Patents

Literature

81results about How to "Stable molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

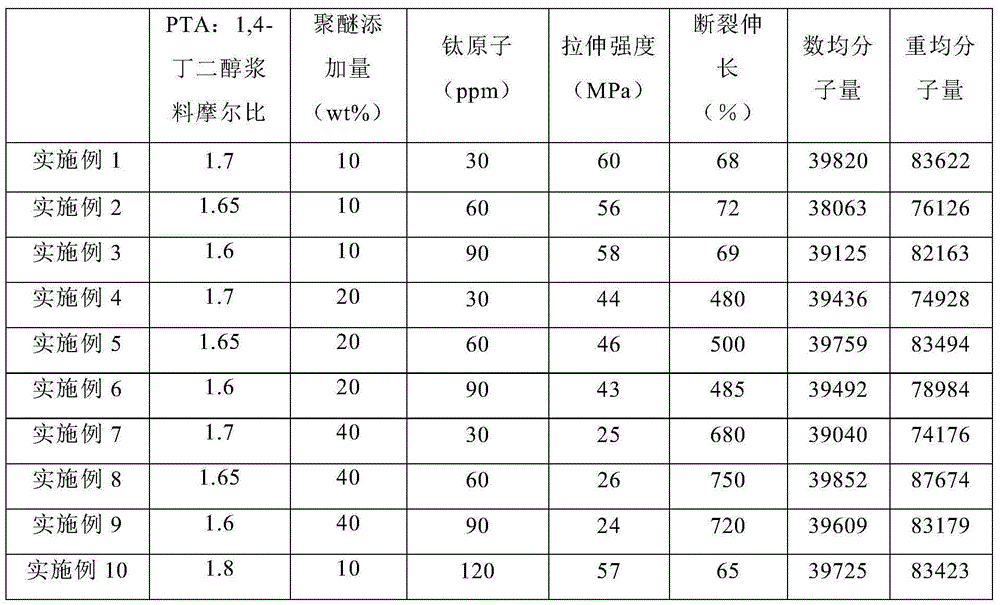

A continuous preparing method for polyether modified copolyester

ActiveCN105585701AChange the order of additionQuick responseMonocomponent copolyesters artificial filamentPolymer scienceCopolyester

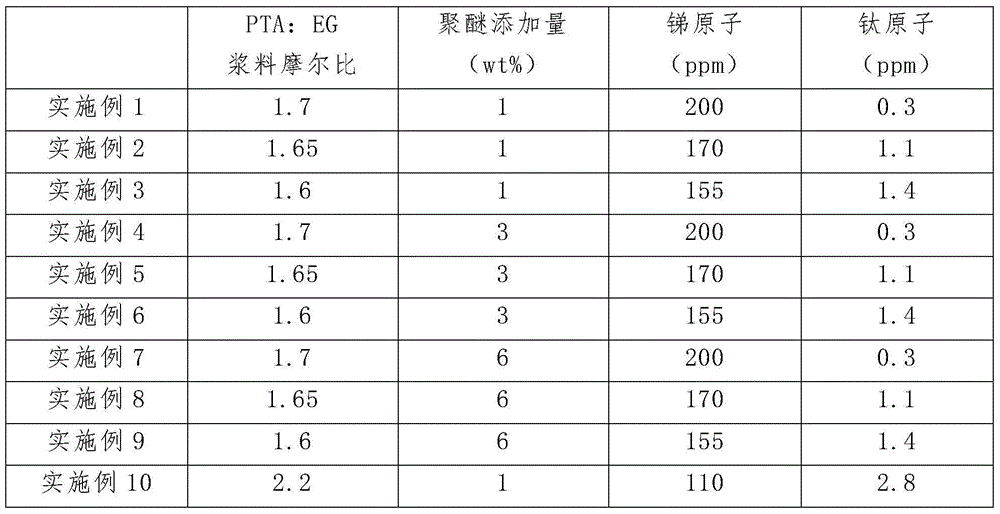

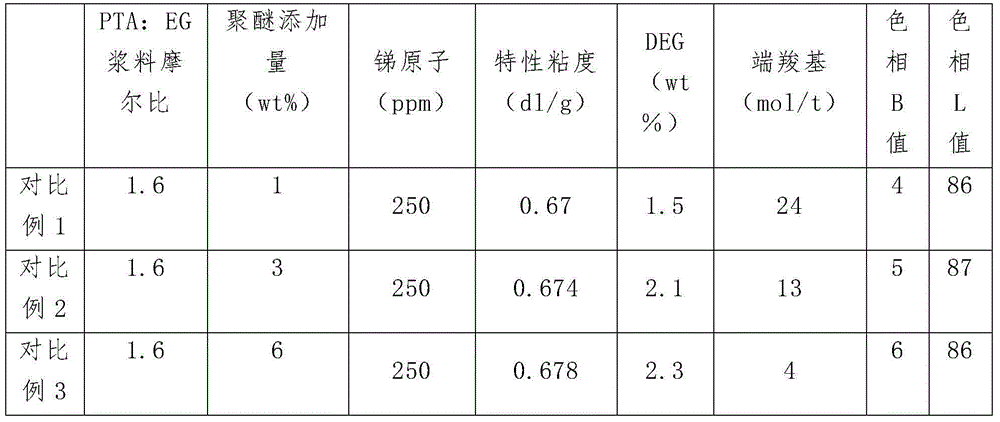

The invention relates to a continuous preparing method for polyether modified copolyester. The method includes mixing an ethylene glycol solution of a titanium catalyst, terephthalic acid and ethylene glycol to prepare slurry, esterifying, mixing an ethylene glycol solution of an antimony catalyst, an ethylene glycol solution of polyether and an intermediate that is bis(hydroxyethyl) terephthalate, pre-polymerizing, performing condensation polymerization, and the like. Problems that polyether macromolecules are prone to thermal degradation and are degraded into chain segments with low molecular weights at high temperature with long reaction time, and modification effects of the chain segments with low molecular weights on polyesters are weakened are overcome by the preparing method. The polyether that is a modifying agent in the prepared polyether modified copolyester is uniform in distribution and stable in molecular weight. A copolyester product is excellent and stable in performance and good in spinnability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing sea cucumber collagen small peptide freeze drying powder extracted from sea cucumber decoction liquor

InactiveCN101532044AEasy to processHigh in nutrientsPeptide preparation methodsFermentationSmall peptideEnzymatic hydrolysis

The invention relates to deep processing of sea cucumbers, in particular to a method for preparing sea cucumber collagen small peptide freeze drying powder extracted from sea cucumber decoction liquor. The method adopts the sea cucumber decoction liquor as the raw material and comprises the steps of A. obtaining the sea cucumber decoction liquor; B. enzymatic hydrolysis; C. purification of sea cucumber collagen small peptide; and D. freeze-drying, drying and product packaging. The method can increase the processing rate and nutritional value of sea cucumbers, and by adopting FD space biological freezing and drying technology, the activity, oxidation resistance, re-polymerization resistance and moisture binding resistance of the sea cucumber collagen small peptide can be kept, and the sea cucumber collagen small peptide can be stored easily due to less moisture.

Owner:DALJANSKOE OOO PO KHIMICHESKOMU MATERIALU TVERDOGO TELA KEHSYTEH

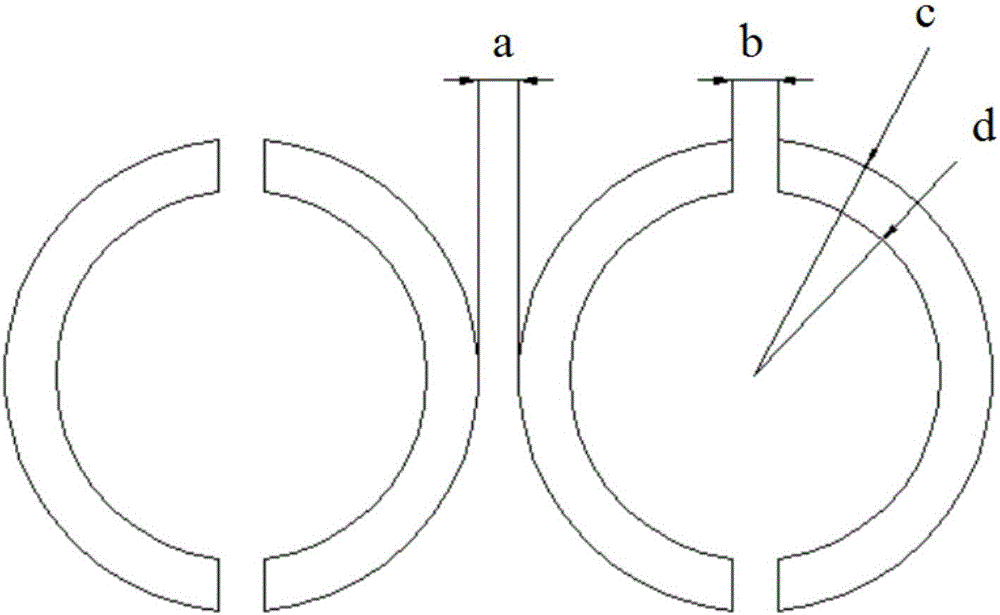

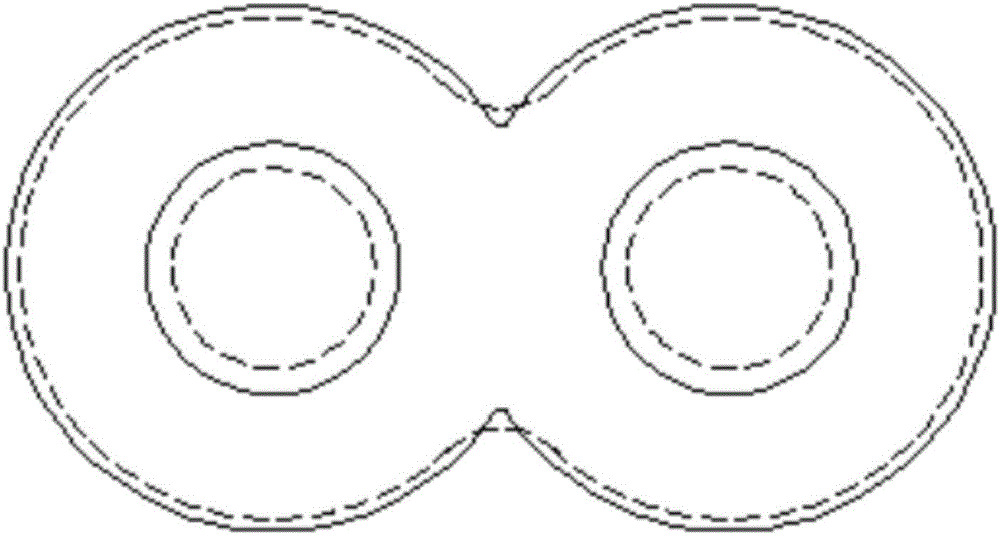

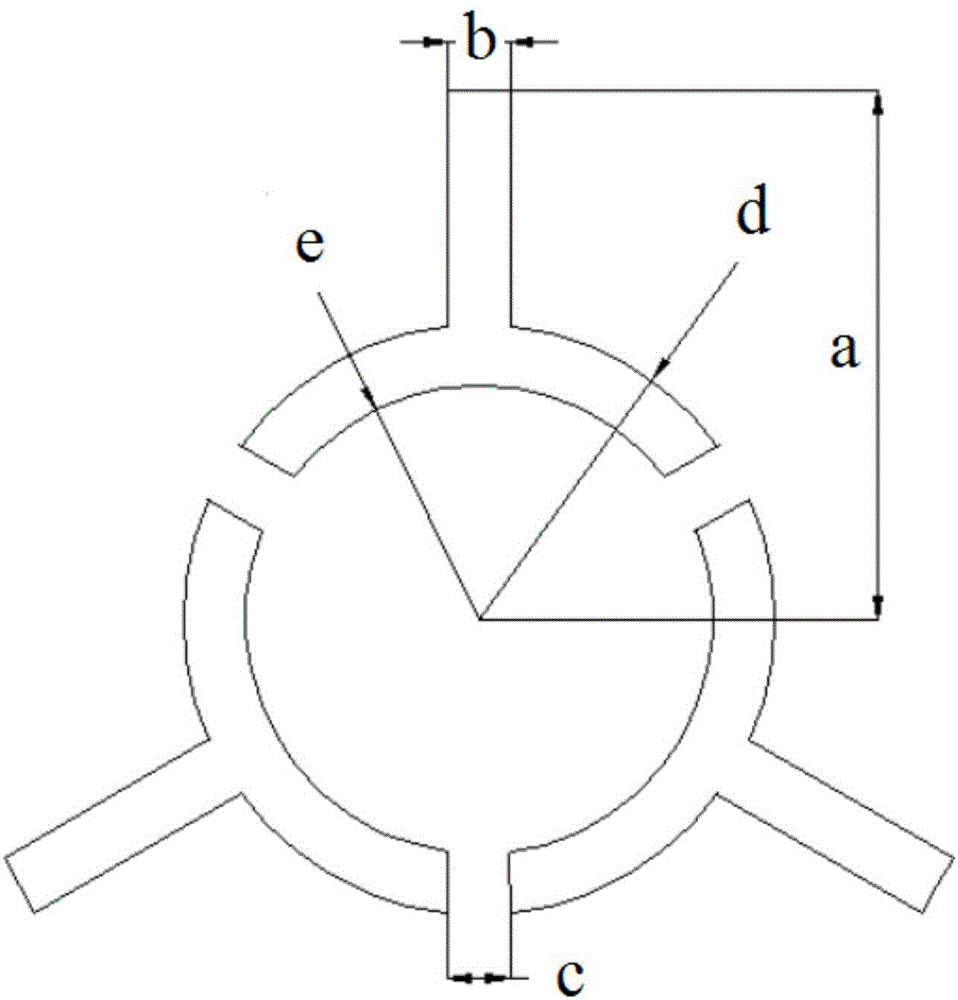

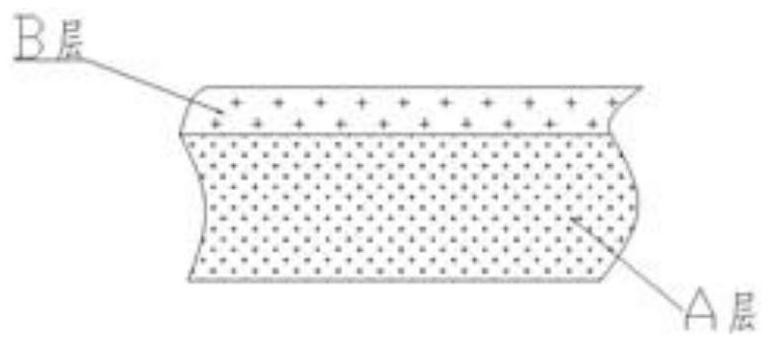

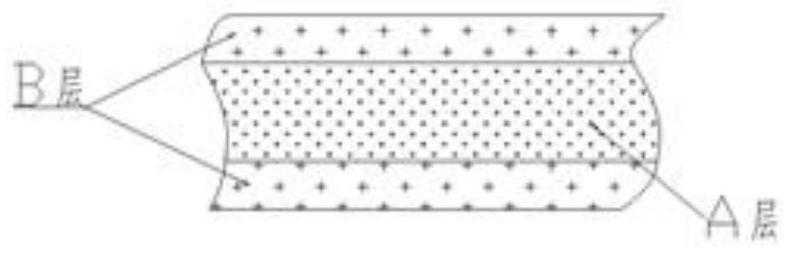

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

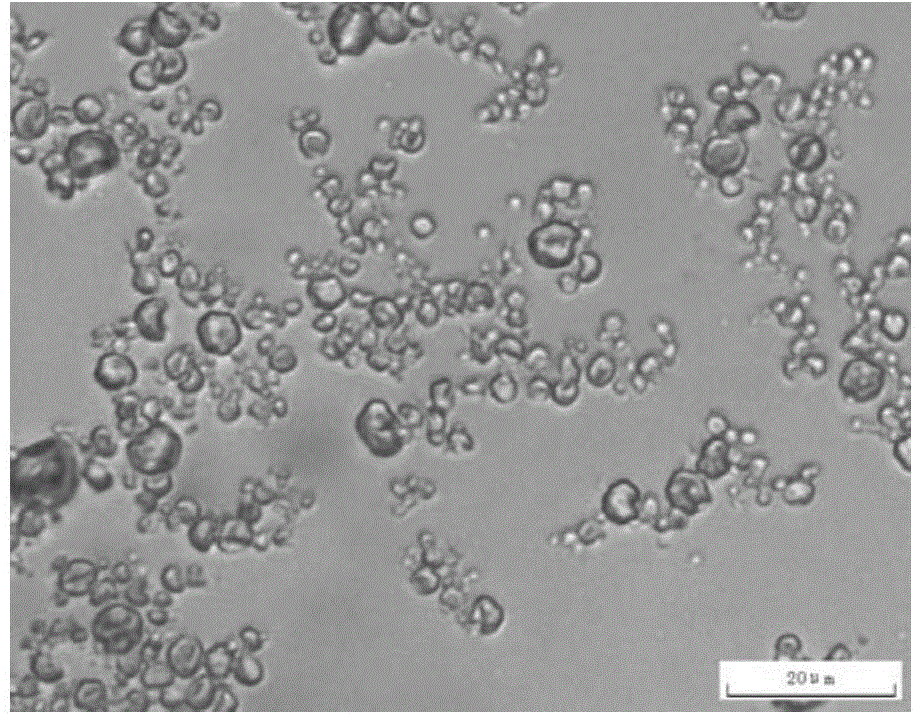

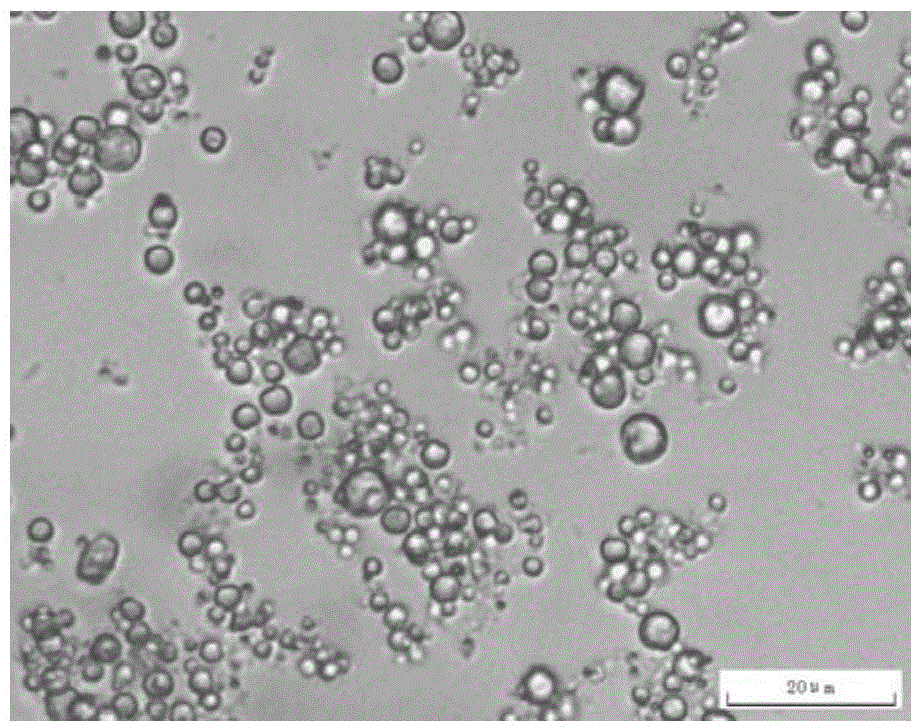

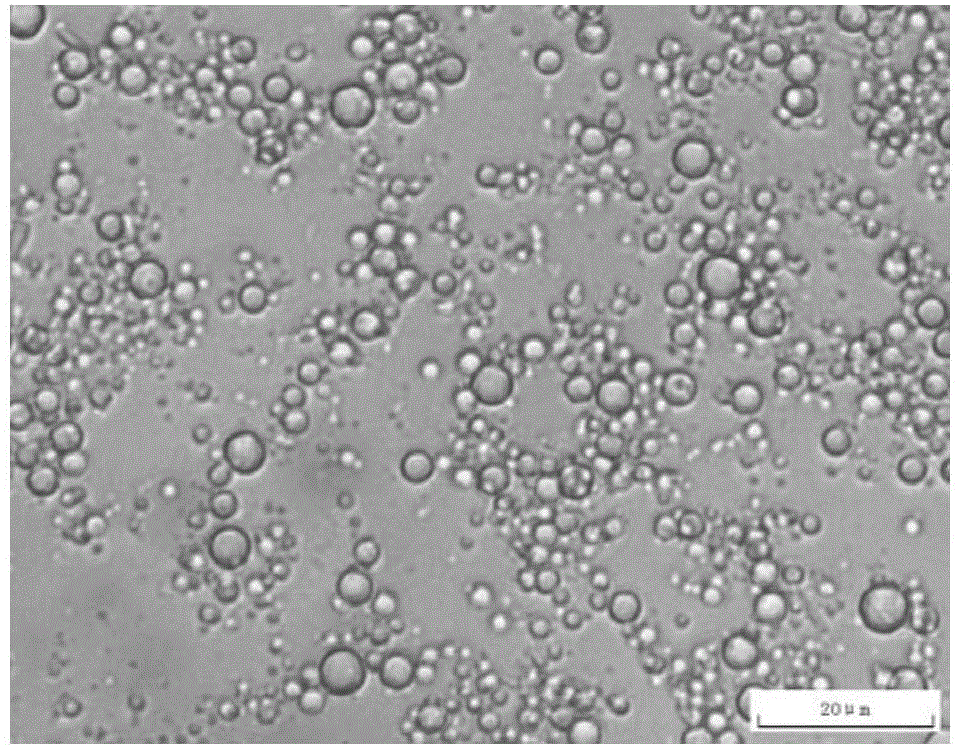

N-tetradecanol phase change microcapsule and preparation method thereof

InactiveCN104558393ALow viscosityStable molecular weightMicroballoon preparationMicrocapsule preparationTemperature resistanceChemistry

The invention discloses an n-tetradecanol phase change microcapsule. The n-tetradecanol phase change microcapsule comprises a polymer shell and an n-tetradecanol core material wrapped in the shell and is prepared by a suspension polymerization method, wherein the polymer shell is obtained by polymerizing monomers in the presence of an initiator and the monomers comprise nitrile, (meth)acrylate and carboxyl-containing monomers. According to the n-tetradecanol phase change microcapsule, nitrile monomers are introduced in the polymer shell so that the temperature resistance of the phase change microcapsule is improved and the application range of the phase change microcapsule is expanded; in addition, since the nitrile monomers has better film-forming property, the phase change microcapsule prepared from the nitrile monomers has better permeability resistance and the leakage of the phase change material can effectively prevented. The phase change microcapsule disclosed by the invention can have wide application prospects in such fields as textile, construction and paints. Since the monomers are free of formaldehyde, the production is safer and more conducive to environmental friendliness and human health.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Preparation method of gel material for adsorbing heavy metal ions and phenolic compound and product of gel material

InactiveCN105399896AHigh strengthStable molecular weightOther chemical processesAlkali metal oxides/hydroxidesMeth-Hexadecyltrimethylammonium bromide

The invention relates to a preparation method of a composite gel material which has excellent adsorption capacity of heavy metal ions, such as lead, cadmium, nickel, chromium, and molybdenum, and a phenolic compound, such as phenol, methylphenol, and xylenol, at the same time, is high in adsorption quantity and efficiency, and can be reused after washing, and relates to a product of the composite gel material. Attapulgite is subjected to water washing and acid washing, and is modified through a sodium chloride solution, hexadecyltrimethylammonium bromide, and a humic acid to prepare humic-acid-modified attapulgite. The humic-acid-modified attapulgite and acrylamide hydrogel are compounded to prepare the product of the composite gel material. The preparation method of adsorption macromolecule hydrogel is simple in process and low in cost, does not require any special equipment, and is easy for industrial application. The strength of the prepared gel is greatly improved.

Owner:TIANJIN JINLIN WATER TREATMENT SCI & TECH CO LTD

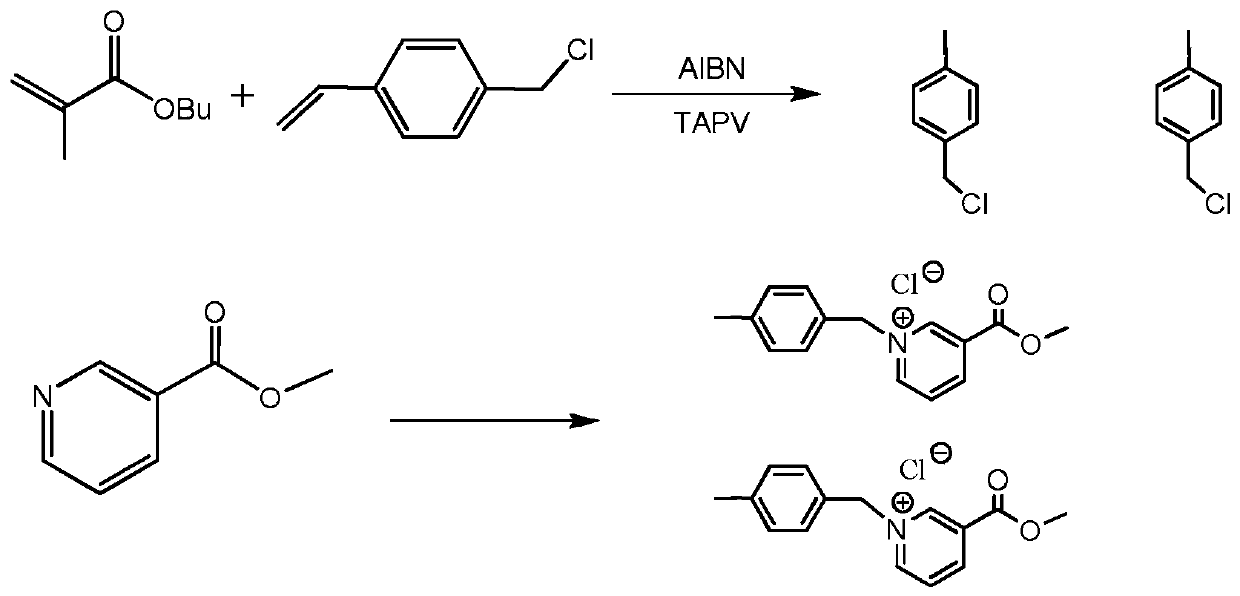

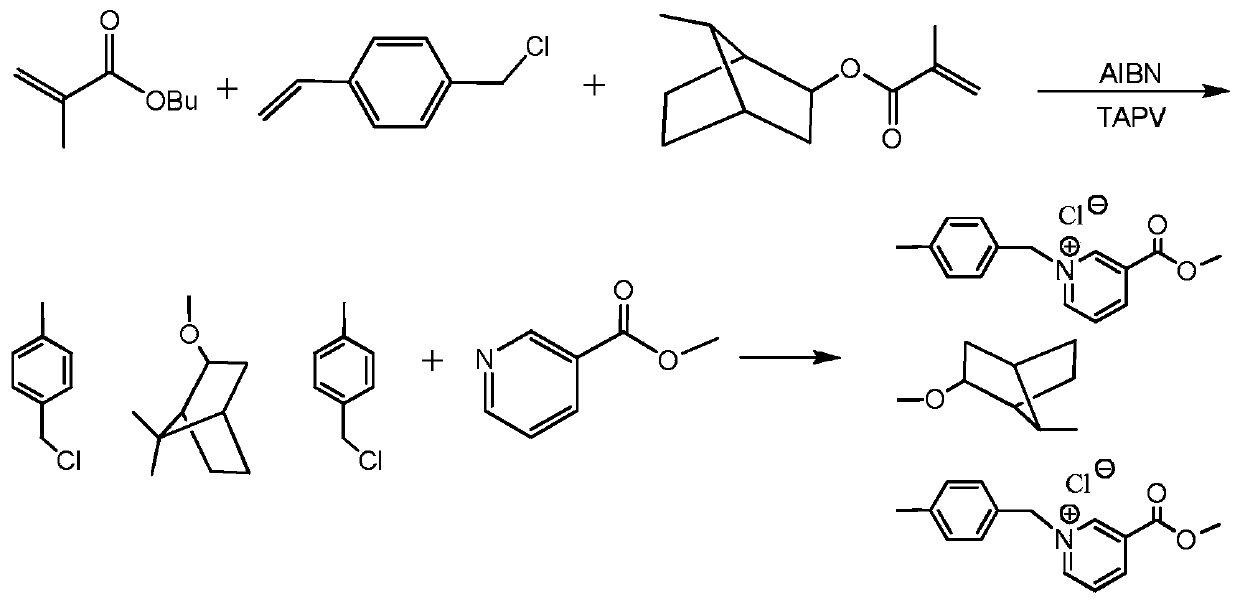

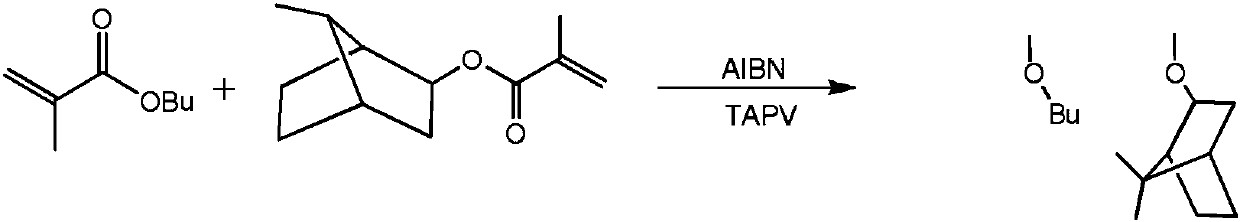

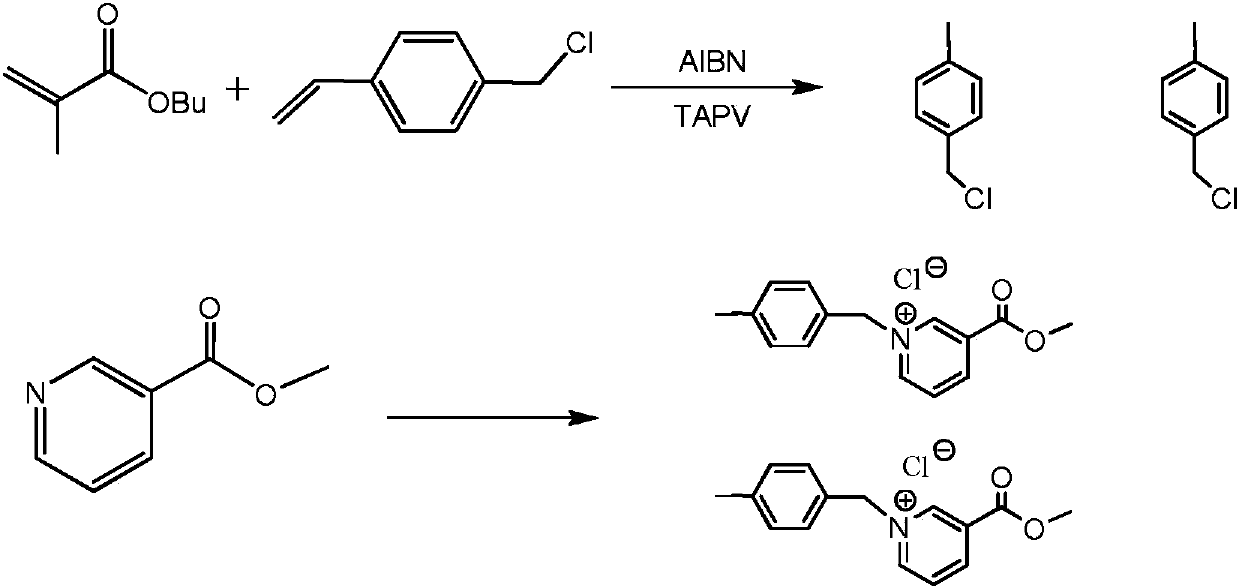

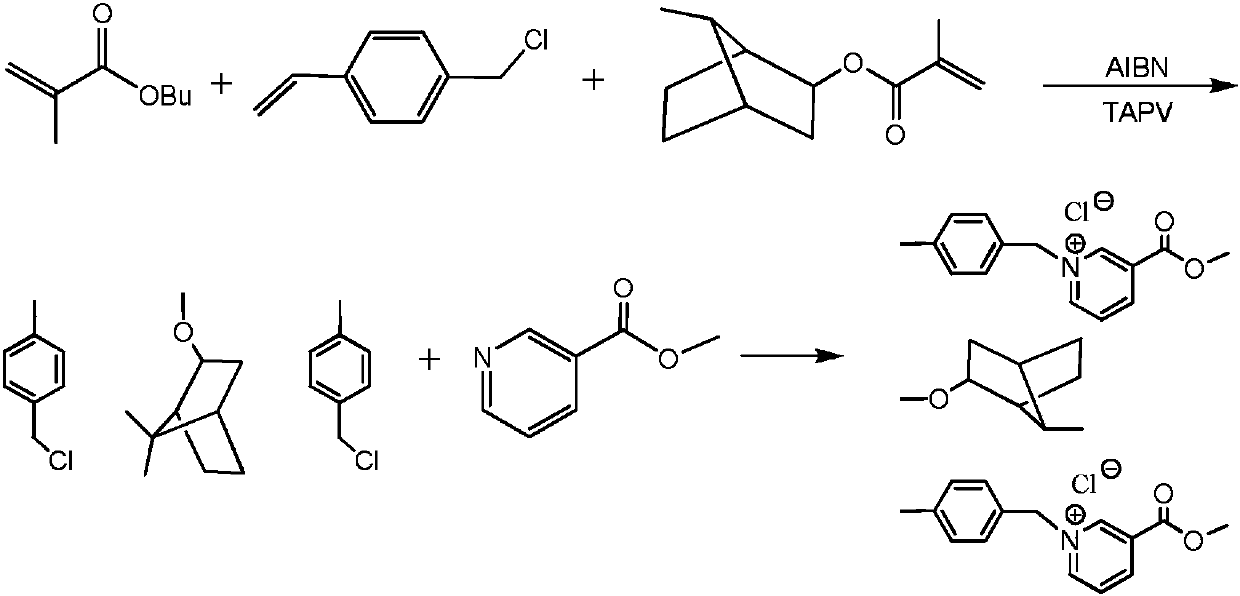

Copper-bearing linear self-polishing marine anti-fouling paint

ActiveCN109836951AStable antifoulingComprehensive antifouling effectAntifouling/underwater paintsPaints with biocidesCopperAntibacterial property

The invention relates to the field of paint and discloses a copper-bearing linear self-polishing marine anti-fouling paint. The paint of the invention contains eight different types of linear self-polishing anti-fouling resins. The synthetic process route of the resins is easier to control and the cost is lower. The resins have stable molecular weight and narrower molecular weight distribution, and have good linear polishing ability. After the resins are used to prepare the copper-bearing marine anti-fouling paint, antibacterial property, antifouling property, adhesion and weatherability are excellent. The paint of the invention is applicable to a long-acting antifouling coating system of ships.

Owner:ZHEJIANG MARINE DEV RES INST

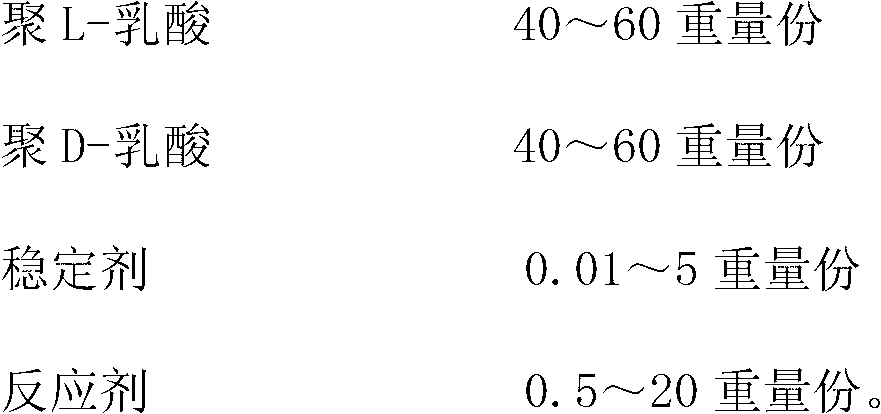

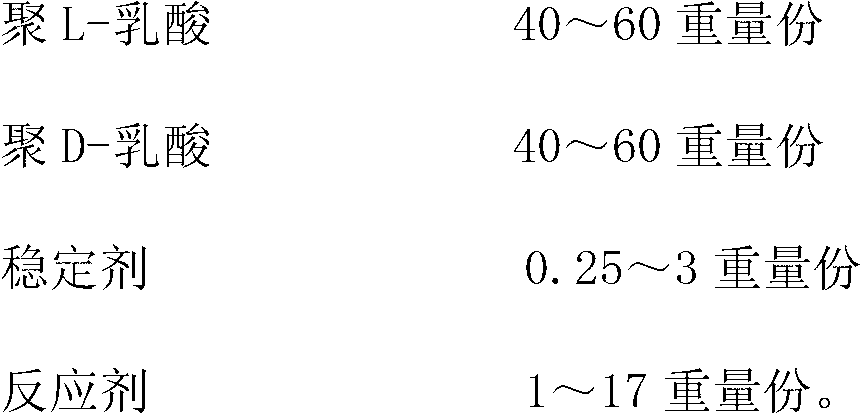

Polylactic acid nucleating agent, preparation method and application thereof

InactiveCN102838858AIncrease the rate of crystallizationHigh transparencyHeat resistanceChemical resistance

The invention relates to the high polymer material field, particularly referring to a novel polylactic acid nucleating agent, a preparation method and an application thereof. The novel polylactic acid nucleating agent comprises following materials by weight: 40-60 parts of poly L-lactic acid, 40-60 parts of poly D-lactic acid, 0.01-5 parts of stabilizer and 0.5-20 parts of reactant. The nucleating agent has simple preparation method; the polylactic acid nucleating agent has the advantages of stable molecular weight, uniform molecular weight distribution and good eutectic structure; the preparation method can effectively improve crystallization rate of polylactic acid, and obtain polylactic acid product with excellent chemical resistance, heat resistance and better transparency; and therefore, the nucleating agent has wide development and application prospect in preparation of the polylactic acid product.

Owner:SHANGHAI TONG JIE LIANG BIOMATERIALS

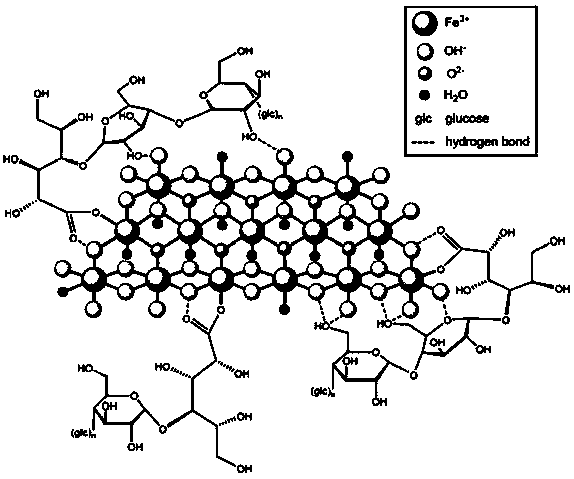

Preparation method of an iron and carbohydrate complex

InactiveCN108129582AStable molecular weightSmall polydispersity indexHypochloriteQuaternary ammonium cation

The invention provides a preparation method of an iron and carbohydrate complex, and particularly relates to a preparation method of ferric carboxymaltose. The preparation method of ferric carboxymaltose comprises the following steps: maltodextrin is oxidized by an oxidant containing tert-butyl hypochlorite in an alkaline aqueous solution in the presence of a phase transfer catalyst; the oxidizedmaltodextrin solution is subjected to a reaction with an aqueous solution of ferric iron salt, wherein the phase transfer catalyst is selected from one or more of quaternary ammonium salts such as trioctylmethylammonium chloride, tributylmethylammonium chloride, tributylmethylammonium bromide, tributylmethylammonium chloride, tetrabutylammonium chloride, and tetrabutylammonium bromide; the oxidantis tert-butyl hypochlorite or a combination of tert-butyl hypochlorite and sodium hypochlorite. Obtained ferric carboxymaltose has MW (molecular weight) of 150-230 kDa, Pd value of 1.2-1.3 and iron content of 26%-31%.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

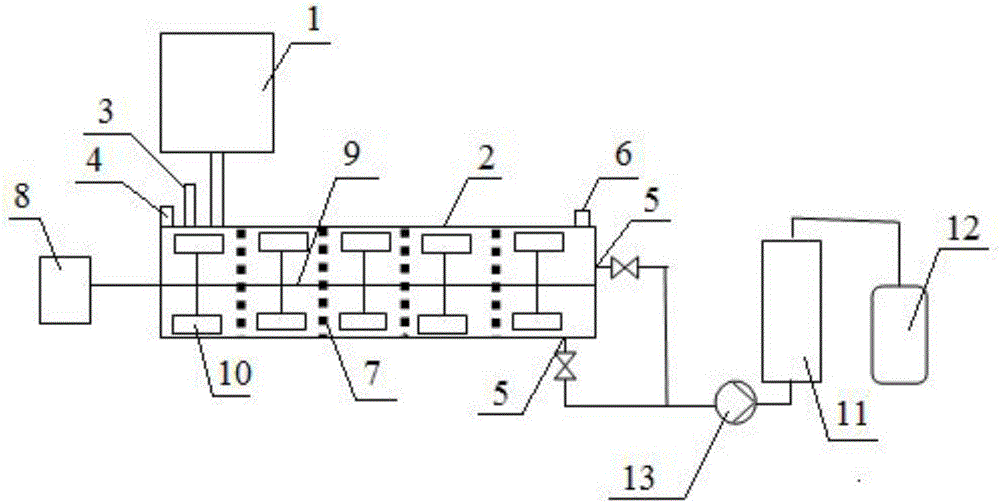

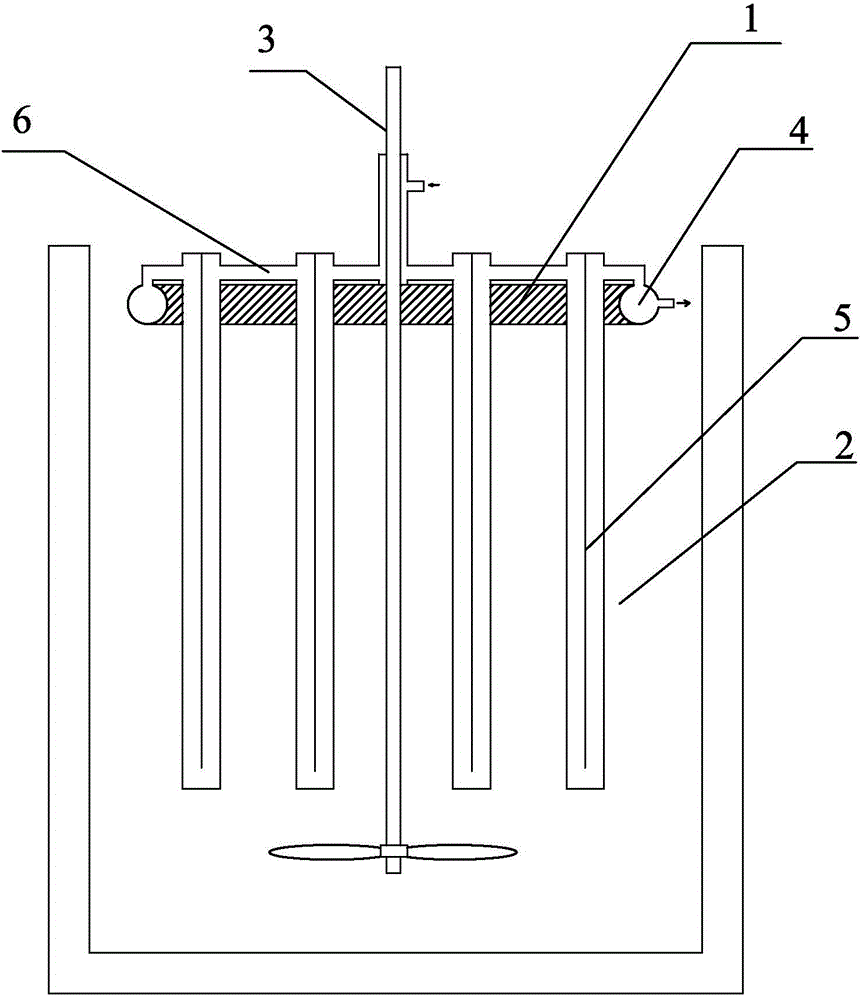

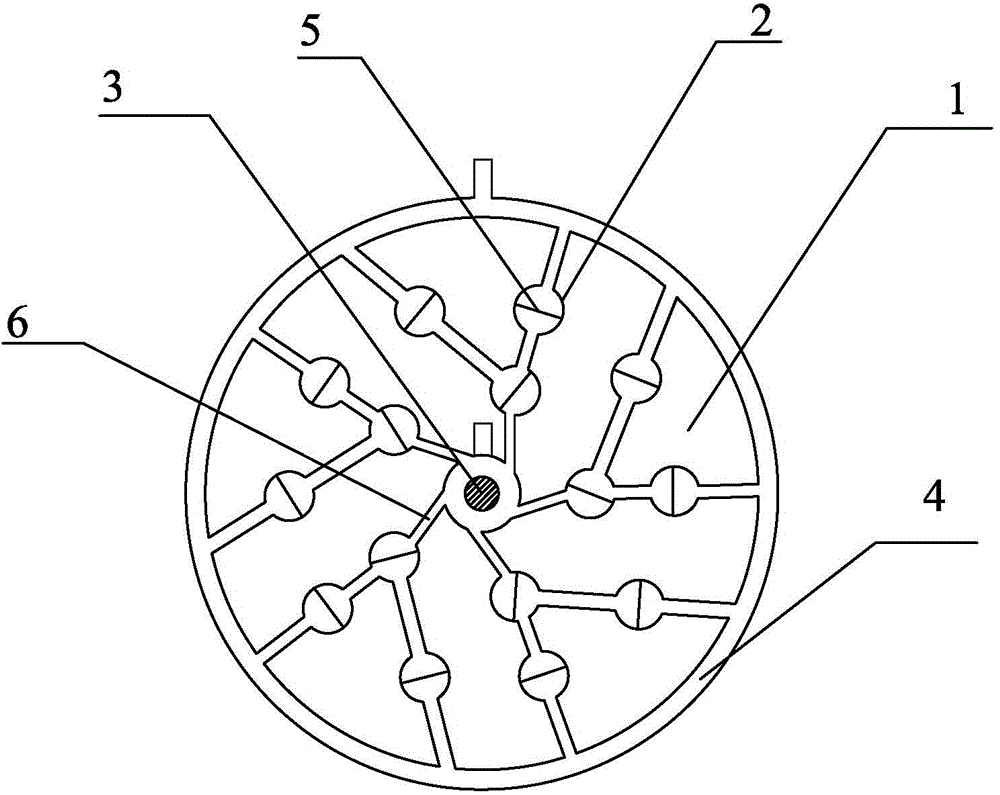

Continuous ursol dissolving device and method

InactiveCN105688706AEliminate quality impactAchieve stabilityTransportation and packagingRotary stirring mixersAramidPolymer chemistry

The invention belongs to the technical field of synthesis of high polymer and relates to a continuous ursol dissolving device and method, in particular to a continuous dissolving device and method for monomer ursol during continuous polymerization of resin for para-aramid fibers, that is, conventional intermittent dissolving is substituted by PPD continuous dissolving. Therefore, all processes of PPTA polymerization are continuous, and stability in resin molecular weight is ensured, and consistency in resin luster is achieved.

Owner:AFCHINA CORP CO LTD +1

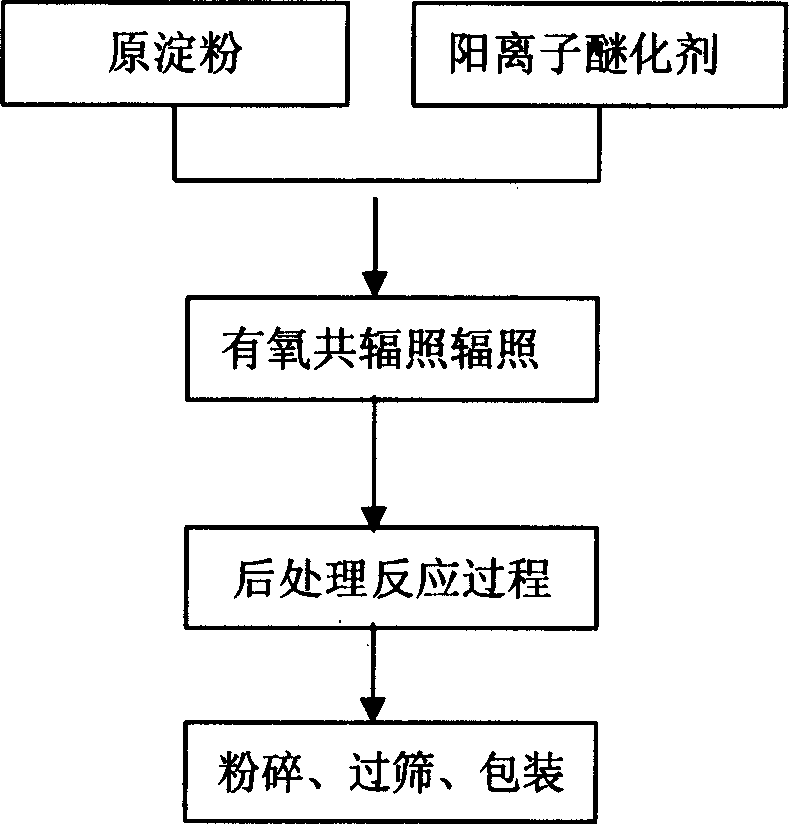

Irradition initiating process for preparing cationic starch

InactiveCN1887911AStable molecular weightNo pollution in the processNon-fibrous pulp additionFibre treatmentOxygenIrradiation

The irradiation initiation process of preparing cationic starch includes the following steps: 1. adding cationic etherifying agent into starch material via stirring to obtain mixture with the cationic etherifying agent adding amount being 1-100 wt% of starch; 2. irradiating the mixture in Co-60 irradiation field of irradiation dose 3-15 KGy to initiate reaction in the presence of oxygen to prepare blend; and 3. post-treatment of the blend through stoving at 130-150 deg.c or 180-200 deg.c inside stove, stirring, crushing and 100 mesh sieving to obtain the cationic starch product. The process is environment friendly, simple and low in cost.

Owner:WUHAN TEXTILE UNIV +1

Multilobal hollow polyester fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106835334AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

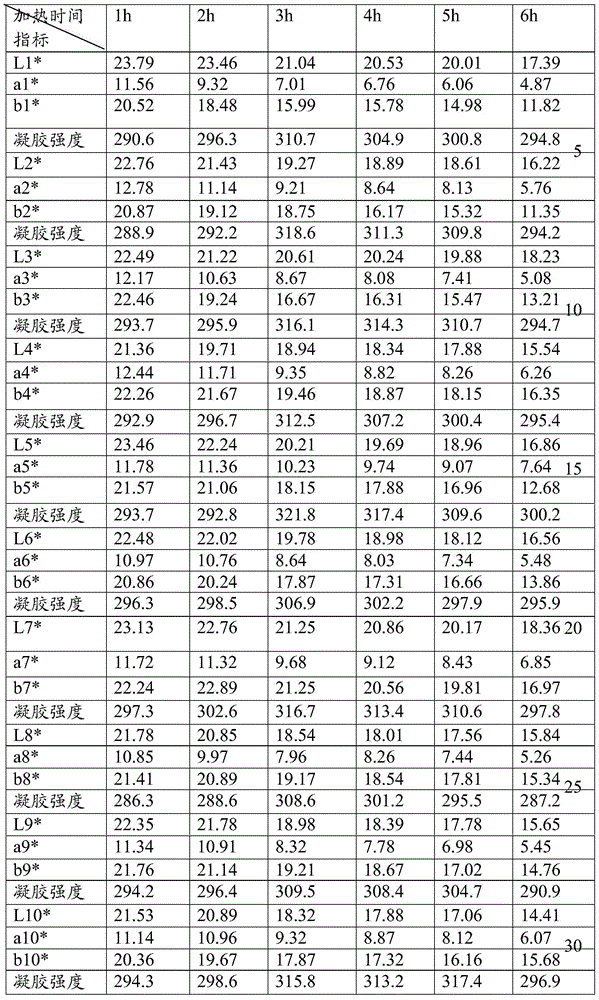

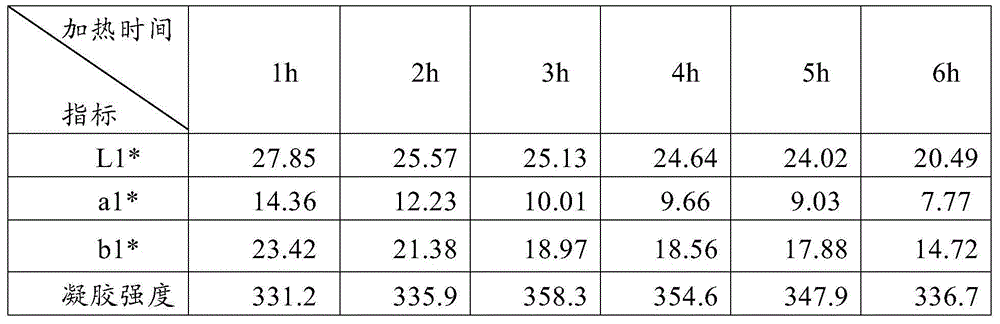

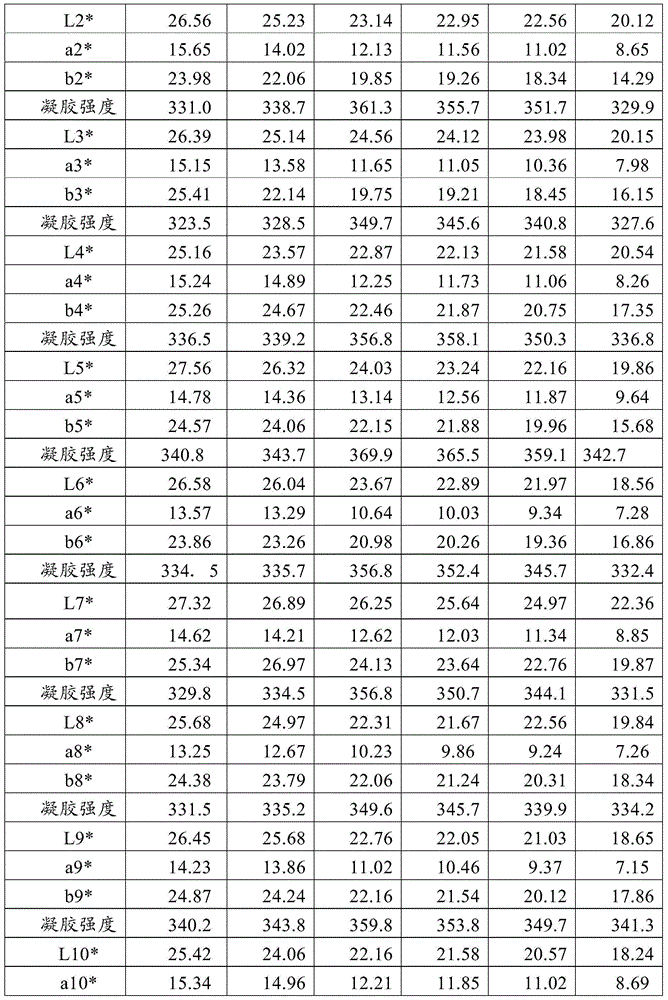

Method for rapidly controlling quality of animal glue products

InactiveCN104568775AImprove qualityStable molecular weightPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringControl quality

The invention relates to a method for rapidly controlling the quality of animal glue products. The method comprises the following steps: sampling when the moisture content of the selected glue solution is 22-26% in the process of concentration to output glue, measuring values L*, a* and b* of glue color by a colorimeter, and evaluating the bloom strength of glue solution by the values L*, a* and b*, wherein when the value L* is 17.56 to 25.13, the value a* is 6.06 to 13.14, the value b* is 14.98 to 22.46, and the corresponding bloom strength of glue solution is 290-370 Bloomg, the obtained animal glue products has better quality. According to the method for rapidly controlling the quality of animal glue products, the change trend of the bloom strength is evaluated by measuring the color of glue solution, the production process can be controlled rapidly and conveniently, the quality of products is ensured, the subjectivity of sensory evaluation is overcome, and a quantitative basis is provided for rapidly controlling the appearance and inherent quality of animal glue products.

Owner:SHAN DONG DONG E E JIAO

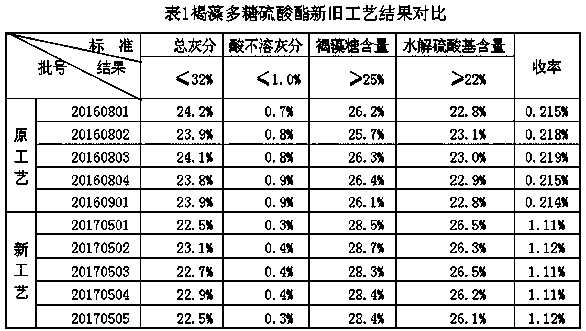

Chondroitin sulfate/dermatan sulfate extraction method

InactiveCN105821097AOvercome the source's shortcomingsWide variety of sourcesFermentationDermatan sulfateHyaluronic acid

The invention discloses a chondroitin sulfate / dermatan sulfate extraction method which comprises the following steps: drying the eggshell matrix and grinding to obtain eggshell matrix powder; separating and extracting total glycosaminoglycan from the eggshell matrix powder; and removing heparin / heparan sulfate, keratan sulfate and hyaluronic acid in the total glycosaminoglycan to obtain high-purity chondroitin sulfate / dermatan sulfate.

Owner:刘长国

Linear self-polishing antifouling resin rich in biological bactericide, and copper-free marine antifouling coating containing linear self-polishing antifouling resin

ActiveCN109762098AOptimize the synthetic routeGood linear polishing abilityAntifouling/underwater paintsPaints with biocidesWeather resistanceCopper

The invention relates to the field of coating, and discloses a linear self-polishing antifouling resin rich in a biological bactericide, and copper-free marine antifouling coating containing the linear self-polishing antifouling resin. The linear self-polishing antifouling resin contains eight different types of corresponding synthetic routes, the synthetic process route of the linear self-polishing antifouling resin is easier to control and lower in cost, and the molecular weight of the obtained resin is stable and narrower in distribution and has the good linear polishing ability; and afterthe copper-free marine antifouling coating is prepared from the linear self-polishing antifouling resin, the antibacterial property, the antifouling property, the adhesion capability and the weather resistance are good, and the copper-free marine antifouling coating is suitable for application of long-lasting antifouling coating systems of ships.

Owner:ZHEJIANG MARINE DEV RES INST

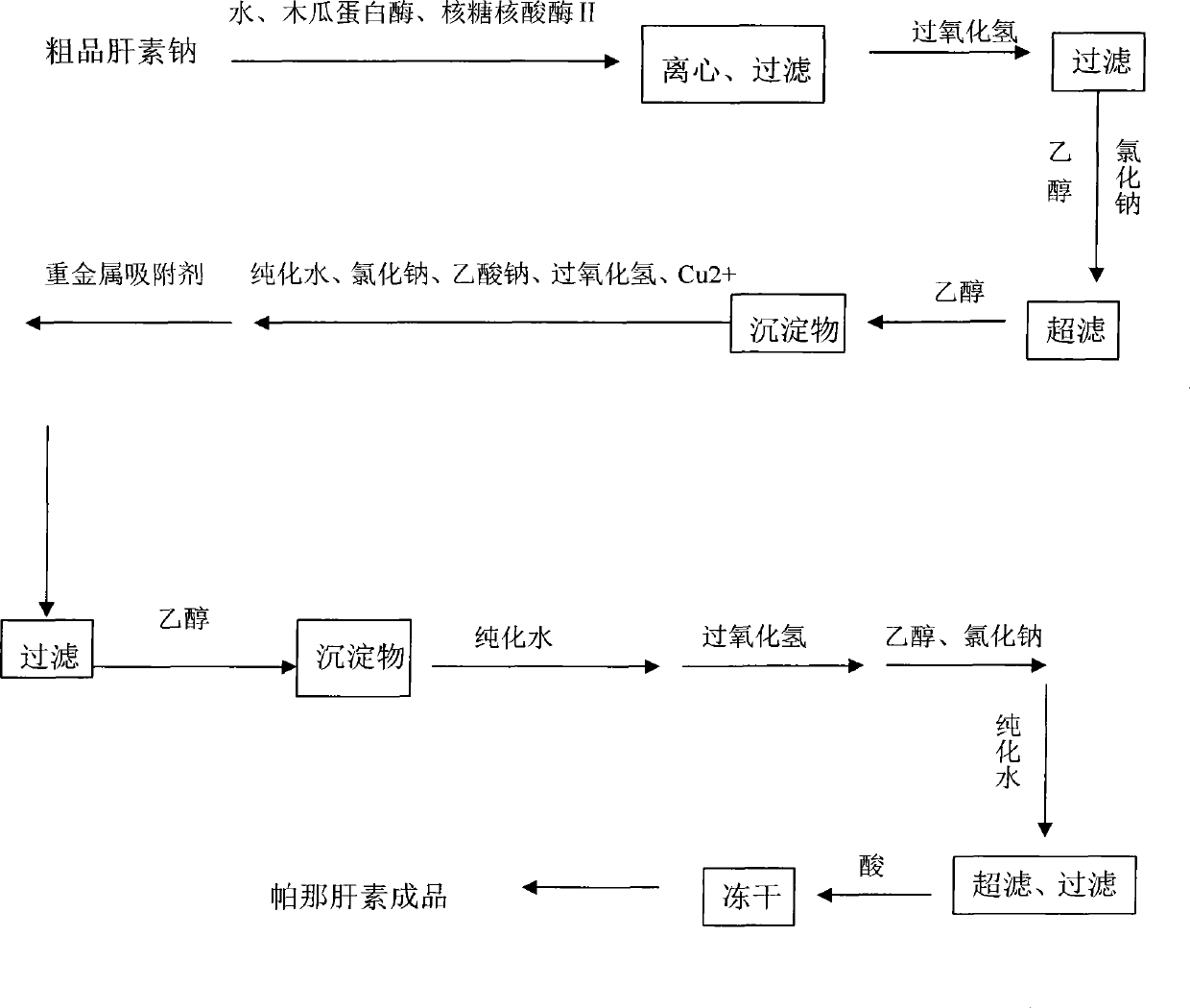

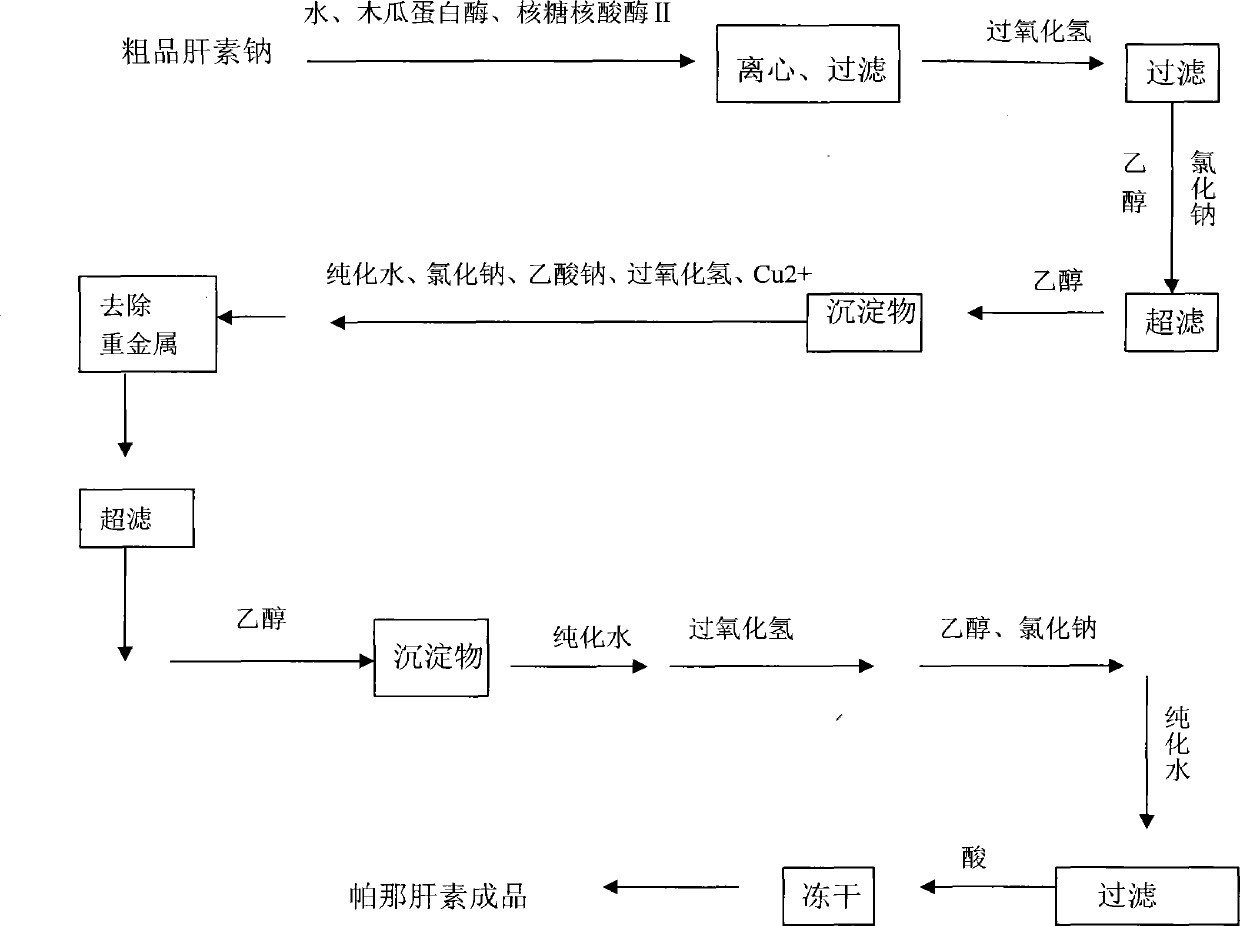

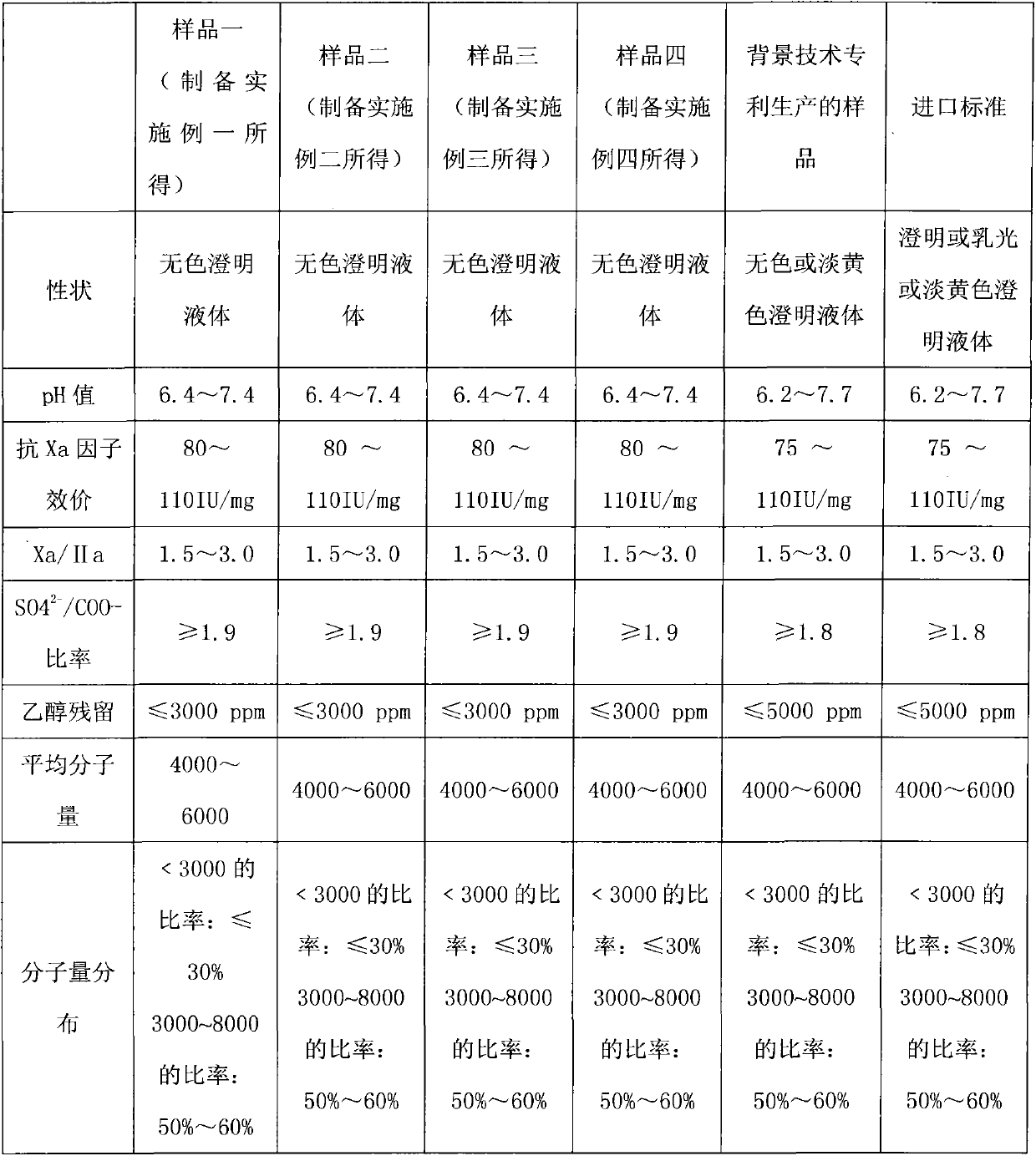

Method for preparing high-quality low molecular parnaparin sodium

ActiveCN103421128AImprove controllabilityAvoid lagging behind cumbersome processingFiltrationUltrafiltration

The invention discloses a method for preparing high-quality low molecular parnaparin sodium, belonging to the field of biological medicine. The method comprises the following steps: using a coarse-product heparin sodium as a raw material, carrying out enzymolysis to the coarse-product heparin sodium through papain and ribonuclease II, oxidation-decoloring and purifying to obtain competitive-product heparin sodium; after dissolving the competitive-product heparin sodium, conducing degradation reaction under the action of a copper acetate catalyst and hydrogen peroxide; after completing the degradation reaction, using a heavy metal absorbent to remove Cu2+ or removing Cu2+ in an ultra-filtration mode, and then separating though a low molecular membrane to obtain a parnaparin sodium coarse-product with specific molecular weight; after decoloring and, alcohol-precipitating the parnaparin sodium coarse-product, and vacuum-freezing and drying to obtain a low molecular parnaparin sodium finished-product with the anti-Xa factor activity being 80-i10 IU / mg, the pH value being 5.5-8.0 and the average molecular weight being 4000-6000D.The preparation process is simple, the stability and antithrombotic activity of the product are good.

Owner:山东辰龙药业有限公司

Polymerization process for fiber-grade polyphenyl thioether production process

InactiveCN101475688AReduce energy consumptionThe process is simple and easy to controlMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a polymerization process during the production of fiber-grade polyphenylene sulfide with simple operation, easily controlled reaction condition, ideal repeatability, short reaction time and reasonable energy consumption. The polymerization process is characterized in that during polymerization reaction of raw materials in a reaction kettle, a continuous heating-up mode is adopted for the reaction kettle and the heating-up speed is controlled between 0.3 and 0.6 DEG C per minute; when the reaction kettle is heated up from a range between 165 and 185 DEG C to another range between 245 and 295 DEG C, the polymerization reaction is finished. PPS products prepared by the method have stable quality and excellent performance and can meet the requirements of fiber-grade PPS resin.

Owner:JIANGSU XINZHONG INVESTMENT

Continuous preparation method of elastic copolyester

The invention discloses a continuous preparation method of an elastic copolyester. The continuous preparation method comprises the following steps: firstly, mixing a butanediol solution of a titanium catalyst, terephthalic acid and butanediol so as to prepare slurry, and performing a primary esterification reaction; secondly, mixing a polyether butanediol solution with the obtained intermediate namely bishydroxybutyl terephthalate, and performing a secondary esterification reaction and a pre-polymerization reaction; and finally performing a condensation polymerization reaction, thereby obtaining the elastic copolyester. By adopting the continuous preparation method disclosed by the invention, the elastic copolyester which is excellent and stable in product ductility can be prepared, and the problems that polyether macromolecules can be easily subjected to thermal degradation in the reaction process, particularly under the conditions of high temperature and relatively long reaction time, the polyether macromolecules can be decomposed into chain segments of a low molecular weight, and furthermore the modification function of generated polyether can be degraded, can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

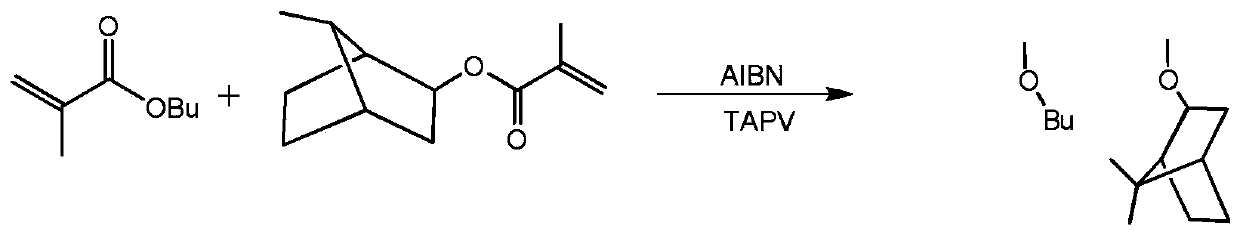

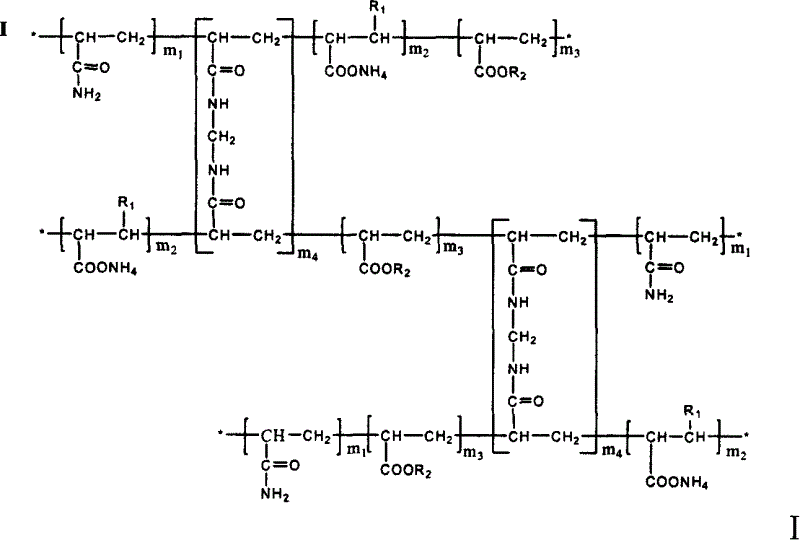

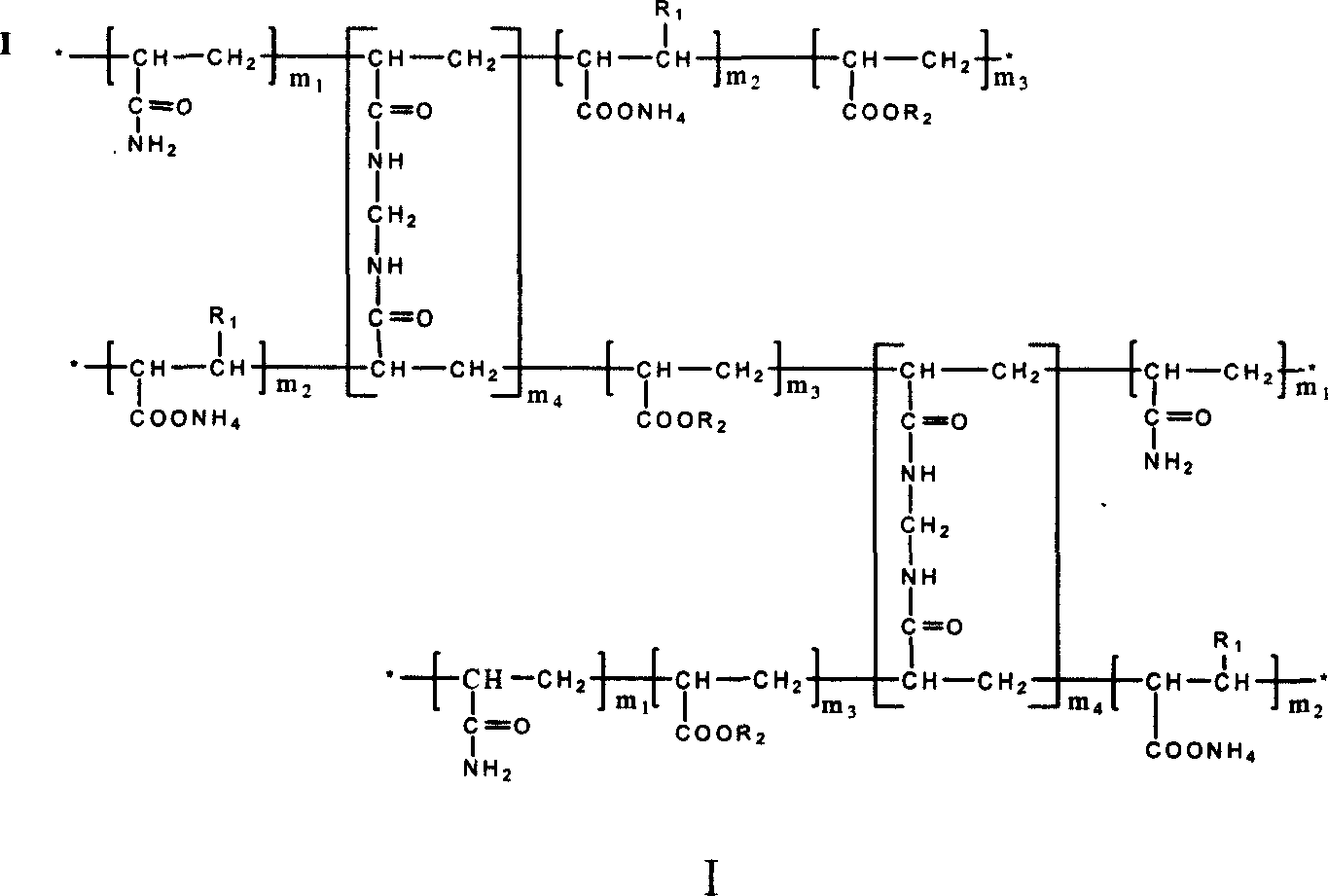

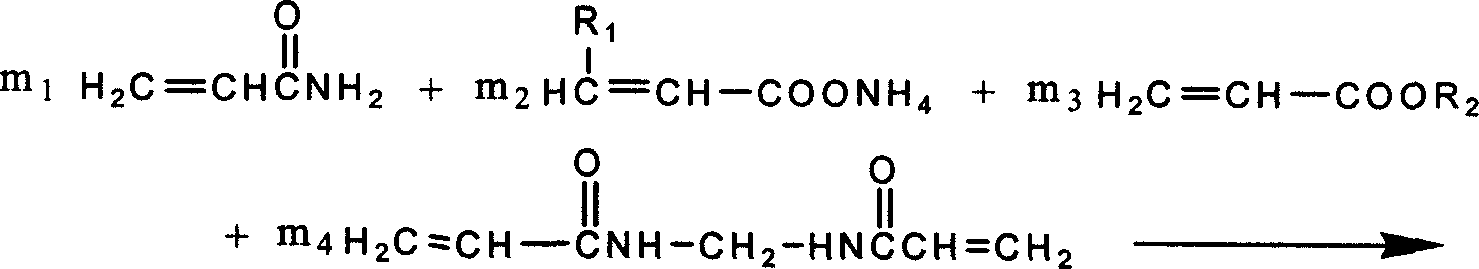

Method for preparing rapidly crosslinkable and easily breakable macromolecule thickener

InactiveCN1654590AExcellent thickening and viscosifying efficiencyAggregation is controllableDrilling accessories

The fast crosslinked and easily cracking anionic polymer thickener has the structural expression I. It is prepared with composition of sorbitan fatty acid ester, emulsfier NP and allcyl polyoxyethylene ether non-ionic emulsifier as emulsifer, acrylamide, acrylic acid or methyl acrylic acid, and N, N-methylene diacrylamide as monomer, as well as water, oil, alcohol, ammonium persulfate and hexane diamine adipate, and through polymerization in reverse phase emulsion system to obtain homogeneous stable reverse phase emulsion, and further crosslinking to obtain thickener jelly.

Owner:HUBEI UNIV

Extraction method for keratin sulfate in egg white

ActiveCN105732838AWide variety of sourcesMolecular weight consistency and stabilityRadiochemistryDermatan sulfate

The invention discloses an extraction method for keratin sulfate in egg white.The extraction method comprises the steps that the egg white is acquired; total glycosaminoglycan is separated and extracted from the egg white; heparin or heparan sulfate, chondroitin sulfate or dermatan sulfate and hyaluronic acid in the total glycosaminoglycan are removed, and then the high-purity keratin sulfate is obtained.

Owner:刘长国

Method for preparing organic silicon high-temperature-resistant adhesive by removing micro-water from methylcyclosiloxane used as raw materials and device therefor

InactiveCN1663938ATrace moisture reductionImprove mechanical propertiesOrganic decompositionPolymer scienceAdhesive

The invention relates to a method for preparing organosilicon high-temperature glue, comprising ventilating nitrogen through the bottom pipe and steam through steam coil to increase temperature directly; dehydrating the mixing methyl in the stock, the favorable improvement of the dehydrating effect of this invention compared with previous technique is that after the dehydrating the micro-hydration in stock decreases dramatically, at an average of below 10ppm. The addition quantity of regent for head closure in the polymerization process preparing high-temperature glue gradually becomes stable, the molecular weight of raw rubber polymerization is relatively stable. The quantity of terminal hydroxyl group decreases dramatically in the high-temperature glue preparing process, the moulding is faster in the process, the storing time of the mixed glue and its physical-mechanical properties and processing property have been improved considerably.

Owner:JIANGSU HONGDA NEW MATERIAL

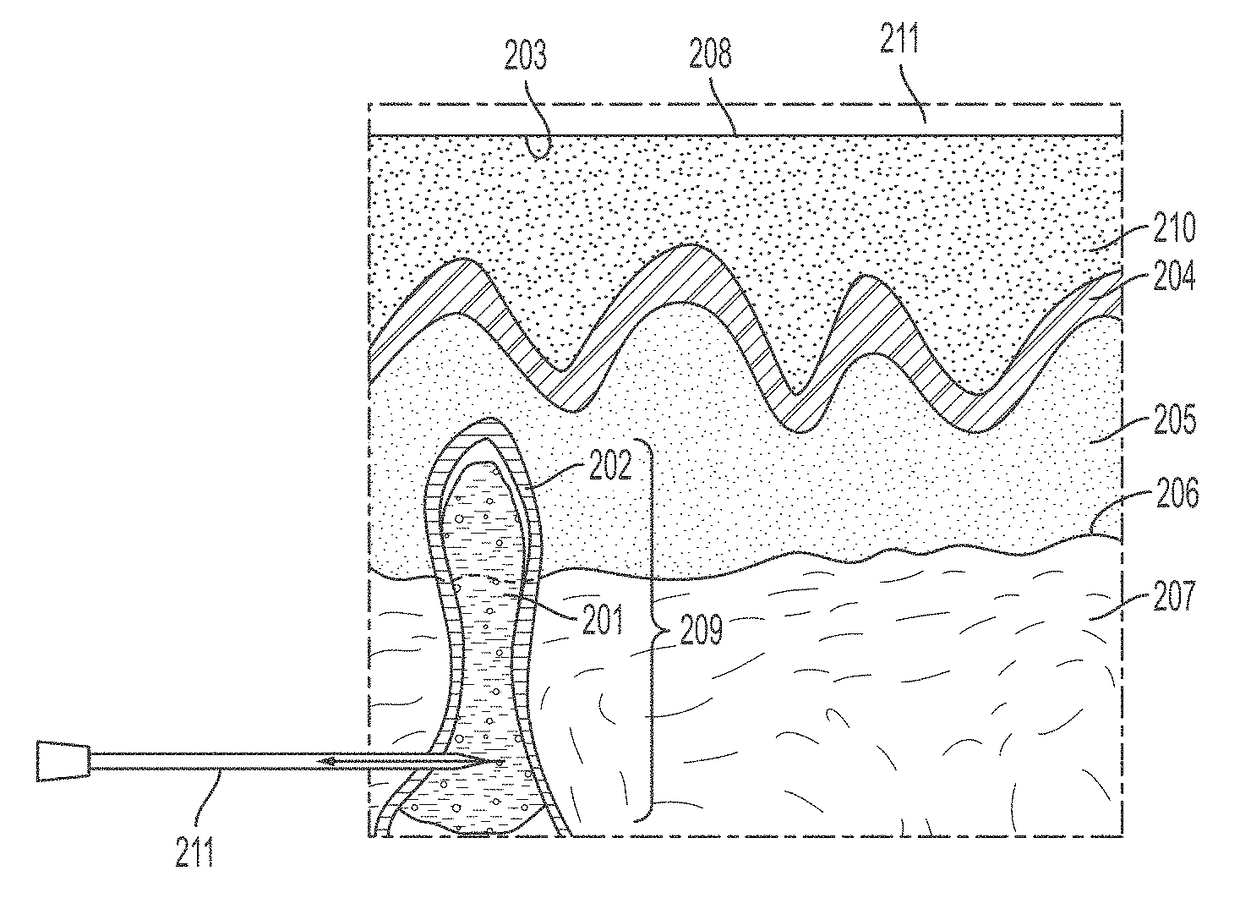

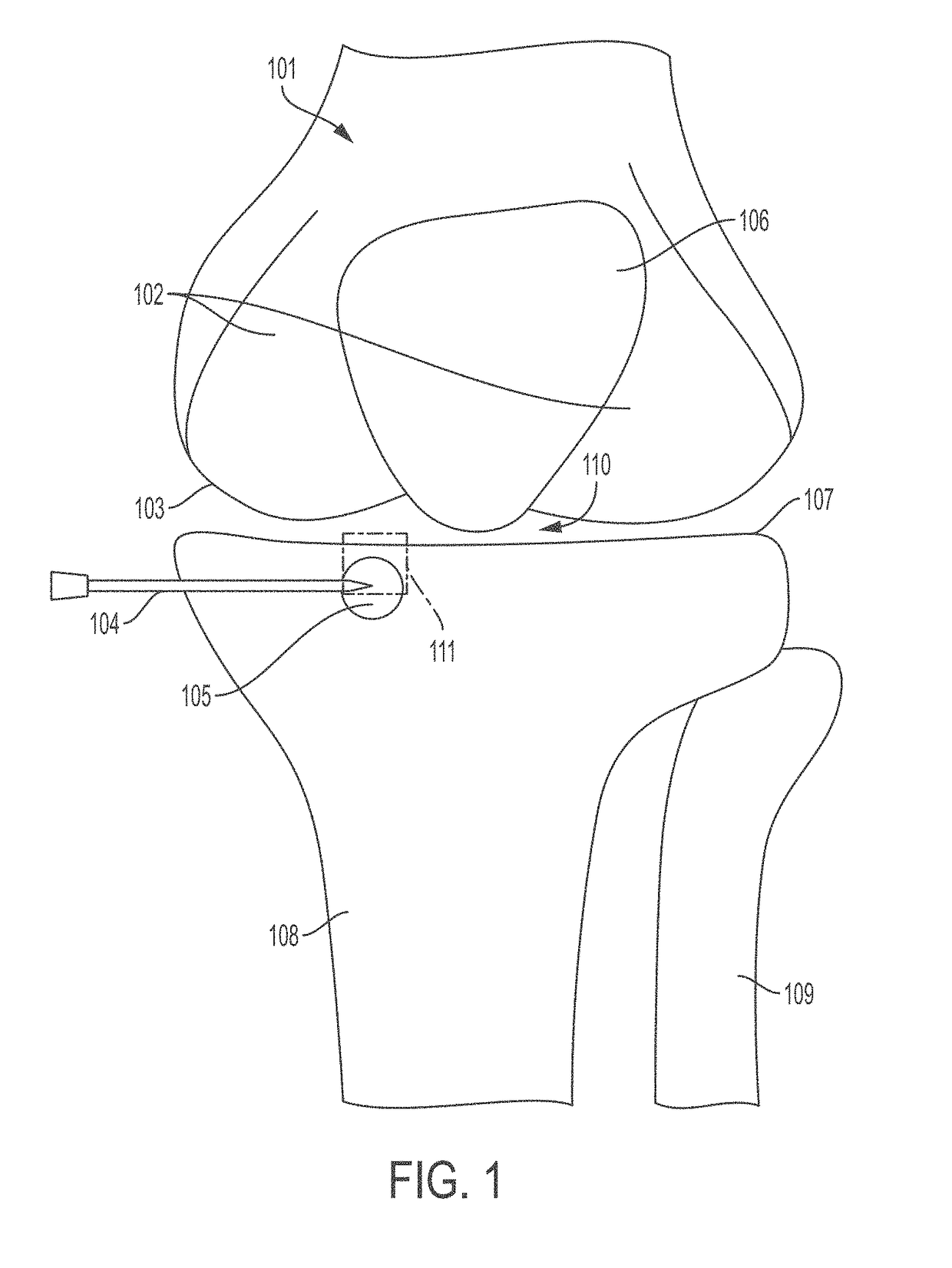

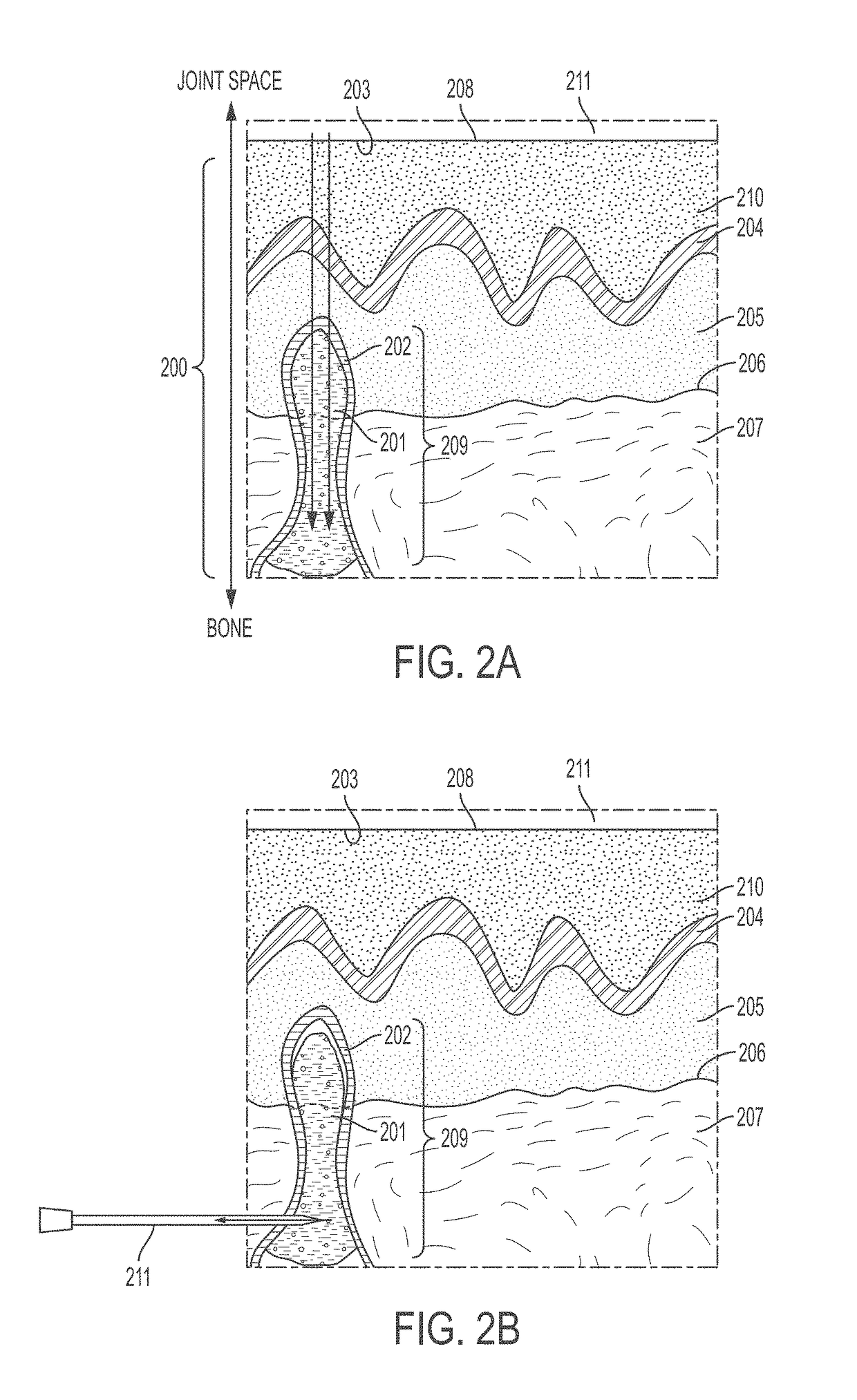

Methods and Compositions For The Treatment of Degenerate Bone

InactiveUS20170312385A1Relieve painShorten the progressSurgical adhesivesSurgical needlesRheumatoid arthritisBone disease

The present disclosure relates to methods and compositions for the treatment of degenerate bone in a patient. In some embodiments, the methods and compositions disclosed herein are useful in the treatment, prevention, or in delaying the progression of a bone disease linked to bone degeneration, such as osteoarthritis (“OA”), rheumatoid arthritis, and avascular necrosis.

Owner:ANIKA THERAPEUTICS INC

Dispersant for waterborne paint

ActiveCN105295502AGood dispersionGood resistance to ambient temperature changesCoatingsPigment particleChemistry

The invention discloses a dispersant for a waterborne paint. The dispersant is prepared from the following components: acrylic acid, methyl methacrylate, white carbon black, glycol, an organic solvent, n-amyl alcohol, propane diacid, an initiator, sodium hydrosulphite and a neutralizer. The dispersant provided by the invention can reduce surface tension of the waterborne paint, improves wetting effect on pigment particles, allows the pigment particles to be stably dispersed in a liquid phase, can rapidly and firmly bond with surface groups of the paint and enables the pigment particles to stably suspend in a hydrosolvent so as to allow pigment to be well dispersed, thereby achieving optimal dispersion effect; and through addition of white carbon black, the effect and speed of dispersion are improved. During preparation of the dispersant, the initiator is added in multiple steps instead of one step in the prior art, so the molecular weight of resultant and product distribution are changed, and the prepared dispersant has good dispersion performance and good capability of tolerating changes of environment temperature.

Owner:宣城市聚源精细化工有限公司

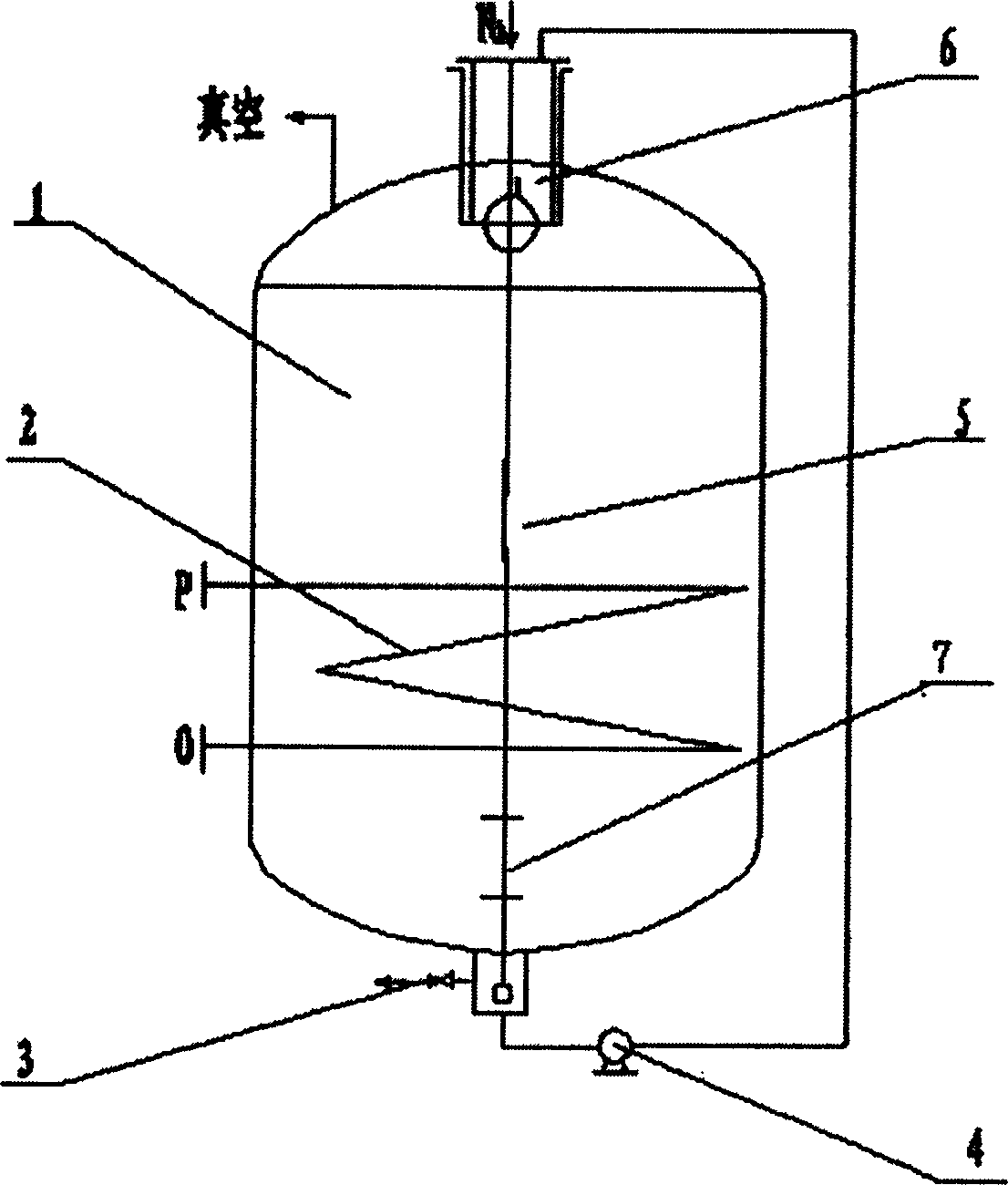

Preparation method of ultrahigh-molecular-weight polyacrylamide

ActiveCN104945548AUniform reaction temperaturePolymerization reaction temperature is stablePolyacrylamideAqueous solution

The invention discloses a preparation method of ultrahigh-molecular-weight polyacrylamide. The preparation method comprises the following steps: (1) preparing an acrylamide aqueous solution; (2) adding the acrylamide aqueous solution into a reactor provided with a liquid internal heat conduction device, introducing water of 6-7 DEG C into a water filling nozzle of the liquid internal heat conduction device, starting a stirrer of the liquid internal heat conduction device, introducing nitrogen to remove oxygen, and adding an initiating agent to perform polymerization reaction, thereby preparing a polymerization product; and (3) cutting and granulating the polymerization product, and then adding the polymerization product into a hydrolyzer to perform hydrolysis reaction, thereby preparing ultrahigh-molecular-weight polyacrylamide. According to the preparation method disclosed by the invention, by adopting reasonable proportioning, combining corresponding process conditions and adopting the self-made liquid internal heat conduction device to uniformize the reaction temperature and stabilize the molecular weight of polyacrylamide, the molecular weight of prepared polyacrylamide reaches 3.4*10<7>.

Owner:ZHEJIANG XINYONG BIOCHEM

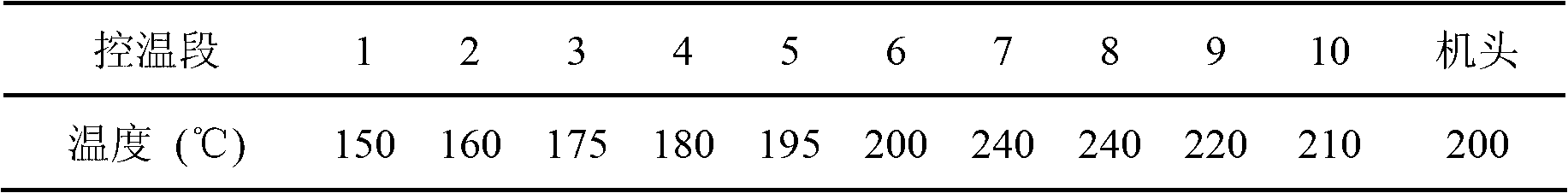

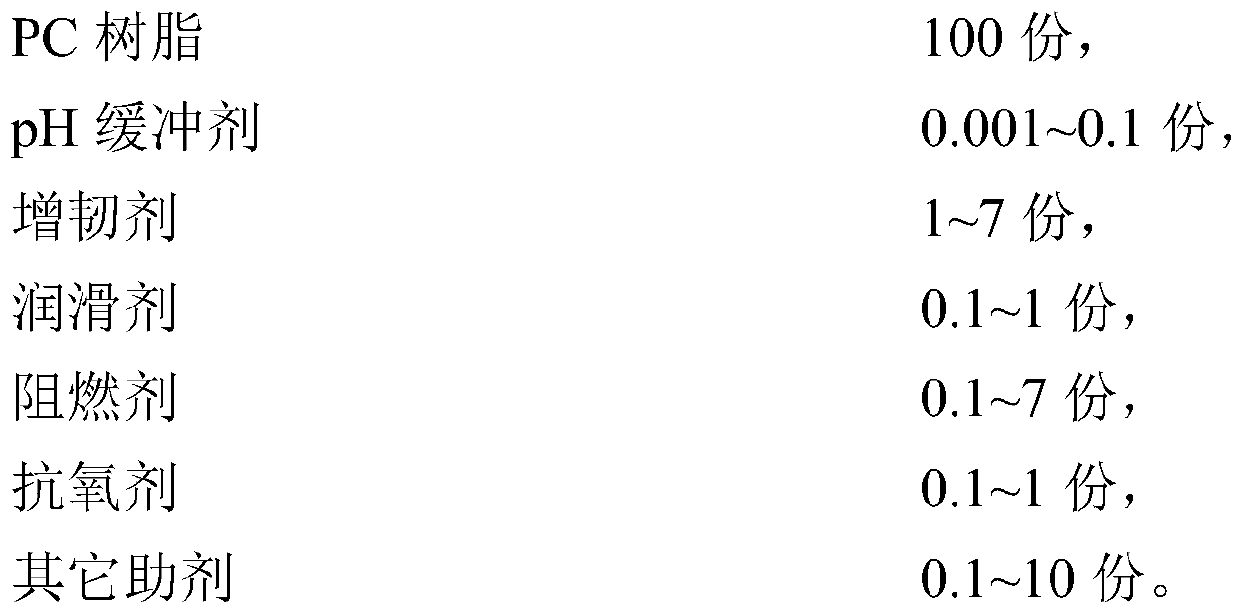

High-temperature-resistant and high-humidity-resistant flame-retardant PC plastic as well as preparation method and application thereof

The invention discloses a high-temperature-resistant and high-humidity-resistant flame-retardant PC plastic as well as a preparation method and application thereof. The flame-retardant PC plastic is prepared from the following raw materials in parts by weight: 100 parts of PC resin, 0.001 to 0.1 part of a pH buffering agent, 1 to 7 parts of a toughening agent, 0.1 to 1 part of a lubricating agent,0.1 to 7 parts of a flame retardant, 0.1 to 1 part of an antioxidant and 0.1 to 10 parts of other auxiliary agents. The preparation method comprises the following steps: uniformly mixing all the rawmaterials in proportion, feeding the mixture into a double-screw extruder through main feeding, plasticizing, exhausting, plasticizing again, vacuumizing, decompressing, extruding and granulating to obtain the product. The high-temperature-resistant and high-humidity-resistant flame-retardant PC plastic is suitable for lighting electric appliances, photovoltaics, IT, mobile phones and the like.

Owner:中广核俊尔(浙江)新材料有限公司 +1

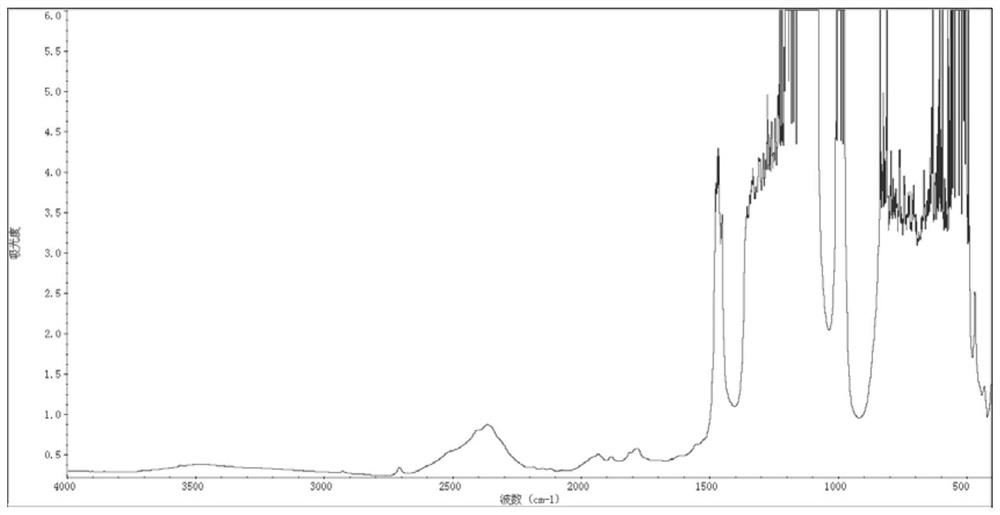

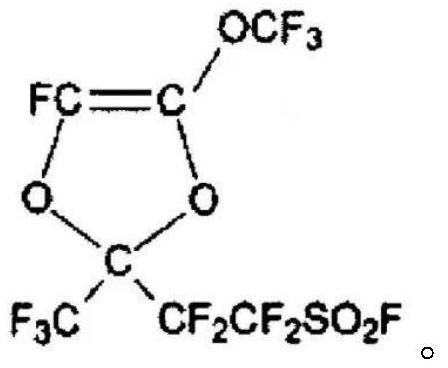

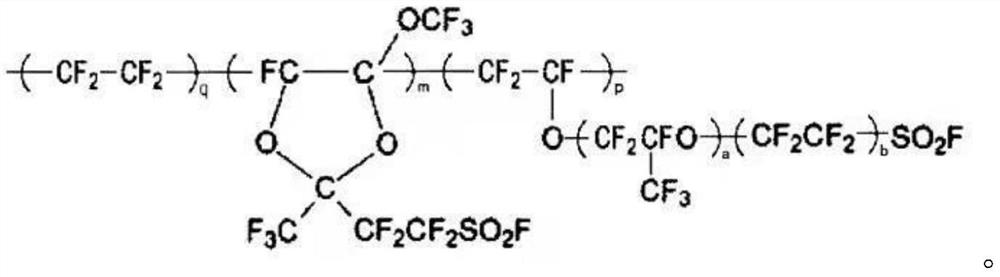

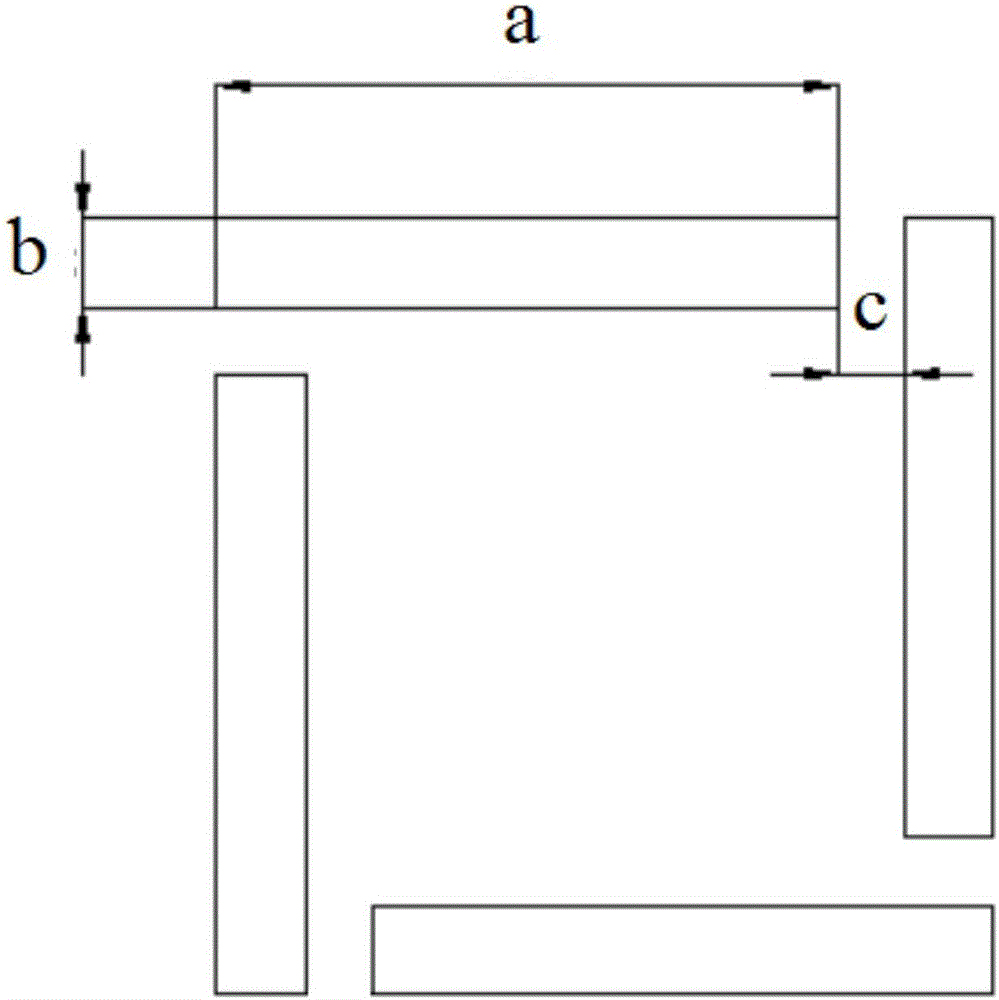

Suspension polymerization preparation method of perfluorinated sulfonic acid resin

The invention discloses a suspension polymerization preparation method of perfluorinated sulfonic acid resin, which comprises the following steps: by taking tetrafluoroethylene A, a monomer B containing a sulfonyl fluoride end group and a monomer C containing a sulfonyl fluoride end group as comonomers, pre-adding deionized water, the monomer B, the monomer C, a dispersing agent and an auxiliary agent into a reactor, replacing until the oxygen content is qualified, adding a catalyst, and reacting for 2-4 hours to obtain the perfluorinated sulfonic acid resin. Stirring is started, tetrafluoroethylene monomers are introduced, an initiator is added to initiate a polymerization reaction, comonomers are supplemented in the reaction process, and finally the sulfonyl fluoride type perfluorinated sulfonic acid resin is obtained. Wherein the structural formula of the monomer B is CF2 = CFO [CF2CF (CF3) O] a [CF2CF2] bSO2F, a is an integer from 0 to 1, and b is an integer from 1 to 2; the structural formula of the monomer C is as follows: the perfluorosulfonic acid resin disclosed by the invention further comprises a fluorine-containing cyclic monomer unit containing a perfluoroalkoxy group of an ether bond and a sulfonyl fluoride group, so that the processability in a general solvent is improved, and the perfluorosulfonic acid resin is high in conductivity and oxygen permeability. The suspension polymerization method has the advantages of stable molecular weight and distribution of the product, simple post-treatment process and low production cost.

Owner:JUHUA GROUP TECH CENT

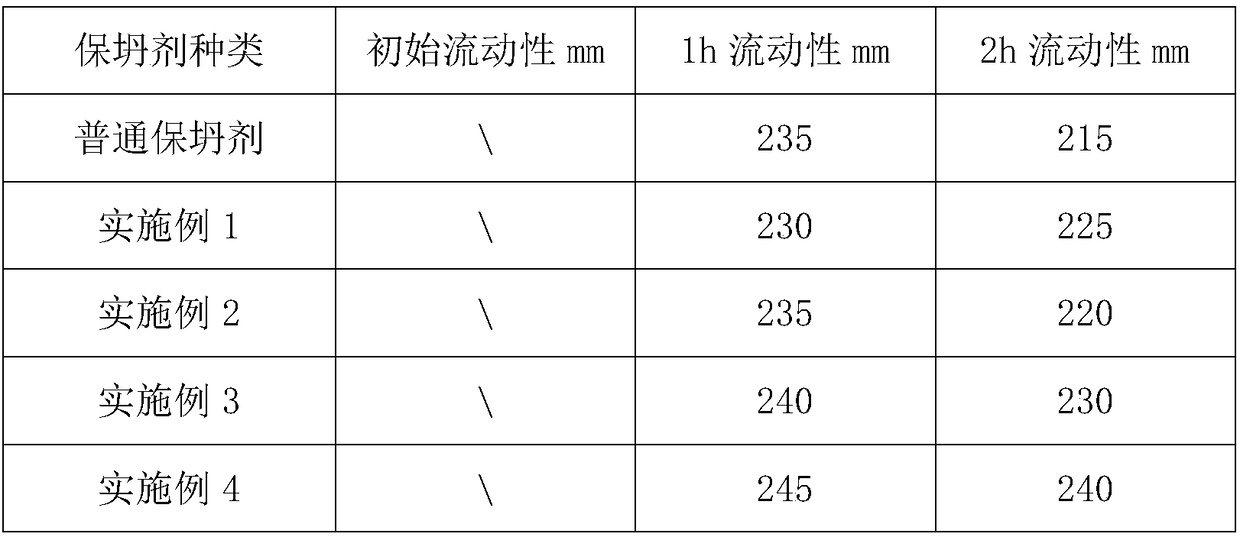

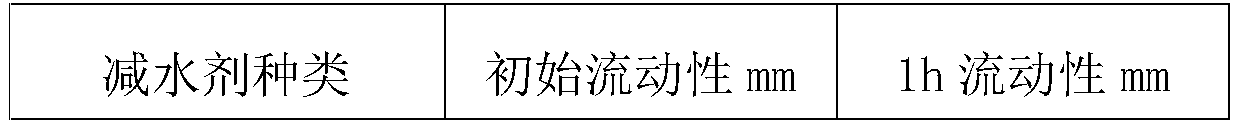

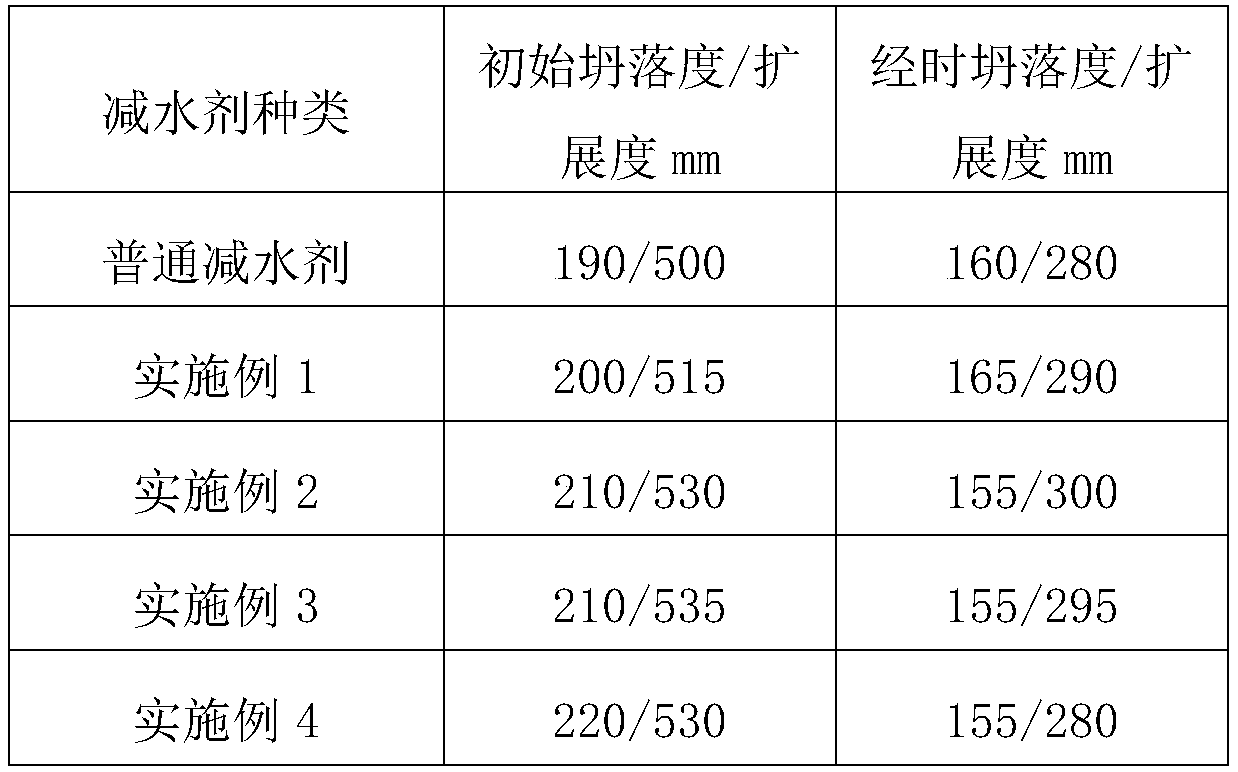

Preparation method of high-adaptability high-solid-content polycarboxylic acid slump retaining agent

The invention provides a preparation method of high-adaptability high-solid-content polycarboxylic acid slump retaining agent. The preparation method comprises the following steps: (1) adding polyether macro monomers and water in a given ratio into a reaction kettle, stirring, heating, and dissolving; (2) controlling the temperature at 70 to 75 DEG C, adding a given amount of solubilizer, chain transferring agent and organic peroxide initiator; (3) 5 minutes later, dropwise adding a solution B, 10 minutes later dropwise adding a solution A, wherein the addition time of the solution A is a hour, the addition time of the solution B is (a+0.5) hours, the solution A is prepared from acrylic alkyl ester, acrylic acid and water in a given ratio, and the solution B is prepared from an azo initiator, an alcohol organic solvent and water; and (4) after the dropwise addition is completed, raising the temperature to 95 to 98 DE C, keeping the temperature constant, curing for b hours, then cooling, slicing, and packaging, thus obtaining the high-adaptability high-solid-content polycarboxylic acid slump retaining agent with the solid content of 92 to 98 percent. The product obtained by the method provided by the invention has the characteristics of high solid content, good adaptability, good slump retaining performance and the like and is suitable for industrialized production.

Owner:HUBEI UNIV OF TECH

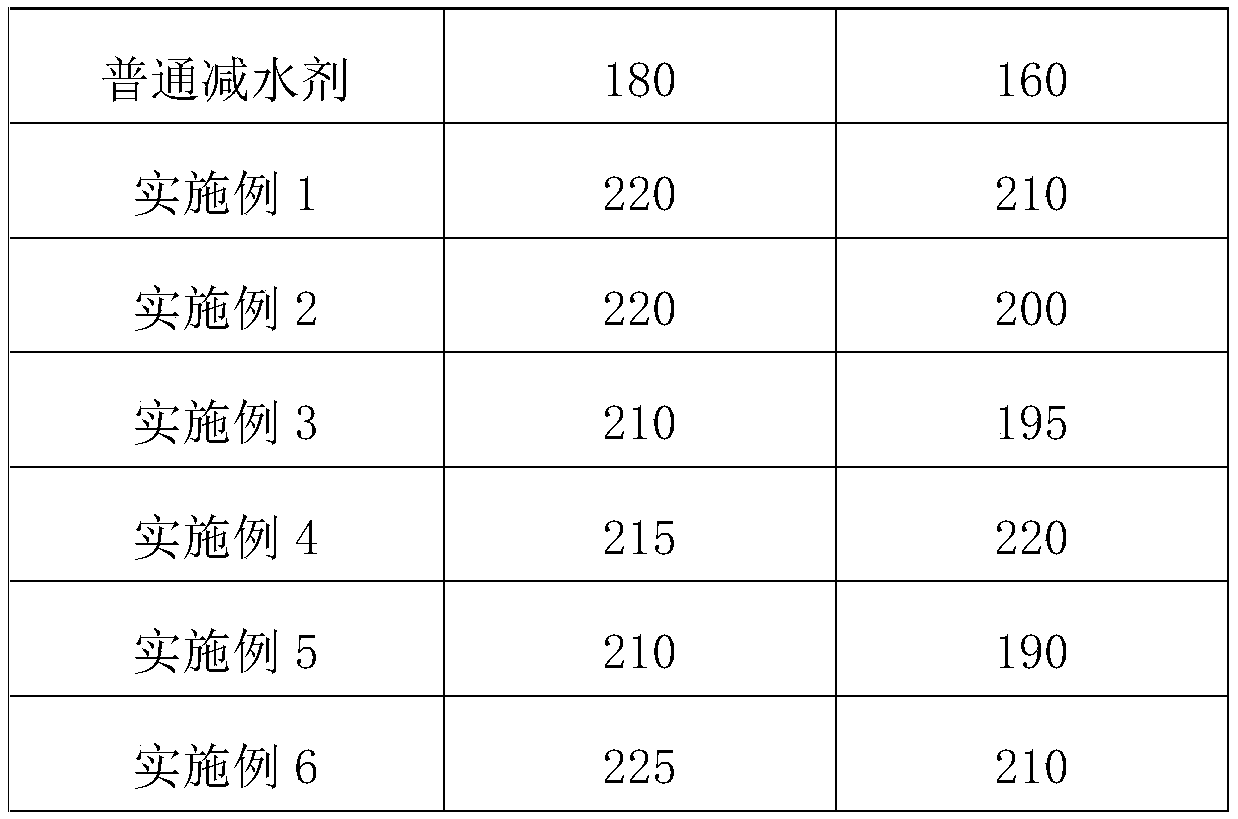

Preparation method of polycarboxylate water reducer with high adaptability and high solid content

The invention provides a preparation method of a polycarboxylate water reducer with high adaptability and high solid content. The preparation method comprises the following steps: 1) adding a polyether macromonomer and water to a reactor according to a certain proportion, stirring and heating till being dissolved; 2) controlling the temperature to be 70 to 75 DEG C, starting to add a certain amount of an organic peroxygen initiator, a solubilizer and a chain transfer agent; 3) after 5min, starting to add a solution B, and after 10min, starting to add a solution A, wherein the dropping time ofthe solution A is a hours, and the dropping time of the solution B is a+0.5 hours; the solution A comprises acrylic acid and water in a certain proportion, and the solution B comprises an azo initiator and an alcohol organic solvent; 4) after dropwise adding, rising the temperature to 95 to 98 DEG C, keeping the temperature constant, curing for b hours, later cooling, slicing and packing to obtainthe polycarboxylate water reducer with the high adaptability and high solid content. The product prepared by the invention has the characteristics of high solid content, good adaptability, high water-reducing rate, good slump retention ability and the like and is suitable for industrial production.

Owner:HUBEI UNIV OF TECH

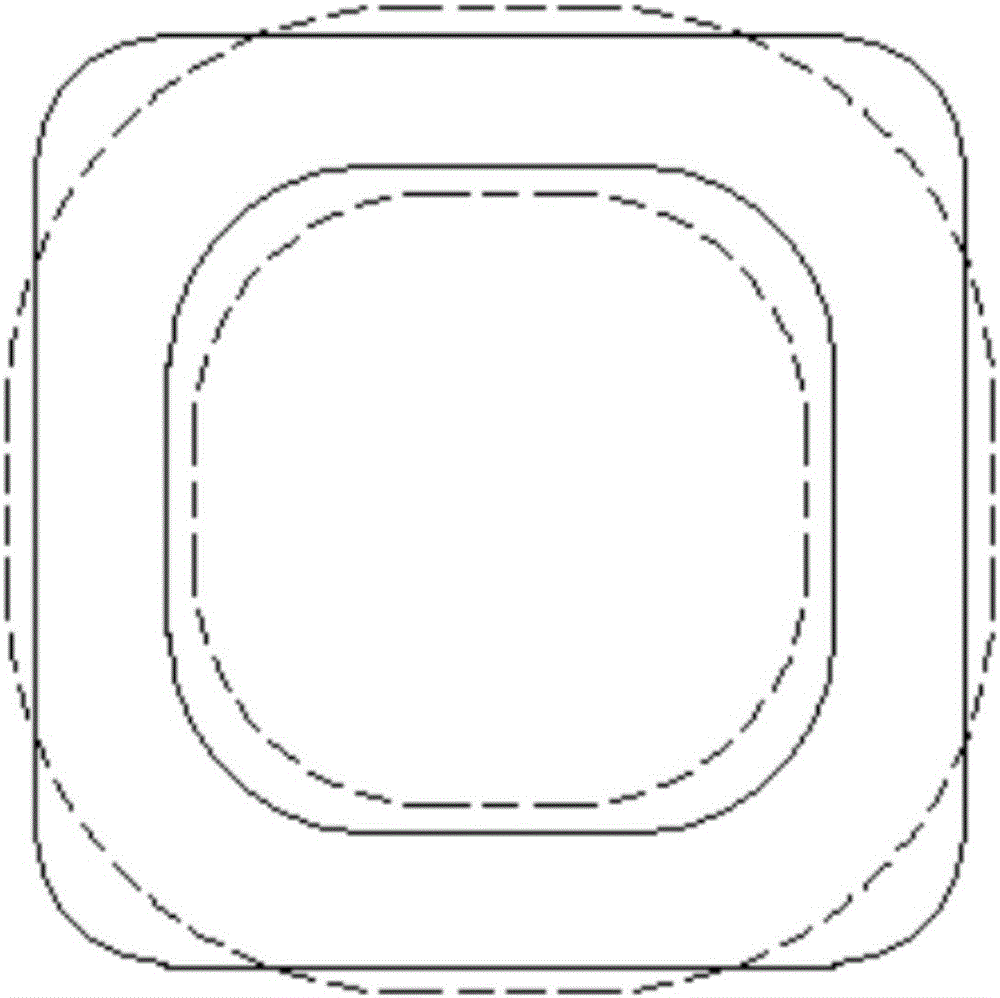

Square hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106835336AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureFilament/thread formingChemistrySaturated fatty acid

The invention belongs to the field of polyester spinning, and relates to a square hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains a saturated fatty acid metal salt and modified polyester; the mass ratio of the saturated fatty acid metal salt to the modified polyester is (0.0005-0.002):1; the saturated fatty acid metal salt is a fatty acid metal salt of which the carbon atom number is 12-22, the melting point is 100-180 DEG C and the power viscosity is less than or equal to 1Pa*s; the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment; the mole ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05):1; the die swell ratio of the spinning melt is 1.21-1.32; the after-filtration pressure of the spinning melt in spinning is 82-123kg / cm<2>. The square hollow polyester fiber FDY provided by the invention is relatively high in hollowness degree and relatively good in conformal effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Environmental-friendly extraction purification method for algal polysaccharide sulfate

The invention relates to the field of pharmacies and discloses an environmental-friendly extraction purification method for algal polysaccharide sulfate. The method comprises the following steps: (1)crushing dry kelp into small pieces, adding 16 times of first-grade purified water, heating till refluxing, and extracting for 5 hours; (2) concentrating an extract, adding 1% calcium chloride into aconcentrated liquid, and leaving to stand for one hour; (3) carrying out primary filtration on a medicinal liquid by using a rotary drum vacuum filtering machine, centrifuging, and filtering centrifuged supernate twice by using a kieselguhr filtration aid filtering system; (4) carrying out two-step ultrafiltration on filtrate; (5) concentrating a medicinal liquid, and decoloring with activated carbon; (6) adding 10% potassium chloride into a concentrated liquid, adding ethanol for a secondary time till an alcohol content is up to 70%, leaving to stand so as to obtain precipitate, centrifuging,and washing filter cakes with 95% ethanol; (7) carrying out vacuum drying on the filter cakes for 4 hours at 60 DEG C; (8) crushing a dried substance, so as to obtain algal polysaccharide sulfate ofmilky white or a light yellow powder. Tests show that the yield of the algal polysaccharide sulfate is increased to 1.2-1.3% from conventional 0.2-0.3%, and a remarkable effect can be achieved.

Owner:吉林省辉南长龙生化药业股份有限公司

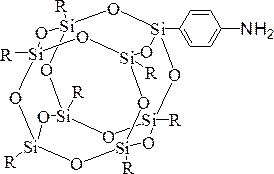

A kind of low dielectric polyimide composite film and preparation method thereof

ActiveCN109228586BLow dielectric constantReduce thicknessSynthetic resin layered productsCoatingsAdhesive cementPolymer science

The invention discloses a low-dielectric polyimide composite film, comprising a thermosetting polyimide layer and a thermoplastic polyimide adhesive layer, and the thermoplastic polyimide adhesive layer covers the thermosetting polyimide layer At least one side of said thermosetting polyimide layer and / or thermoplastic polyimide adhesive layer contains cage polysilsesquioxane. The present invention also correspondingly provides a method for preparing the above-mentioned low-dielectric polyimide composite film. In the present invention, cage-type polysilsesquioxane is introduced into the thermosetting polyimide layer and the thermoplastic polyimide adhesive layer, and after being dispersed in the polyimide, molecular-scale holes are introduced into the polyimide, It can effectively reduce the dielectric constant of polyimide film. In addition, the present invention uses a thermoplastic polyimide adhesive layer instead of a traditional adhesive layer, which can reduce the thickness of the film layer while ensuring excellent bonding performance.

Owner:株洲时代华昇新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com