Two-stage fluidization and activation integrated furnace and method for preparing activated carbon by physical method

A technology for the preparation of activated carbon and physical methods, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of inhibiting high-quality activated carbon space, difficult to handle activated tail gas, and low conversion rate of finished products, and achieve stable and uniform quality. Reduce invalid ablation, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

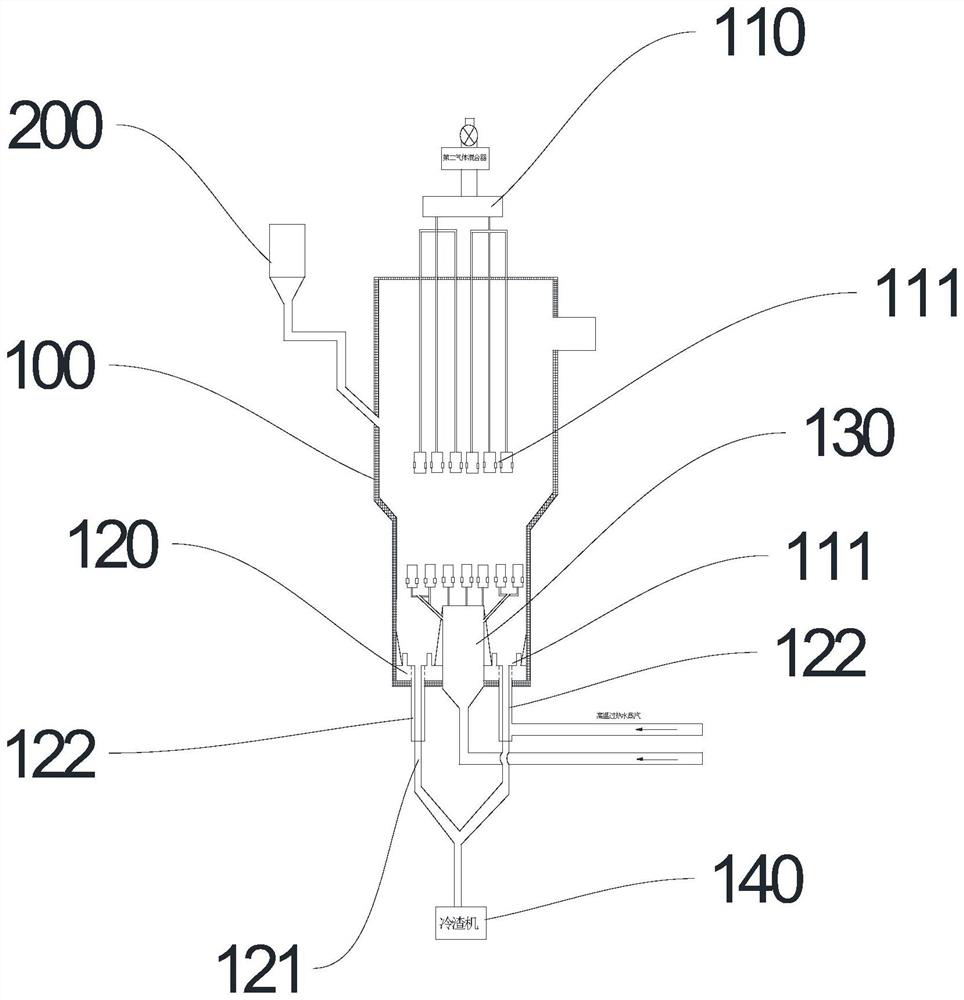

[0045] like figure 1 and figure 2As shown, the present invention provides a two-stage fluidization and activation integrated furnace for preparing activated carbon by a physical method. The integrated furnace includes a furnace body 100, and the furnace body 100 includes an upper fluidized zone, a middle fluidized zone and a lower fluidized zone; the upper fluidized zone An upper air electrode box 110 is arranged in the upper part of the area, and a plurality of air caps 111 are arranged in the upper fluidization area, and the air caps 111 are communicated with the upper air electrode box 110; a mixed gas electrode box 130 is arranged in the middle fluidization area, so that the high temperature air and the high temperature pass through. Hot water and steam are mixed, and a plurality of air caps 111 are arranged on the upper part of the mixed gas electrode box 130; the lower fluidization zone is built with an annular gas electrode box 120, the annular gas electrode box 120 is...

Embodiment 2

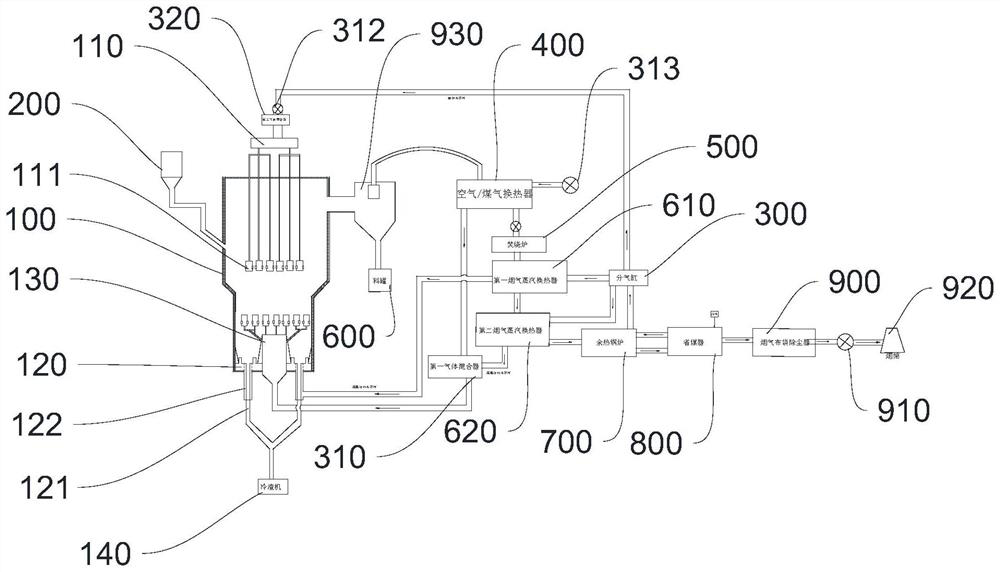

[0053] The present invention also provides a system for preparing activated carbon by physical method, which includes a two-stage fluidized activation integrated furnace, a cyclone separator 930, an air-gas heat exchanger 400, a first flue gas steam heat exchanger 610, a second flue gas steam Heat exchanger 620, sub-cylinder 300, waste heat steam boiler 700, first gas mixer 310 and second gas mixer 320; the gas outlet of the upper fluidization zone of the activation integrated furnace passes through the cyclone separator 930 and the air-gas heat exchanger 400 connection; the air-gas heat exchanger 400 is connected with the first gas mixer 310 and the incinerator 500 respectively; the first flue gas steam heat exchanger 610 is respectively the second flue gas steam heat exchanger 620, the sub-cylinder 300 and the air jacket 122 is connected; the second flue gas steam heat exchanger 620 is respectively connected with the sub-cylinder 300, the waste heat steam boiler 700, and the ...

Embodiment 3

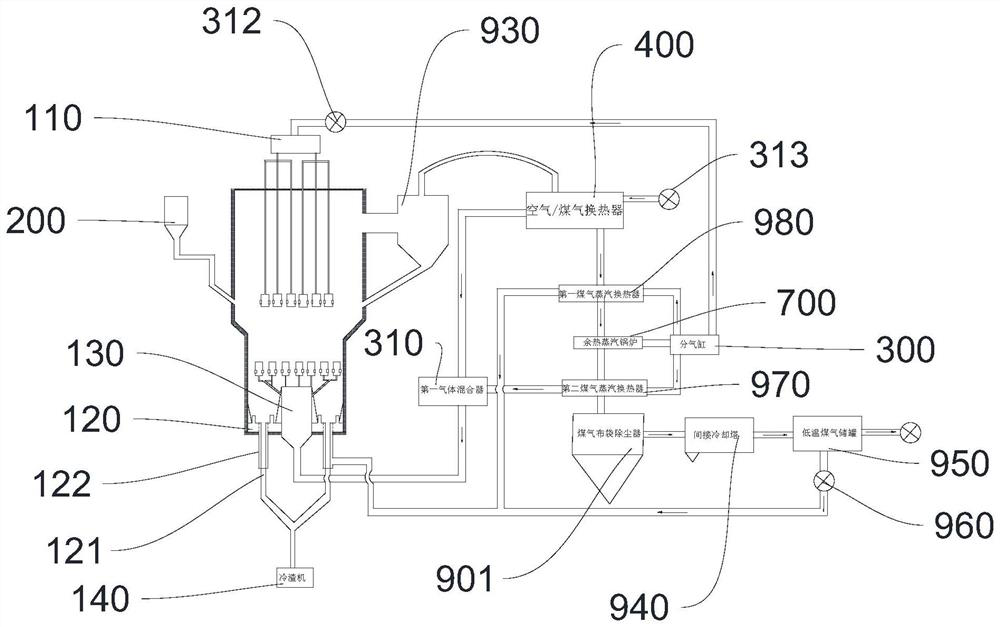

[0058] like image 3 As shown, the present invention also provides a system for preparing activated carbon by a physical method, the system includes a two-stage fluidized activation integrated furnace, a cyclone separator 930, an air-gas heat exchanger 400, a first gas-steam heat exchanger 980, a second Gas steam heat exchanger 970, sub-cylinder 300, waste heat steam boiler 700, first gas mixer 310, gas bag filter 901, gas indirect cooling tower 940, low temperature gas storage tank 950; The gas outlet is connected to the air-gas heat exchanger 400 through the cyclone separator 930; the air-gas heat exchanger 400 is connected to the first gas mixer 310 and the first gas-steam heat exchanger 980 respectively; the first gas-steam heat exchanger 980 They are respectively connected with the waste heat steam boiler 700 , the sub-cylinder 300 and the mixed gas pole box 130 ; the waste heat steam boiler 700 is respectively connected with the second gas-steam heat exchanger 970 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com