Preparation method of polycarboxylate water reducer with high adaptability and high solid content

An adaptable, high-solids technology, applied in the field of building materials and concrete admixtures, can solve the problems of equipment duplication, high cost, performance degradation, etc., and achieve the effect of smooth transition, enlarged molecular weight distribution, and stable molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

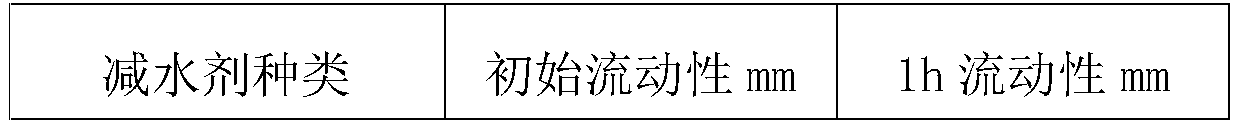

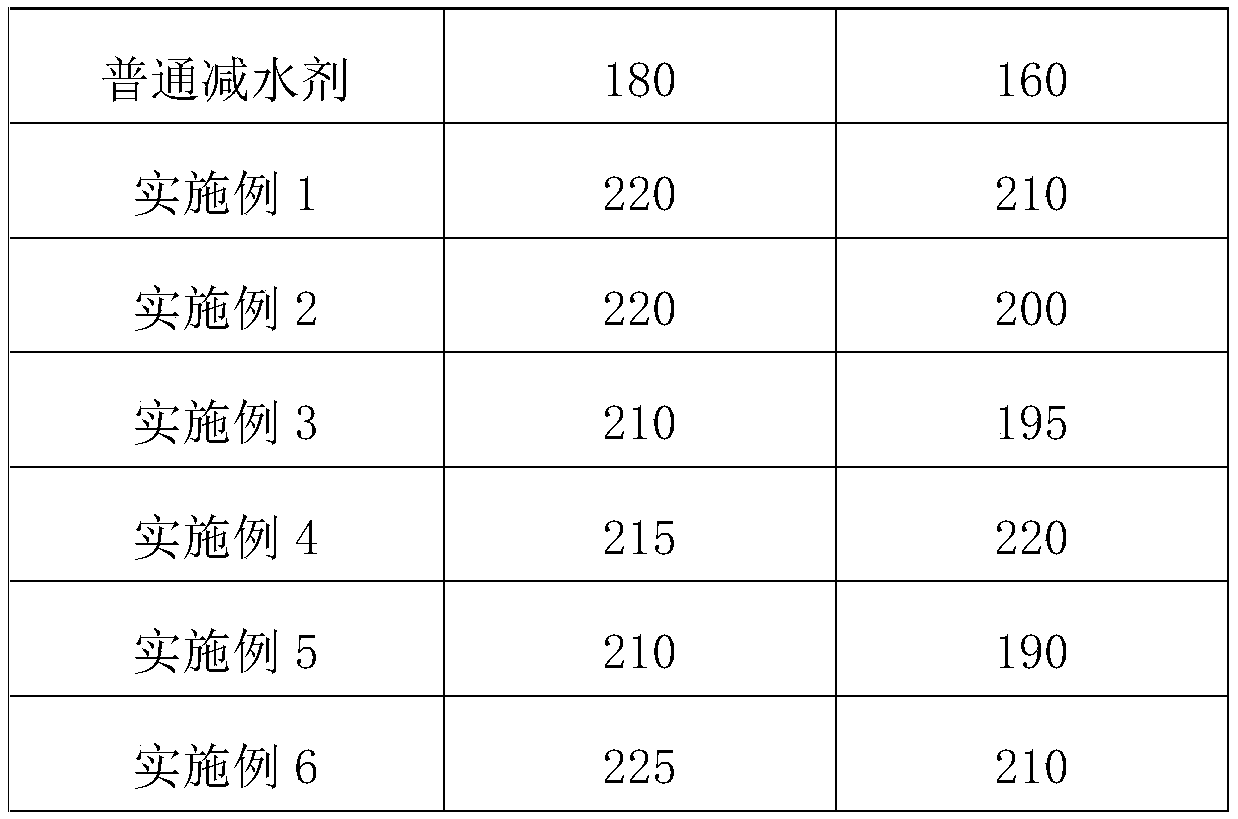

Examples

Embodiment 1

[0032] A highly adaptable high solid polycarboxylate water reducer, characterized in that: the highly adaptable high solid polycarboxylate water reducer is prepared from the following components: polyether macromonomer, azo Initiator, alcoholic organic solvent, acrylic acid, organic peroxygen initiator, solubilizer, chain transfer agent, neutralizing agent; the preparation method comprises the following steps:

[0033] 1) Add 590 parts of prenol polyoxyethylene ether and 220 parts of water into the reaction kettle, stir and heat until it dissolves;

[0034]2) Measure the temperature in the kettle, control the temperature at 70°C, and after the temperature is stable, add 2.2 parts of a composition of sodium tripolyphosphate and magnesium lauryl sulfate with a mass ratio of 1:2 at one time, and 7 parts with a mass ratio of 1:2. 1 composition of sodium styrene sulfonate and 2-acrylamide-2-methylpropanesulfonic acid, 2.5 parts of tert-butyl peroxy t-valerate and diisopropyl peroxy...

Embodiment 2

[0038] A highly adaptable high solid polycarboxylate water reducer, characterized in that: the highly adaptable high solid polycarboxylate water reducer is prepared from the following components: polyether macromonomer, azo Initiator, alcoholic organic solvent, acrylic acid, organic peroxygen initiator, solubilizer, chain transfer agent, neutralizing agent; the preparation method comprises the following steps:

[0039] 1) Add 603 parts of vinyl butyl ether polyoxyethylene ether and 210 parts of water into the reaction kettle, stir and heat until it dissolves;

[0040] 2) Measure the temperature in the kettle, control the temperature at 72°C, and after the temperature is stable, add 3.8 parts of a composition of sodium tripolyphosphate and magnesium lauryl sulfate at a mass ratio of 1:1 at one time, and 9 parts with a mass ratio of 1:1 1 composition of sodium styrene sulfonate and sodium hypophosphite, 2.8 parts of tert-butyl peroxy tert-valerate;

[0041] 3) After 5 minutes, ...

Embodiment 3

[0044] A highly adaptable high solid polycarboxylate water reducer, characterized in that: the highly adaptable high solid polycarboxylate water reducer is prepared from the following components: polyether macromonomer, azo Initiator, alcoholic organic solvent, acrylic acid, organic peroxygen initiator, solubilizer, chain transfer agent, neutralizing agent; the preparation method comprises the following steps:

[0045] 1) Add 615 parts of allyl polyoxyethylene ether and 200 parts of water into the reaction kettle, stir and heat until it dissolves;

[0046] 2) Measure the temperature in the kettle, control the temperature at 72°C, and after the temperature is stable, add 2.4 parts of a composition of sodium tripolyphosphate and sodium lauryl sulfate at a mass ratio of 2:1 at one time, and 6 parts with a mass ratio of 1: 1 composition of sodium methacrylsulfonate and 2-acrylamide-2-methylpropanesulfonic acid, 3 parts of diisopropyl peroxydicarbonate;

[0047] 3) After 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com