Method for rapidly controlling quality of animal glue products

A technology for product quality and rapid control, applied in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, and the measurement of color/spectral properties. Quality consistency, subjectivity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

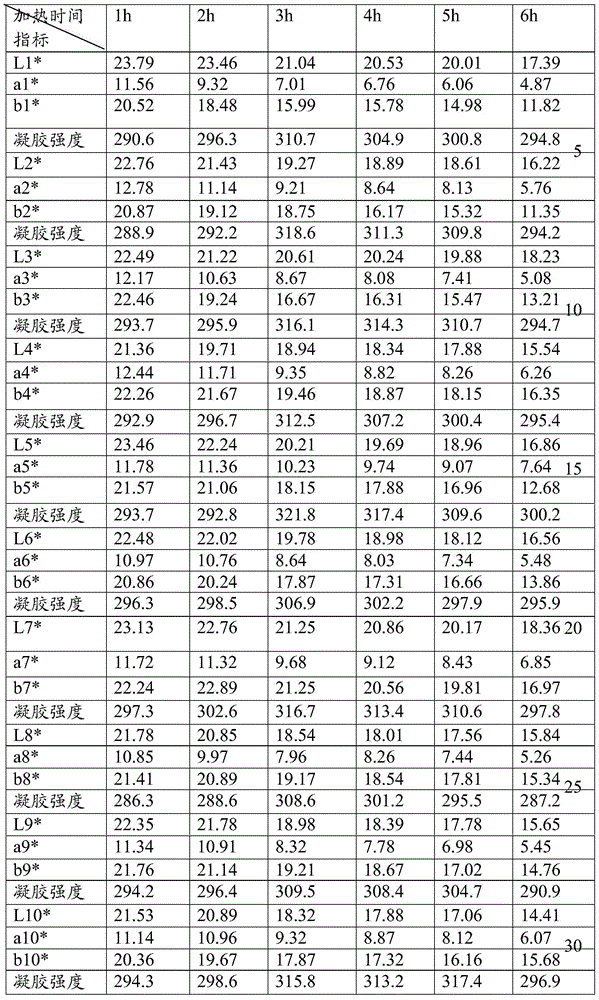

[0015] In the process of gelatin gelatin concentration and gelatinization, after the auxiliary materials—rice wine, rock sugar, and soybean oil are added, adjust the pressure of the steam to control the gelation time within 1, 2, 3, 4, 5, and 6 hours, and control the moisture content. Between 25-26%, take a sample, place it in a transparent vessel, and measure it. Set up and calibrate the colorimeter before measuring the color of the glue: first turn on the power of the colorimeter, select the D65 light source, and select the CIE Lab and CIE1967Eab modes for the color space and index; according to the CIE standard, the observer angle is 10°, and the sample average is set The number of measurements is 3, and then the black and white plate calibration is performed. After the instrument is calibrated, the container containing the glue solution is placed in the measurement port for measurement. The color difference results are shown in Table 1.

[0016] When the water content of ...

Embodiment 2

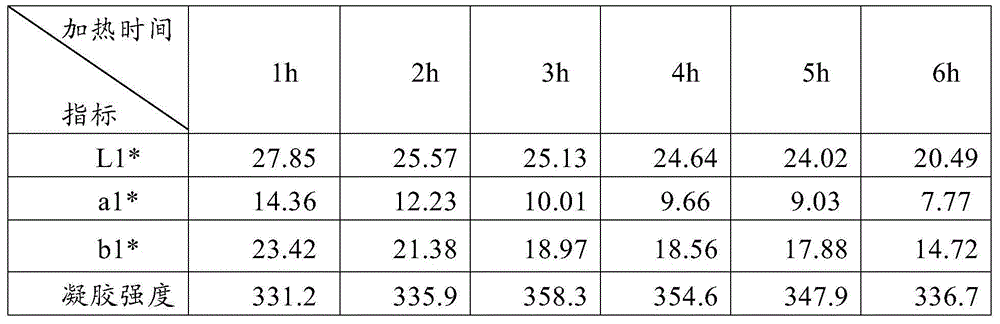

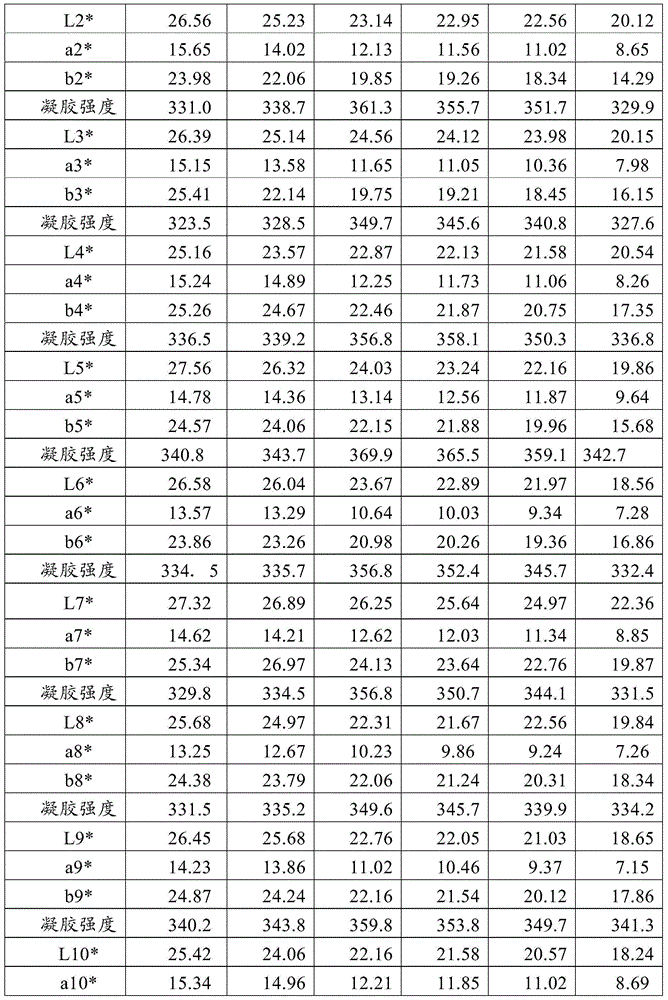

[0021] In the process of concentrating and extruding the deer horn glue, after the auxiliary materials—rice wine, rock sugar, and soybean oil are added, adjust the pressure of the steam so that the glue exuding time is controlled within 1, 2, 3, 4, 5, and 6 hours, and the moisture Control it between 22-23%, take a sample, place it in a transparent vessel, and measure it. Set up and calibrate the colorimeter before measuring the color of the glue: first turn on the power of the colorimeter, select the D65 light source, and select the CIE Lab and CIE1967Eab modes for the color space and index; according to the CIE standard, the observer angle is 10°, and the sample average is set The number of measurements is 3, and then the black and white plate calibration is performed. After the instrument is calibrated, the container containing the glue solution is placed in the measurement port for measurement. The color difference results are shown in Table 2.

[0022] When the water cont...

Embodiment 3

[0029] In the process of concentrating the tortoise shell glue, after the auxiliary materials—rice wine, rock sugar, and soybean oil are added, adjust the pressure of the steam to control the glue out time within 1, 2, 3, 4, 5, and 6 hours. Between 22-23%, take a sample, place it in a transparent vessel, and measure it. Set up and calibrate the colorimeter before measuring the color of the glue: first turn on the power of the colorimeter, select the D65 light source, and select the CIE Lab and CIE1967Eab modes for the color space and index; according to the CIE standard, the observer angle is 10°, and the sample average The number of measurements is 3, and then the black and white plate calibration is performed. After the instrument is calibrated, the container containing the glue solution is placed in the measurement port for measurement. The color difference results are shown in Table 3.

[0030]When the moisture content of the glue solution is 22-23%, take a sample into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com