Copper-bearing linear self-polishing marine anti-fouling paint

A marine anti-fouling and self-polishing technology, applied in the field of coatings, can solve the problems of unstable anti-fouling performance and slow release rate of Cu ions, and achieve the effects of comprehensive anti-fouling period, long anti-fouling period and stable anti-fouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

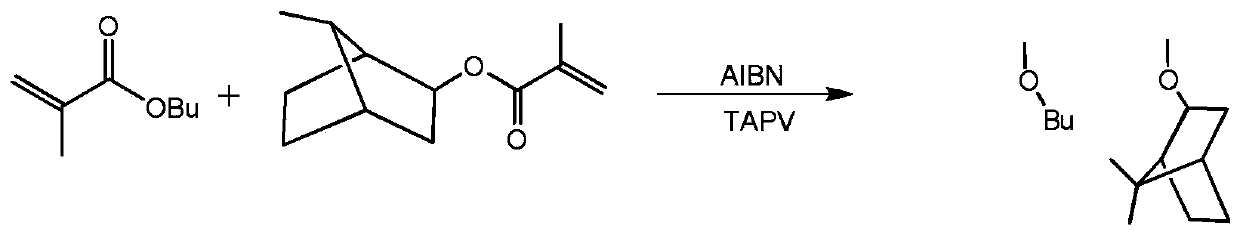

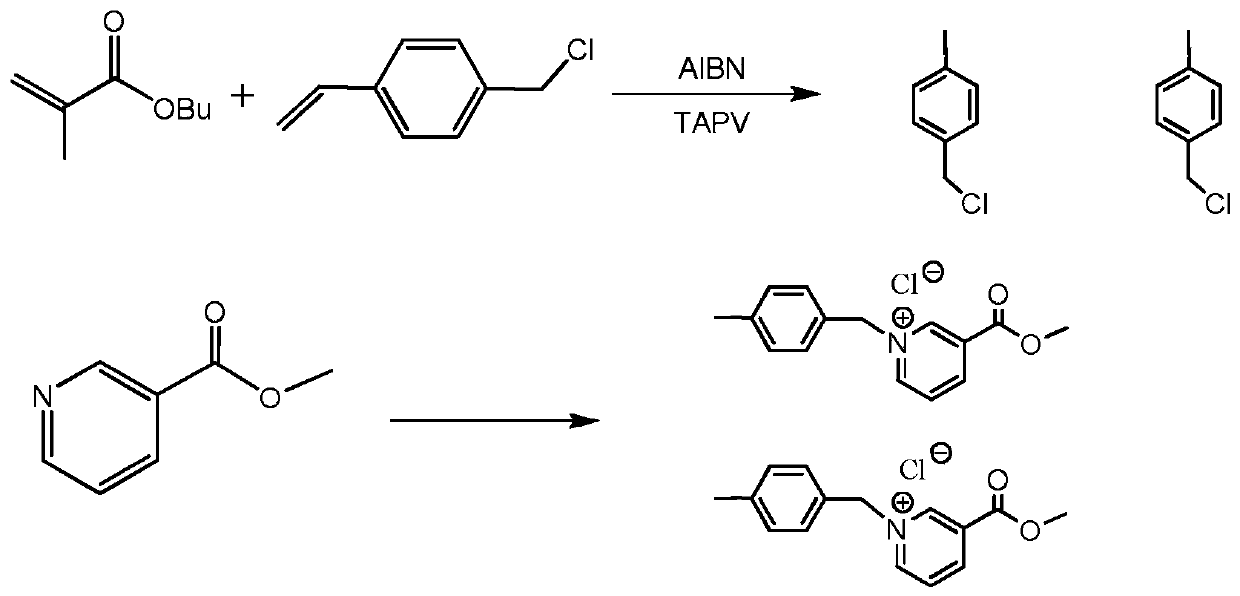

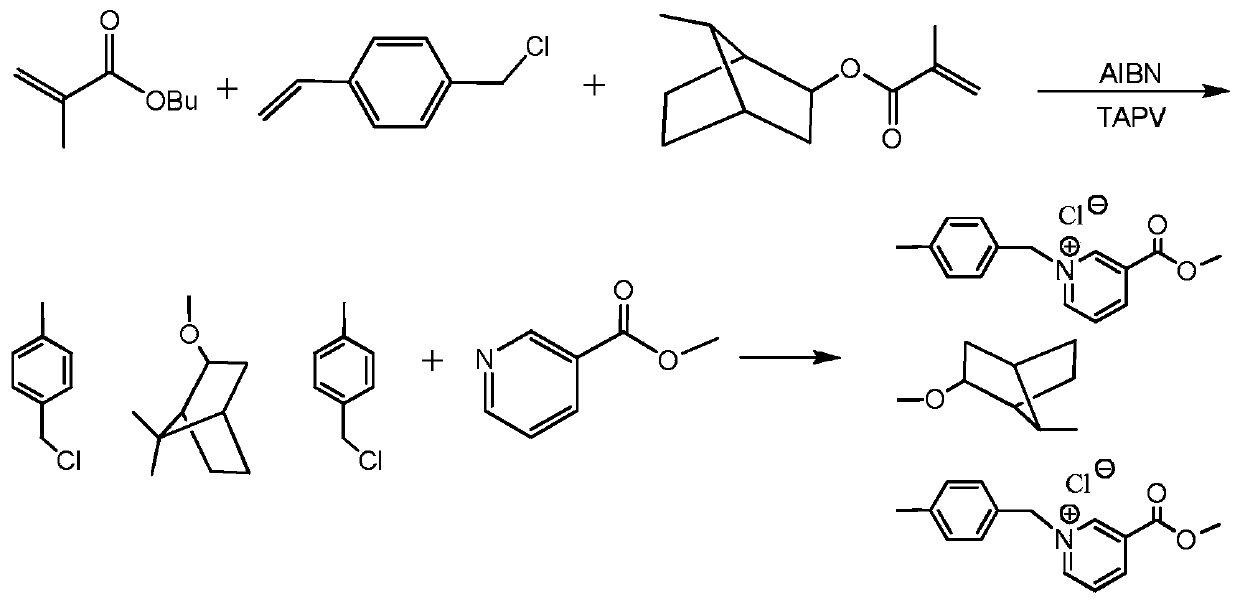

Method used

Image

Examples

Embodiment 1

[0308] Low copper content linear self-polishing marine antifouling coating formulation composition:

[0309]

[0310]

Embodiment 2

[0312] The high-copper-containing linear self-polishing marine antifouling paint is compounded with 2-year and 3-year formulations according to different deadlines.

[0313]1. Two-year high copper-containing linear self-polishing marine antifouling coating formula composition:

[0314]

[0315]

[0316] 2. Three-year high-copper-containing linear self-polishing marine antifouling coating formula composition:

[0317]

[0318]

2 weeks

4 weeks

6 weeks

8 weeks

10 weeks

12 weeks

14 weeks

16 weeks

C1A4

11.2

7.6

4.3

2.8

2.9

3.3

2.8

2.7

C1B4

13.3

9.3

6.2

4.5

4.9

4.2

4.6

4.3

C1C4

14.5

10.4

8.7

6.4

6.5

6.6

6.3

6.1

C1D4

13.3

8.9

7.1

5.1

5.0

4.6

5.1

4.9

C5A4

18.2

13.3

9.5

6.8

6.9

6.7

6.6

6.5

C6A4

18.3

13.2

8.8

7.3

7.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com