Linear self-polishing antifouling resin rich in biological bactericide, and copper-free marine antifouling coating containing linear self-polishing antifouling resin

A biocidal agent and antifouling resin technology, applied in the field of copper-free marine antifouling coatings, linear self-polishing antifouling resin, can solve the problems of slow Cu ion release rate and unstable antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

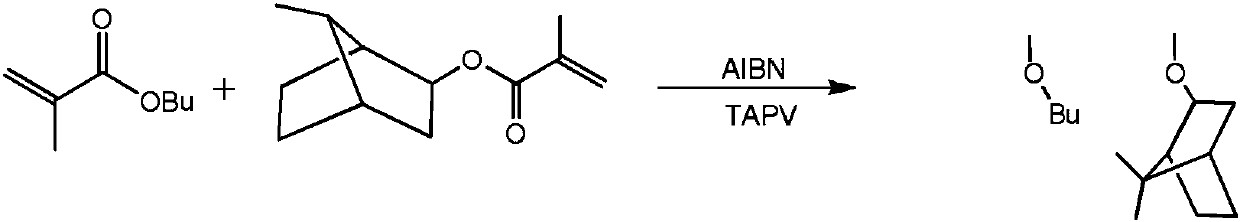

[0273] Synthesis of isobornyl methacrylate / butyl methacrylate binary copolymer resin:

[0274] (1) Synthesis of resin 1A: add 0.3g of azobisisobutyronitrile (AIBN), 0.2g of 3-mercaptopropionic acid, 0.2 g ethyl 3-mercaptopropionate, 187g xylene, 10g propylene glycol monomethyl ether, heat up to 100°C, then weigh 160g butyl methacrylate, 40g isobornyl methacrylate, 1.2g AIBN, 1.0g mercaptopropyl For the mixed solution of acid, after 2 hours of constant-speed dripping with a needle propeller, turn off the heating temperature, and continue to use the needle-type propeller to drop at a constant speed for 1 hour, then add 0.1g of tert-amyl peroxyacetate (TAPV) , and then slowly raised the temperature to 110° C., kept the temperature for 2.5 hours, and then cooled to room temperature to complete the reaction.

[0275] According to the GPC test, the number average molecular weight of the resin is 9544, the weight average molecular weight is 17405, and the dispersion degree is 1.824....

Embodiment 2

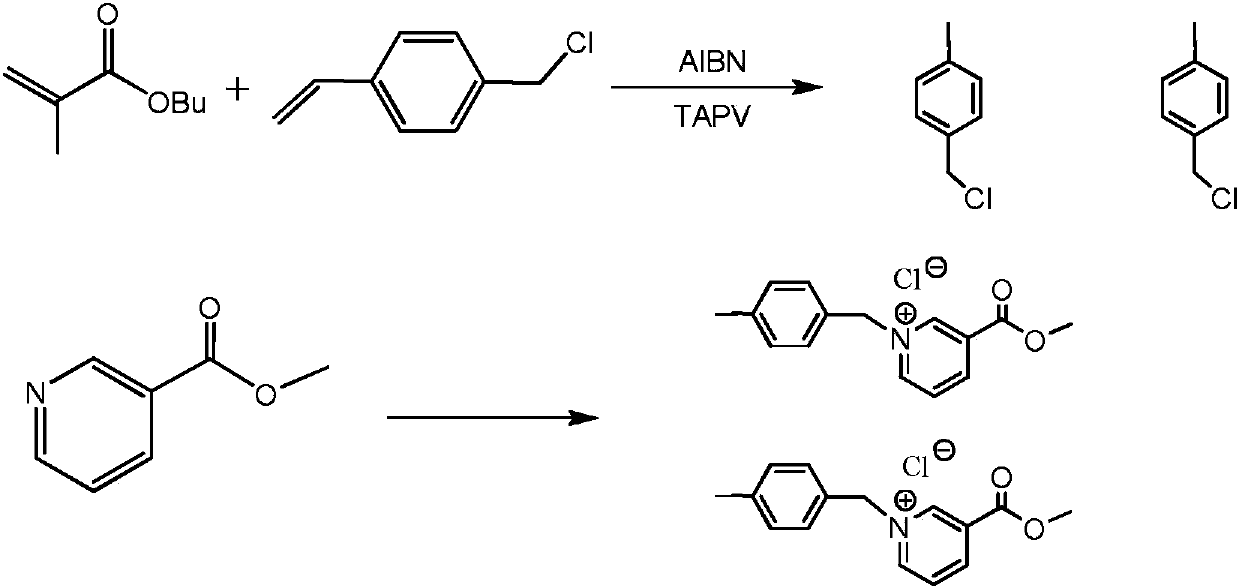

[0283] Synthesis of p-chloromethylstyrene / butyl methacrylate binary copolymer resin grafted with methyl nicotinate pyridinium salt:

[0284] Preparation of resin 2A: add 0.3g azobisisobutyronitrile (AIBN), 0.2g 3-mercaptopropionic acid, 0.2g 3- Ethyl mercaptopropionate, 187g xylene, 10g propylene glycol monomethyl ether, heat up to 100°C, then weigh the mixture containing 40g p-chloromethylstyrene, 160g butyl methacrylate, 1.2g AIBN, 1.0g mercaptopropionic acid Liquid, after 2 hours of constant-velocity dripping with a needle-type propeller, turn off the heating temperature, continue to use a needle-type propeller to drop at a constant speed for 1 hour and complete, add 0.1g tert-amyl peroxyacetate (TAPV), and then slowly Raise the temperature to 110°C, keep it warm for 2.5 hours, then cool to 45°C, add 36g of methyl nicotinate and 64g of dimethylformamide, keep it warm for 18h, then cool to room temperature to complete the reaction.

[0285] According to the GPC test, the nu...

Embodiment 3

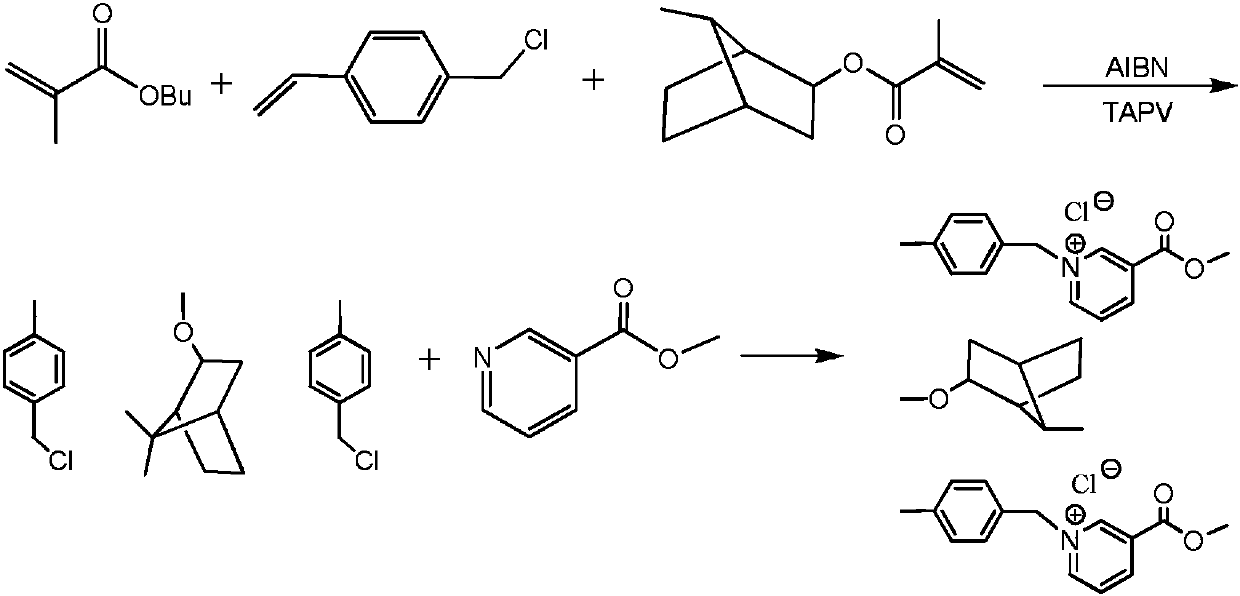

[0287] Synthesis of p-chloromethylstyrene / butyl methacrylate / isobornyl methacrylate terpolymer resin grafted with methyl nicotinate pyridinium salt:

[0288] Preparation of 3A: Add 0.3g azobisisobutyronitrile (AIBN), 0.2g 3-mercaptopropionic acid, 0.2g 3-mercapto Ethyl propionate, 187g of xylene, 10g of propylene glycol monomethyl ether, heated up to 100°C, and then weighed 40g of p-chloromethylstyrene, 110g of butyl methacrylate, 50g of isobornyl methacrylate, 1.2g of AIBN, 1.0g of the mixed solution of mercaptopropionic acid was added dropwise at a constant speed for 2 hours with a needle propeller, then the heating temperature was turned off, and continued to be added dropwise with a needle propeller at a constant speed for 1 hour, and 0.1 g of tert-amyl peroxyacetate was added. ester (TAPV), and then slowly raised the temperature to 110°C, kept warm for 2.5h, cooled to 45°C, added 36g of methyl nicotinate, 64g of dimethylformamide, kept warm for 18h, cooled to room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com