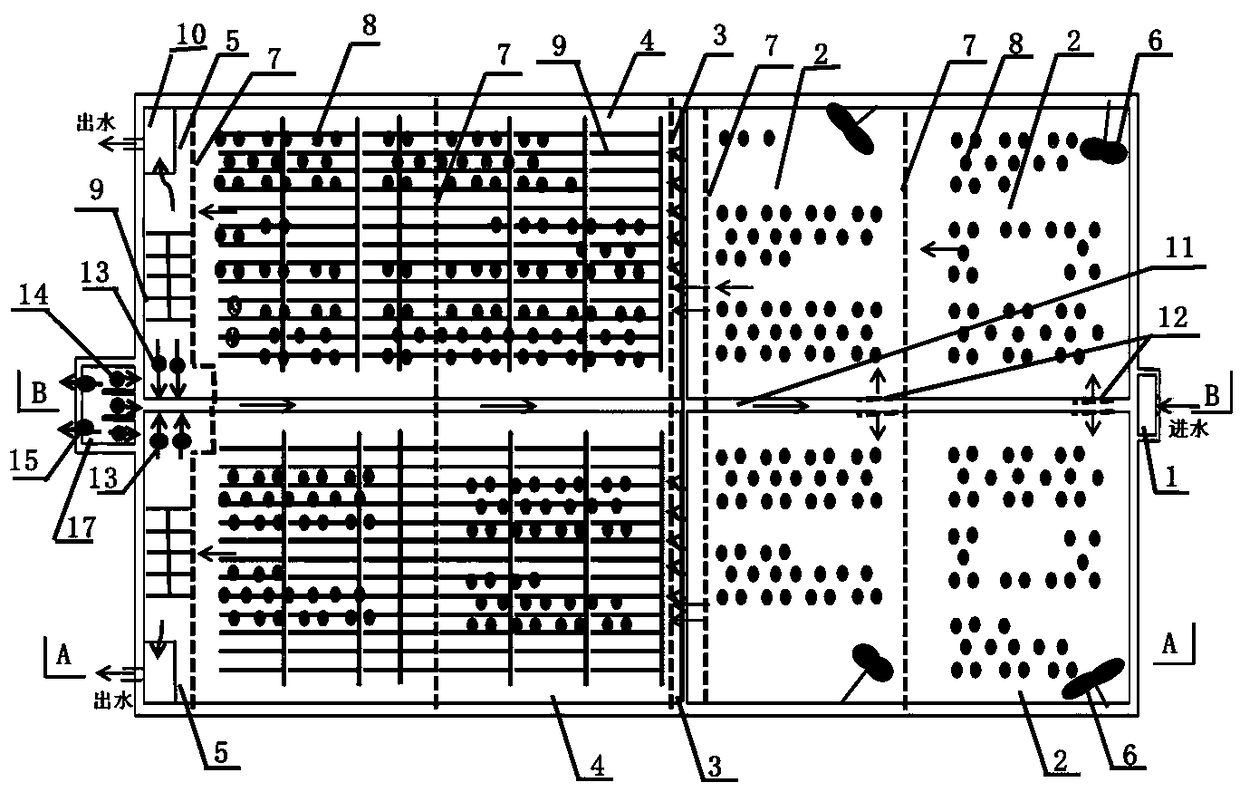

Biochemical treatment method for pharmaceutical wastewater on basis of MBBR process

A pharmaceutical wastewater treatment method technology, applied in aerobic and anaerobic process treatment, multi-stage water treatment, biological treatment equipment, etc., to achieve the effect of ensuring the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

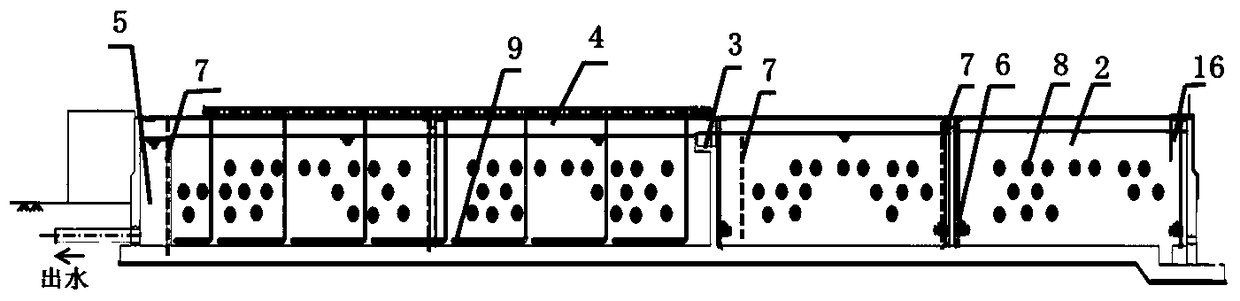

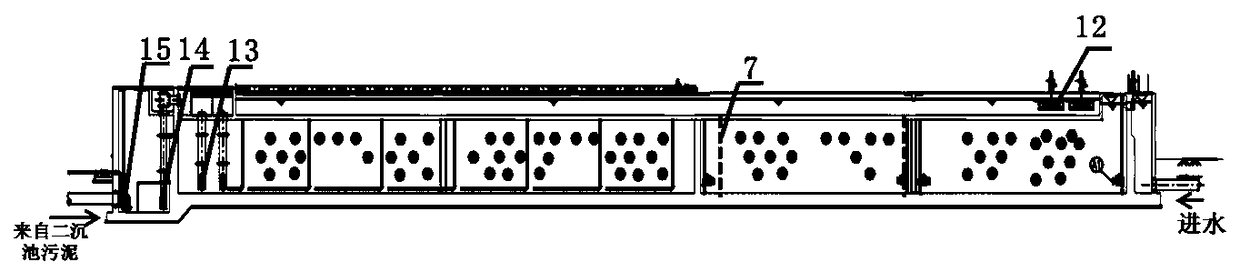

Method used

Image

Examples

Embodiment 1

[0041] The design scale of a pharmaceutical wastewater treatment plant is 25,000 m³ / d. The influent water is mainly biopharmaceutical industrial sewage discharged by Joincare Biological Products Co., Ltd. The influent water quality is as follows: BOD5≤45mg / L, CODcr≤180mg / L, SS≤ 4240 mg / L, NH3-N≤50mg / L, TN≤75mg / L, TP≤43mg / L. The plant adopts the present invention and adds 3000m³ MBBR suspension carrier. The material of the suspension carrier filler is high-density polyethylene (HDPE). It will neither deposit nor float on the water surface; the bulk density of the suspended carrier is 95±2kg / m³; the suspended filler has sufficient strength, wear resistance and long service life, and the service life is guaranteed to be at least 20 years. The intercepting screen used in the factory is perforated steel plate, made of stainless steel AISI304, and the supporting expansion bolts and other accessories for installing the intercepting screen are made of AISI304 stainless steel. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com