N-tetradecanol phase change microcapsule and preparation method thereof

A phase-change microcapsule, n-tetradecanol technology, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of slow heat transfer, poor temperature resistance of wall materials, etc., and achieves large latent heat, production safety, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Preparation of the water phase: the sodium chloride of 20g is dissolved in the deionized water of 100g, the 1% sodium nitrite aqueous solution of 1g and the 1% methyl cellulose aqueous solution of 1g are added, then the 25% colloidal dihydrogen of 10g is added Silicon oxide aqueous solution, and then add 9% hydrochloric acid aqueous solution to adjust the pH value of the solution to 4, adjust the temperature to 40° C., and stir at a speed of 500 rpm until a uniform aqueous solution is formed.

[0066] (2) Preparation of the oil phase: mix 15g of molten n-tetradecyl alcohol with 6g of acrylonitrile, 3.5g of butyl acrylate, 0.5g of methacrylic acid, 0.12g of benzoyl peroxide and 0.2g of trimethylolpropane trimethyl Base acrylate mixed, ultrasonic 5min, to get a homogeneous oil phase.

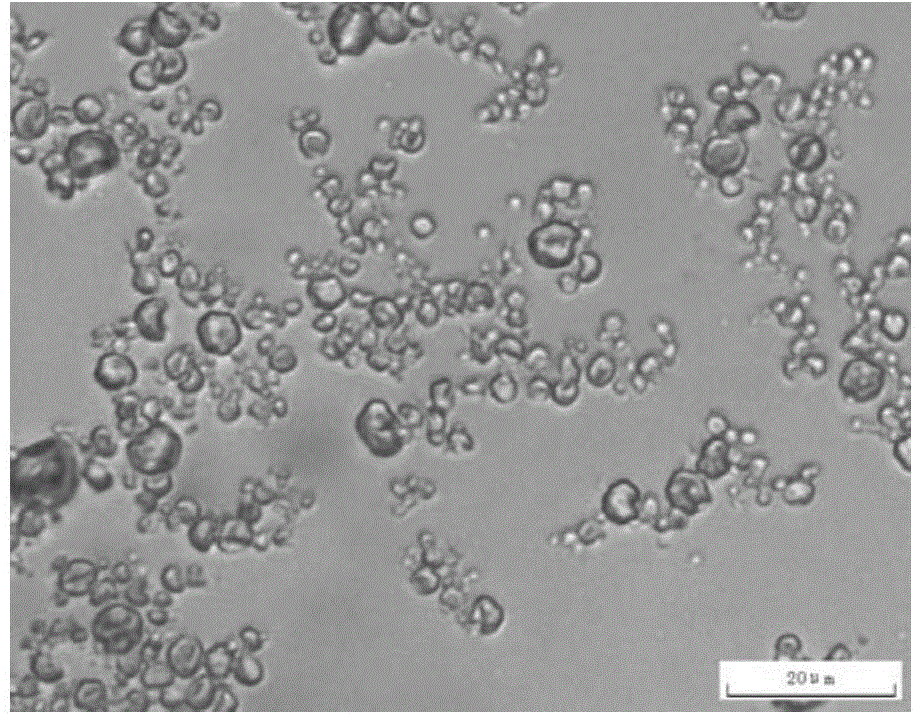

[0067] (3) Preparation of phase-change microcapsules: Slowly drop the oil phase into the water phase, keep the temperature at 40°C, and homogenize at a speed of 1200rpm for 30min, so th...

Embodiment 2

[0069] (1) Preparation of the water phase: the sodium chloride of 20g is dissolved in the deionized water of 100g, the 1% sodium nitrite aqueous solution of 1g and the 1% methyl cellulose aqueous solution of 1g are added, then the 25% colloidal dihydrogen of 10g is added Silicon oxide aqueous solution, and then add 9% hydrochloric acid aqueous solution to adjust the pH value of the solution to 4, adjust the temperature to 40° C., and stir at a speed of 500 rpm until a uniform aqueous solution is formed.

[0070] (2) Preparation of oil phase: mix 18g of molten n-tetradecyl alcohol with 7g of acrylonitrile, 2.5g of butyl acrylate, 0.5g of methacrylic acid, 0.12g of azobisisobutyronitrile and 0.2g of trimethylolpropane Methacrylates were mixed and ultrasonicated for 5 minutes to obtain a homogeneous oil phase.

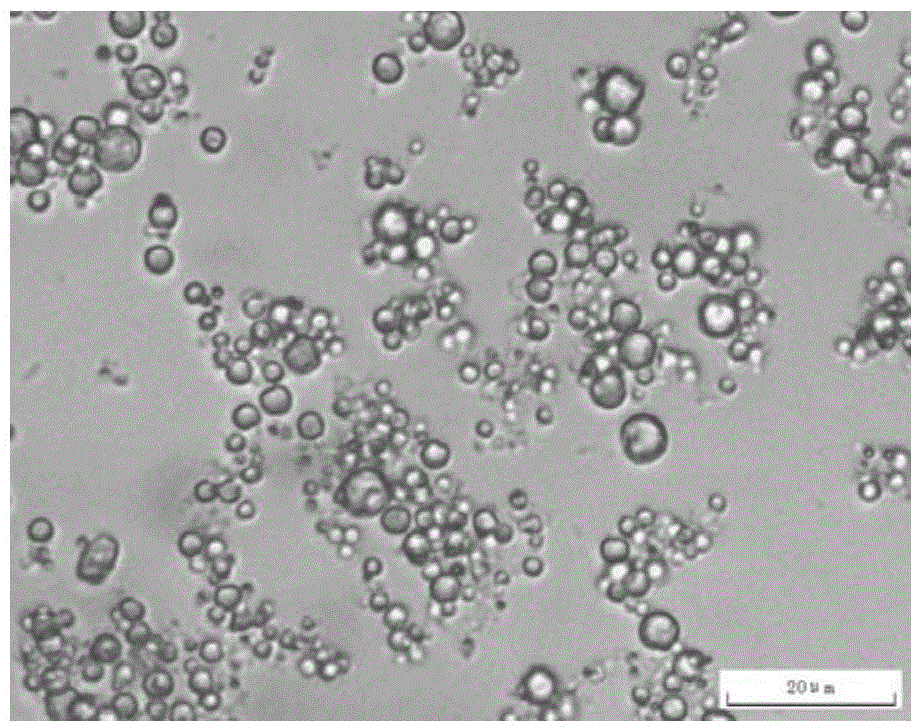

[0071] (3) Preparation of phase-change microcapsules: Slowly drop the oil phase into the water phase, keep the temperature at 40°C, and homogenize at a speed of 1200rpm f...

Embodiment 3~10

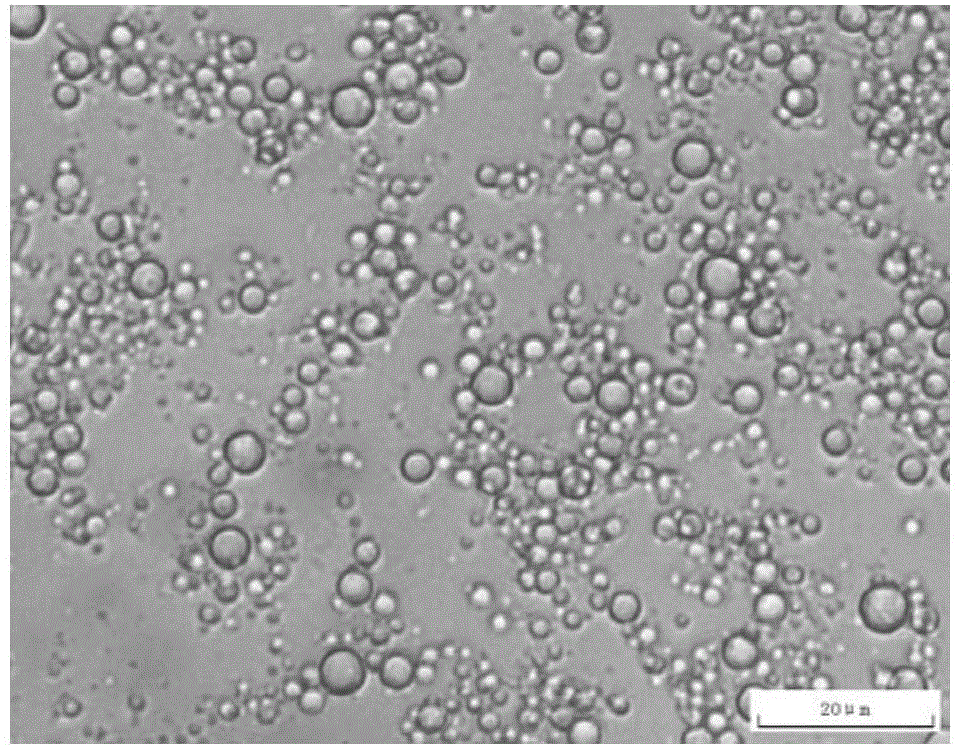

[0073] Except changing the type and amount of monomers used, crosslinking agents, initiators and the amount of core material and polymerization temperature (see Table 1 for details), other conditions are the same as in Example 1, and different phase change microcapsules are prepared. The properties are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com