Powder supplying system

A feeding system and powder technology, applied in the direction of conveying bulk materials, transportation and packaging, conveyors, etc., can solve the problems of uneven powder density, fluctuation of material volume, damage to downstream processes, etc., and achieve simple design structure and low cost Low, convenient powder conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

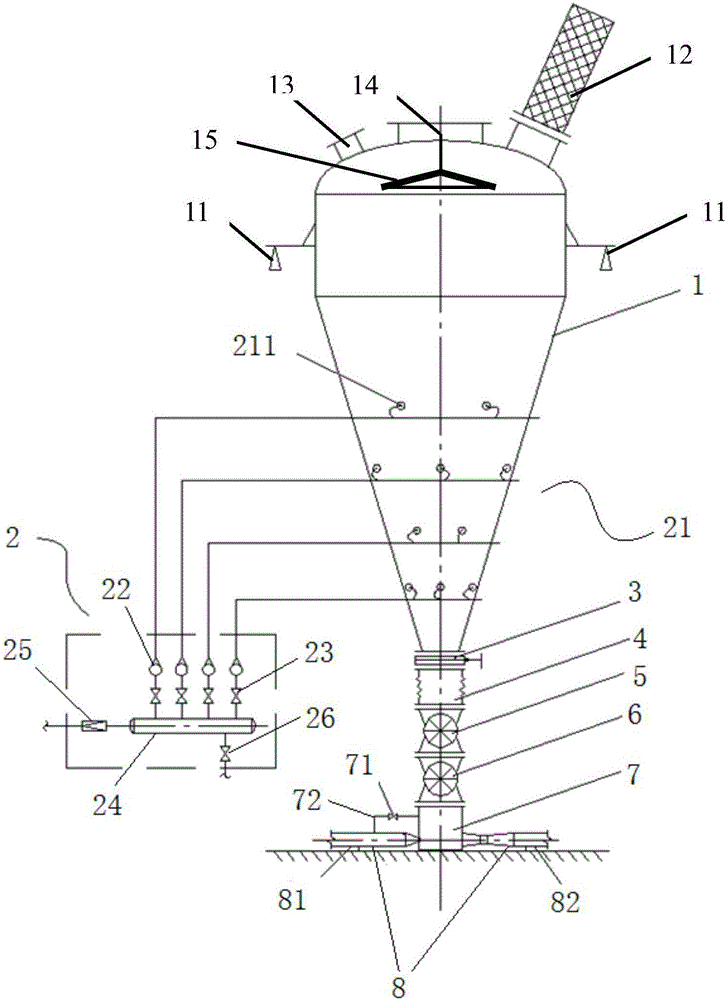

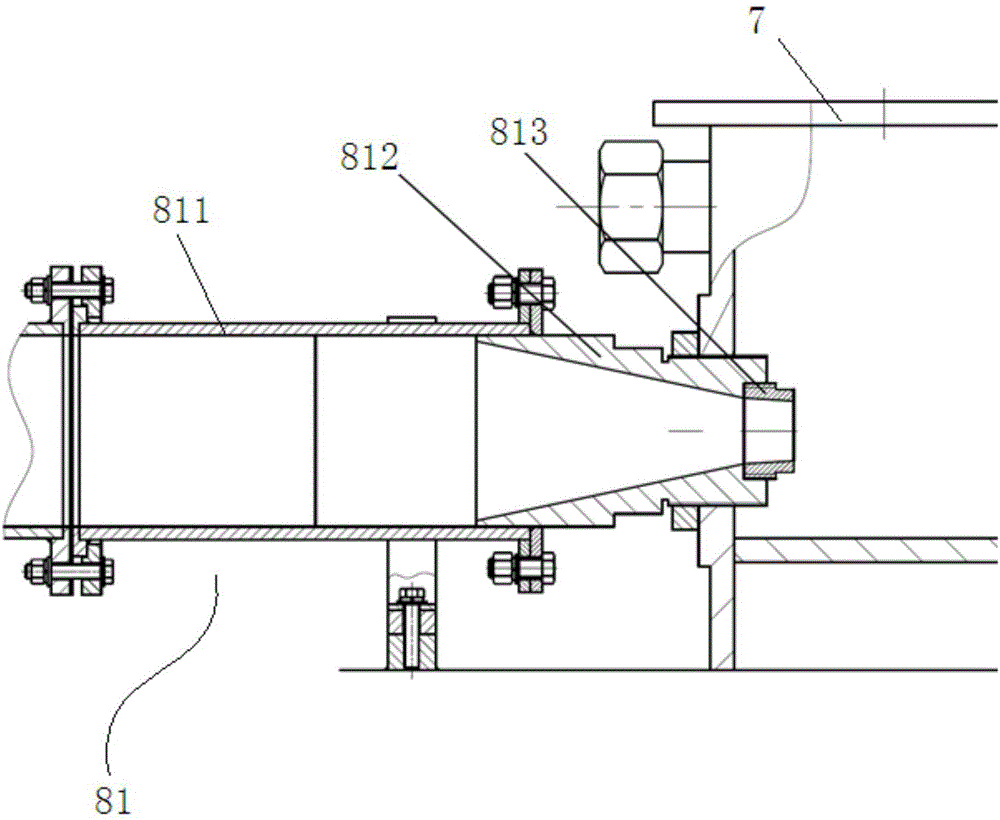

[0016] like figure 1 As shown, the powder feeding system of the present invention includes a buffer bin 1, a fluidization system 2, a plug valve 3, a soft connection 4, a star rotary feed valve 5, and a multi-block star rotary valve 6 , a mixing chamber 7 and a delivery pipeline 8;

[0017] The fluidization system 2 includes more than two stages of fluidization combination devices 21, more than two flowmeters 22, more than two flow regulating valves 23, an air storage tank 24, a pressure reducing valve 25 and a blowdown valve 26; The fluidized combination devices 21 above the stage are fixedly arranged on the outer wall of the buffer bin 1 at longitudinal intervals, and each level of the fluidized combined device 21 is connected to the gas storage tank 24 through a flow meter 22 and a flow regulating valve 23 in sequence, and the gas storage tank 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com