Preparation method of an iron and carbohydrate complex

A technology of carbohydrates and complexes, which is applied in the field of preparation of iron carbohydrate complexes and carboxymaltose iron, which can solve the problems of large molecular weight difference, large polydispersity index, and low product uniformity, and achieve good uniformity and high product quality. The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

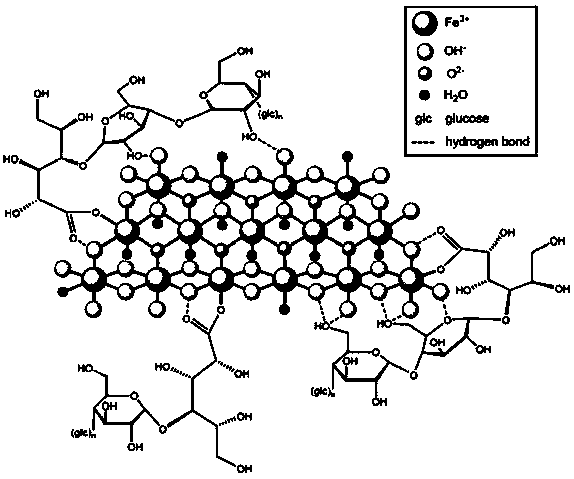

Image

Examples

Embodiment 1

[0029] Embodiment 1 Preparation of carboxymaltose iron

[0030] At 20-35°C, stir and dissolve 100g of maltodextrin (DE=11) in 300ml of purified water, add 13.8g of trioctylmethylammonium chloride and 0.7g of sodium bromide in turn, stir, and keep it at pH 10-10.5 Add 50g of tert-butyl hypochlorite, react for 3 hours, and adjust the pH to 13.0-13.5 with 30% NaOH solution.

[0031] Slowly add 432g ferric chloride solution (9.8% Fe, 205g ferric chloride hexahydrate dissolved in 227g water), 620g sodium carbonate solution (16.8%, 104g sodium carbonate dissolved in 516g water) to the above oxidized maltose In dextrin, react for 9 hours, adjust the pH to 10.5-11.5 with 30% sodium hydroxide solution, heat the solution to 45-50°C, react for 30 minutes, then adjust the pH to 5.0-6.0 with 37% hydrochloric acid, React at ~50°C for 30 minutes, then heat to 95-100°C, and continue to react for 30 minutes. After the solution was cooled to room temperature, the pH was adjusted to 6.0-6.5. ...

Embodiment 2

[0033]Embodiment 2 Preparation of carboxymaltose iron

[0034] Stir and dissolve 100g of maltodextrin (DE=11) in 300ml of purified water at 20-35°C, add 13g of tributylmethylammonium chloride and 0.7g of sodium bromide in turn, stir, and add 40g of it at pH 10-10.5 Tert-butyl hypochlorite, reacted for 3 hours, and adjusted the pH to 13.0-13.5 with 30% NaOH solution.

[0035] Slowly add 432g ferric chloride solution (9.8% Fe) and 620g sodium carbonate solution (16.8%) to the above oxidized maltodextrin, react for 10 hours, adjust the pH to 11.5-12.5 with 30% sodium hydroxide solution , heat the solution to 45-50°C, react for 30 minutes, then adjust the pH to 5.0-6.0 with 37% hydrochloric acid, react at 45-50°C for 30 minutes, then heat to 90-100°C, and continue the reaction for 30 minutes. After the solution was cooled to room temperature, the pH was adjusted to 6.0-6.5.

[0036] Add 20g of activated carbon to the reaction solution, filter it with diatomaceous earth after sti...

Embodiment 3

[0037] Embodiment 3 Preparation of carboxymaltose iron

[0038] At 20-35°C, stir and dissolve 100g of maltodextrin (DE=11) in 300ml of purified water, add 13.8g of trioctylmethylammonium chloride and 0.7g of sodium bromide in turn, stir, and keep it at pH 10-10.5 Add 16.5g sodium hypochlorite solution (14.6% active chlorine), 30g tert-butyl hypochlorite, react for 3 hours, and adjust the pH to 13.0-13.5 with 30% NaOH solution.

[0039] Slowly add 432g ferric chloride solution (9.8% Fe) and 620g sodium carbonate solution (16.8%) to the above oxidized maltodextrin, react for 8 hours, adjust the pH to 10.5-11.5 with 30% sodium hydroxide solution , heat the solution to 45-50°C, react for 30 minutes, then adjust the pH to 5.0-6.0 with 37% hydrochloric acid, react at 45-50°C for 30 minutes, then heat to 95-100°C, and continue the reaction for 30 minutes. After the solution was cooled to room temperature, the pH was adjusted to 6.0-6.5.

[0040] Add 20g of activated carbon to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com