Comprehensive utilization method and device for pulverized coal

A pulverized coal, first-class technology, applied in the field of pulverized coal comprehensive utilization methods and devices, can solve problems such as cracking, affecting tar yield, high asphaltene and dusty tar increasing processing difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

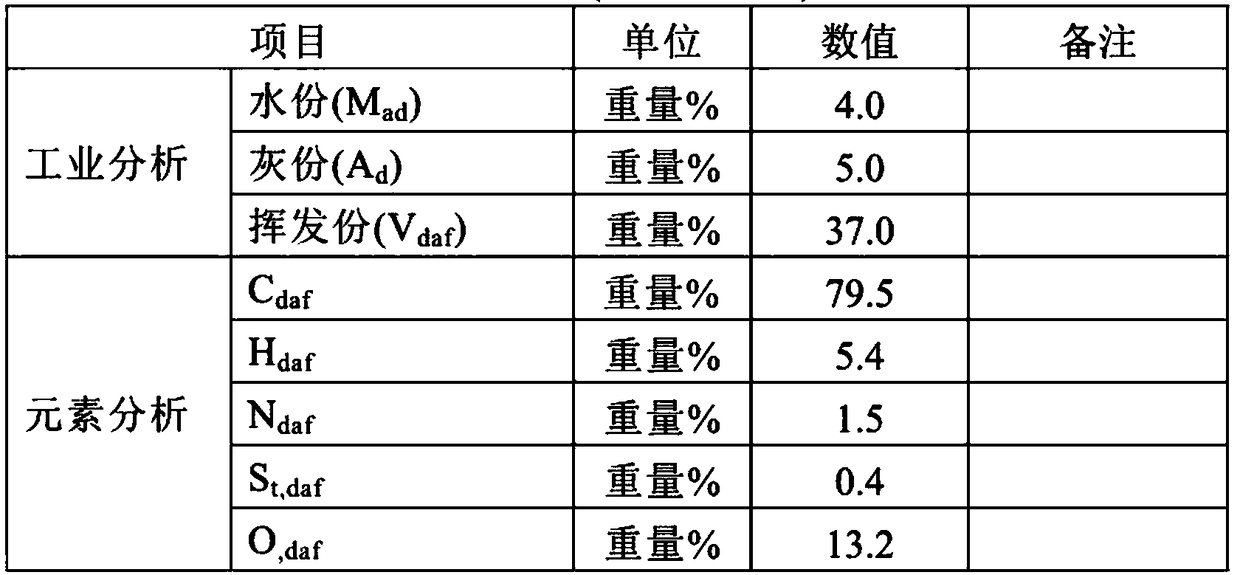

[0109] In this embodiment, the pulverized coal comprehensive utilization device of the present invention is used to process long-flame coal.

[0110] The main properties of the long-flame coal used are shown in Table 1.

[0111] Table 1 Main properties of long-flame coal (raw coal 1)

[0112]

[0113] Raw material pulverized coal particle size range: particle size <5mm, 0.1-1mm range is greater than 70%;

[0114] Experimental method of working condition 1:

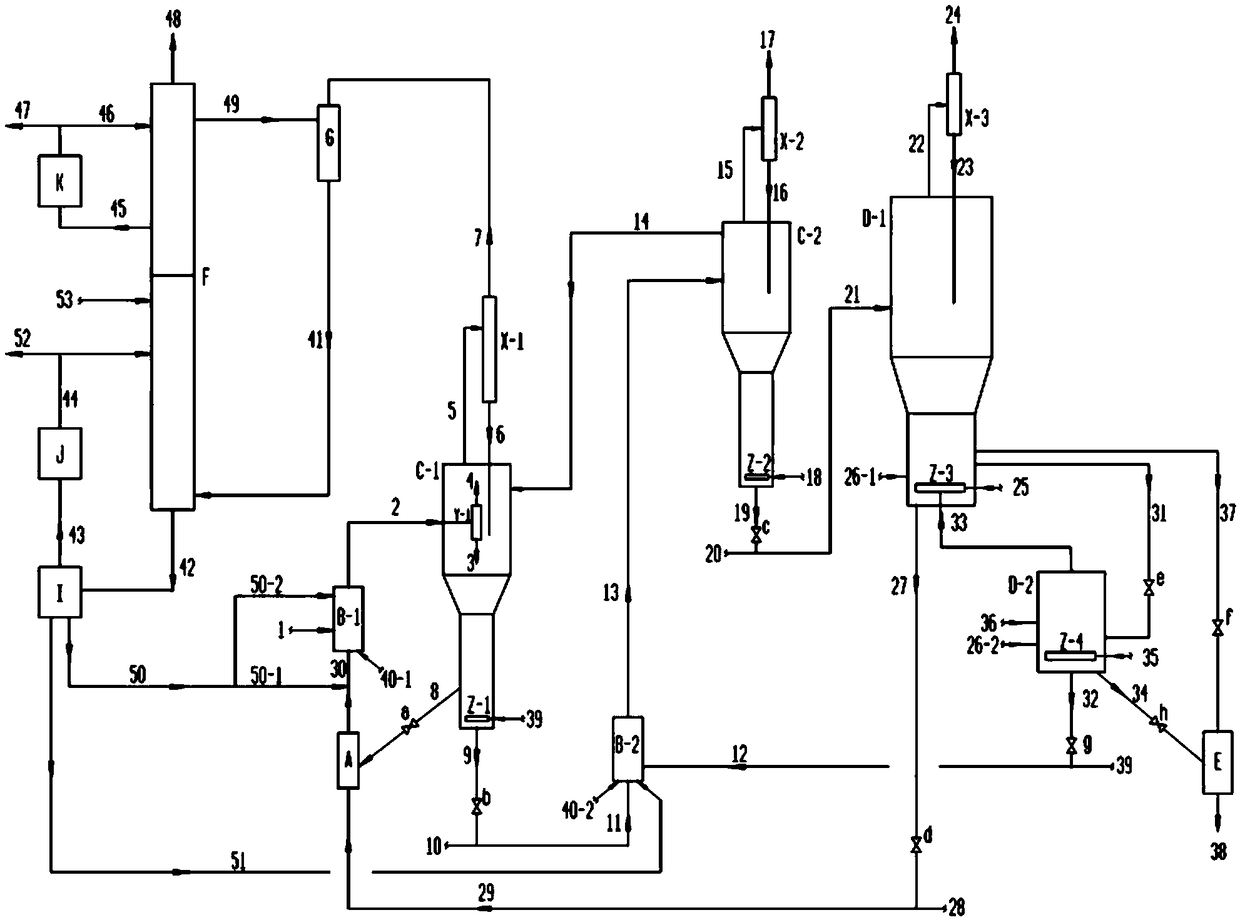

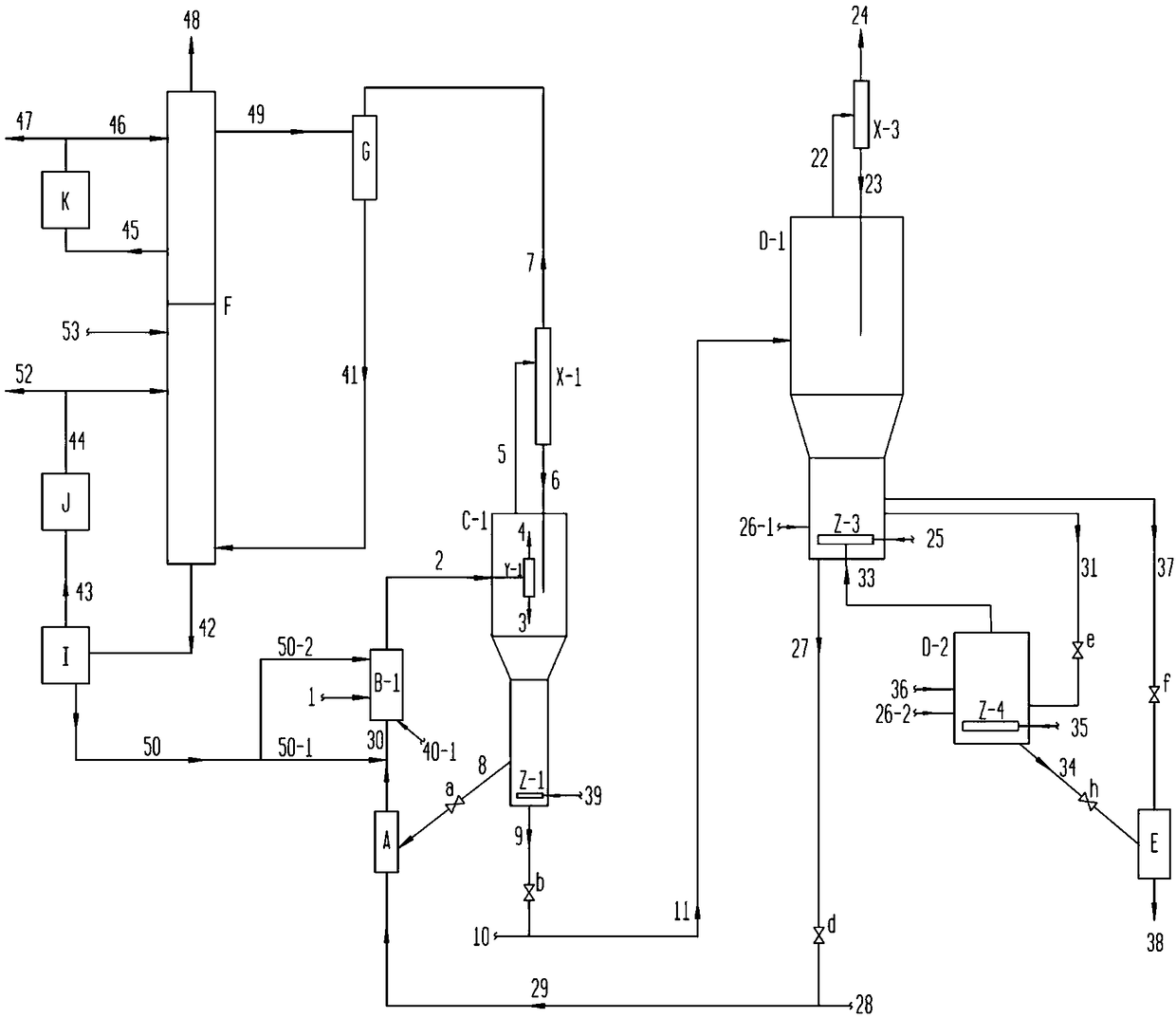

[0115] Such as figure 1 As mentioned above, the primary pyrolysis semi-coke 8 after air stripping from the primary settler C-1 is mixed with the high-temperature heating semi-coke 29 lifted from the primary heater D-1 in the premixer A to obtain High temperature material 30.

[0116] Raw pulverized coal 1 and high-temperature material 30 quickly achieve sufficient back-mixing and mass transfer and heat transfer in the primary pyrolyzer B-1 to obtain primary pyrolysis reaction material 2 .

[0117] The primary pyrol...

Embodiment 2

[0170] This embodiment uses the pulverized coal comprehensive utilization device of the present invention to process lignite.

[0171] The main properties of the lignite used are shown in Table 4.

[0172] Table 4 lignite (feed) main properties

[0173]

[0174] Raw material pulverized coal particle size range: particle size <5mm, 0.1-1mm range is greater than 70%;

[0175] (1) adopt the experimental method of 1 of working condition in embodiment 1, main operation condition is as follows, other with reference to embodiment 1:

[0176] The operating conditions of the primary pyrolyzer B-1 are: the pressure is 0.2-0.4MPa(G), and the temperature is 480-550°C;

[0177] The operating conditions of the primary settler C-1 are: the pressure is 0.2~0.4MPa(G), the temperature is 480~540℃;

[0178] The operating conditions of premixer A are: pressure 0.2-0.4MPa(G), temperature 580-620°C;

[0179] The operating conditions of the secondary pyrolyzer B-2 are: pressure 0.2~0....

Embodiment 3

[0189] The present embodiment is to use the pulverized coal comprehensive utilization device of the present invention to process raw materials comprising lignite 90% by weight+heavy oil 10% by weight.

[0190] The main properties of the lignite used are shown in Table 6.

[0191] Table 6 lignite (feed) main properties

[0192]

[0193] Raw material pulverized coal particle size range: particle size <5mm, 0.1-1mm range is greater than 70%;

[0194] Table 7 The main properties of heavy oil (feed) blended

[0195] project

unit

value

Remark

density

20℃,kg / m 3

1050

carbon residue

%weight

22.5%

Sulfur content

% heavy scene

2.0%

heavy metal content

ppm

200

Colloid + asphaltenes

%weight

45%

Solid content

%weight

0.1%

[0196] (1) adopt the experimental method of 1 of working condition in embodiment 1, main operation condition is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com