Preparation method of ultra-high molecular weight polyacrylamide

A technology of polyacrylamide and ultra-high molecular weight, which is applied in the field of preparation of ultra-high molecular weight polyacrylamide, can solve the problems that the reaction temperature is difficult to control uniformly, and it is difficult to stably obtain polyacrylamide with ultra-high relative molecular mass, and achieves High yield, stable polymerization reaction temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of ultra-high molecular weight polyacrylamide, comprising the following steps:

[0021] 1) Prepare an aqueous solution of acrylamide with a mass fraction of 27% and a temperature of 0°C;

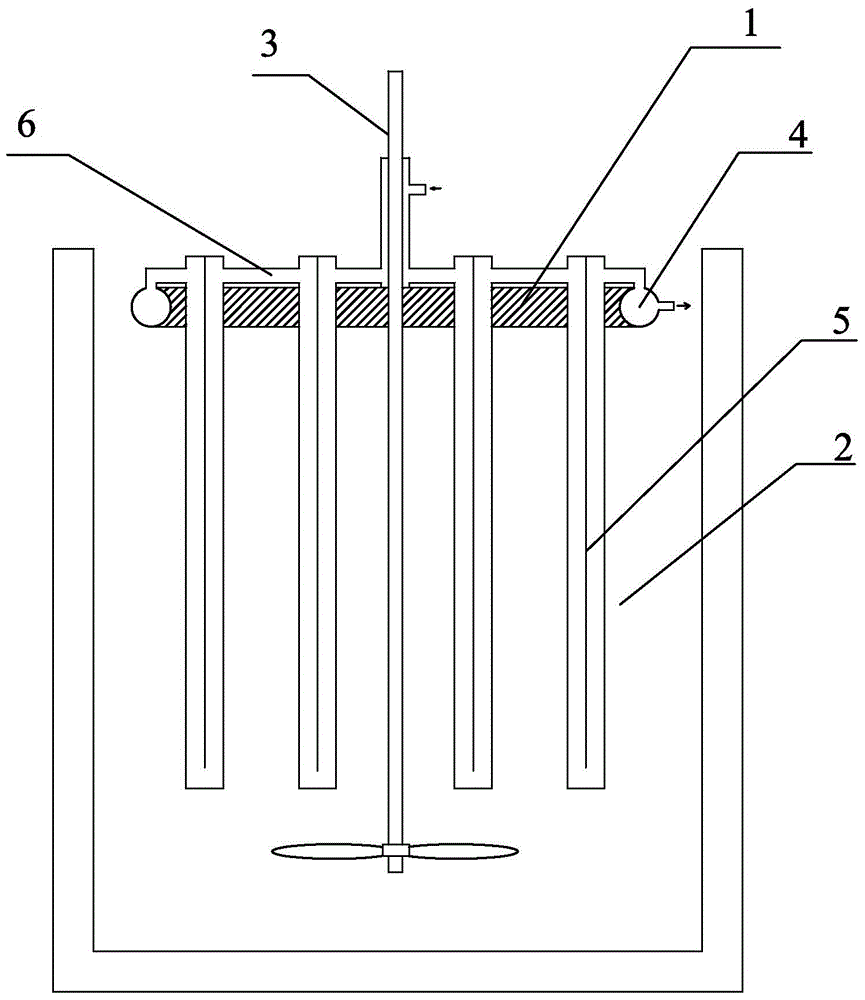

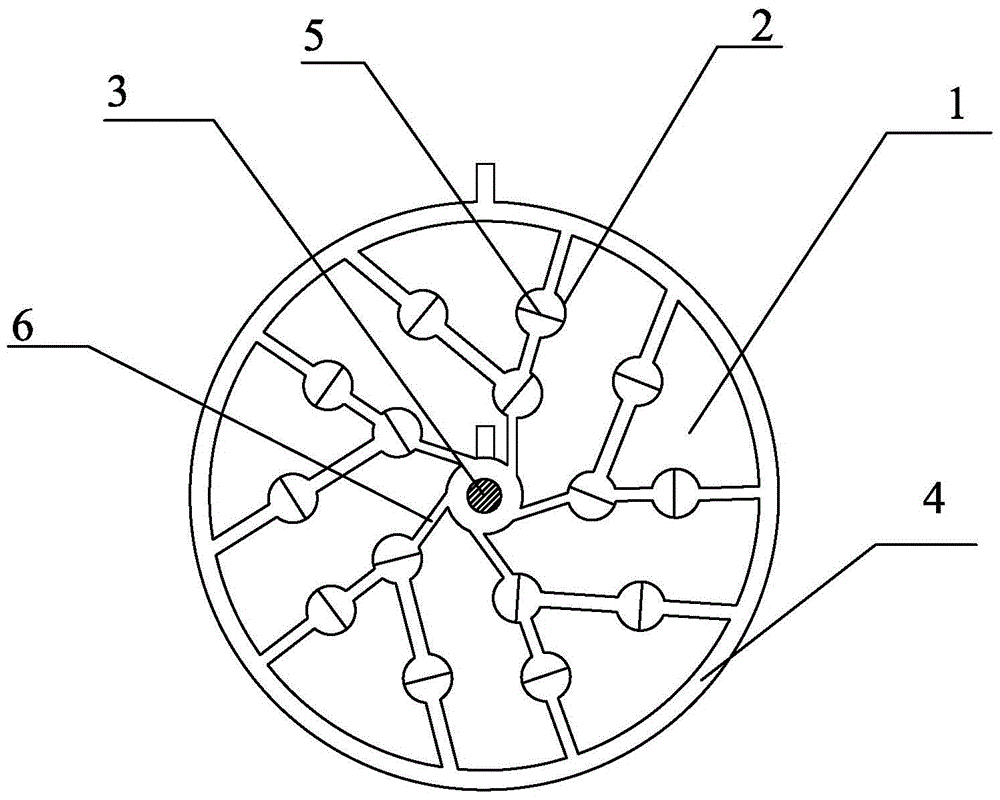

[0022] 2) Add the acrylamide aqueous solution prepared in step 1) into the reactor equipped with an internal heat conduction device, such as Figure 1-2 As shown, the heat conduction device in the liquid includes a circular base plate 1, and the circular base plate 1 is provided with several layers of annular hole arrays concentric with the circular base plate 1; each hole of the annular hole array is provided with a 1 vertical straight water pipe 2; the circular base plate 1 is also provided with an agitator rotating shaft 3 connected to the agitator through the center of the circular base plate 1, and an annular water pipe 4 surrounding the side wall of the circular base plate 1; the straight water pipe 2 is A partition plate 5 is provided to divide the straigh...

Embodiment 2

[0030] A preparation method of ultra-high molecular weight polyacrylamide, comprising the following steps:

[0031] 1) Prepare an aqueous solution of acrylamide with a mass fraction of 28% and a temperature of 2°C;

[0032] 2) Add the acrylamide aqueous solution prepared in step 1 into the reactor equipped with an internal heat conduction device, such as Figure 1-2 As shown, the heat conduction device in the liquid includes a circular base plate 1, and the circular base plate 1 is provided with several layers of annular hole arrays concentric with the circular base plate 1; each hole of the annular hole array is provided with a 1 vertical straight water pipe 2; the circular base plate 1 is also provided with an agitator rotating shaft 3 connected to the agitator through the center of the circular base plate 1, and an annular water pipe 4 surrounding the side wall of the circular base plate 1; the straight water pipe 2 is A partition plate 5 is provided to divide the straight...

Embodiment 3

[0040] A preparation method of ultra-high molecular weight polyacrylamide, comprising the following steps:

[0041] 1) Prepare an aqueous solution of acrylamide with a mass fraction of 27% and a temperature of 3°C;

[0042]2) Add the acrylamide aqueous solution prepared in step 1 into the reactor equipped with an internal heat conduction device, such as Figure 1-2 As shown, the heat conduction device in the liquid includes a circular base plate 1, and the circular base plate 1 is provided with several layers of annular hole arrays concentric with the circular base plate 1; each hole of the annular hole array is provided with a 1 vertical straight water pipe 2; the circular base plate 1 is also provided with an agitator rotating shaft 3 connected to the agitator through the center of the circular base plate 1, and an annular water pipe 4 surrounding the side wall of the circular base plate 1; the straight water pipe 2 is A partition plate 5 is provided to divide the straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com