Coal powder conveying device

A pulverized coal transportation and pulverized coal technology, which is applied in the direction of granular/powdered fuel gasification and joint combustion mitigation, can solve the problem of large carrier gas into the furnace, and achieve less carrier gas usage, sufficient fluidization, and reduced load The effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

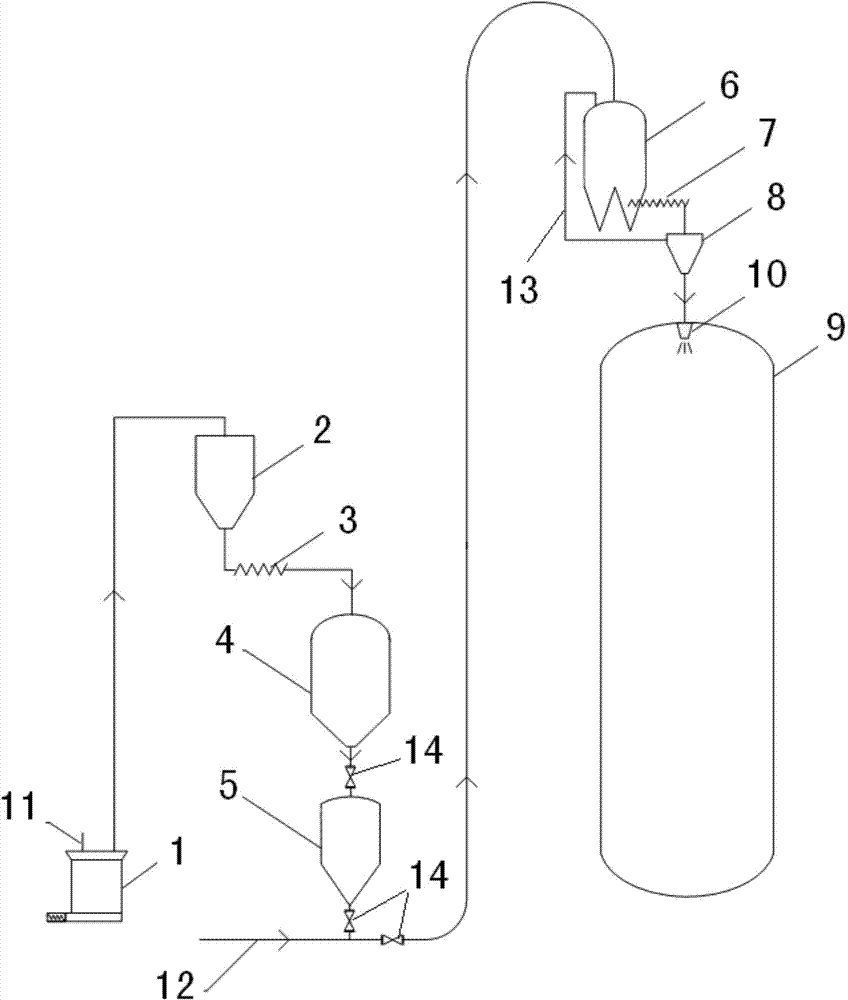

[0014] Such as figure 1 As shown, the present invention provides a pulverized coal conveying device, in which pulverized coal is mainly fed into the gasifier by means of mechanical feeding, supplemented by pneumatic conveying. The present invention comprises a coal mill 1, a pulverized coal filter 2, a screw feeder 3, an atmospheric bin 4, a lock hopper 5, a feeding bin 6, a mechanical feeding device 7, a gas cone 8, a gasification furnace 9 and a gasification The burner 10 in the furnace 9. The coal mill 1 is provided with a raw coal inlet 11, and the outlet of the coal mill 1 is connected to the inlet of the pulverized coal filter 2 through a pipeline. Located below the pulverized coal filter 2, the outlet of the pulverized coal filter 2 is connected with a screw feeder 3, an atmospheric chamber 4 and a lock bucket 5 sequentially through the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com