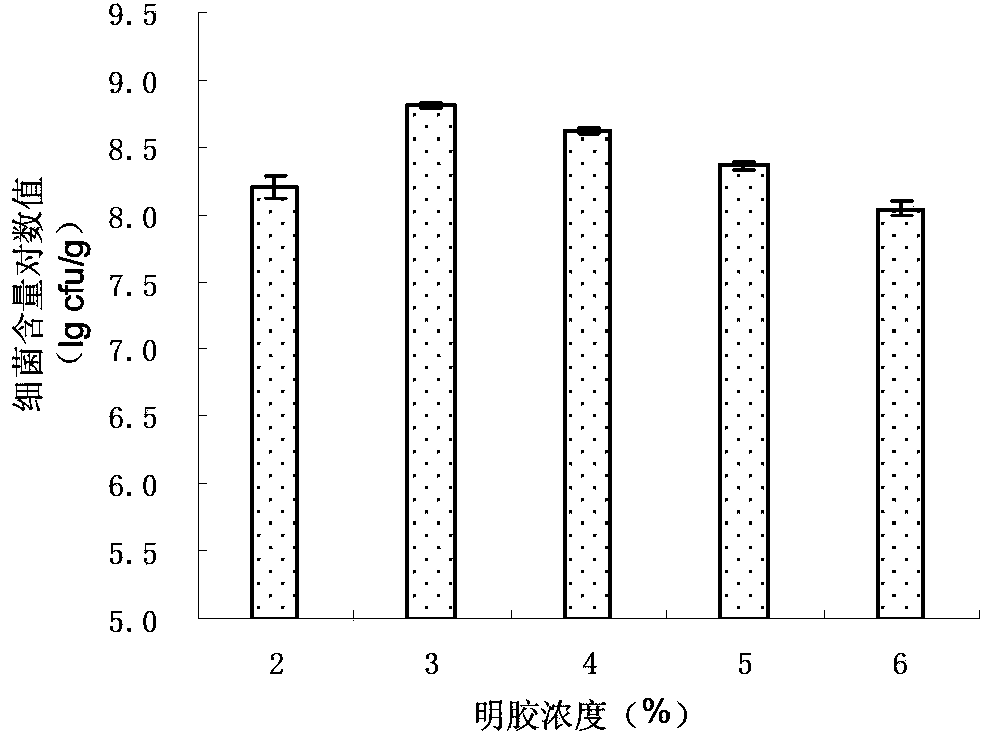

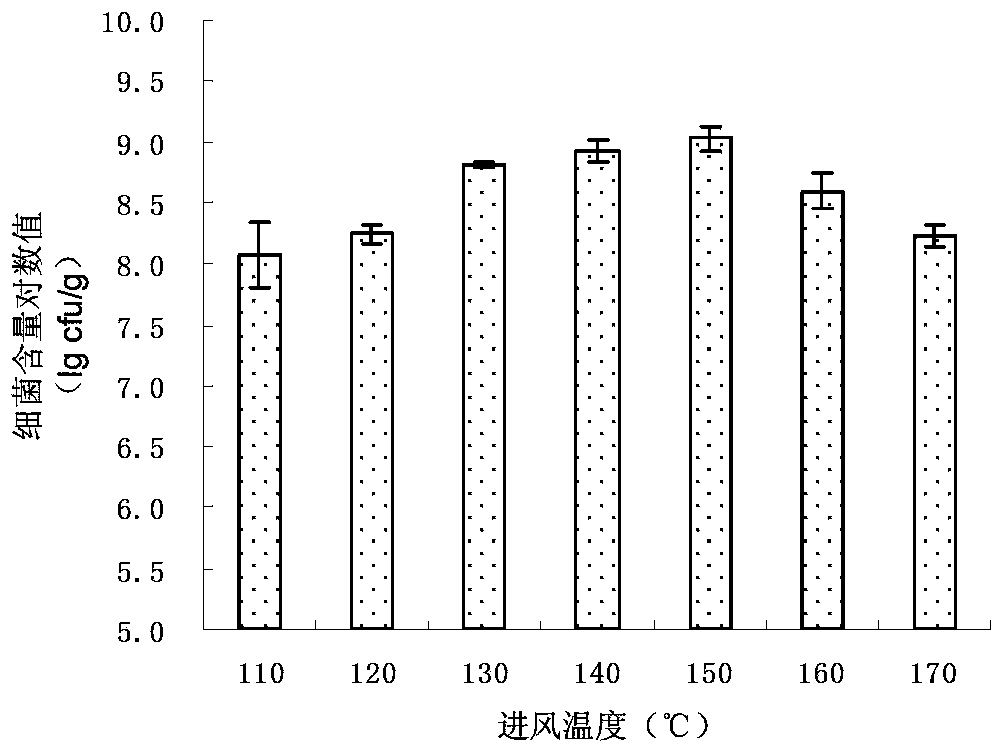

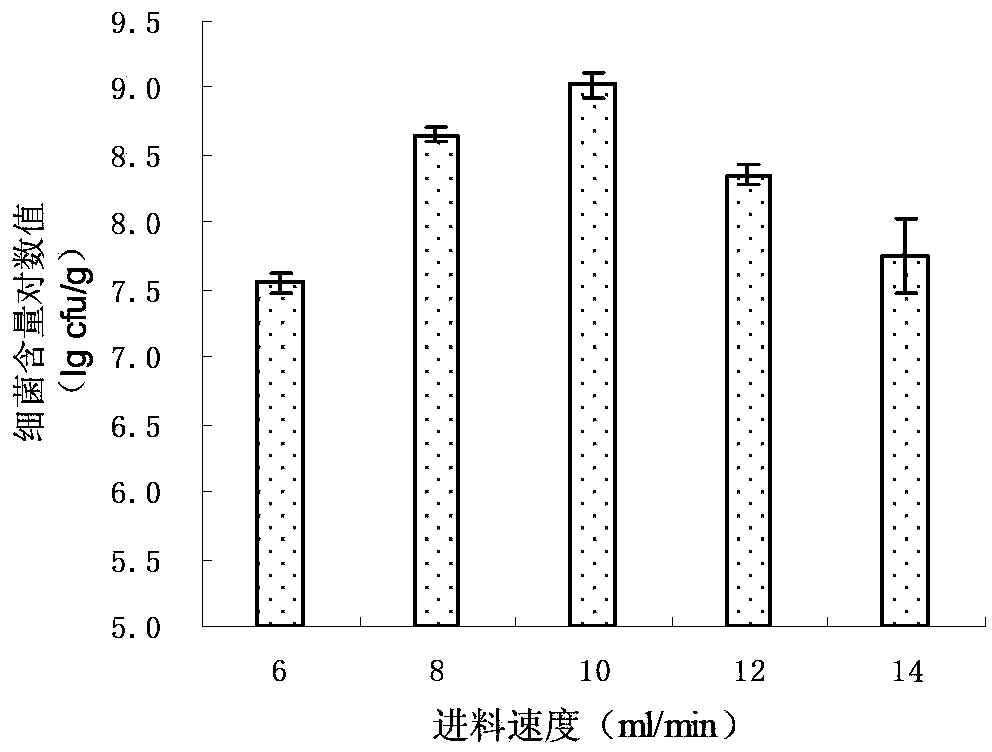

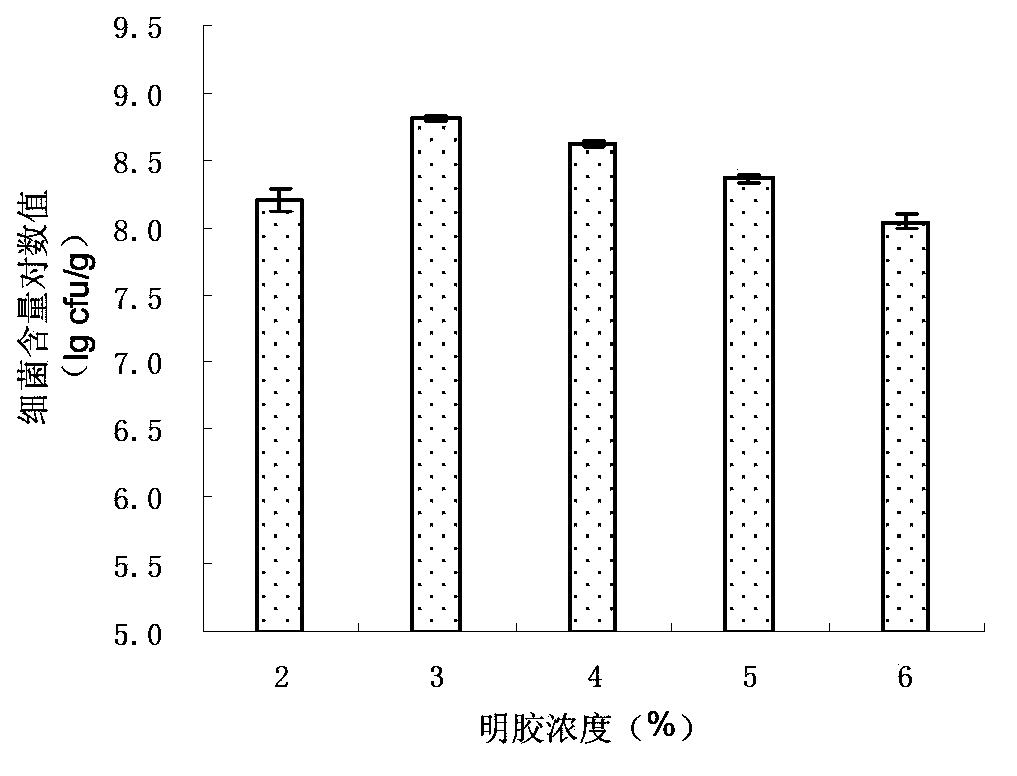

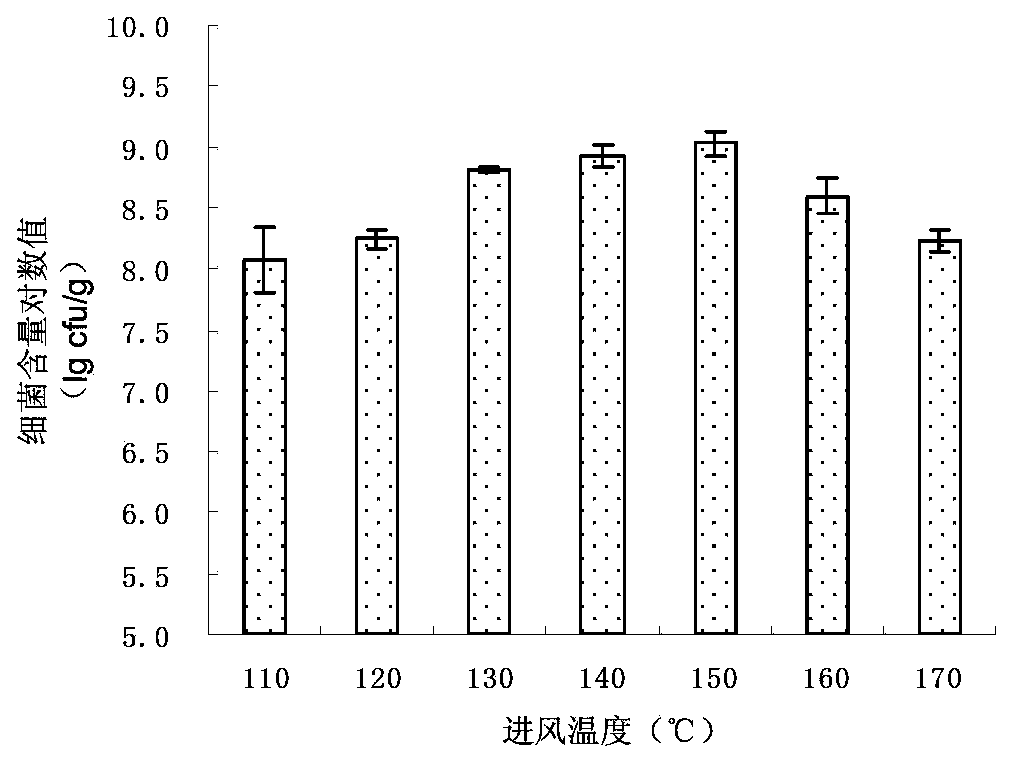

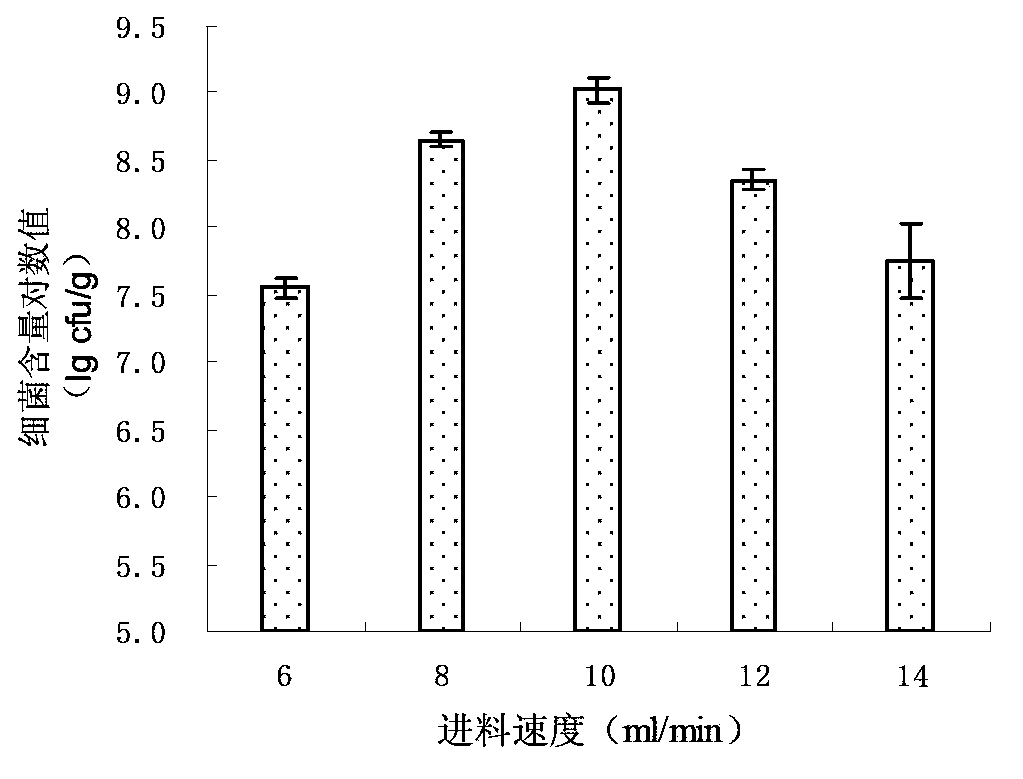

Bacillus amyloliquefaciens Sh1 microcapsule and preparing method therefor

InactiveCN103621796AFully fluidizedAvoid adsorptionAnimal feeding stuffEmulsionBacillus amyloliquefaciens

The invention discloses a bacillus amyloliquefaciens Sh1 microcapsule. A microcapsule particle is approximately ball-shaped, depressions exist on the surface of the microcapsule particle, but apertures and cracks do not exist on the surface of the microcapsule particle. The particle size of the microcapsule particle is 8-12 [mu]m, the particles are evenly distributed, and the logarithm value of effective bacterial amount is 6.64-9.28. The invention also provides a preparing method for the microcapsule, and the method comprises following steps: (1) uniformly mixing the bacillus amyloliquefaciens Sh1 solution, emulsion, suspension or pulp with aseptic gelatin solution; and (2) spray drying the mixed product obtained by step (1), and finally preparing microcapsule powder. The method is characterized in that the concentration of the aseptic gelatin utilized in the step (1) is 2-6%.

Owner:SHANGHAI OCEAN UNIV

AOAO mud chemical wastewater treatment method

PendingCN108238675AReduce concentrationLarge biomassTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSludge

The invention relates to an AOAO mud chemical wastewater treatment method, and belongs to the field of industrial sewage treatment. The method comprises two completely identical parallel groups of biochemical treatment tanks, wherein each group of biochemical treatment tank comprises a water distribution trench, a pre-anoxic area, an MBBR mud aerobic area, a post-anoxic area, an active sludge aerobic area and a water outlet trench which are communicated with one another; the water distribution trench is communicated with the pre-anoxic area through a cross-section overflow hole at the top of apartition wall; the pre-anoxic area is divided into two serially connected cells which are communicated through a square water through hole in the middle of the partition wall between the two cells;a suspension carrier is added into the pre-anoxic area; the water outlet place in the MBBR mud aerobic area is communicated with the post-anoxic area through a rectangular water through hole in the upper end side of the partition wall; and the water outlet place of the latter cell of the post-anoxic area is communicated with the active sludge aerobic area through a rectangular water through hole in the partition wall. The method provided by the invention overcomes the defects of COD decomposition difficulty, high ammonia and nitrogen and high TN in traditional technology, and can be applied tochemical wastewater treatment.

Owner:济宁市孚源环保科技有限公司

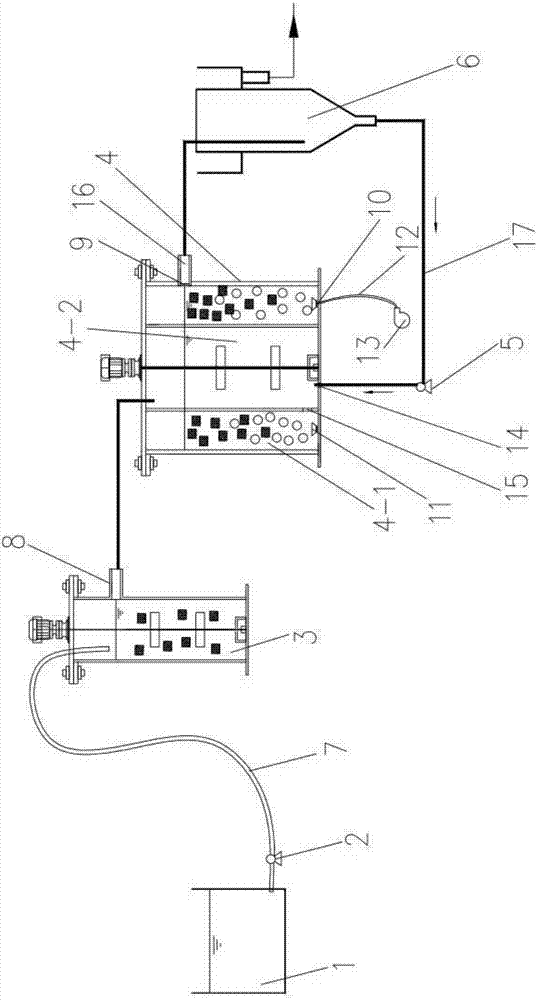

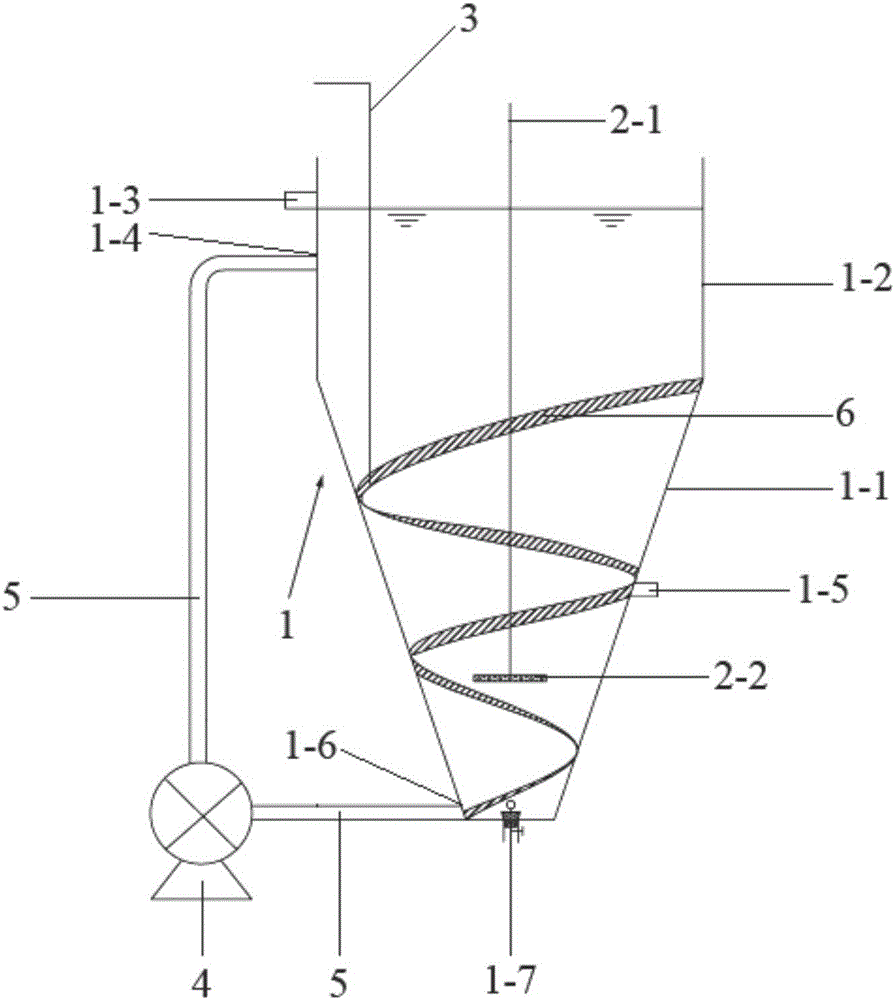

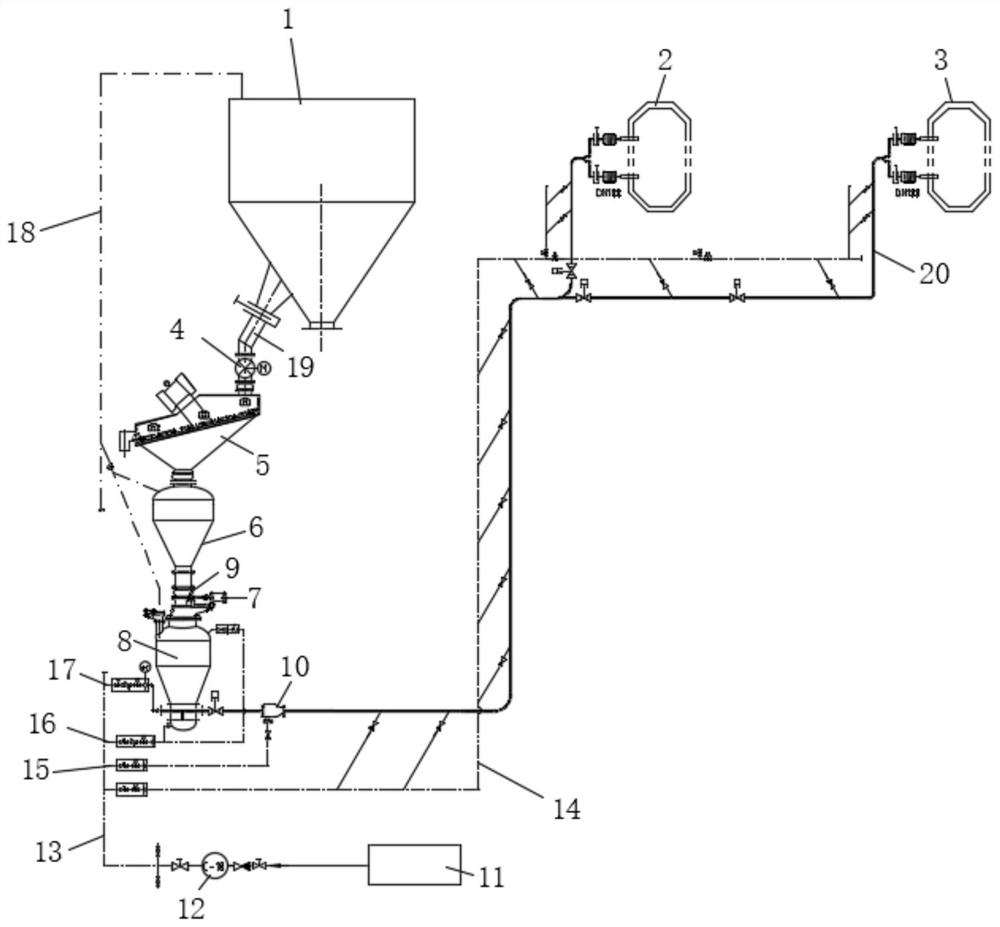

Powder supplying system

ActiveCN105668239AControl air powder mixing degreeContinuous and stable fluidizationBulk conveyorsSewagePressure reduction

The invention relates to a powder supplying system. The powder supplying system comprises a fluidization system, a buffer bin and a mixing chamber; the fluidization system comprises two or more stages of fluidization combination devices and an air storage tank; the two or more stages of fluidization combination devices are longitudinally and fixedly arranged on the outer wall of the buffer bin at intervals, and each stage of fluidization combination device is connected with an air outlet of the air storage tank sequentially through a flow meter and a flow adjusting valve; an air inlet of the air storage tank is connected with external compressed air through a pressure reduction valve and a drain outlet of the air storage tank is connected with an external sewage storage device through a sewage draining valve; and a discharging opening of the buffer bin is connected with the mixing chamber. It can be ensured that power continuously and stably enters an external conveying pipeline.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

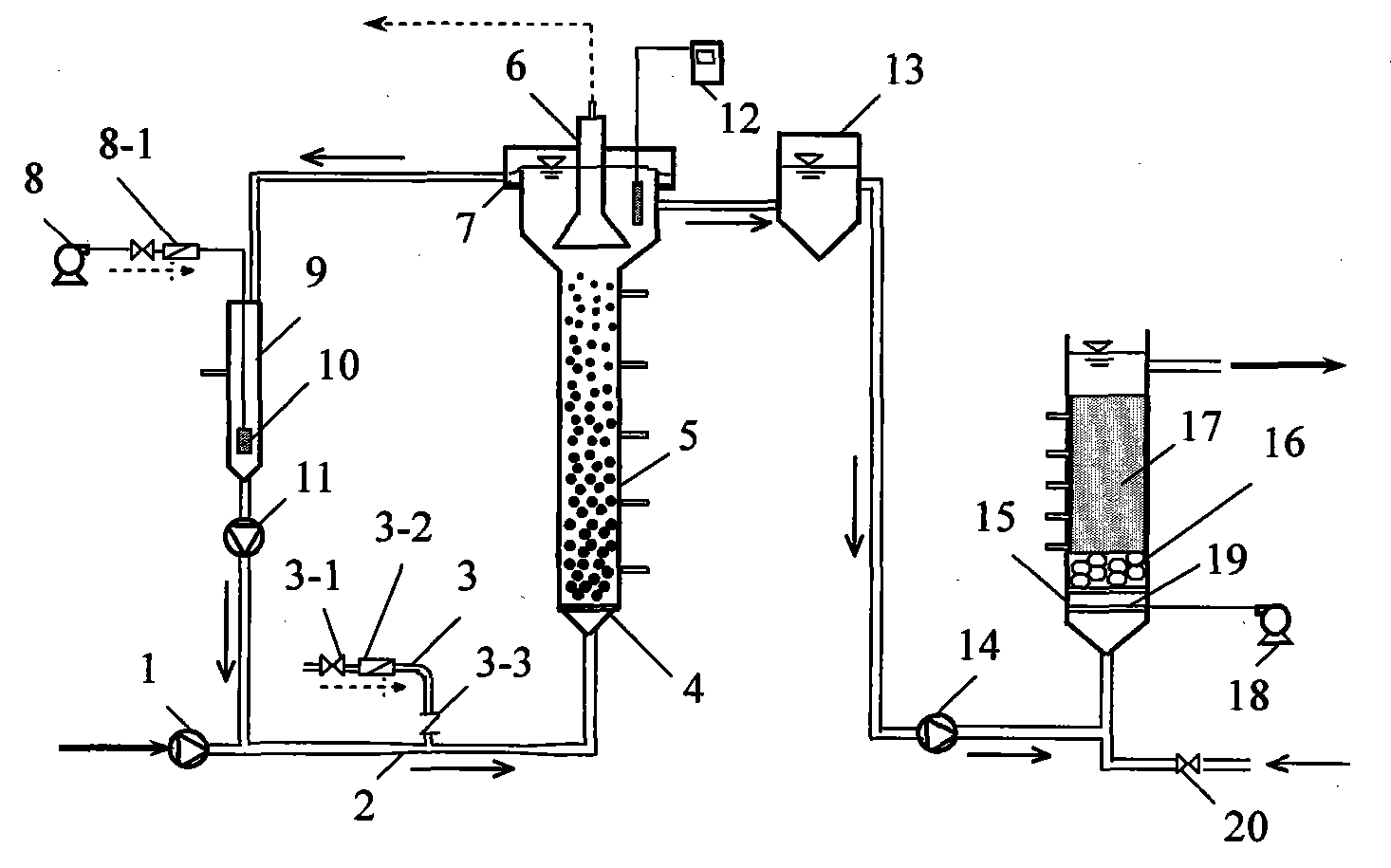

Sewage treating system for micro-aerobic expanded granular sludge bed-steel slag biological filter pond

InactiveCN103058459AReduce aeration energy consumptionFully inflatedTreatment using aerobic processesTreatment with aerobic and anaerobic processesActivated sludgeChemical oxygen demand

The invention discloses a sewage treating system with a compact structure and low operation cost for a micro-aerobic expanded granular sludge bed-steel slag biological filter pond. According to the sewage treatment system, the problems of great occupied area, high aeration energy consumption and high yield of residual sludge in an aerobic activated sludge method are solved. The sewage treating system is formed by combining a micro-aerobic expanded granular sludge bed reactor and a steel slag biological filter pond in series, wherein the micro-aerobic expanded granular sludge bed reactor adopts an oxygenating mode combining jet flow air suction with reflow water external aeration. Inflowing sewage enters the micro-aerobic expanded granular sludge bed reactor firstly to remove pollutants such as COD (Chemical Oxygen Demand), ammonia nitrogen and total nitrogen and then enters a biological aerated filter pond taking steel slag as filler to remove total phosphorus and further improve the quality of effluent. According to the sewage treating system, small area is occupied, energy consumption is saved and the yield of sludge is low; and the sewage treating system is suitable for treating municipal sewage.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Biochemical treatment method for pharmaceutical wastewater on basis of MBBR process

PendingCN108191062APromote growthEasy to hang filmWater contaminantsBiological treatment apparatusRefluxSludge

The invention discloses a biochemical treatment method for pharmaceutical wastewater on the basis of an MBBR process and belongs to the field of industrial sewage biochemical treatment. The method involves two parallel group pools which are connected with each other and are identical in structure. Each parallel group pool comprises an MBBR anoxic zone, an MBBR aerobic zone, a sludge aerobic zone and a sludge reflux zone, wherein the MBBR anoxic zones are communicated with the MBBR aerobic zones through rectangular overflow openings in the tops of overflow partition walls, stirrers are arrangedon the inner side walls of the MBBR anoxic zones, and two suspension carrier intercepting screen meshes used for the MBBR process are arranged along the entire cross sections of the MBBR anoxic zones; the MBBR aerobic zones are communicated with the sludge aerobic zones through the intercepting screen meshed arranged along the entire cross sections of the MBBR aerobic zones. One sides of the sludge aerobic zones are provided with overflow and outflow channels; holes are formed in the outer walls of the middles of the two parallel group pools and communicated with the sludge reflux zones. According to the method, deep denitrification treatment can be carried out on the pharmaceutical wastewater with relatively low content of carbon and nitrogen so that the quality of effluent water can reach the standards stably.

Owner:济宁市孚源环保科技有限公司

Anaerobic/anoxic suspension filler

InactiveCN107758856AReasonable designEasy to manufactureWater treatment compoundsTreatment with anaerobic digestion processesNutrients substancesAeration

The invention relates to anaerobic / anoxic suspension filler. The filler is composed of high-density polyethylene, a specific gravity adjusting material and a microbial nutrient substance, wherein theweight ratio of the high-density polyethylene is 95.0-98.0%, the weight ratio of the specific gravity adjusting materials is 1.5-4.9%, and the weight ratio of the microbial nutrient substance is 0.1-0.5%. The suspension filler is reasonable in design and convenient to manufacture, and the specific gravity of the suspension filler can be closer to that of water, so that under the condition that aeration is not used and only is a flow pusher or a stirrer used, more complete fluidization can be achieved, and it is ensured that the filler takes full effect in an anaerobic / anoxic tank.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

Improved blast furnace coal injection tank and injection method

InactiveCN105177201AImprove accuracy and uniformityReduce consumption and equipment damageBlast furnace componentsBlast furnace detailsProcess engineeringFluidized bed

The invention provides an improved blast furnace coal injection tank and an injection method, and belongs to the technical field of blast furnace coal injection. Lower conical part fluidization holes are formed between upper conical part fluidization holes in a coal injection tank body and a fluidized bed, and a pressure-stabilized fluidization hole is formed between the upper conical part fluidization holes and a fluidization plate. The lower portion of a lower coal valve is connected with a nitrogen purging pipe, and a nitrogen purging valve is arranged on the nitrogen purging pipe. An acceleration device is arranged in a metal flexible connector between a coal discharge hand valve and a coal discharge valve. A nitrogen reversely-purging pipe is installed on a coal discharge pipe body between the coal discharge valve and a coal feed valve. A gas filter net is installed on a powder return pipe. Injection achieved through the improved blast furnace coal injection tank includes a diffusing process, a coal loading process, a pressurized fluidization process and an injection pressure-stabilizing control process. By means of the improved blast furnace coal injection tank and the injection method, the problems of insufficient fluidization, uneven coal discharge and an unstable rate of the coal injection tank in the background technology are solved, and the accuracy and the uniformity ratio of coal injection are increased; meanwhile, gas energy consumption and equipment damage are reduced, the blast furnace coal rate is increased indirectly, the coke rate is lowered, the technological process of a coal injection system is improved, and the injection stability is improved.

Owner:HANGANG GRP HANBAO IRON & STEEL

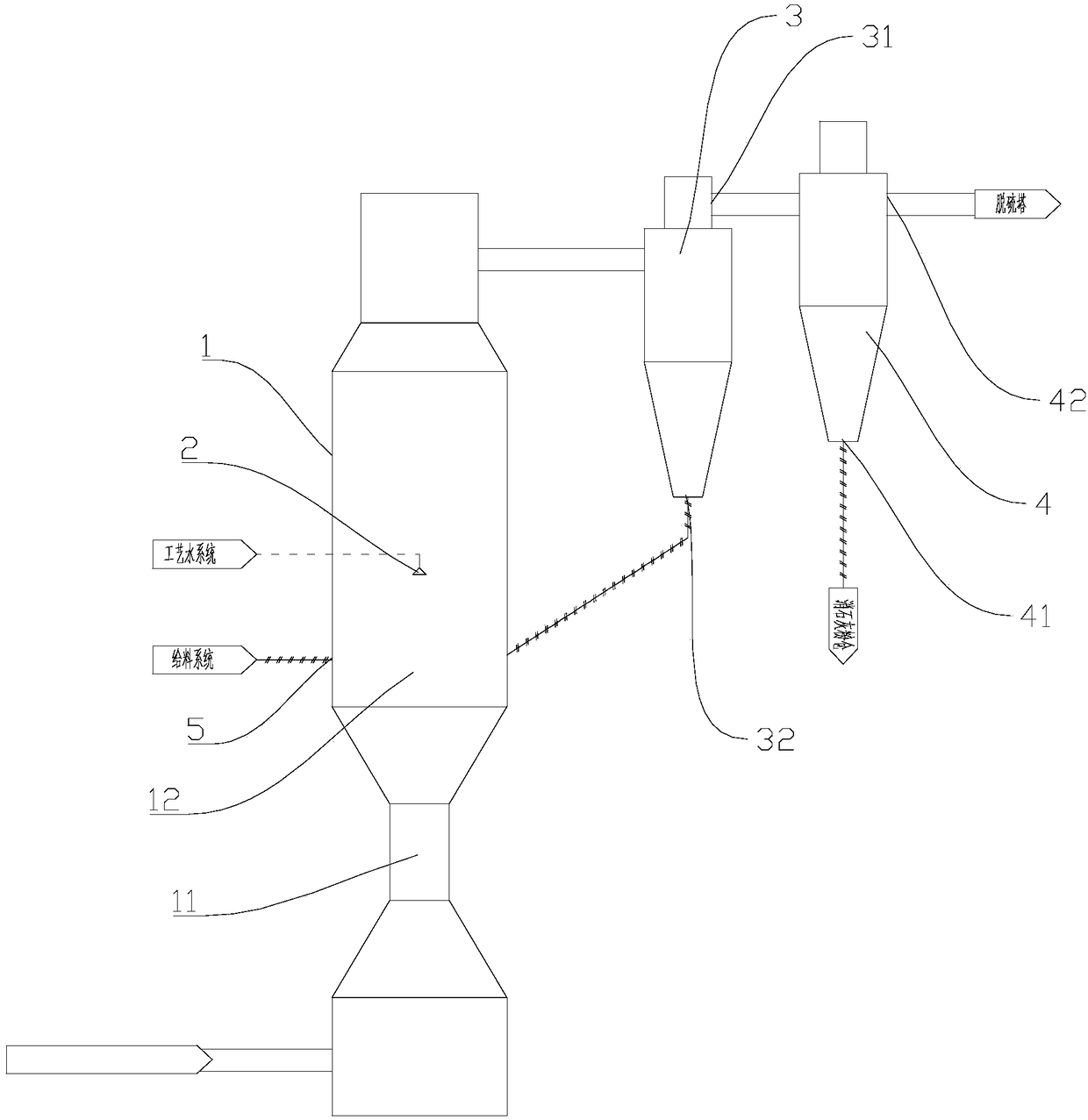

Quicklime circulating fluidized bed grading dry digestion system

The invention discloses a quicklime circulating fluidized bed grading dry digestion system, and relates to the technical field of quicklime dry digestion systems. The system comprises a digestion tower, wherein the digestion tower comprises a venturi; a digestion tower is communicated, at the upper part of the venturi, with a feeding system and is communicated, at the lower part of the venture, with a desulfurizing tower; a fluidized bed area is formed above the venturi; the digestion tower is provided, above a fluidized bed area, with a water feeding device; the digestion tower is communicated, above the water feeding device, with a separation device; the separation device comprises a primary cyclone separator and a secondary cyclone separator; an inlet of the primary cyclone separator iscommunicated with the digestion tower; a lower outlet of the primary cyclone separator is communicated with the fluidized bed area; an upper outlet of the primary cyclone separator is communicated with an inlet of the secondary cyclone separator; the secondary cyclone separator comprises a hydrated lime outlet and a smoke outlet. According to the quicklime circulating fluidized bed grading dry digestion system disclosed by the invention, the digestibility of the quicklime can be improved, a requirement on quality of inlet quicklime is reduced, and smoke can be reused, so that energy is conserved and an influence on an environment is reduced.

Owner:江苏佳鑫环保工程有限公司

Coal slime treatment method

InactiveCN109000221AImprove thermal efficiencyStable oxidation temperatureFluidized bed combustionApparatus for fluidised bed combustionResource utilizationFlue gas

The invention discloses a coal slime treatment method. The treatment method comprises the following steps: enabling coal slime to enter a reactor and be in contact with temperature-regulating medium particles in the reactor, carrying out a reaction under the effect of fluidizing air, performing separating treatment on the reacted flue gas, separating the large-size temperature-regulating medium particles taken out by the flue gas, returning to the reactor, and performing subsequent treatment on ground fine powder of small-particle coal slime and temperature-regulating medium particles in a flyash form along with the flue gas. According to the coal slime treatment method disclosed by the invention, due to use of the temperature-regulating medium particles in the reactor, a stable coal slime temperature is provided, coal slime reduction, innocent treatment and high-efficiency resource utilization can be realized, oxidation burning can be performed by taking pure coal slime as the raw material for recovering the heat, and the coal slime oxidation efficiency and thermal efficiency of the device are high.

Owner:DALIAN EAST REFRIGERATION EQUIP +1

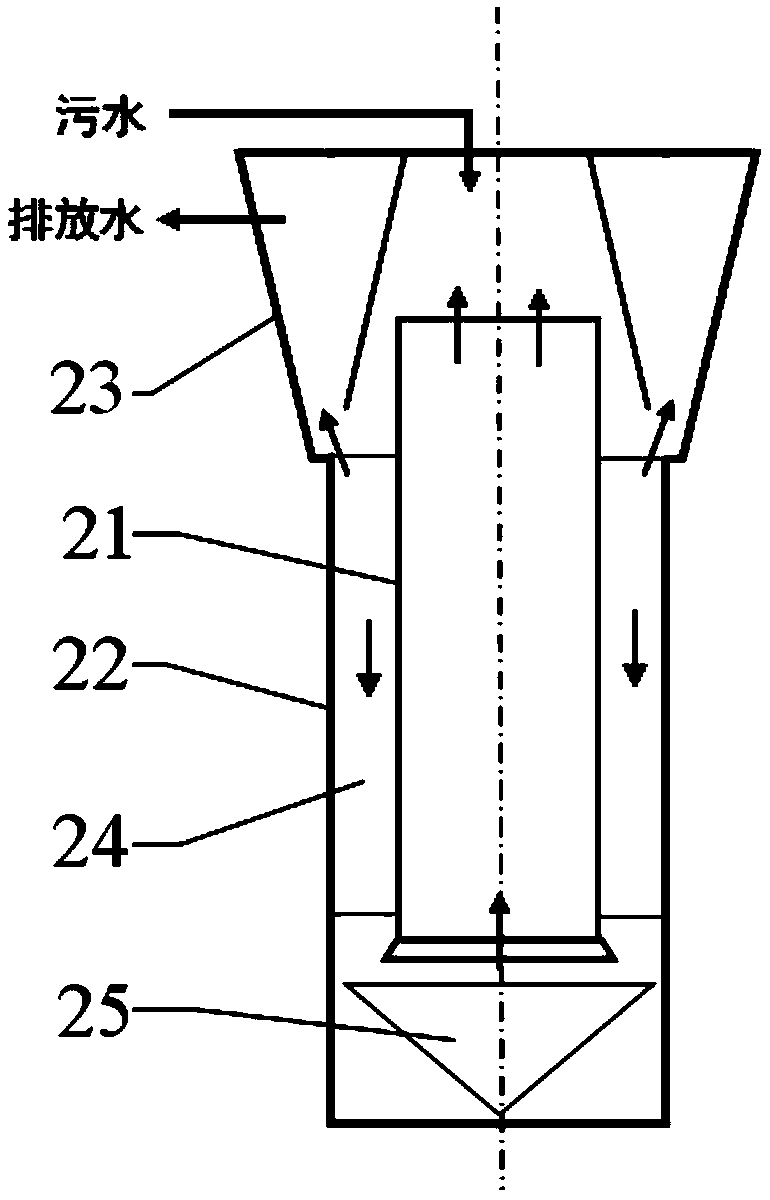

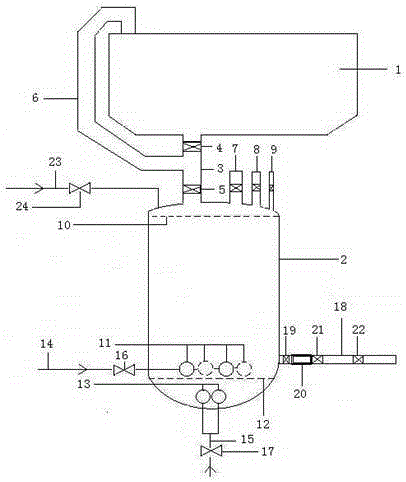

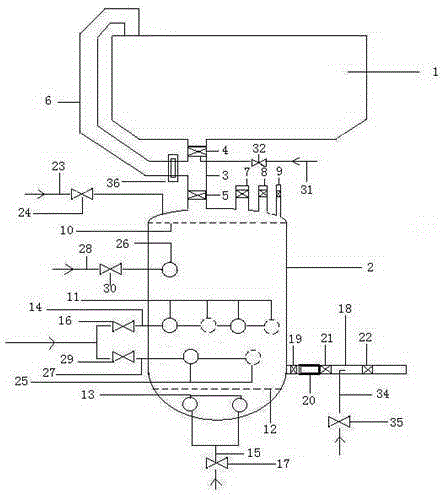

Advanced oxidation reactors as well as toxic and refractory wastewater treatment devices and methods

ActiveCN106082422AImprove processing efficiencyStable fluidizationWater treatment parameter controlWater treatment compoundsFenton reactionTreatment effect

The invention belongs to the field of toxic and refractory wastewater treatment and provides advanced oxidation reactors with two structural forms and toxic and refractory wastewater treatment devices with two structural forms. Each toxic and refractory wastewater treatment device integrates three stages of reactors through coupling. The invention further provides toxic and refractory wastewater treatment methods. According to the methods, persulfate and a micro-grade microelectrolysis material are added to first-stage reactors of the wastewater treatment devices, hydrogen peroxide and persulfate are added to second-stage reactors, the micro-grade microelectrolysis material is added to second-stage reactors, and then a Fenton-like reaction, a Fenton reaction and an activated persulfate oxidization reaction are effectively coupled in the three stages of reactors; with the adoption of the methods, the wastewater treatment effect can be enhanced and improved, and the wastewater treatment cost can be reduced.

Owner:成都柏溪环境科技有限公司

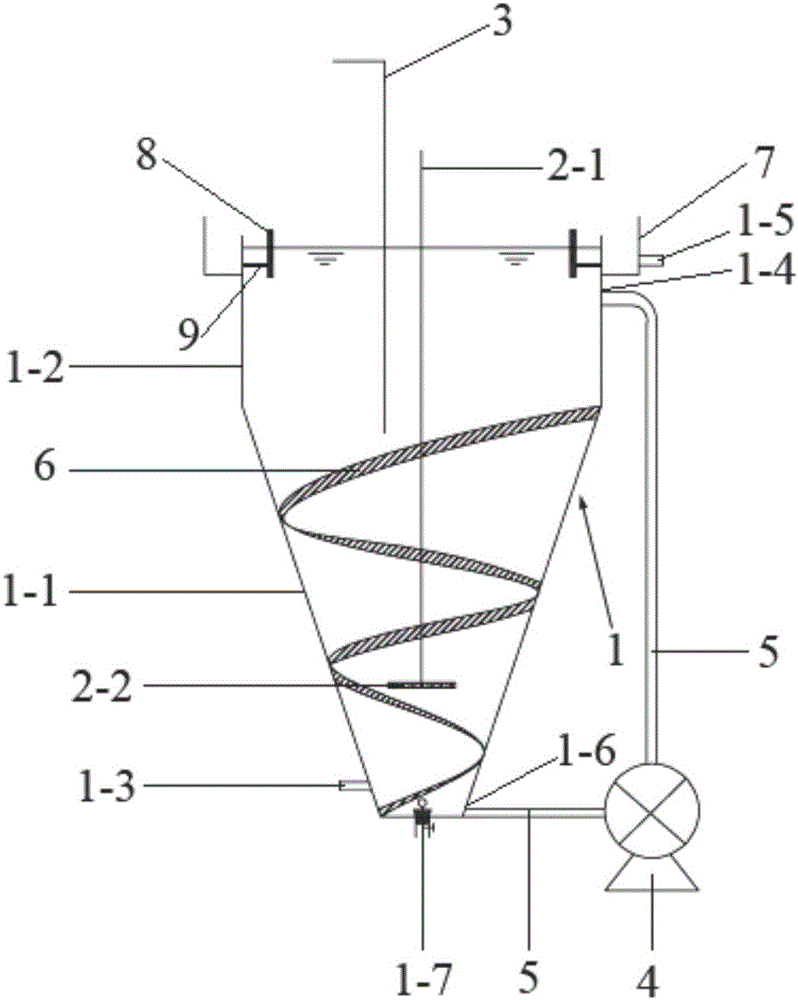

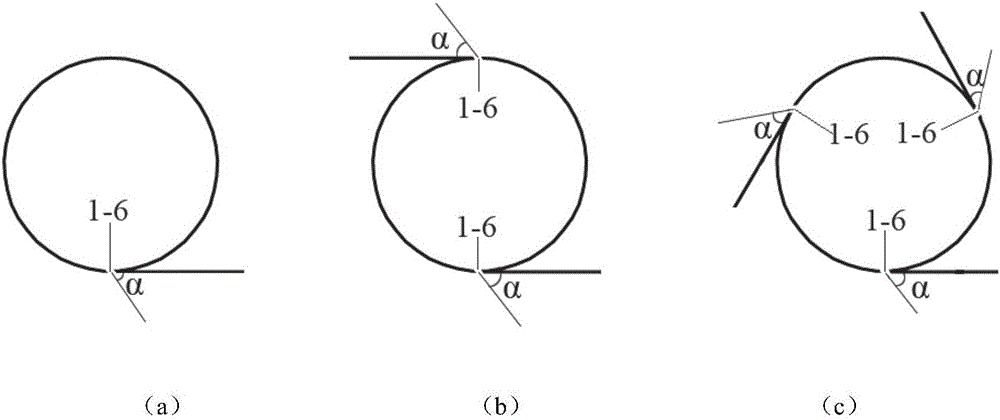

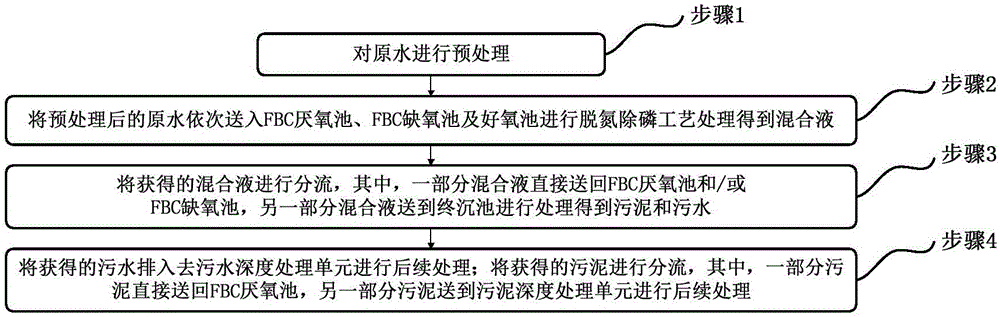

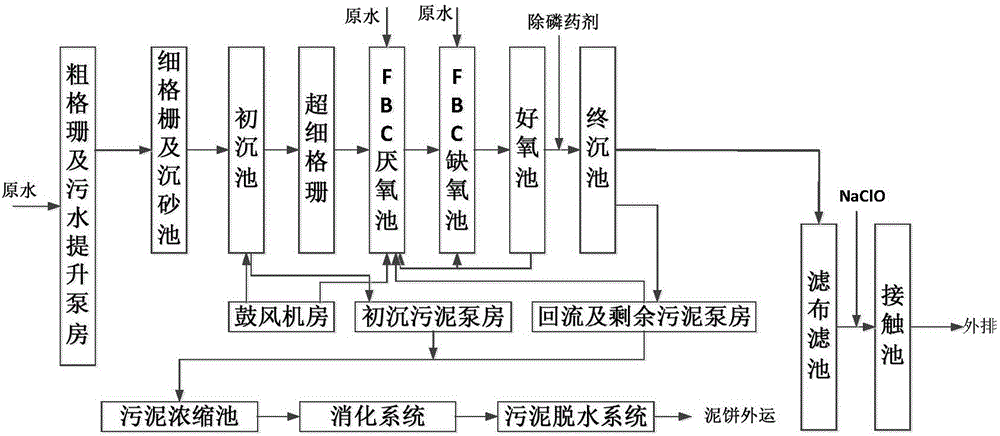

Sewage treatment method and system based on anaerobic-anoxic fluidized biological carrier

PendingCN106630133AFully fluidizedCarbon savingWater treatment parameter controlTreatment using aerobic processesSludgeNitrogen

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment method and system based on an anaerobic-anoxic fluidized biological carrier. The sewage treatment method based on the anaerobic-anoxic fluidized biological carrier comprises the following steps of sequentially sending pretreated raw water into an FBC (fluidized bed combustion) anaerobic tank, an FBC anoxic tank and an aerobic tank, and treating by a nitrogen and phosphorus removal technology, so as to obtain mixed liquid; separating the flows of the obtained mixed liquid, directly sending one part of the mixed liquid back into the FBC anaerobic tank and / or the FBC anoxic tank, and sending the other part of the mixed liquid into a final settling tank to treat, so as to obtain sludge and sewage; draining the obtained sewage into a sewage removal deep treatment unit, and performing subsequent treatment; separating the flows of the obtained sludge, directly sending one part of the sludge back into the FBC anaerobic tank, and sending the other part of the sludge into a sludge deep treatment unit to perform subsequent treatment. The sewage treatment method has the advantages that the biological carrier is added into the anaerobic tank and the anoxic tank to perform enhanced nitrogen and phosphorus removal on the raw water, the effect is good, the energy consumption is low, and the running cost is low.

Owner:THUNIP HLDG +1

Integrated toxic degradation-resistant wastewater treatment device and treatment method

ActiveCN111908722AEnsure swirlReduce processing energy consumptionWater treatment compoundsMultistage water/sewage treatmentEnvironmental chemistryOxidation response

The invention discloses an integrated toxic degradation-resistant wastewater treatment device and treatment method. The device comprises an adjusting tank, a first-stage reactor, a second-stage reactor, a third-stage reactor, a coagulative precipitation tank and a biochemical reaction tank which are sequentially connected in series, and further comprises an aeration blower, wherein the first-stagereactor and the third-stage reactor are advanced oxidation reactors, the second-stage reactor is a Fenton reactor, the coagulative precipitation tank comprises 2-4 stages, each stage of coagulative precipitation tank is formed by connecting a coagulative reaction tank, a primary precipitation tank and a secondary precipitation tank in series, and the biochemical reaction tank is formed by connecting an anoxic tank, an aerobic tank, a precipitation tank and a clean water tank in series. According to the wastewater treatment method provided by the invention, a toxic degradation-resistant wastewater treatment device is combined with reasonable process parameters, a Fenton-like reaction and a Fenton reaction are effectively coupled and cooperate with each other, and proper coagulating sedimentation and biochemical reaction processes are matched, so that the wastewater treatment effect can be enhanced, the wastewater treatment efficiency is improved, and the wastewater treatment cost is reduced.

Owner:SICHUAN UNIV

Device and method for carrying out chemical energy storage/release by utilizing carbide slag

The invention discloses a device and a method for carrying out chemical energy storage / release by utilizing carbide slag. The device comprises a circulating fluidized bed reactor, a steam particle separator, a water pump, an electric heater and an atomizing nozzle, wherein an electric heating plate and a heat exchange tube are arranged in the circulating fluidized bed reactor, a gas distribution plate is arranged at the bottom of the circulating fluidized bed reactor, and a fluidization gas inlet of the circulating fluidized bed reactor is formed in the bottom of the circulating fluidized bed reactor; a circulating solid inlet and a feeding hole are respectively formed in the side wall of the bottom of the circulating fluidized bed reactor; the feeding hole is used for conveying carbide slag powder; an outlet of the water pump is sequentially connected with the atomizing nozzle, the electric heater and the fluidized gas inlet, a gas outlet of the circulating fluidized bed reactor is connected with an inlet of the steam particle separator, and a solid phase outlet of the steam particle separator is connected with a circulating solid inlet of the circulating fluidized bed reactor. The two gaseous substances can be prevented from being adopted in the energy storage / release process, the gas port can be prevented from being blocked, and the technological process is simplified.

Owner:TSINGHUA UNIV

Fluid bed reactor used for gasoline desulfuration

ActiveCN101780389BRestore filter capacityEasy to hang outCombination devicesHydrocarbon oils refiningGasolineProduct gas

The invention provides a fluid bed reactor used for gasoline desulfuration, which belongs to the field of petrochemical industry and is characterized in that an automatic back wash filter, a dust reduction machine, a catalyst bed, a backflow prevention distributor and an impact prevention distributor are arranged in a reactor, and the reactor is externally connected with a reductor and an acceptor. By utilizing the reactor, the filtering performance of the filter can be automatically and efficiently restored in time, thereby reducing the labor strength; catalyst particles are prevented from flowing back below the reactor, thereby enabling gas to be evenly distributed on the section of the whole reactor; the dust content of the gas is effectively reduced, thereby greatly reducing the load of the automatic back wash filter, effectively prolonging the operating period of the automatic back wash filter and reducing equipment investments and maintenance charges; the influent gas is prevented from impacting the backflow prevention distributor, thereby promoting the even distribution of the gas and improving the benefit of the reactor; and moreover, reaction gas and a catalyst flow out of different paths after entering the reactor through different paths, thereby realizing high-treatment capacity continuous operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed reactor gases distributing plate

InactiveCN1207088CIncreased jet velocityEnhanced anti-deposition abilityChemical/physical processesFluidized bedEngineering

The invention discloses a gas distribution plate of a fluidized bed reactor. It has a gas distribution plate, with air inlet holes on the gas distribution plate, and a hood is welded on each air inlet hole of the gas distribution plate, and two or more circular and square injection holes are opened on the hood. Or a long jet slit, its size parameter is: the equivalent diameter D of the jet hole on the hood or the long jet slit i and distribution plate inlet hole diameter D 0 Ratio D i / D 0 =0.2~0.6, the angle β=0°~75° between the injection direction and the horizontal line, a circular, square or conical leak-proof weir is arranged at the inside of the wind cap and the upper end of the air inlet hole. Advantages of the present invention: 1) the The pressure drop on the distribution plate of the invention is transferred to the injection hole, ensuring that large particles are not deposited on the plate, and the anti-sedimentation ability is enhanced; 2) A layer of gas film is formed on the surface of the distribution plate of the fluidized bed, so that the entire bed material is lifted, thereby fully Fluidization; 3) The operation stability of the fluidized bed is increased, and the production cycle of the fluidized bed is improved; 4) The cleaning and modification of the wind cap are convenient, and the flexibility is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

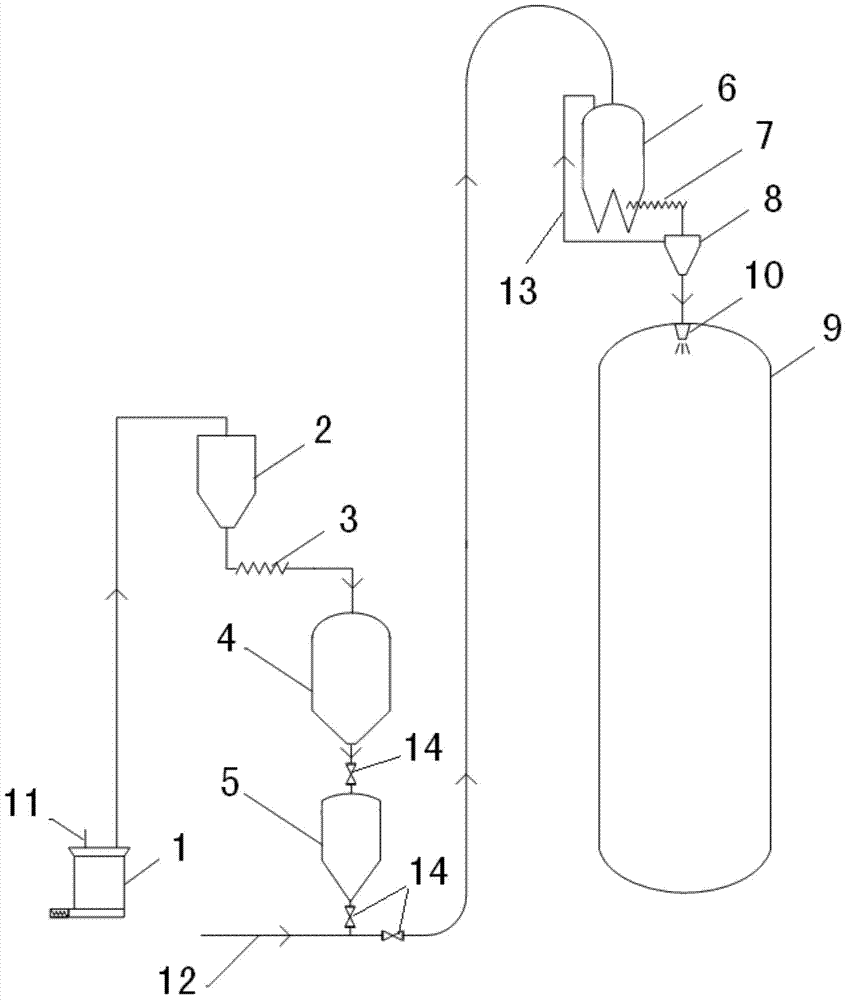

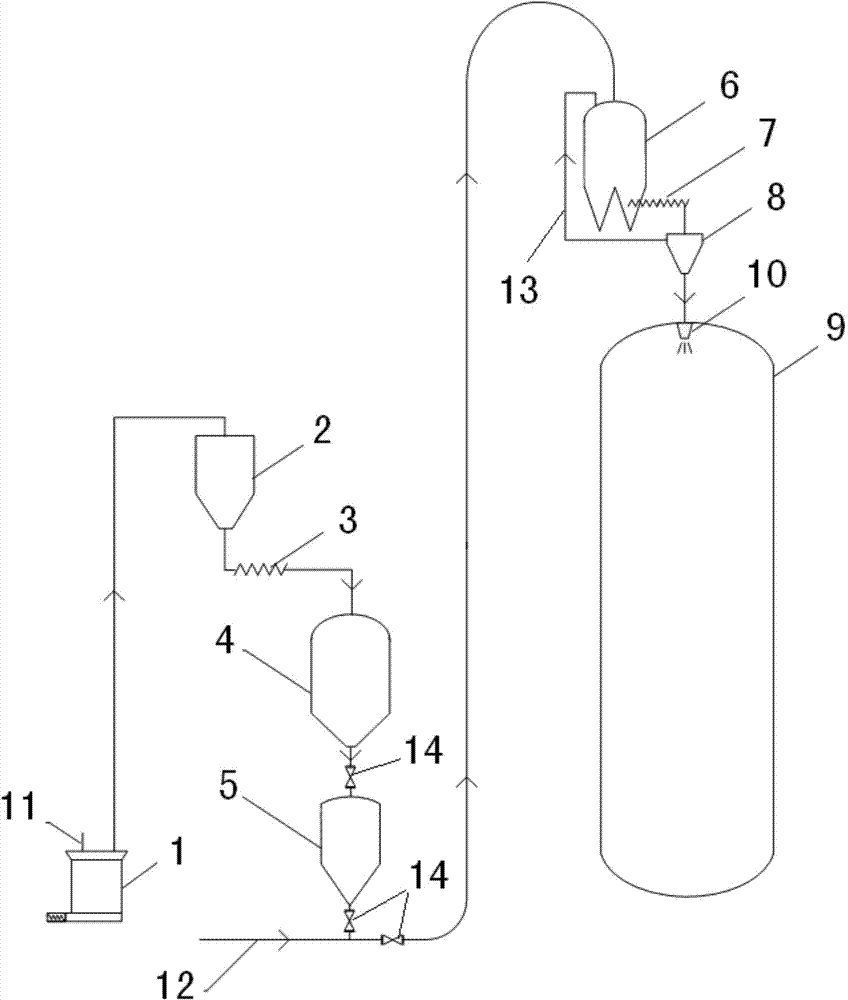

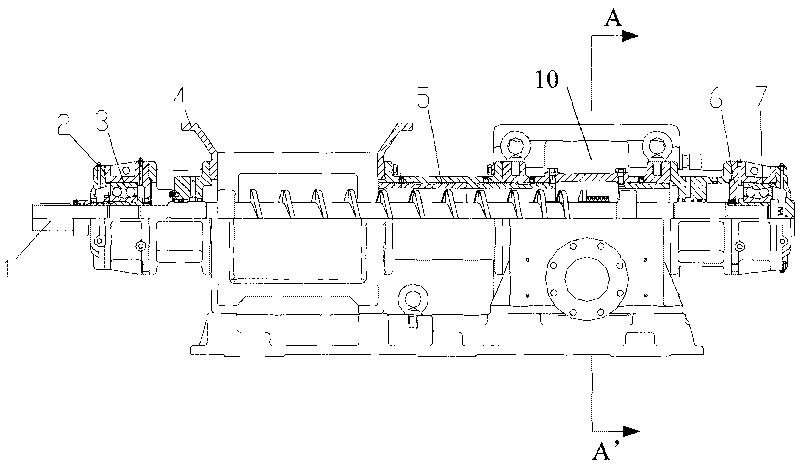

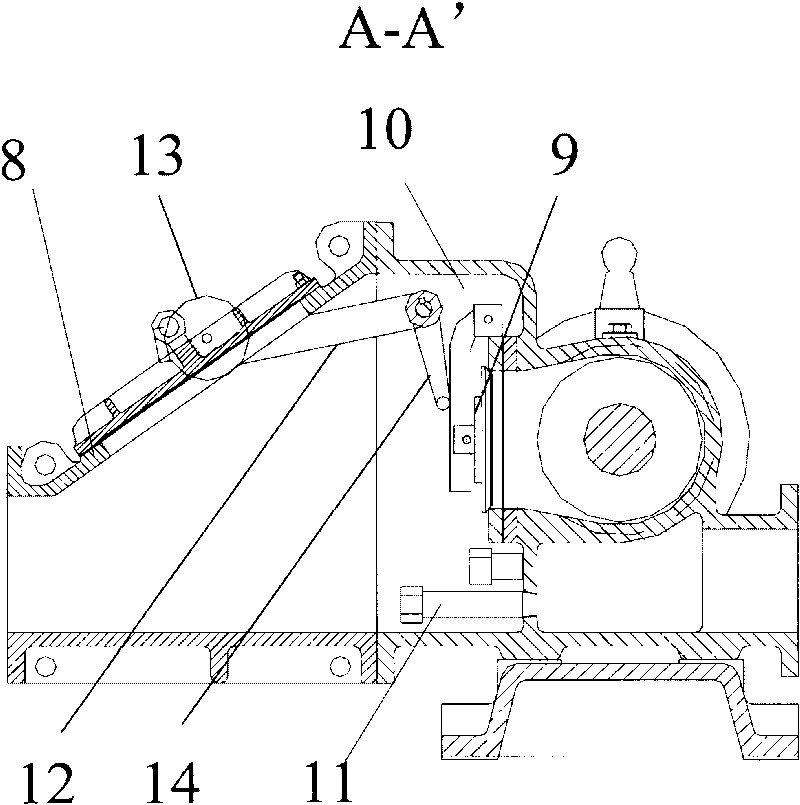

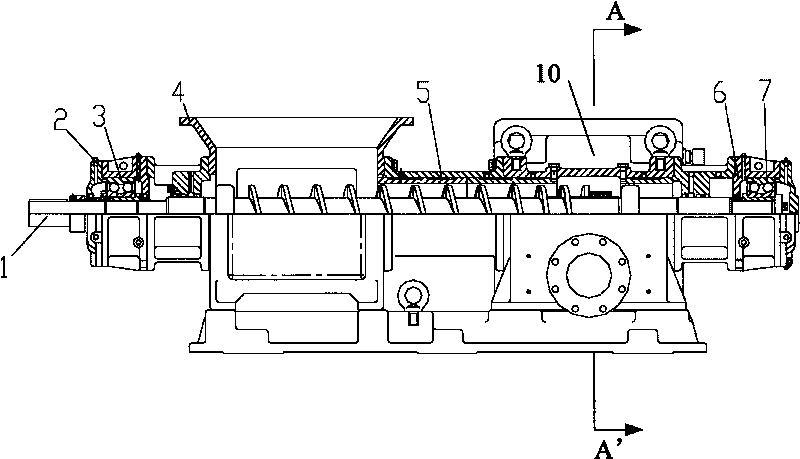

Coal powder conveying device

ActiveCN103789044BStable fluidizationFully fluidizedCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringCoal

The invention relates to a coal powder conveying device which comprises a coal grinder, wherein a raw coal inlet is formed in the coal grinder; an outlet of the coal grinder is connected with an inlet of a coal powder filter; an outlet positioned in the lower side of the coal powder filter is connected with a spiral feeder, a normal pressure cabin and a lock bucket through pipelines in sequence from top to bottom; an outlet pipeline of the lock bucket is communicated with a carrier gas pipeline and is connected with an inlet of a feeding cabin above the coal powder filter through the carrier gas pipeline; an outlet in the bottom of the feeding cabin is connected with a mechanical feeding device below the feeding cabin; an outlet positioned in the lower side of the mechanical feeding device is connected with a gas coning part and a burning nozzle of a gasification furnace through pipelines in sequence from top to bottom, and coal powder is sprayed into the gasification furnace through the burning nozzle; the burning nozzle of the gasification furnace is lower than the feeding cabin, and the lock bucket is arranged below the burning nozzle of the gasification furnace. The coal powder conveying device has the characteristics of stability in coal powder conveying, accuracy in metering, energy conservation, consumption reduction and the like, and is capable of reducing carrier gas entering the furnace.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

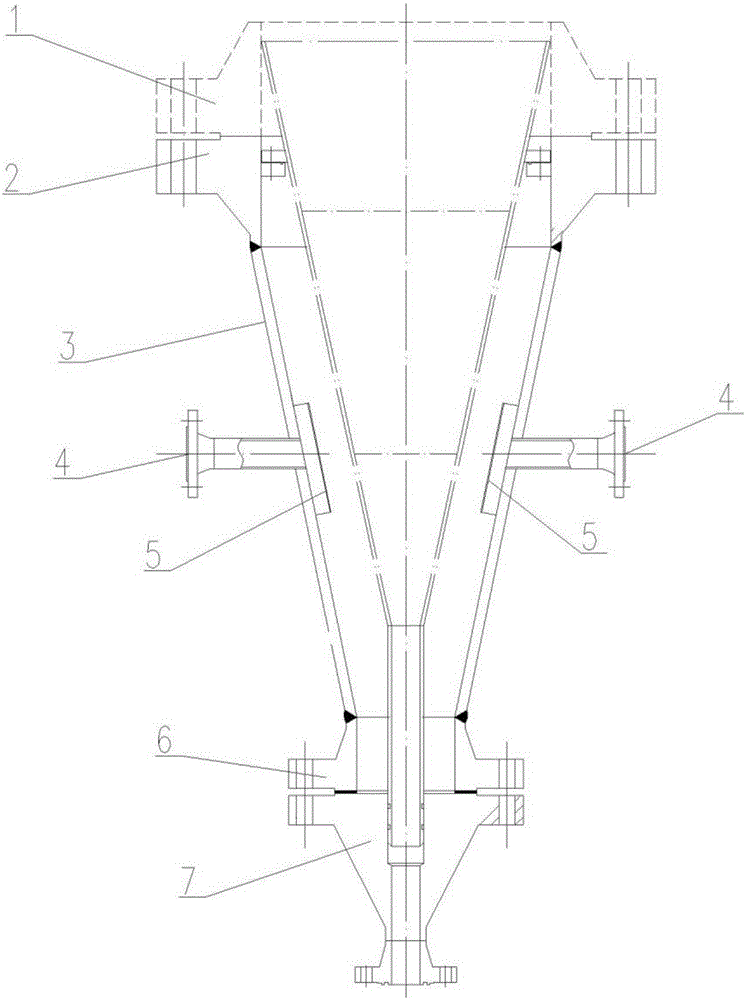

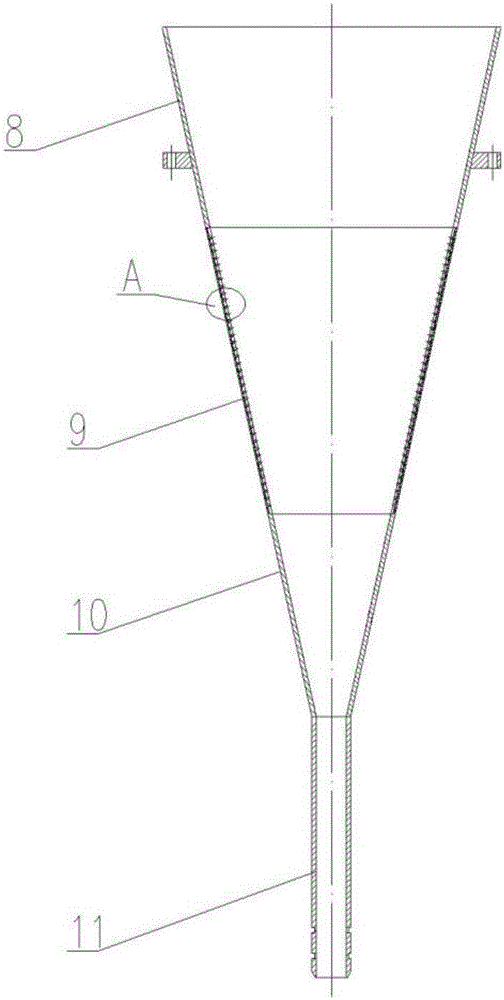

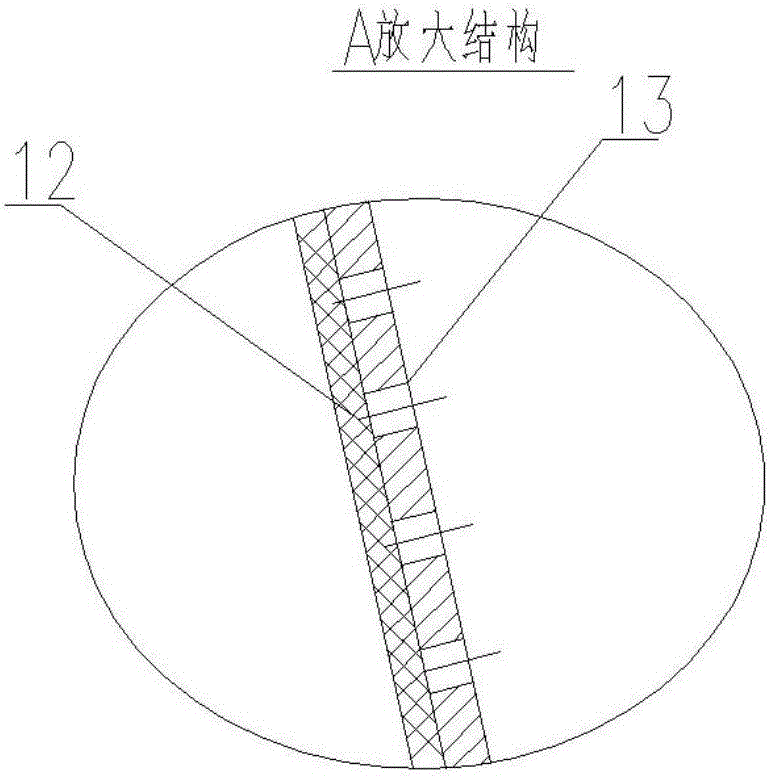

Pulverized coal pressurized fluidization conveying device

The invention discloses a pulverized coal pressurized fluidization conveying device which comprises a taper barrel and a fluidization element installed inside the taper barrel coaxially. The fluidization element is of a taper structure and comprises a fluidization area. A wall at the fluidization area comprises a porous inner reinforcing barrel on the inner layer, and multi-layer composite sintering metal felt fixed to the outer surface of the porous inner reinforcing barrel. A plurality of through holes are distributed in the porous inner reinforcing barrel. The inner layer and the outer layer of the multi-layer composite sintering metal felt are both precision screens. The taper barrel is provided with two inert gas inlets symmetrically, and the inert gas inlets are opposite to the fluidization area of the fluidization element. According to the pulverized coal pressurized fluidization conveying device, online fluidization of pulverized coal is achieved, fluidization is conducted in the conveying process of pulverized coal, fluidizing gas provides pressure for conveying of the pulverized coal at the same time, the structure of a pneumatic conveying system is simplified, and the fluidization effect is improved. Besides, the structure of the fluidization device is modified, and the problems of pipeline blockage and supply interruption of the pulverized coal are solved.

Owner:LUXI CHEM GRP

Coal powder conveying device

ActiveCN103789044AStable fluidizationFully fluidizedCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringEngineering

The invention relates to a coal powder conveying device which comprises a coal grinder, wherein a raw coal inlet is formed in the coal grinder; an outlet of the coal grinder is connected with an inlet of a coal powder filter; an outlet positioned in the lower side of the coal powder filter is connected with a spiral feeder, a normal pressure cabin and a lock bucket through pipelines in sequence from top to bottom; an outlet pipeline of the lock bucket is communicated with a carrier gas pipeline and is connected with an inlet of a feeding cabin above the coal powder filter through the carrier gas pipeline; an outlet in the bottom of the feeding cabin is connected with a mechanical feeding device below the feeding cabin; an outlet positioned in the lower side of the mechanical feeding device is connected with a gas coning part and a burning nozzle of a gasification furnace through pipelines in sequence from top to bottom, and coal powder is sprayed into the gasification furnace through the burning nozzle; the burning nozzle of the gasification furnace is lower than the feeding cabin, and the lock bucket is arranged below the burning nozzle of the gasification furnace. The coal powder conveying device has the characteristics of stability in coal powder conveying, accuracy in metering, energy conservation, consumption reduction and the like, and is capable of reducing carrier gas entering the furnace.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Automatic bed material adding system

PendingCN112747310AReduce washoutFully fluidizedFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringAir compressor

The invention belongs to the technical field of circulating fluidized bed boilers, and particularly relates to an automatic bed material adding system. The automatic bed material adding system comprises a slag bin, a first boiler, a second boiler, a variable-frequency electric feeder, a vibrating screen, a surge bin, a sending device and a conveying pipeline, a discharging pipe is fixed to the bottom of the slag bin, the variable-frequency electric feeder is mounted at the bottom of the discharging pipe, vibrating screen is connected to the bottom of the variable-frequency electric feeder, the surge bin is assembled at bottom of the vibrating screen, the sending device is arranged below the surge bin, a gas inlet pipe is connected to one end of a gas pipeline, a gas storage tank is mounted at the lower end of the gas inlet pipe in a matched mode, an air compressor is connected to one end of the gas storage tank, a gas inlet pipe is connected to the end, away from the air compressor, of the gas storage tank, a first air supplementing pipe is connected between the gas inlet pipe and an ash-air mixer, and a second air supplementing pipe is connected to the gas inlet pipe and the lower end of the conveying pipeline. The pressure difference can be met to the maximum extent, it is ensured that materials enter the pipeline after being fully fluidized, instantaneous pressure relief cannot be formed, and the fluidization effect cannot be reduced.

Owner:JIANGSU JIUSHENG ENVIRONMENTAL PROTECTION EQUIP

Spiral pump for pneumatic transmission

InactiveCN101725538AFully fluidizedAxial flow pumpsNon-positive displacement fluid enginesWear resistantCompressed air

The invention discloses a spiral pump for pneumatic transmission, which comprises a feeding box, a spiral shaft, a wear-resistant sleeve, a nozzle, a mixing box and a discharging box. The feeding box, the wear-resistant sleeve, the mixing box and the discharging box are communicated in order. The spiral shaft penetrates a space formed by the feeding box and the wear-resistant sleeve in order, and two ends of the spiral shaft can rotate around the self-axis through a bearing; and the mixing box is connected with the nozzle. After entering the feeding box, powdery materials pass through the wear-resistant sleeve from the feeding box along a screw of the spiral shaft, finally the powdery materials are brought into the mixing box. After the materials are discharged into the mixing box, compressed air is injected into the mixing box through the nozzle, so that the materials are fully fluidized, and then the fluidized materials are conveyed to a conveying pipeline which is connected with the end part of the mixing box. In the whole conveying process, the spiral shaft can uniformly convey the materials from the feeding box to the mixing box, so that the materials in the mixing box can be fully fluidized, and finally the materials smoothly pass through the conveying pipeline.

Owner:ZHUZHOU SMELTER GRP +1

Method for preparing bacillus amyloliquefaciens Sh1 microcapsule

InactiveCN103623750AFully fluidizedAvoid adsorptionMicroorganism based processesAnimal feeding stuffEmulsionBacillus amyloliquefaciens

The invention discloses a method for preparing a bacillus amyloliquefaciens Sh1 microcapsule. The method comprises following steps: (1) uniformly mixing the bacillus amyloliquefaciens Sh1 solution, emulsion, suspension or pulp with aseptic gelatin solution; and (2) spray drying the mixed product obtained by step (1), and finally preparing microcapsule powder. The method is characterized in that the air flow in a spray drying process of the step (2) is 600-800 L / h.

Owner:SHANGHAI OCEAN UNIV +1

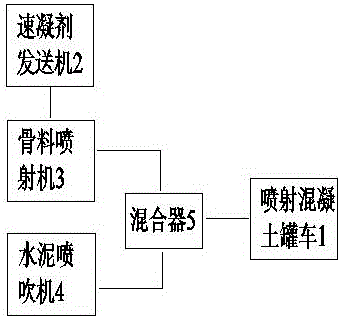

Sprayed concrete material conveying and mixing system

The invention discloses a sprayed concrete material conveying and mixing system and belongs to the technical field of engineering construction mechanical equipment.The sprayed concrete material conveying and mixing system is composed of a sprayed concrete tank car, a n accelerator conveying machine, an aggregate sprayer, a cement spray blower and a mixer.The mixer is composed of an aggregate feed pipe, a cement feed pipe and a discharge pipe.The aggregate feed pipe is communicated with the discharge pipe, and the cement feed pipe is communicated with the aggregate feed pipe.The accelerator conveying machine is connected with the aggregate sprayer, the aggregate sprayer is connected with the aggregate feed pipe of the mixer, the cement spray blower is connected with the cement feed pipe of the mixer, and the discharge pipe of the mixer is connected with the sprayed concrete tank car.The sprayed concrete material conveying and mixing system is reasonable in structural design, labor is reduced, working efficiency is improved, enterprise cost is reduced, and high application and popularization value is achieved.

Owner:山东海纳智能装备科技股份有限公司 +1

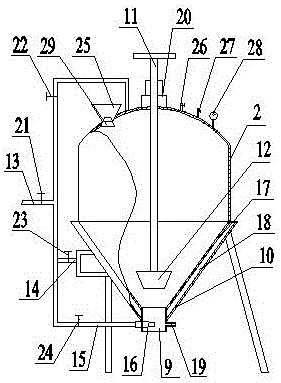

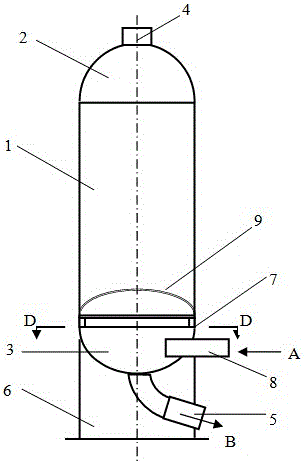

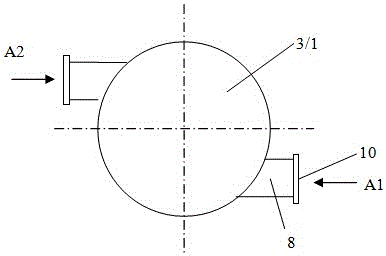

Pressure container and gas inlet thereof

InactiveCN106076204AEasy to installImprove fluidityPressure vessels for chemical processFluidized bedEngineering

The invention provides a gas inlet of a pressure container. The gas inlet is located in a barrel or a shell cover below a distribution plate on the lower portion in a shell of the vertical pressure container, and circumferential openings are formed in the distribution plate. The gas inlet of the pressure container comprises at least two tangential penetration type oblique openings formed in axial symmetry along the shell. The pressure container is provided with at least two gas inlets formed in axial symmetry in shape and position, gas inflow connecting pipes are conveniently installed, the flow state of process gas entering the shell is improved, the flow speed is reduced, pressure is balanced, impact vibration is avoided, then the process gas flows out through the radial openings in the gas flow distribution plate, materials from the upper portion of a reactor to which the pressure container belongs form a balanced fluidized bed, and the capacity large scale is achieved. The invention further discloses the pressure container. Gas flow balance, particle product fluidity and internal structure fatigue resistance can be considered at the same time, the advantages of being high in anti-deposition capacity, stable in production and the like are achieved, the spatial arrangement is safer and more scientific, and the service life of the pressure container can be prolonged.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com