A kind of low dielectric polyimide composite film and preparation method thereof

A polyimide, composite film technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve problems affecting the uniformity of film properties, FPC heat resistance, unsatisfactory electrical properties, thick thickness And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

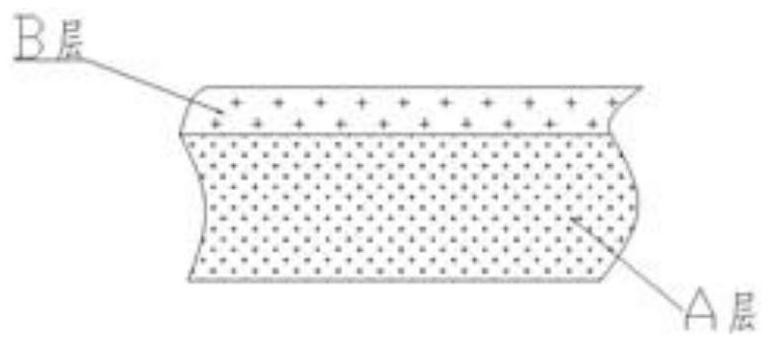

[0036] Such as figure 1 As shown, a double-layer low-dielectric polyimide composite film, including a thermosetting polyimide layer, a thermoplastic polyimide adhesive layer and cage polysilsesquioxane (POSS), thermoplastic polyimide The adhesive layer is bonded to one side of the thermosetting polyimide layer, and the cage polysilsesquioxane is dispersed in the thermosetting polyimide layer. Wherein, the thickness of the thermosetting polyimide layer is 25 μm, and the thickness of the thermoplastic polyimide adhesive layer is 3 μm.

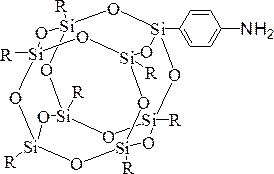

[0037] In the above-mentioned double-layer low-dielectric polyimide composite film, POSS is selected from the aforementioned structural formula (IV).

[0038] The preparation method of the above-mentioned double-layer low-dielectric polyimide composite film comprises the following steps:

[0039] (1) Preparation of precursor resin a: first dissolve 40.0kg of 4,4'-diaminodiphenyl ether, 2.1kg of p-phenylenediamine and 23.0kg of POSS (Ⅳ) in 468.8...

Embodiment 2

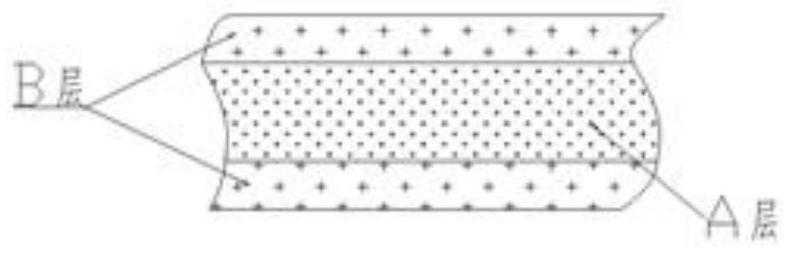

[0043] A double-layer low-dielectric polyimide composite film, comprising a thermosetting polyimide layer, a thermoplastic polyimide adhesive layer and cage polysilsesquioxane (POSS), a thermoplastic polyimide adhesive layer bonded Bonded to one side of the thermosetting polyimide layer, the cage polysilsesquioxane is dispersed in the thermosetting polyimide layer and the thermoplastic polyimide adhesive layer. Wherein, the thickness of the thermosetting polyimide layer is 25 μm, and the thickness of the thermoplastic polyimide adhesive layer is 5 μm.

[0044] In the above-mentioned double-layer low-dielectric polyimide composite film, the POSS is selected from the aforementioned structural formulas (II) and (IV).

[0045] The preparation method of the above-mentioned double-layer low-dielectric polyimide composite film comprises the following steps:

[0046] (1) Preparation of precursor resin a: first dissolve 43.2kg of 4,4'-diaminodiphenyl ether, 2.1kg of p-phenylenediamine...

Embodiment 3

[0050] A double-layer low-dielectric polyimide composite film, comprising a thermosetting polyimide layer, a thermoplastic polyimide adhesive layer and cage polysilsesquioxane (POSS), a thermoplastic polyimide adhesive layer bonded Bonded to one side of the thermosetting polyimide layer, the cage polysilsesquioxane is dispersed in the thermosetting polyimide layer and the thermoplastic polyimide adhesive layer. Wherein, the thickness of the thermosetting polyimide layer is 25 μm, and the thickness of the thermoplastic polyimide adhesive layer is 6 μm.

[0051] In the above-mentioned double-layer low-dielectric polyimide composite film, the POSS is selected from the aforementioned structural formulas (III) and (V).

[0052] The preparation method of the above-mentioned double-layer low-dielectric polyimide composite film comprises the following steps:

[0053] (1) Preparation of precursor resin a: first dissolve 45.6kg of 4,4'-diaminodiphenylmethane, 2.2kg of p-phenylenediamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com